Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 49

• Engine Coolant Temperature Sensor

• Distributor Pick-up

• Manifold Absolute Pressure (MAP) Sensor

• Oxygen Sensor

• SCI Receive

• Speed Control System Controls

• Throttle Position Sensor

• Park/Neutral Switch (automatic transaxle)

• Vehicle Speed Sensor

PCM Outputs:

• Air Conditioning Clutch Relay

• Generator Field

• Idle Air Control Motor

• Auto Shutdown (ASD) and Fuel Pump Relays

• Canister Purge Solenoid

• Malfunction Indicator Lamp (Check Engine Lamp)

• Data Link Connector

• Electric EGR Transducer (EET)

• Fuel Injectors

• Ignition Coil

• Torque Converter Clutch Solenoid

• Radiator Fan Relay

• Speed Control Solenoids

• Tachometer Output

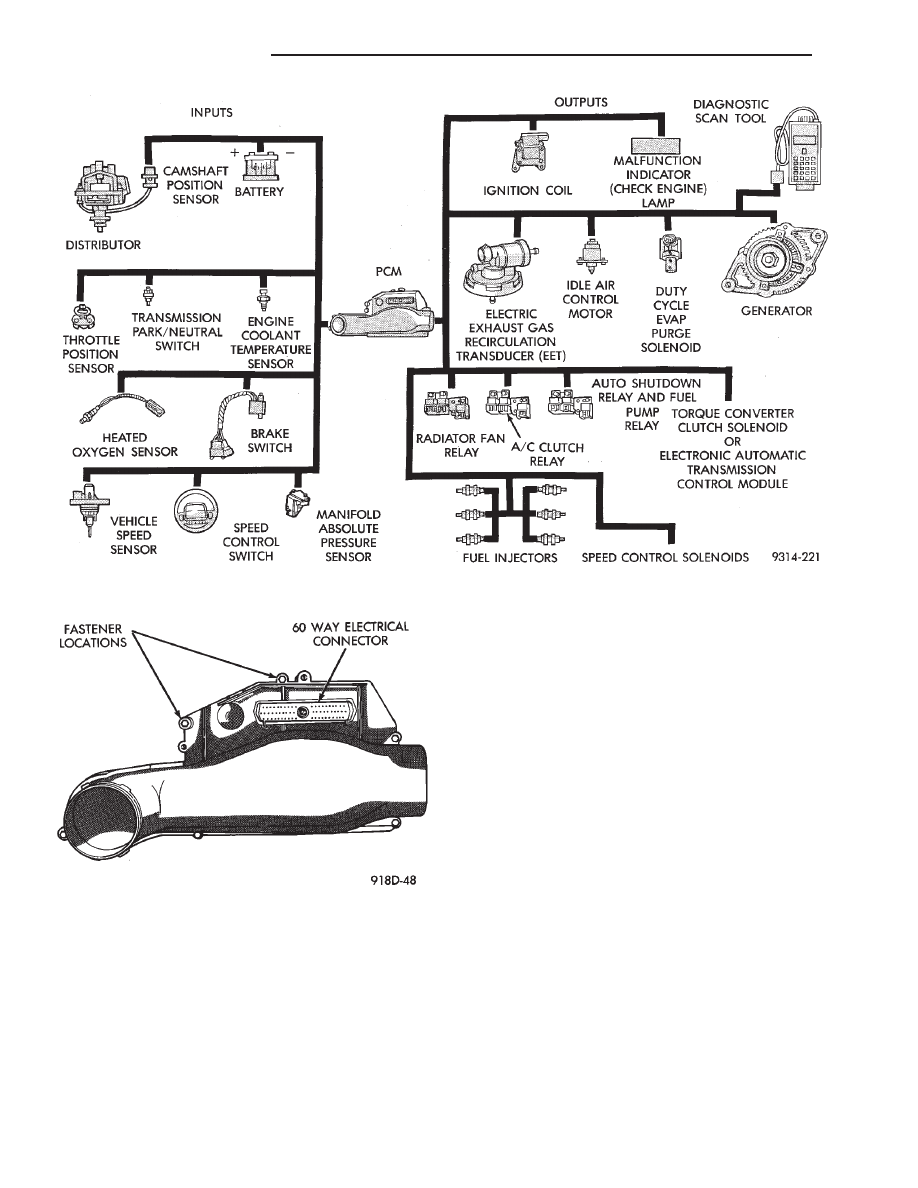

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark ad-

vance, ignition coil dwell and canister purge opera-

tion.

The

PCM

regulates

the

cooling

fan,

air

conditioning and speed control systems. The PCM

changes generator charge rate by adjusting the gen-

erator field.

The PCM adjusts injector pulse width (air-fuel ra-

tio) based on the following inputs.

• battery voltage

• engine coolant temperature

• exhaust gas content

• engine speed (distributor pick-up)

• manifold absolute pressure

• throttle position

Fig. 1 Multi-Port Fuel Injection Components

Fig. 2 PCM

14 - 114

FUEL SYSTEMS

Ä

The PCM adjusts ignition timing based on the fol-

lowing inputs.

• engine coolant temperature

• engine speed (distributor pick-up)

• manifold absolute pressure

• throttle position

The Automatic Shut Down (ASD) and Fuel Pump

relays are mounted externally, but turned on and off

by the PCM through the same circuit.

The distributor pick-up signal is sent to the PCM.

If the PCM does not receive a distributor signal

within approximately one second of engine cranking,

the ASD relay and fuel pump relay are deactivated.

When these relays are deactivated, power is shut off

to the fuel injector, ignition coil, oxygen sensor heat-

ing element and fuel pump.

The

PCM

contains

a

voltage

converter

that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the distributor pick-up and vehicle

speed sensor. The PCM also provides a 5.0 volts sup-

ply for the coolant temperature sensor, manifold ab-

solute pressure sensor and throttle position sensor.

AIR CONDITIONING SWITCH SENSE (AA, AG, AJ

BODY)—PCM INPUT

When the air conditioning or defrost switch is in

the ON position and the low pressure and high pres-

sure switches are closed, the PCM receives an input

for air conditioning. After receiving this input, the

PCM activates the A/C compressor clutch by ground-

ing the A/C clutch relay. The PCM also adjusts idle

speed to a scheduled RPM to compensate for in-

creased engine load.

AIR CONDITIONING SWITCH SENSE (AC

BODY)—PCM INPUT

When the air conditioning or defrost switch is in

the ON position and the low pressure, high pressure

and ambient temperature switches are closed, the

PCM receives an input for air conditioning. After re-

ceiving this input, the PCM activates the A/C com-

pressor clutch by grounding the A/C clutch relay.

The PCM also adjusts idle speed to a scheduled RPM

to compensate for increased engine load.

BATTERY VOLTAGE—PCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low, the PCM will in-

crease injector pulse width.

BRAKE SWITCH—PCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. After receiving this input the PCM main-

tains idle speed to a scheduled RPM through the idle

air control motor. The brake switch is mounted on

the brake pedal support bracket.

ENGINE COOLANT TEMPERATURE SENSOR—PCM

INPUT

The coolant temperature sensor is a variable resis-

tor with a range of -40° to 265°. The sensor is in-

stalled next to the thermostat housing.

The PCM supplies 5.0 volts to the coolant temper-

ature sensor. The sensor provides an input voltage to

the PCM (Fig. 3). As coolant temperature varies, the

sensors resistance changes, resulting in a different

input voltage to the PCM.

The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature.

This sensor is also used for cooling fan control.

DISTRIBUTOR PICK-UP—PCM INPUT

The distributor pick-up provides two inputs to the

PCM. From one input the PCM determines RPM (en-

gine speed). From the other input it derives crank-

shaft

position.

The

PCM

regulates

injector

synchronization and adjusts ignition timing and en-

gine speed based on these inputs.

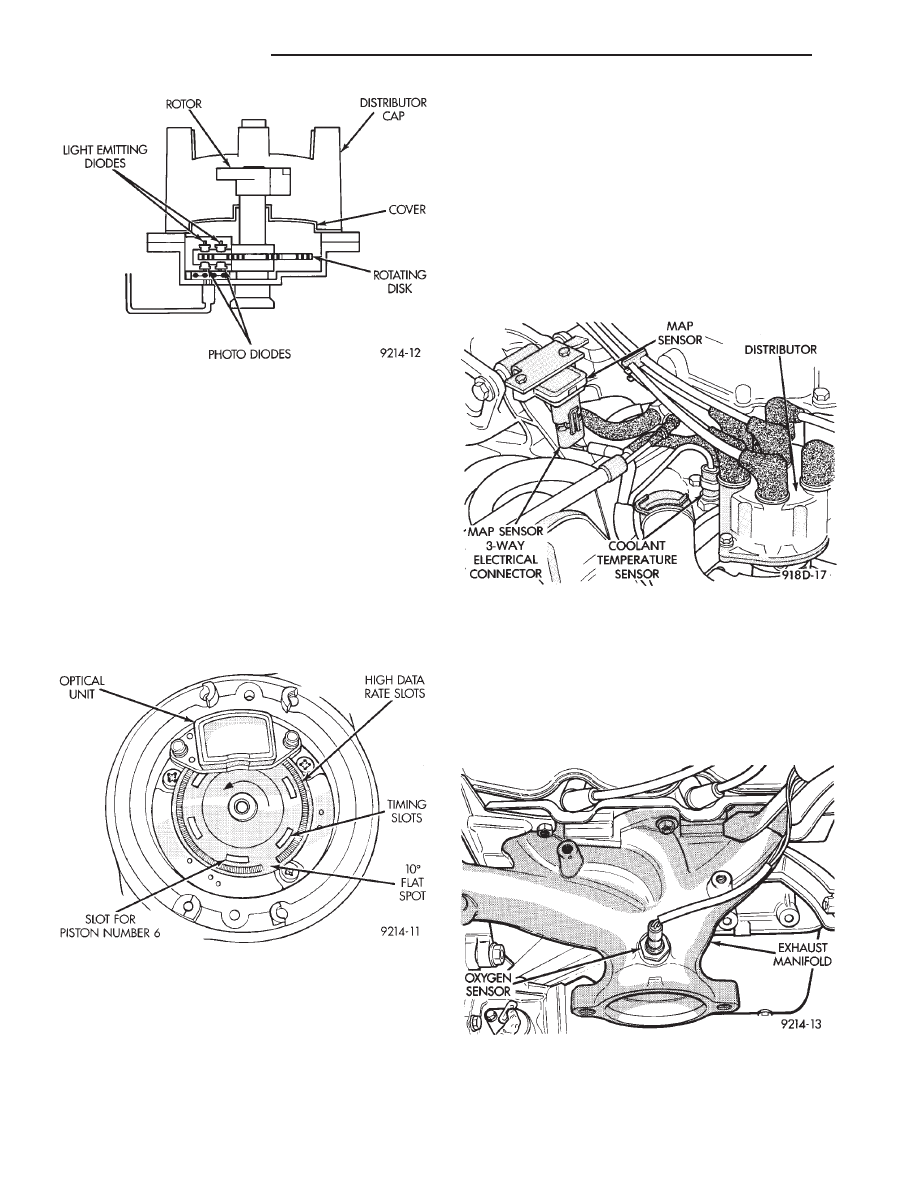

The distributor pick-up contains two signal gener-

ators. The pick-up unit consists of 2 light emitting

diodes (LED), 2 photo diodes, and a separate timing

disk. The timing disk contains two sets of slots. Each

set of slots rotates between a light emitting diode

and a photo diode (Fig. 4). The inner set contains 6

large slots, one for each cylinder. The outer set con-

tains several smaller slots.

The outer set of slots on the rotating disk repre-

sents 2 degrees of crankshaft rotation. Up to 1200

engine RPM, the PCM uses the input from the outer

set of slots to increase ignition timing accuracy.

The outer set of slots contains a 10 degree flat spot

(Fig. 5). The flat spot tells the PCM that the next

piston at TDC will be number 6. The position of each

piston is referenced by one of the six inner slots (Fig.

5).

As each slot on the timing disk passes between the

diodes, the beam from the light emitting diode is in-

Fig. 3 Coolant Temperature Sensor

Ä

FUEL SYSTEMS

14 - 115

terrupted. This creates an alternating voltage in

each photo diode which is converted into on-off

pulses. The pulses are the input to the PCM.

During

cranking,

the

PCM

cannot

determine

crankshaft position until the 10 degree flat spot on

the outer set of slots passes through the optical unit.

Once the flat spot is detected, the PCM knows piston

number 6 will be the next piston at TDC.

Since the disk rotates at half crankshaft speed, it

may take 2 engine revolutions during cranking for

the PCM to determine the position of piston number

6. For this reason the PCM will energize all six in-

jectors at the same time until it senses the position

of piston number 6.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR—PCM INPUT

The PCM supplies 5 volts to the MAP sensor. The

Map sensor converts intake manifold pressure into

voltage. The PCM monitors the MAP sensor output

voltage. As vacuum increases, MAP sensor voltage

decreases proportionately. Also, as vacuum decreases,

MAP sensor voltage increases proportionately.

During cranking, before the engine starts running,

the PCM determines atmospheric air pressure from

the MAP sensor voltage. While the engine operates,

the PCM determines intake manifold pressure from

the MAP sensor voltage.

Based on MAP sensor voltage and inputs from

other sensors, the PCM adjusts spark advance and

the air/fuel mixture.

The MAP sensor (Fig. 6) mounts on a bracket at-

tached to the generator bracket. The sensor is con-

nected to the throttle body with a vacuum hose and

to the PCM electrically.

HEATED OXYGEN SENSOR (O

2

SENSOR)—PCM

INPUT

The O

2

sensor is located in the exhaust manifold

and provides an input voltage to the PCM. The input

tells the PCM the oxygen content of the exhaust gas

(Fig. 7). The PCM uses this information to fine tune

the air-fuel ratio by adjusting injector pulse width.

The O

2

sensor produces voltages from 0 to 1 volt,

depending upon the oxygen content of the exhaust

gas. When a large amount of oxygen is present

Fig. 4 Distributor Pick-up

Fig. 5 Inner and Outer Slots of Rotating Disk

Fig. 6 Map Sensor

Fig. 7 Heated Oxygen Sensor—3.0L Engine

14 - 116

FUEL SYSTEMS

Ä

(caused by a lean air-fuel mixture), the sensor pro-

duces a low voltage. When there is a lesser amount

present (rich air-fuel mixture) it produces a higher

voltage. By monitoring the oxygen content and con-

verting it to electrical voltage, the sensor acts as a

rich-lean switch.

The oxygen sensor is equipped with a heating ele-

ment that keeps the sensor at proper operating tem-

perature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into Closed Loop operation sooner.

Also, it allow the system to remain in Closed Loop

operation during periods of extended idle.

In Closed Loop operation the PCM monitors the O

2

sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During Open

Loop operation the PCM ignores the O

2

sensor input.

The PCM adjusts injector pulse width based on pre-

programmed (fixed) values and from inputs of other

sensors.

SPEED CONTROL—PCM INPUT

The speed control system provides four separate

voltages (inputs) to the PCM. The voltages corre-

spond to the On/Off, Set, and Resume.

The speed control ON voltage informs the PCM

that the speed control system has been activated.

The speed control SET voltage informs the PCM that

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control OFF voltage

tells the PCM that the speed control system has de-

activated. Refer to Group 8H for further speed con-

trol information.

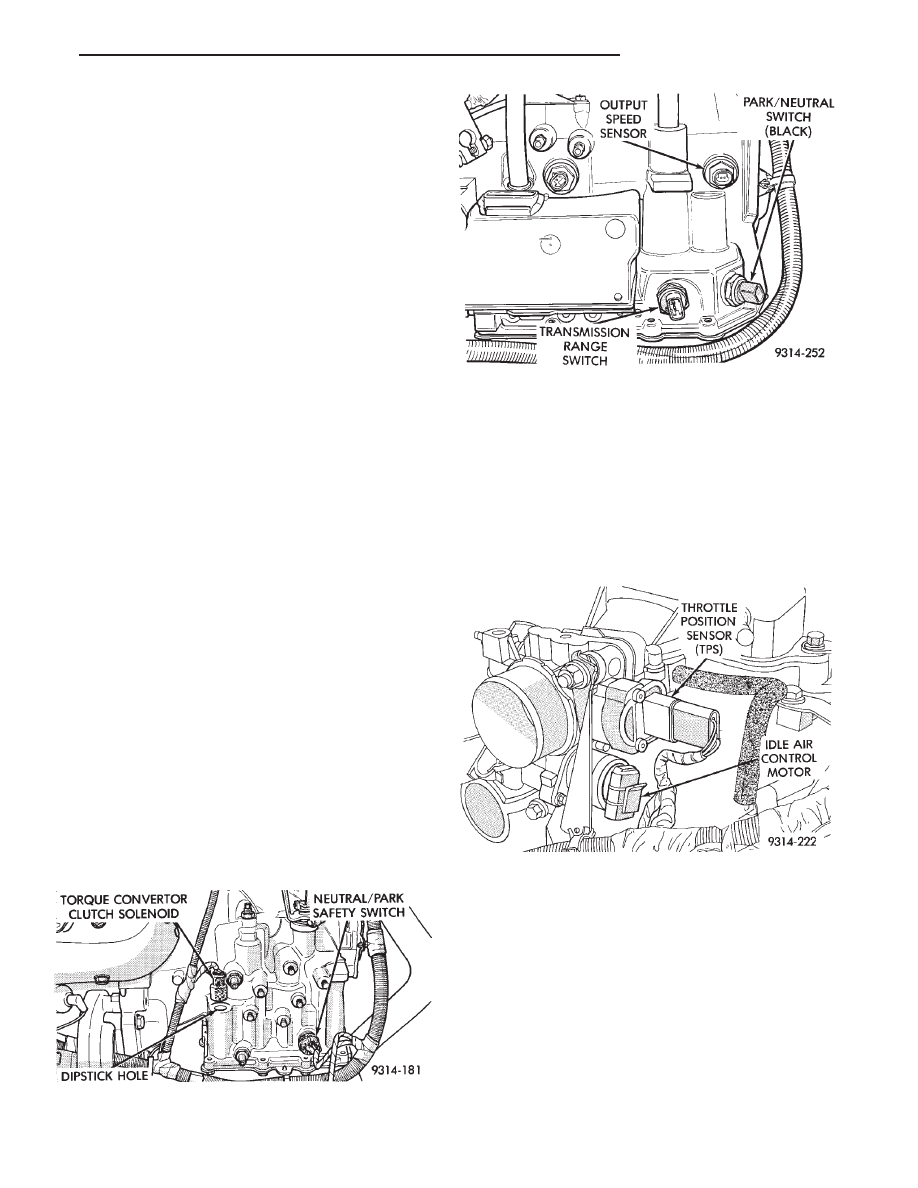

PARK/NEUTRAL SWITCH—PCM INPUT

The park/neutral switch is located on the transaxle

housing (Fig. 8 or Fig. 9). It provides an input to the

PCM indicating whether the automatic transaxle is

in Park or Neutral. This input is used to determine

idle speed (varying with gear selection), fuel injector

pulse width, and ignition timing advance. The park/

neutral switch is sometimes referred to as the neu-

tral safety switch.

THROTTLE POSITION SENSOR (TPS)—PCM INPUT

The Throttle Position Sensor (TPS) is mounted on

the throttle body and connected to the throttle blade

shaft (Fig. 10). The TPS is a variable resistor that

provides the PCM with an input signal (voltage) rep-

resenting throttle blade position. As the position of

the throttle blade changes, the resistance of the TPS

changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents throttle blade position. The TPS

output voltage to the PCM varies from approxi-

mately 0.5 volt at minimum throttle opening (idle) to

3.5 volts at wide open throttle. The wide open throt-

tle input is approximately 3 volts more than the min-

imum throttle opening value.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine op-

erating conditions. After determining the current op-

erating conditions, the PCM adjust fuel injector pulse

width and ignition timing.

Fig. 8 Park Neutral Switch—3-Speed Automatic

Transaxle

Fig. 9 Park Neutral Switch—4-Speed Electronic

Automatic Transaxle

Fig. 10 Throttle Position Sensor

Ä

FUEL SYSTEMS

14 - 117

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст