Infiniti FX35, FX50 (S51). Manual — part 608

FRONT OIL SEAL

DLN-267

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R230]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

Removal and Installation

INFOID:0000000005249273

REMOVAL

CAUTION:

Verify identification stamp of replacement frequency put in the lower part of gear carrier to determine

replacement for collapsible spacer when replacing front oil seal. Refer to “Identification stamp of

replacement frequency of front oil seal”. If collapsible spacer replacement is necessary, remove final

drive assembly and disassemble it to replace front oil seal and collapsible spacer. Refer to

NOTE:

The reuse of collapsible spacer is prohibited in principle. However, it is reusable on a one-time basis

only in cases when replacing front oil seal.

Identification stamp of replacement frequency of front oil seal

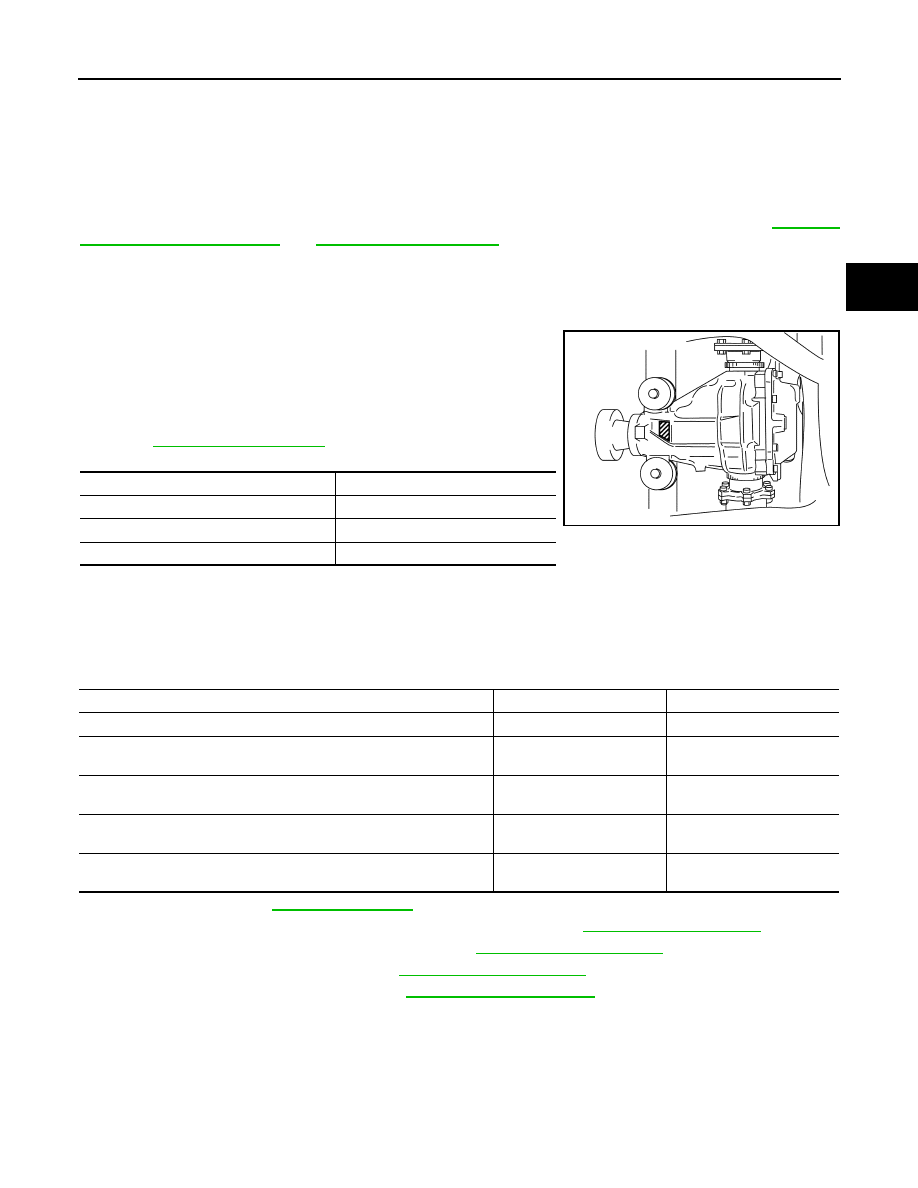

• The diagonally shaded area in the figure shows stamping point for

replacement frequency of front oil seal.

• The following table shows if collapsible spacer replacement is

needed before replacing front oil seal.

When collapsible spacer replacement is required, disassemble

final drive assembly to replace collapsible spacer and front oil seal.

Refer to

CAUTION:

Make a stamping after replacing front oil seal.

• After replacing front oil seal, make a stamping on the stamping point in accordance with the table below in

order to identify replacement frequency.

CAUTION:

Make a stamping from left to right.

1.

Drain gear oil. Refer to

.

2.

Remove the drive shafts from the rear final drive assembly. Refer to

.

3.

Remove the side flanges and side oil seals. Refer to

4.

Remove the rear propeller shaft. Refer to

5.

Measure the total preload torque. Refer to

NOTE:

Record the total preload torque measurement.

Stamp

collapsible spacer replacement

No stamp

Not required

“0” or “0” on the far right of stamp

Required

“01” or “1” on the far right of stamp

Not required

PDIA0976E

Stamp before stamping

Stamping on the far right

Stamping

No stamp

0

0

“0”

(Front oil seal was replaced once.)

1

01

“01”

(Collapsible spacer and front oil seal were replaced last time.)

0

010

“0” is on the far right.

(Only front oil seal was replaced last time.)

1

...01

“1” is on the far right.

(Collapsible spacer and front oil seal were replaced last time.)

0

...010

DLN-268

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R230]

FRONT OIL SEAL

6.

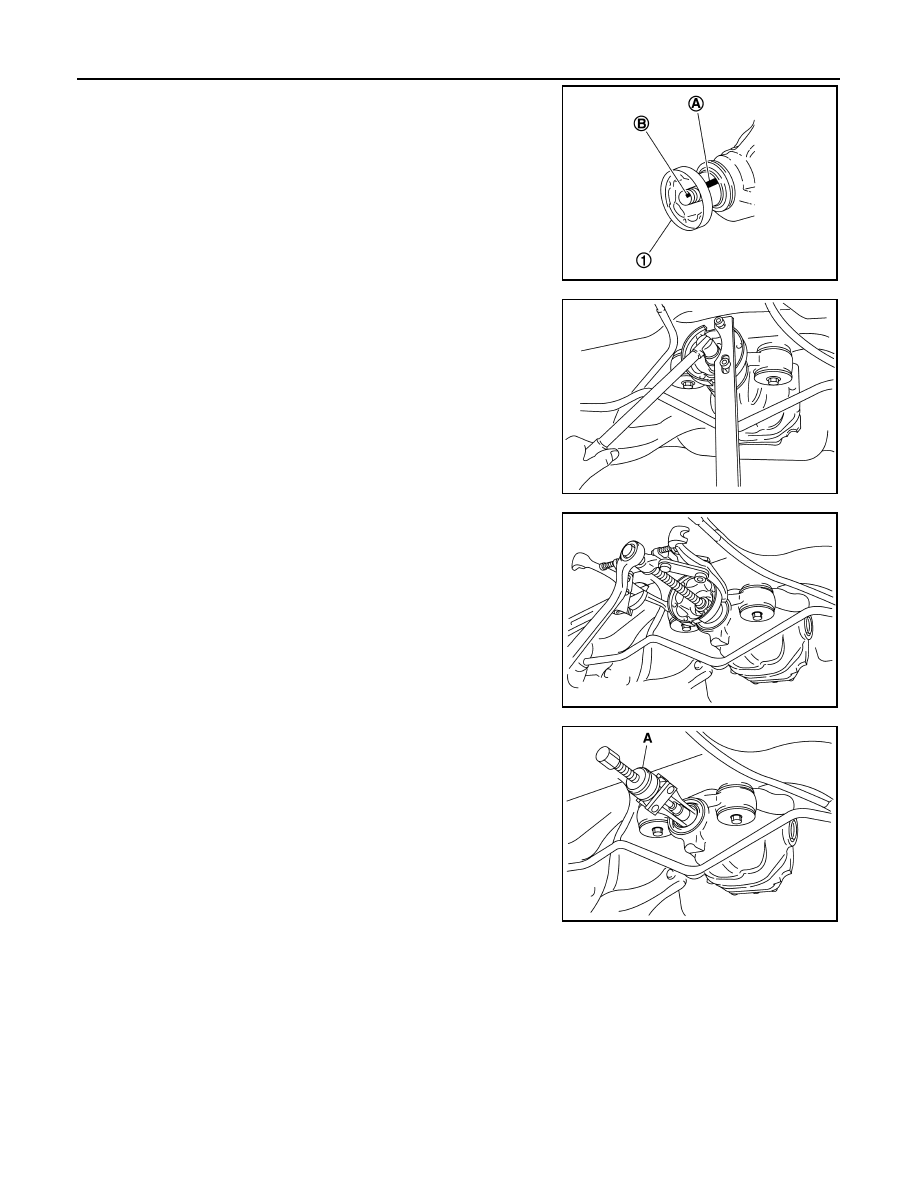

Put matching mark (B) on the end of the drive pinion. The

matching mark (A) on companion flange (1).

CAUTION:

For matching mark, use paint. Never damage companion

flange and drive pinion.

7.

Remove the drive pinion lock nut using a flange wrench.

8.

Remove the companion flange using a puller.

9.

Remove the front oil seal using the puller (A) [SST:KV381054S0

(J-34286).

INSTALLATION

PDIA0750J

PDIA0978E

PDIA0979E

PDIA0980E

FRONT OIL SEAL

DLN-269

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R230]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

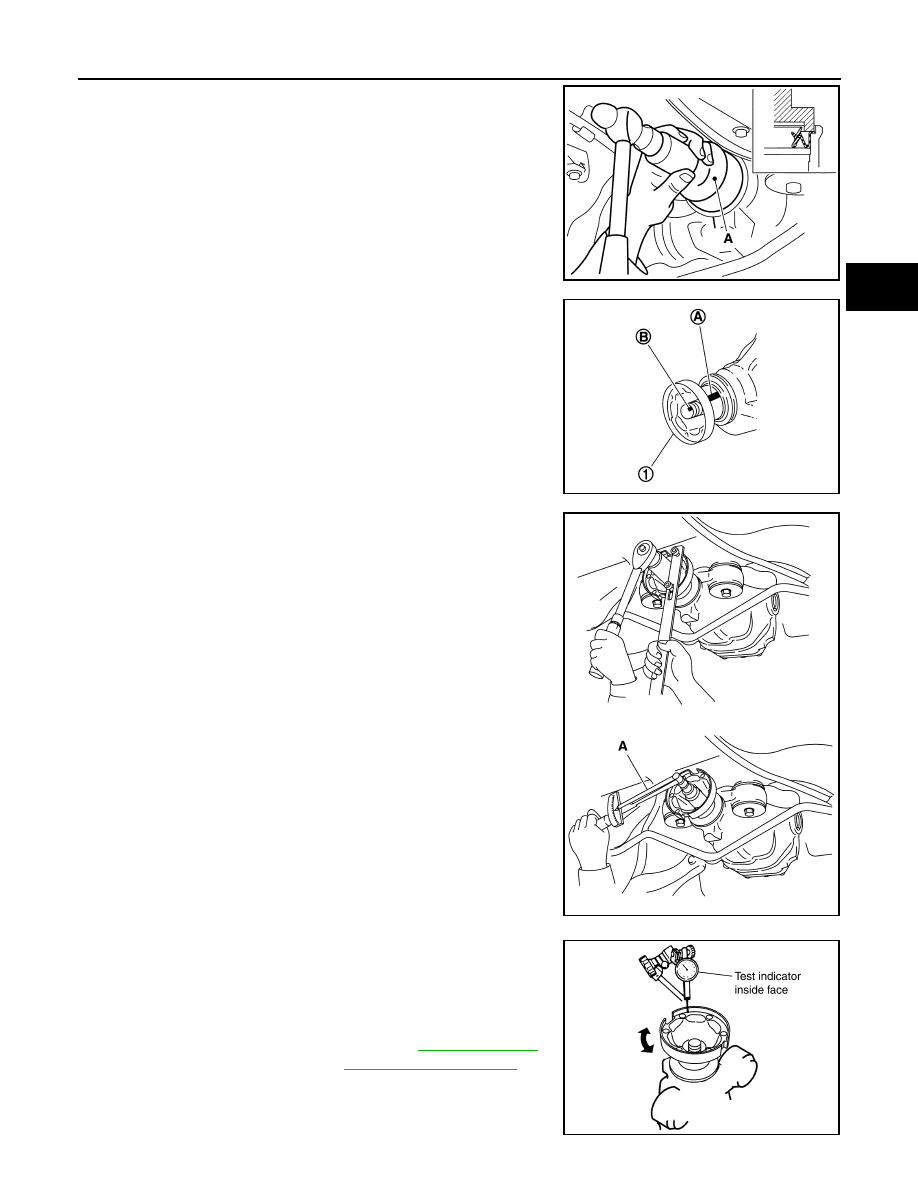

1.

Apply multi-purpose grease to the lips of the new front oil seal.

Then drive the new front oil seal in evenly until it becomes flush

with the gear carrier using the drift (A) [SST: KV40100621 (J-

25273)].

CAUTION:

• Never reuse front oil seal.

• Never incline the new front oil seal when installing.

2.

Align the matching mark (B) of drive pinion with the matching

mark (A) of companion flange (1), and then install the compan-

ion flange.

3.

Apply anti-corrosion oil to the thread and seat of new drive pin-

ion lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Never reuse drive pinion lock nut.

4.

Tighten drive pinion lock nut within the limits of specified torque

so as to keep the pinion bearing preload within a standard val-

ues.

CAUTION:

• Adjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

• If the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Never

loosen drive pinion lock nut to adjust the preload torque.

5.

Fit a test indicator to the inner side of companion flange (socket

diameter).

6.

Rotate companion flange to check for runout.

• If the runout value is outside the runout limit, follow the proce-

dure below to adjust.

PDIA0752J

PDIA0750J

A

: Preload gauge [SST: ST3127S000 (J-25765-A)]

Standard

Total preload torque

: A value that add 0.1 – 0.4

N·m (0.01 – 0.04 kg-m, 0.1 –

0.3 in-lb) to the measured

value before removing.

PDIA0981E

Limit

Companion flange runout

: Refer to

.

PDIA0490E

DLN-270

< REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: R230]

FRONT OIL SEAL

- Check for runout while changing the phase between companion flange and drive pinion by 90

°

step, and

search for the position where the runout is the minimum.

- If the runout value is still outside of the limit after the phase has been changed, possible cause will be an

assembly malfunction of drive pinion and pinion bearing and malfunction of pinion bearing. Check for

these items and repair if necessary.

- If the runout value is still outside of the limit after the check and repair, replace companion flange.

7.

Make a stamping for identification of front oil seal replacement frequency. Refer to “Identification stamp of

replacement frequency of front oil seal”.

CAUTION:

Make a stamping after replacing front oil seal.

8.

Install rear propeller shaft. Refer to

9.

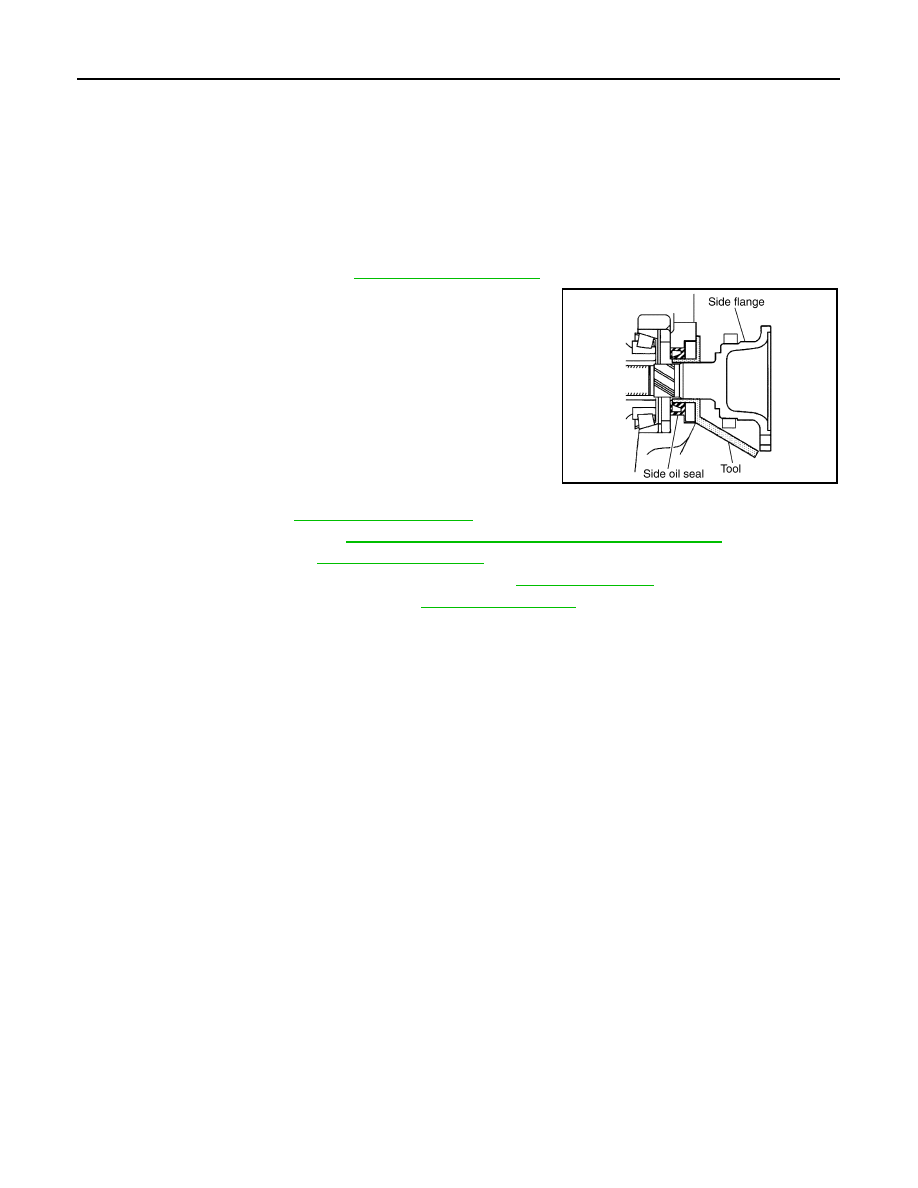

Install side flange with the following procedure.

a.

Attach the protector [SST: KV38107900 (J-39352)] to side oil

seal.

b.

After the side flange is inserted and the serrated part of side

gear has engaged the serrated part of flange, remove the pro-

tector.

c.

Put a suitable drift on the center of side flange, then drive it until

sound changes.

NOTE:

When installation is completed, driving sound of the side flange

turns into a sound that seems to affect the whole final drive.

10. Install drive shaft. Refer to

11. Install rear wheel sensor. Refer to

BRC-132, "REAR WHEEL SENSOR : Exploded View"

12. Install center muffler. Refer to

.

13. Refill gear oil to the final drive and check oil level. Refer to

.

14. Check the final drive for oil leakage. Refer to

SDIA0822E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст