Infiniti FX35 / FX45. Manual — part 121

ATC-80

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Low-pressure Side Sometimes Becomes Negative

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycle

Probable cause

Corrective action

Both high- and low-pressure sides

are too low.

• There is a big temperature

difference between liquid

tank outlet and inlet. Outlet

temperature is extremely

low.

• Liquid tank inlet and expan-

sion valve are frosted.

Liquid tank inside is slightly

clogged.

• Replace liquid tank.

• Check lubricant for contami-

nation.

• Temperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

• Expansion valve inlet is

frosted.

• Temperature difference oc-

curs somewhere in high-

pressure side.

High-pressure pipe located be-

tween liquid tank and expan-

sion valve is clogged.

• Check and repair malfunc-

tioning parts.

• Check lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or slightly cool

when touched.

Low refrigerant charge.

↓

Leaking fittings or compo-

nents.

Check refrigerant for leaks.

Refer to

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.

Expansion valve closes a little

compared with the specifica-

tion.

↓

1.

Improper expansion

valve adjustment.

2.

Malfunctioning expansion

valve.

3.

Outlet and inlet may be

clogged.

• Remove foreign particles by

using compressed air.

• Replace expansion valve.

• Check lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.

Low-pressure pipe is clogged

or crushed.

• Check and repair malfunc-

tioning parts.

• Check lubricant for contami-

nation.

Air flow volume is not enough

or is too low.

Evaporator is frozen.

• Check intake sensor circuit.

Refer to

.

• Replace compressor.

• Repair evaporator fins.

• Replace evaporator.

• Refer to

.

AC353A

Gauge indication

Refrigerant cycle

Probable cause

Corrective action

Low-pressure side sometimes be-

comes negative.

• Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

• The system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.

Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant.

• Drain water from refrigerant

or replace refrigerant.

• Replace liquid tank.

AC354A

TROUBLE DIAGNOSIS

ATC-81

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

M

A

B

ATC

N

O

P

DIAGNOSIS PROCEDURE FOR INSUFFICIENT COOLING

SYMPTOM: Insufficient cooling

1.

CHECK POWER SUPPLY FOR ECV (ELECTRONIC CONTROL VALVE)

1.

Disconnect compressor (ECV) connector.

2.

Turn ignition switch ON.

3.

Check voltage between compressor (ECV) harness connector

F6 terminal 2 and ground.

OK or NG

OK

>> GO TO 2.

NG

>>

Check power supply circuit and 10A fuse [No. 12,

located in the fuse block (J/B)]. Refer to

• If fuse is OK, check harness for open circuit. Repair or

replace if necessary.

• If fuse is NG, check harness for short circuit and

replace fuse.

2.

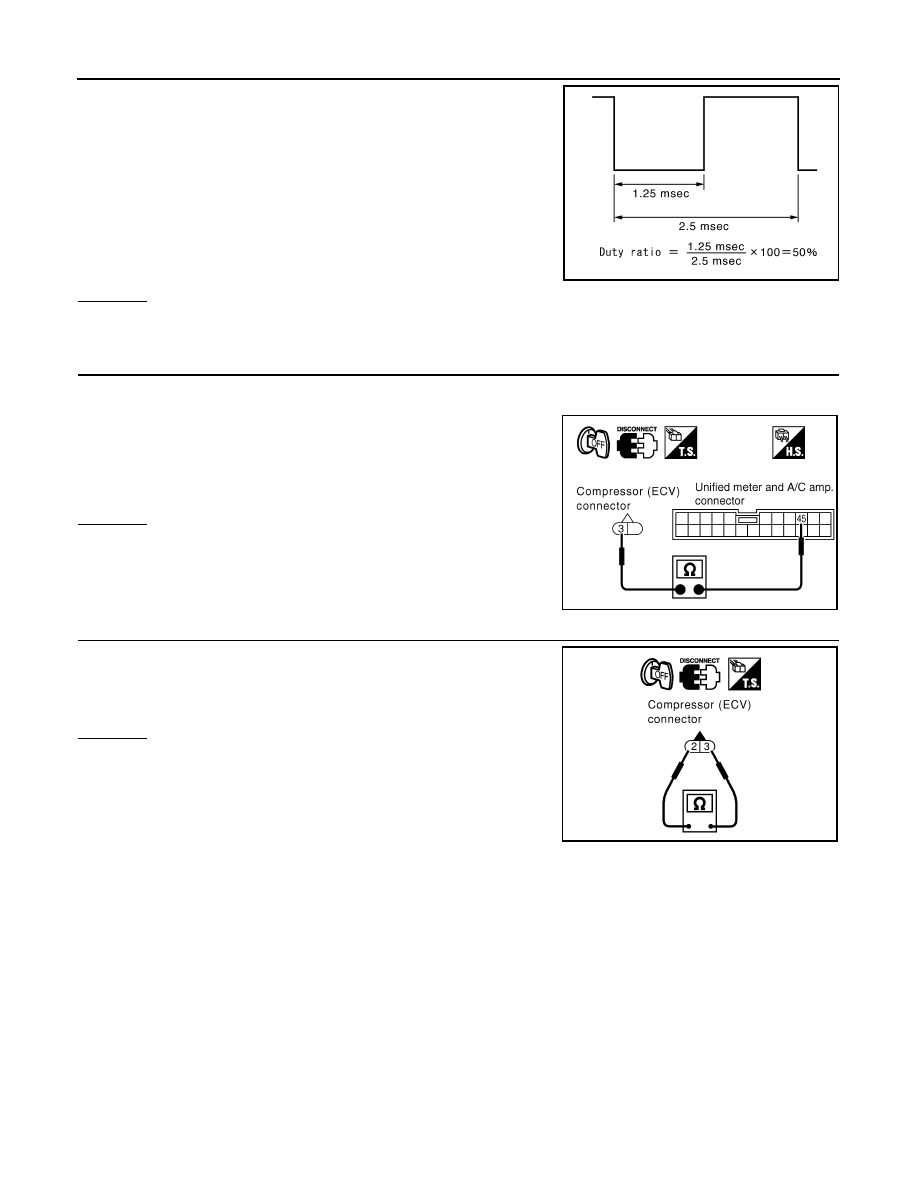

CHECK ECV CONTROL SIGNAL

1.

Turn ignition switch OFF.

2.

Reconnect compressor (ECV) connector.

3.

Perform self-diagnosis. Refer to

ATC-43, "Self-Diagnosis Function"

4.

Set in self-diagnosis STEP-4 (Code No. 45). Refer to

ATC-43, "Self-Diagnosis Function"

.

5.

Confirm ECV control signal between unified meter and A/C amp.

harness connector M57 terminal 45 and ground using an oscillo-

scope.

Gauge indication

Refrigerant cycle

Probable cause

Corrective action

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side of

expansion valve’s pipe is frost-

ed or wet with dew.

High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.

Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth-

ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check lubricant for contami-

nation.

AC362A

2 – ground

: Battery voltage

RJIA2294E

RJIA2295E

ATC-82

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

OK or NG

OK

>> Replace compressor.

NG

>> GO TO 3.

3.

CHECK CIRCUIT CONTINUITY BETWEEN ECV AND UNIFIED METER AND A/C AMP.

1.

Turn ignition switch OFF.

2.

Disconnect compressor (ECV) and unified meter and A/C amp. connector.

3.

Check continuity between compressor (ECV) harness connector

F6 terminal 3 and unified meter and A/C amp. harness connec-

tor M57 terminal 45.

OK or NG

OK

>> GO TO 4.

NG

>> Repair harness or connector.

4.

CHECK ECV

Check continuity between compressor (ECV) connector F6 terminals

2 and 3.

OK or NG

OK

>> Replace unified meter and A/C amp.

NG

>> Replace compressor.

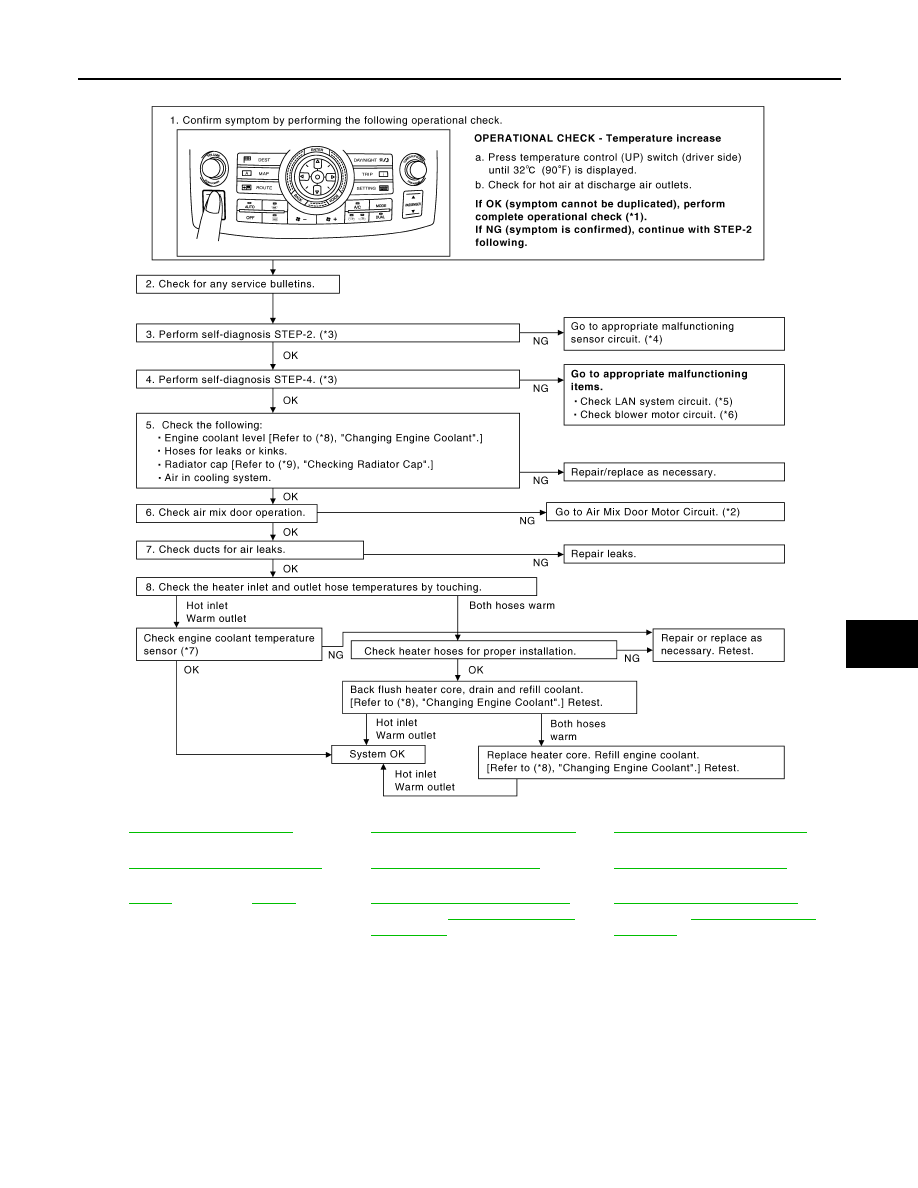

Insufficient Heating

INFOID:0000000001328192

SYMPTOM: Insufficient heating

INSPECTION FLOW

SJIA1765E

3 – 45

: Continuity should exist.

RJIA2296E

2 – 3

: Continuity should exist.

RJIA2297E

TROUBLE DIAGNOSIS

ATC-83

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

M

A

B

ATC

N

O

P

Noise

INFOID:0000000001328193

SYMPTOM: Noise

INSPECTION FLOW

*1

*2

ATC-59, "Air Mix Door Motor Circuit"

*3

ATC-43, "Self-Diagnosis Function"

see No. 4 to 6.

*4

ATC-43, "Self-Diagnosis Function"

see No. 13.

*5

*6

ATC-64, "Blower Motor Circuit"

*7

(VK45DE)

*8

CO-10, "Changing Engine Coolant"

(VQ35DE) or

(VK45DE)

*9

CO-14, "Checking Radiator Cap"

(VQ35DE) or

SJIA1593E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст