Infiniti EX35. Manual — part 1215

2008 EX35 – Electrical

ELECTRICAL

General Specifications - Charging: CHG – 31

Battery Hydrometer

Temperature Corrections:

BATTERY CONDITION

Battery Sulphation:

A battery will be completely discharged if it is left unattended for a long time and the specific

gravity becomes less than 1.100. This may result in sulphation on the cell plates. To

determine if a battery has been sulfated, note its voltage and current when charging. If low

current and higher voltages are observed in the initial stages of charging a sulfated battery is

likely. A sulfated battery may sometimes be brought back into service by means of a long slow

charge, 12 hours or more.

• Do not quick charge a fully discharged battery.

• After charging, if the specific gravity of any two cells varies more then .050, the battery

should be replaced.

RAX-1

TRANSMISSION & DRIVELINE

C

E

F

G

H

I

J

K

L

M

SECTION

RAX

A

B

RAX

N

O

P

CONTENTS

REAR AXLE

SYMPTOM DIAGNOSIS . . . . . . . ...

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING . . . . . . . .

NVH Troubleshooting Chart . . . . . . . . . ..

PRECAUTION . . . . . . . . . . . ...

PRECAUTIONS . . . . . . . . . . . . ...

Precautions for Drive Shaft . . . . . . . . . ...

PREPARATION . . . . . . . . . . .

PREPARATION . . . . . . . . . . . . ...

Special Service Tool . . . . . . . . . . . .....

Commercial Service Tool . . . . . . . . . . ..

ON-VEHICLE MAINTENANCE . . . . . .

REAR WHEEL HUB AND HOUSING . . . . .

Inspection . . . . . . . . . . . . . . . . ..

REAR DRIVE SHAFT . . . . . . . . . . ..

Inspection . . . . . . . . . . . . . . . . ..

ON-VEHICLE REPAIR . . . . . . . . ..

REAR WHEEL HUB AND HOUSING . . . .

Exploded View . . . . . . . . . . . . . . ..

Removal and Installation . . . . . . . . . . ..

Inspection . . . . . . . . . . . . . . . . .

REAR DRIVE SHAFT . . . . . . . . . . .

Exploded View . . . . . . . . . . . . . . ..

Removal and Installation . . . . . . . . . . ..

WHEEL SIDE . . . . . . . . . . . . . . . ..

WHEEL SIDE : Disassembly and Assembly . . ...

FINAL DRIVE SIDE . . . . . . . . . . . . .

FINAL DRIVE SIDE : Disassembly and Assembly .

Inspection . . . . . . . . . . . . . . . .

SERVICE DATA AND SPECIFICATIONS

(SDS) . . . . . . . . . . . . . . .

SERVICE DATA AND SPECIFICATIONS

(SDS) . . . . . . . . . . . . . . . . .

Wheel Bearing . . . . . . . . . . . . . . .

RAX-2

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

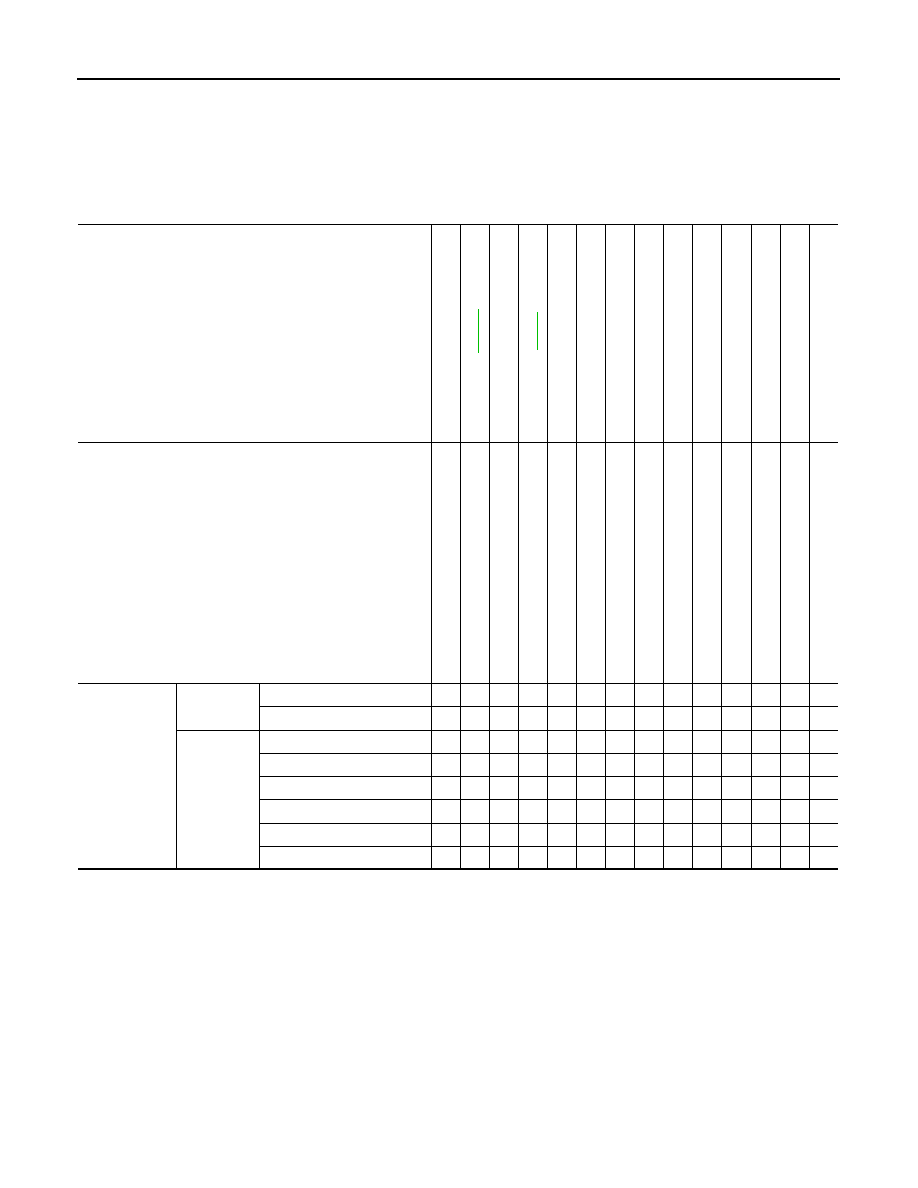

NVH Troubleshooting Chart

INFOID:0000000003138875

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

—

—

—

NVH in DLN

section.

NVH in DLN

section.

NVH in RAX and RSU sections.

Re

fer

to RE

AR AXL

E in

th

is ch

art

.

NVH in WT

section.

NVH in WT

section.

Refe

r to

DRIVE

SHAFT i

n

thi

s

cha

rt.

NVH in BR

section.

NVH in ST section.

Possible cause and SUSPECTED PARTS

Ex

ce

ss

iv

e joi

nt an

gl

e

Jo

in

t sl

id

in

g

re

si

st

a

n

c

e

Im

ba

la

nc

e

Imp

rop

er i

ns

ta

lla

ti

o

n,

lo

os

en

es

s

Part

s interf

erence

PROPELLER S

H

AFT

DIFF

ERENTIAL

REAR A

X

LE

AND REAR SUSPE

NSION

REAR A

XLE

TI

RE

ROAD WHEE

L

DRIVE SHAFT

BRAKE

STE

E

RING

Symptom

DRIVE

SHAFT

Noise

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

×

REAR AXLE

Noise

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

Judder

×

×

×

×

×

×

Poor quality ride or handling

×

×

×

×

×

PRECAUTIONS

RAX-3

< PRECAUTION >

C

E

F

G

H

I

J

K

L

M

A

B

RAX

N

O

P

PRECAUTION

PRECAUTIONS

Precautions for Drive Shaft

INFOID:0000000003756668

CAUTION:

Note the following precautions when disassembling and assembling drive shaft.

• Joint sub-assembly does not disassemble because it is non-overhaul parts.

• Perform work in a dust-free location.

• Before disassembling and assembling, clean the parts.

• Prevent the entry of foreign objects during disassembly of the service location.

• Disassembled parts must be carefully reassembled in the correct order. If work is interrupted, a

clean cover must be placed over parts.

• Paper waste must be used. Fabric shop cloths must not be used because of the danger of lint adher-

ing to parts.

• Disassembled parts (except for rubber parts) should be cleaned with kerosene which shall be

removed by blowing with air or wiping with paper waste.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст