Infiniti EX35. Manual — part 1465

TM-248

< DISASSEMBLY AND ASSEMBLY >

[5AT: RE5R05A]

TRANSMISSION ASSEMBLY

74. Install oil pan gasket to transmission case.

CAUTION:

• Do not reuse oil pan gasket.

• Install it in the direction to align hole positions.

• Completely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

75. Install oil pan (2) and clips (1) to transmission case.

CAUTION:

• Install it so that drain plug (3) comes to the position as

shown in the figure.

• Be careful not to pinch harnesses.

• Completely remove all moisture, oil and old gasket, etc.

from oil pan mounting surface.

76. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening them.

Tighten oil pan mounting bolts to the specified torque.

CAUTION:

Do not reuse oil pan mounting bolts.

77. Install drain plug to oil pan. Tighten drain plug to the specified

torque.

CAUTION:

Do not reuse drain plug gasket.

78. Pour ATF into torque converter.

• Approximately 2 liter (2-1/8 US qt, 1-3/4 Imp qt) of ATF is

required for a new torque converter.

• When reusing old torque converter, add the same amount

of ATF as was drained.

79. Install torque converter while aligning notches of torque con-

verter with notches of oil pump.

CAUTION:

Install torque converter while rotating it.

: Front

: Oil pan mounting bolt

SCIA8117E

: Front

JPDIA0021ZZ

SAT428DA

SCIA5010E

TRANSMISSION ASSEMBLY

TM-249

< DISASSEMBLY AND ASSEMBLY >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

80. Measure distance (A) to make sure that torque converter is in

proper position.

Inspection

INFOID:0000000003130650

INSPECTION AFTER REMOVAL

• Check foreign materials in oil pan to help determine causes of mal-

function. If the ATF is very dark, smells burned, or contains foreign

particles, the frictional material (clutches, band) may need replace-

ment. A tacky film that will not wipe clean indicates varnish build

up. Varnish can cause valves, servo, and clutches to stick and can

inhibit pump pressure.

- If frictional material is detected, perform A/T fluid cooler

cleaning. Refer to

.

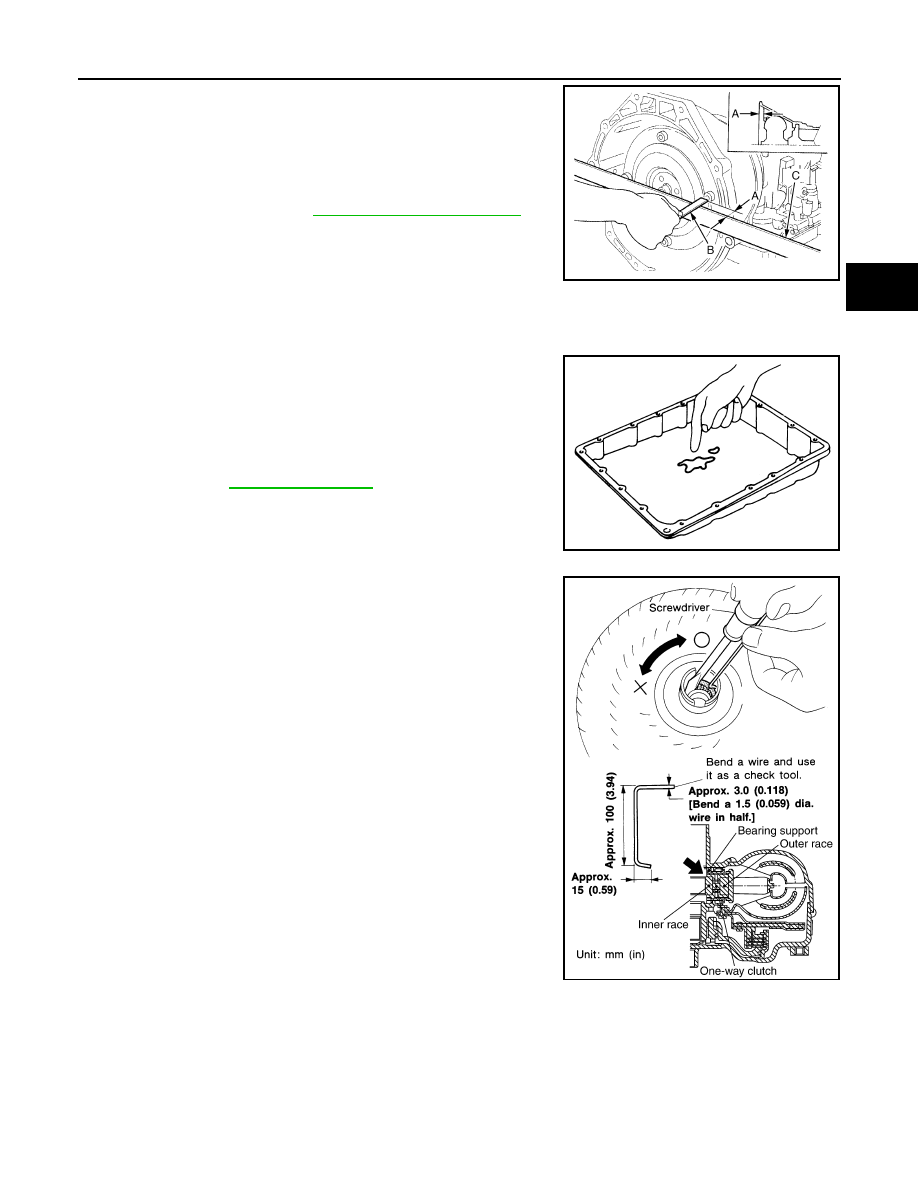

• Check torque converter one-way clutch using a check tool as

shown at figure.

1.

Insert a check tool into the groove of bearing support built into

one-way clutch outer race.

2.

When fixing bearing support with a check tool, rotate one-way

clutch spline using a screwdriver.

3.

Make sure that inner race rotates clockwise only. If not, replace

torque converter assembly.

B

: Scale

C

: Straightedge

Distance (A)

: Refer to

.

JPDIA0042ZZ

SCIA5199E

SCIA3171E

TM-250

< DISASSEMBLY AND ASSEMBLY >

[5AT: RE5R05A]

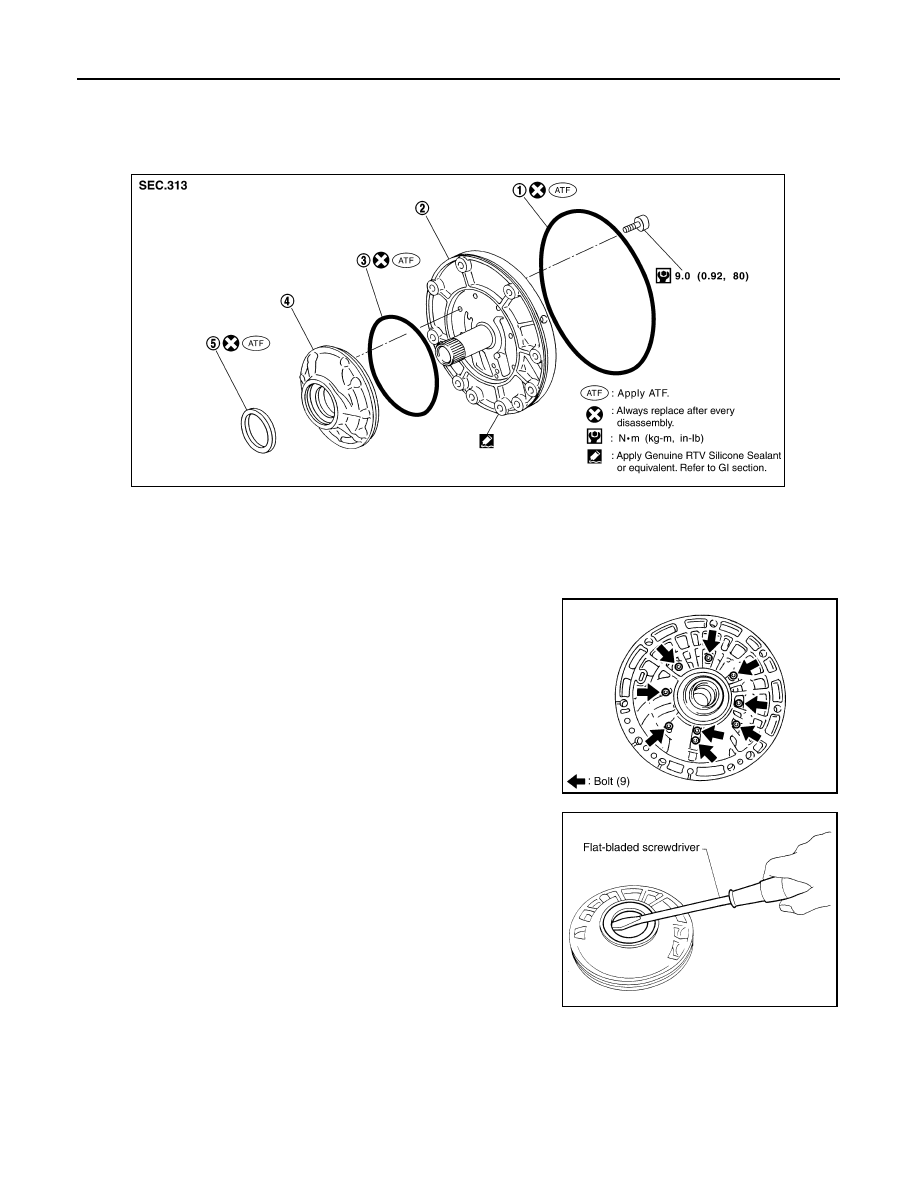

OIL PUMP

OIL PUMP

Exploded View

INFOID:0000000003130651

Disassembly

INFOID:0000000003130652

1.

Remove oil pump housing from oil pump cover.

2.

Remove oil pump housing oil seal using a flat-bladed screw-

driver.

CAUTION:

Be careful not to scratch oil pump housing.

1.

O-ring

2.

Oil pump cover

3.

O-ring

4.

Oil pump housing

5.

Oil pump housing oil seal

SCIA5227E

SCIA5228E

SCIA2840E

OIL PUMP

TM-251

< DISASSEMBLY AND ASSEMBLY >

[5AT: RE5R05A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

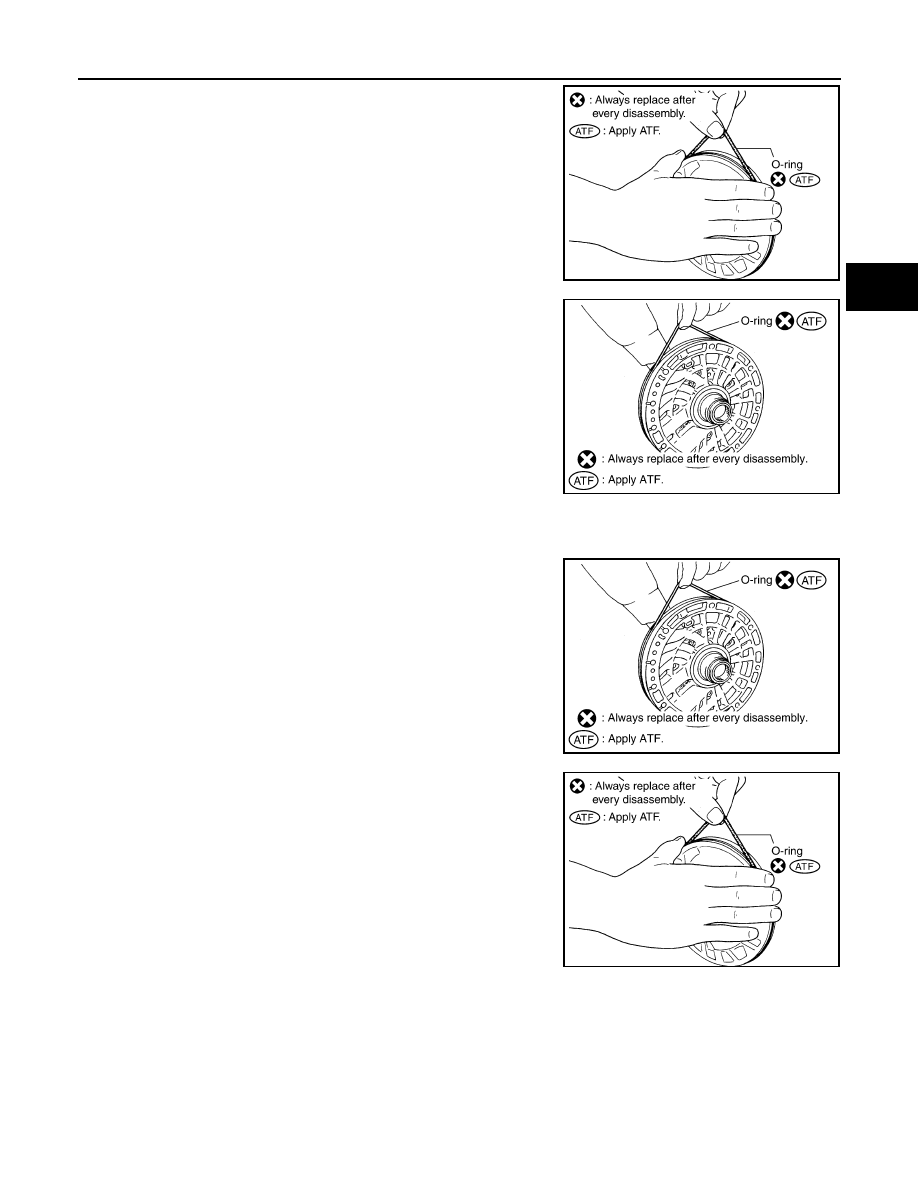

3.

Remove O-ring from oil pump housing.

4.

Remove O-ring from oil pump cover.

Assembly

INFOID:0000000003130653

1.

Install O-ring to oil pump cover.

2.

Install O-ring to oil pump housing.

SCIA2841E

SCIA5230E

SCIA5230E

SCIA2841E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст