Infiniti FX35, FX50 (S51). Manual — part 1579

RSU-14

< REMOVAL AND INSTALLATION >

SUSPENSION ARM

Appearance

Check the following items, and replace the part if necessary.

• Suspension arm and bushing for deformation, cracks or damage.

• Boot of ball joint for cracks or damage, and also for grease leakage.

Ball Joint Inspection

Manually move ball stud at least ten times by hand to check for smooth movement.

Swing Torque Inspection

• Hook spring balance (A) at cotter pin mounting hole. Confirm

spring balance measurement value is within specifications when

ball stud begins moving.

- If swing torque exceeds the standard range, replace suspension

arm assembly.

Rotating Torque Inspection

• Attach the mounting nut to ball stud. Make sure that rotating torque

is within the specifications with a preload gauge (A) [SST:

ST3127S000 (J-25765-A)].

- If rotating torque exceeds the standard range, replace suspension

arm assembly.

Axial End Play Inspection

• Move tip of ball stud in axial direction to check for looseness.

- If axial end play exceeds the standard range, replace suspension arm assembly.

INSPECTION AFTER INSTALLATION

1.

Check wheel alignment. Refer to

2.

Adjust neutral position of steering angle sensor. Refer to

BRC-9, "ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Special Repair Requirement"

.

Swing torque

: Refer to

.

JPEIA0005ZZ

Rotating torque

: Refer to

.

PDIA1258E

Axial end play

: Refer to

.

RADIUS ROD

RSU-15

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

RSU

N

O

P

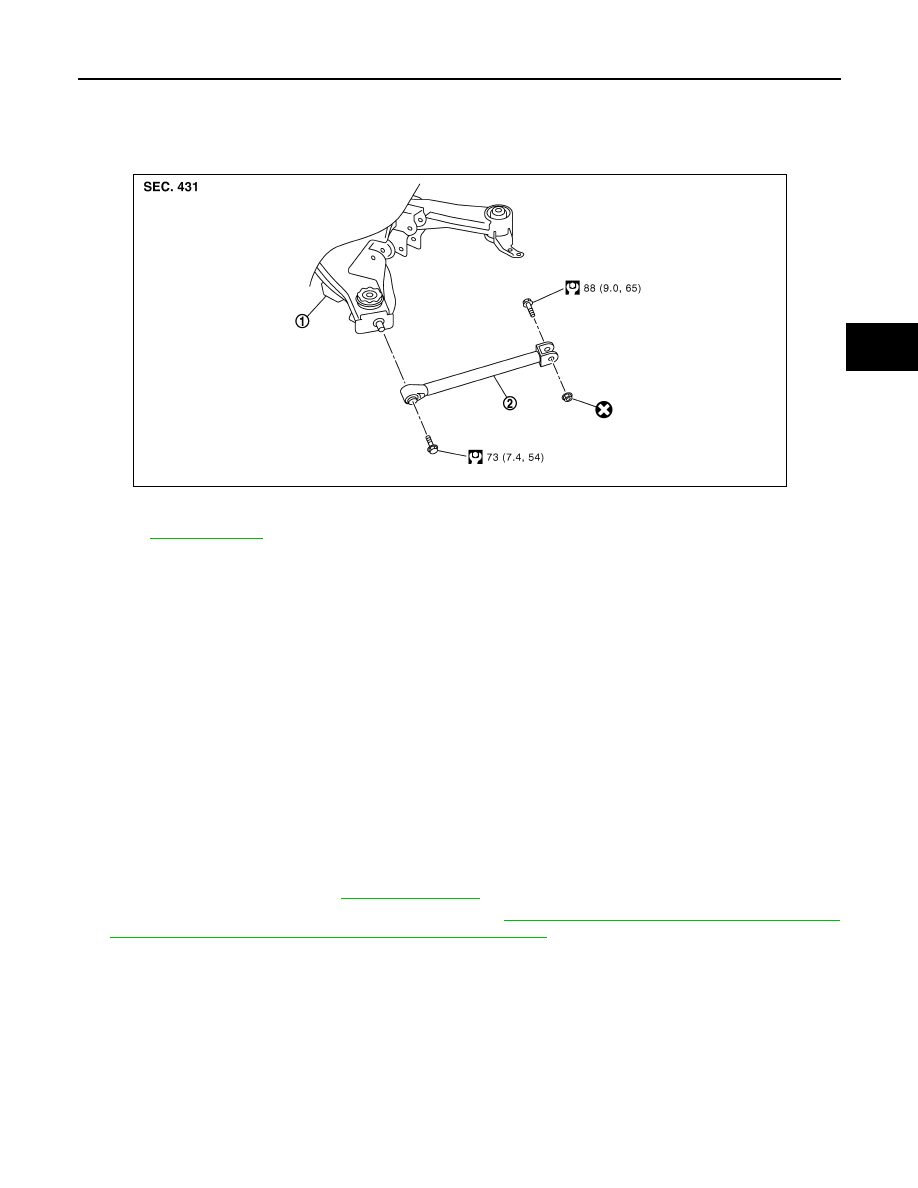

RADIUS ROD

Exploded View

INFOID:0000000005249862

Removal and Installation

INFOID:0000000005249863

REMOVAL

1.

Remove tire with power tool.

2.

Remove radius rod mounting bolt and nut (axle housing side) with power tool.

3.

Remove radius rod mounting bolt (rear suspension member side) with power tool, and remove radius rod.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of rear suspension member and axle installation position (rubber bushing), under

unladen conditions with tires on level ground.

Inspection

INFOID:0000000005249864

INSPECTION AFTER REMOVAL

Check radius rod and bushing for any deformation, cracks, or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1.

Check wheel alignment. Refer to

2.

Adjust neutral position of steering angle sensor. Refer to

BRC-9, "ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Special Repair Requirement"

.

1.

Rear suspension member

2.

Radius rod

for symbols in the figure.

JPEIB0092GB

RSU-16

< REMOVAL AND INSTALLATION >

FRONT LOWER LINK

FRONT LOWER LINK

Exploded View

INFOID:0000000005249865

WITHOUT RAS

WITH RAS

Removal and Installation

INFOID:0000000005249866

REMOVAL

1.

Upper seat

2.

Coil spring

3.

Rubber seat

4.

Rear lower link

5.

Adjusting bolt

6.

Front lower link

7.

Rear suspension member

Refer to

for symbols in the figure.

JPEIB0114GB

1.

Upper seat

2.

Coil spring

3.

Rubber seat

4.

Rear lower link

5.

Adjusting bolt

6.

Front lower link

7.

Rear suspension member

Refer to

for symbols in the figure.

JPEIB0121GB

FRONT LOWER LINK

RSU-17

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

RSU

N

O

P

1.

Remove tire with power tool.

2.

Set suitable jack under axle assembly to relieve the coil spring tension.

3.

Remove shock absorber mounting bolts from front lower link. Refer to

4.

Remove front lower link mounting bolts and nuts from axle housing with power tool.

5.

Remove stabilizer clamp and stabilizer bushing. Refer to

6.

Remove front lower link mounting bolts and nuts from rear suspension member with power tool, and

remove front lower link.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of rear suspension member and axle installation position (rubber bushing), under

unladen conditions with tires on level ground.

Inspection

INFOID:0000000005249867

INSPECTION AFTER REMOVAL

Check front lower link and bushing for any deformation, cracks, or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1.

Check wheel alignment. Refer to

2.

Adjust neutral position of steering angle sensor. Refer to

BRC-9, "ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Special Repair Requirement"

.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст