Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 220

SERVICE PRECAUTIONS

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS CAN

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS

AND

CANCER.

EXTREME

CARE

SHOULD

BE

EXERCISED

WHILE

SERVICING

BRAKE ASSEMBLIES OR COMPONENTS.

DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH.

DO NOT CREATE DUST BY SANDING, GRINDING,

AND/OR SHAVING BRAKE LININGS OR PADS UN-

LESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT.

DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS.

FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRONMEN-

TAL PROTECTION AGENCY. FOR THE HANDLING,

PROCESSING, AND DISPOSITION OF DUST OR DIRT

WHICH MAY CONTAIN ASBESTOS FIBERS.

IT IS RECOMMENDED NOT TO BREATH ANY TYPE

OF BRAKE LINING MATERIAL DUST EVEN ASBES-

TOS FREE, DUE TO THE FIBROUS NATURE OF THE

MATERIALS BEING USED.

Grease or any other foreign material must be kept off

caliper assembly, surfaces of braking disc and external

surfaces of hub, during service procedures.

Handling of the braking disc and caliper. Should be

done in such a way as to avoid deformation of the disc

and scratching or nicking of the brake linings.

If inspection reveals that the square sectioned cali-

per piston seal is worn or damaged, it should be

replaced immediately.

During removal and installation of a wheel and tire

assembly, use care not to strike the caliper.

Before vehicle is moved after any brake service

work, be sure to obtain a firm brake pedal.

5 - 34

BRAKES

Ä

KELSEY HAYES DOUBLE PIN FAMILY CALIPER

BRAKE SHOE SERVICE PROCEDURES

BRAKE SHOE REMOVAL

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting Information in the Lubrication

and Maintenance section of this manual.

(2) Remove front wheel and tire assemblies.

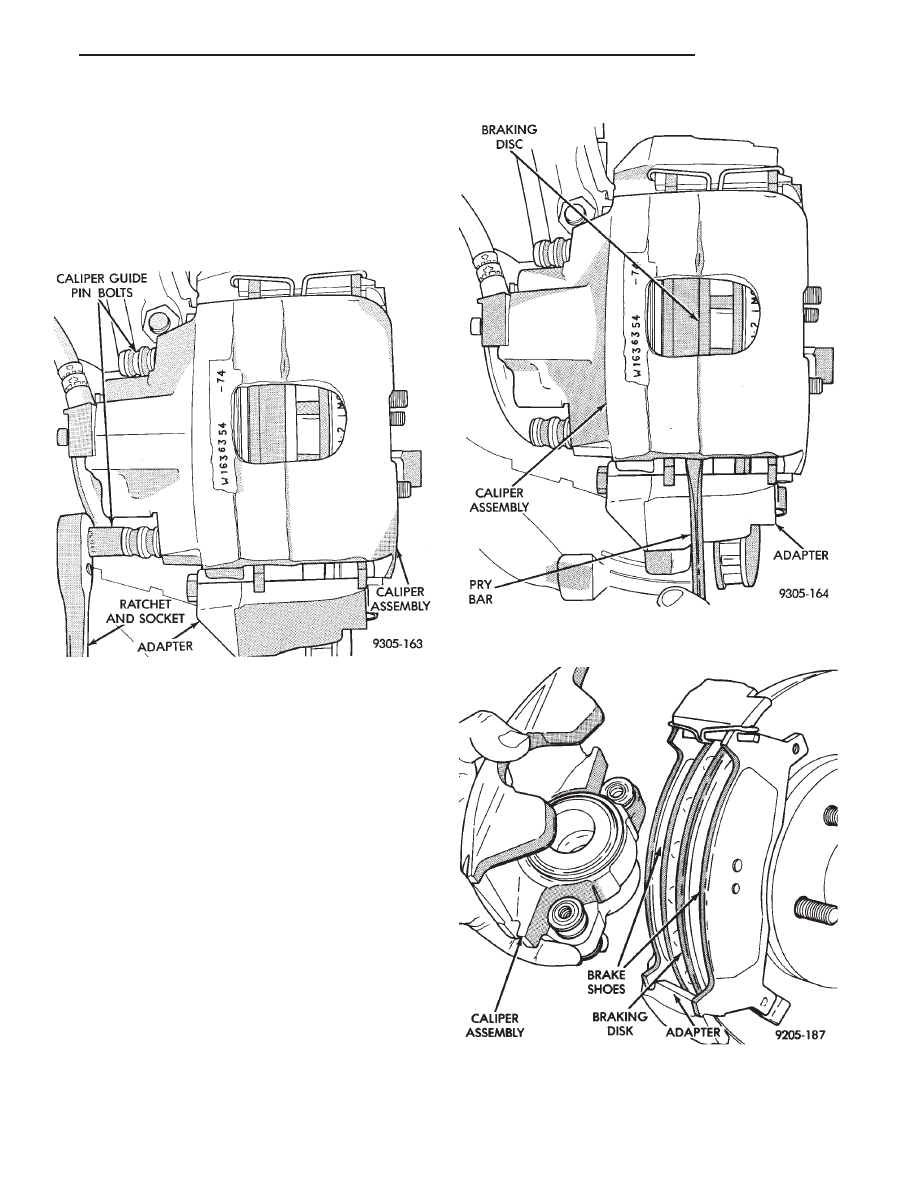

(3) Remove caliper guide pin bolts (Fig. 1).

(4) After removing caliper guide pin bolts. Lift cal-

iper away from braking disc using a pry bar or

screwdriver (Fig. 2).

(5) Remove caliper assembly from braking disc and

adapter by sliding the assembly out and away from

the braking disc and adapter (Fig. 3).

(6) Support caliper firmly to prevent weight of cal-

iper from damaging the flexible brake hose (Fig. 4).

(7) Remove the outboard brake shoe assembly from

the caliper adapter (Fig. 5).

(8) Remove the braking disk (rotor) from the hub

by pulling it straight off the wheel mounting studs

(Fig. 6).

Fig. 1 Removing or Installing Caliper Guide Pin

Bolts

Fig. 2 Loosening Family Caliper Assembly From

Adapter And Rotor

Fig. 3 Removing or Installing Caliper Assembly

Ä

BRAKES

5 - 35

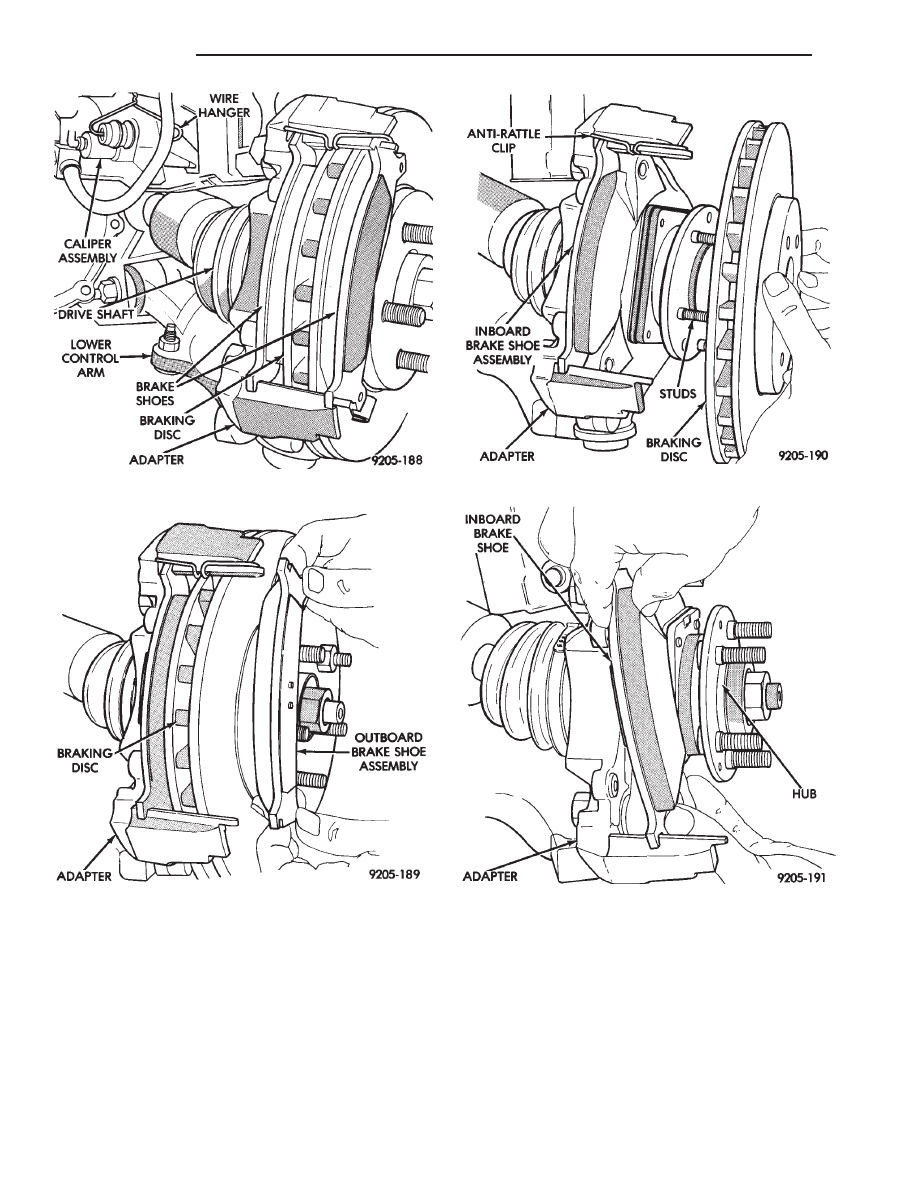

(9) Remove the inboard brake shoe assembly by

sliding it out along the bottom adapter abutment un-

til brake shoe assembly loosens from anti-rattle clip

(Fig. 7).

(10) Remove the anti-rattle clip from the top

adapter abutment (Fig. 8).

BRAKE SHOE INSTALLATION

(1) Thoroughly clean and lubricate both adapter

abutments with a liberal amount of Mopar

t Multi-

purpose Lubricant, or equivalent.

(2) Install the anti-rattle clip on the upper abut-

ment of the caliper mounting adapter (Fig. 8).

(3) Install the new inboard brake shoe assembly on

the adapter by sliding it along the adapter abut-

ments. Be careful not to get any grease from the

adapter abutment on the surface of the brake lining

Fig. 4 Storing Caliper

Fig. 5 Removing and Installing Outboard Shoe

Assembly

Fig. 6 Removing or Installing Braking Disc

Fig. 7 Removing or Installing Inboard Shoe

Assembly

5 - 36

BRAKES

Ä

material, (Fig. 7). Be sure inboard brake shoe assem-

bly is correctly positioned against anti-rattle clip

(Fig. 6).

(4) Reinstall the Braking Disk on the hub, by in-

stalling it over the wheel studs until it is seated

against the face of the hub (Fig. 6).

(5) Slide the new outboard brake shoe assembly on

the adapter abutment, (Fig. 5).

(6) Carefully lower caliper over the braking disk and

brake shoe assemblies (Fig. 3). Make sure that the

caliper guide pin bolt, bushings and sleeves are clear of

the adapter.

(7) Install the caliper guide pin bolts and tighten to

34 to 37 N

Im (25 to 35 ft. lbs.). Extreme caution

should be taken not to cross the threads of the

caliper guide pin bolts.

(8) Install the wheel and tire assembly. Tighten the

wheel mounting stud nuts in proper sequence (Fig. 9)

until all nuts are torqued to half specification. This is

important. Then repeat the tightening sequence to the

full specified torque of 129 N

Im (95 ft. lbs.).

(9) Remove jackstands or lower hoist. Before mov-

ing vehicle, pump the brake pedal several times

to insure the vehicle has a firm brake pedal to

adequately stop vehicle..

(10) Road test the vehicle and make several stops to

wear off any foreign material on the brake linings and

to seat the brake shoe linings.

Fig. 8 Remove Or Replace Anti-Rattle Clip

Fig. 9 Tightening Wheel Nuts

Ä

BRAKES

5 - 37

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст