Infiniti FX35 / FX45. Manual — part 589

DTC P2135 TP SENSOR

EC-1117

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

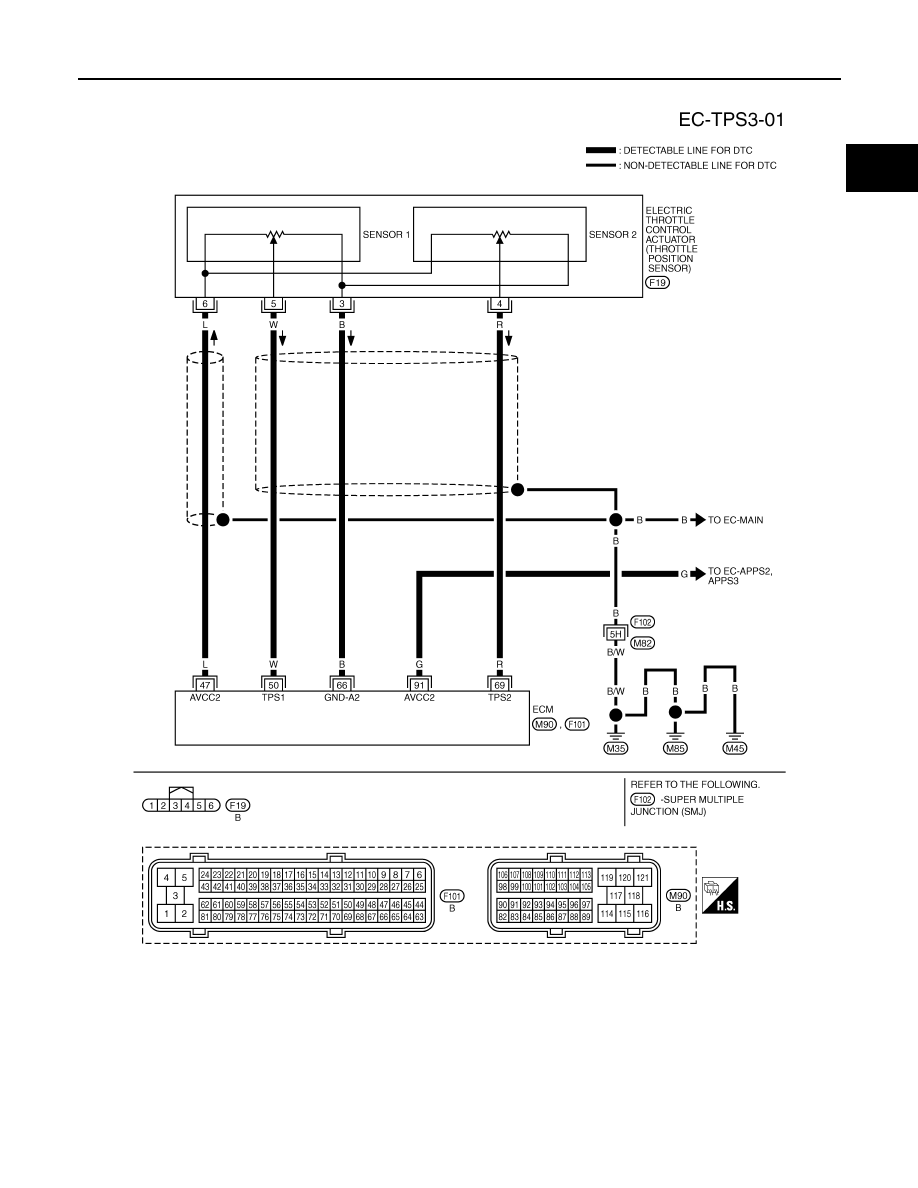

Wiring Diagram

INFOID:0000000001327020

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TBWM1356E

EC-1118

< SERVICE INFORMATION >

[VK45DE]

DTC P2135 TP SENSOR

Diagnosis Procedure

INFOID:0000000001327021

1.

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Loosen and retighten three ground screws on the body.

Refer to

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT-I

TER-

MI-

NAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

47

L

Sensor power supply (Throt-

tle position sensor)

[Ignition switch: ON]

Approximately 5V

50

W

Throttle position sensor 1

[Ignition switch: ON]

• Engine stopped

• Selector lever: D

• Accelerator pedal: Fully released

More than 0.36V

[Ignition switch: ON]

• Engine stopped

• Selector lever: D

• Accelerator pedal: Fully depressed

Less than 4.75V

66

B

Sensor ground

(Throttle position sensor)

[Engine is running]

• Warm-up condition

• Idle speed

Approximately 0V

69

R

Throttle position sensor 2

[Ignition switch: ON]

• Engine stopped

• Selector lever: D

• Accelerator pedal: Fully released

Less than 4.75V

[Ignition switch: ON]

• Engine stopped

• Selector lever: D

• Accelerator pedal: Fully depressed

More than 0.36V

91

G

Sensor power supply

(APP sensor 2)

[Ignition switch: ON]

Approximately 5V

PBIB2195E

DTC P2135 TP SENSOR

EC-1119

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

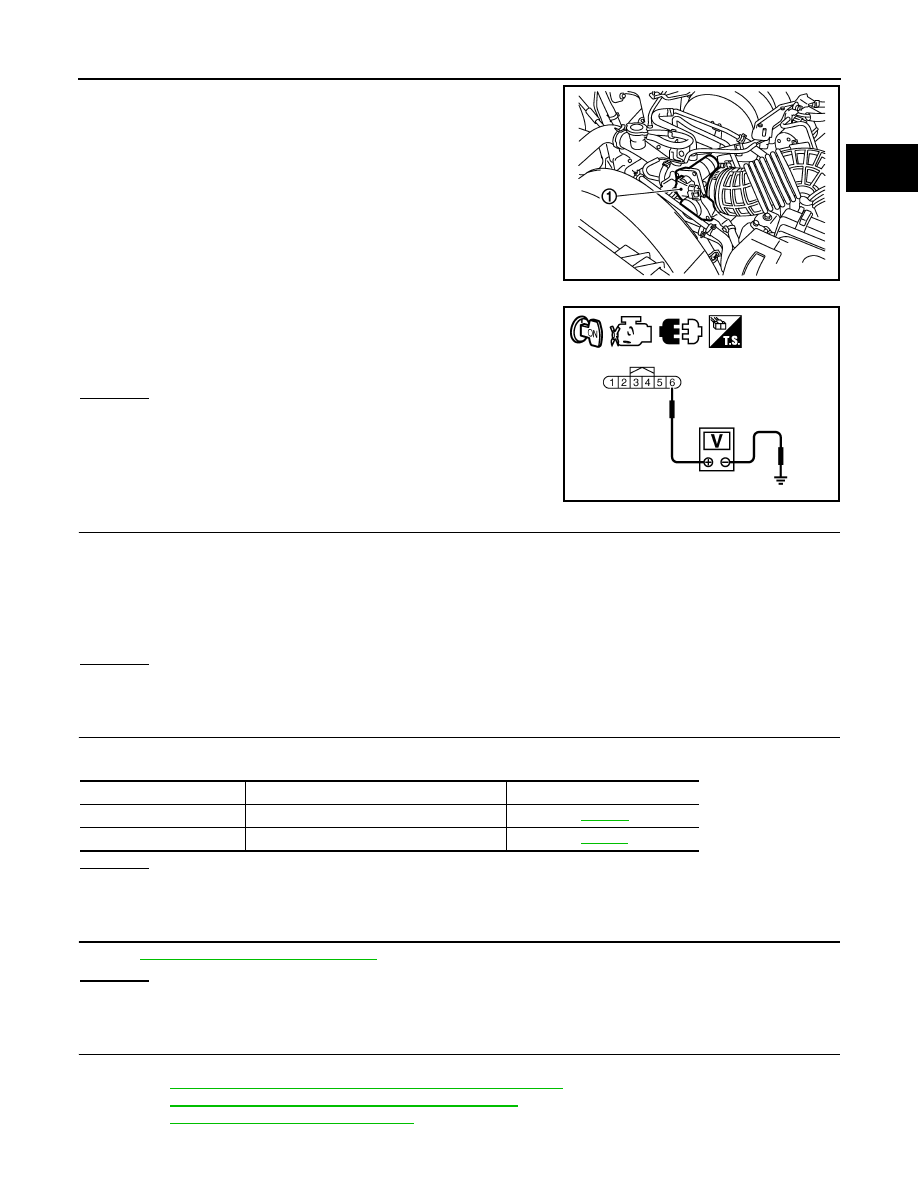

1.

Disconnect electric throttle control actuator (1) harness connec-

tor.

2.

Turn ignition switch ON.

3.

Check voltage between electric throttle control actuator terminal

6 and ground with CONSULT-III or tester.

OK or NG

OK

>> GO TO 7.

NG

>> GO TO 3.

3.

CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check harness continuity between electric throttle control actuator terminal 6 and ECM terminal 47.

Refer to Wiring Diagram.

OK or NG

OK

>> GO TO 4.

NG

>> Repair open circuit.

4.

CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT-III

Check harness for short to power and short to ground, between the following terminals.

OK or NG

OK

>> GO TO 5.

NG

>> Repair short to ground or short to power in harness or connectors.

5.

CHECK APP SENSOR

EC-1115, "Component Inspection"

.

OK or NG

OK

>> GO TO 11.

NG

>> GO TO 6.

6.

REPLACE ACCELERATOR PEDAL ASSEMBLY

1.

Replace accelerator pedal assembly.

2.

EC-662, "Accelerator Pedal Released Position Learning"

.

3.

EC-663, "Throttle Valve Closed Position Learning"

4.

EC-663, "Idle Air Volume Learning"

.

PBIB3232E

Voltage: Approximately 5V

PBIB3250E

Continuity should exist.

ECM terminal

Sensor terminal

Reference Wiring Diagram

47

Electric throttle control actuator terminal 6

91

APP sensor terminal 4

EC-1120

< SERVICE INFORMATION >

[VK45DE]

DTC P2135 TP SENSOR

>> INSPECTION END

7.

CHECK THROTTLE POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check harness continuity between electric throttle control actuator terminal 3 and ECM terminal 66.

Refer to Wiring Diagram.

4.

Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 8.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.

CHECK THROTTLE POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check harness continuity between ECM terminal 50 and electric throttle control actuator terminal 5, ECM

terminal 69 and electric throttle control actuator terminal 4.

Refer to Wiring Diagram.

2.

Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 9.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.

CHECK THROTTLE POSITION SENSOR

EC-1120, "Component Inspection"

.

OK or NG

OK

>> GO TO 11.

NG

>> GO TO 10.

10.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace the electric throttle control actuator.

2.

EC-663, "Throttle Valve Closed Position Learning"

3.

EC-663, "Idle Air Volume Learning"

.

>> INSPECTION END

11.

CHECK INTERMITTENT INCIDENT

>> INSPECTION END

Component Inspection

INFOID:0000000001327022

THROTTLE POSITION SENSOR

1.

Reconnect all harness connectors disconnected.

2.

EC-663, "Throttle Valve Closed Position Learning"

3.

Turn ignition switch ON.

4.

Set selector lever to D position.

Continuity should exist.

Continuity should exist.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст