SsangYong Korando II (1996-2006 year). Manual — part 33

1B1 -- 104 M162 ENGINE MECHANICAL

DAEWOO MY_2000

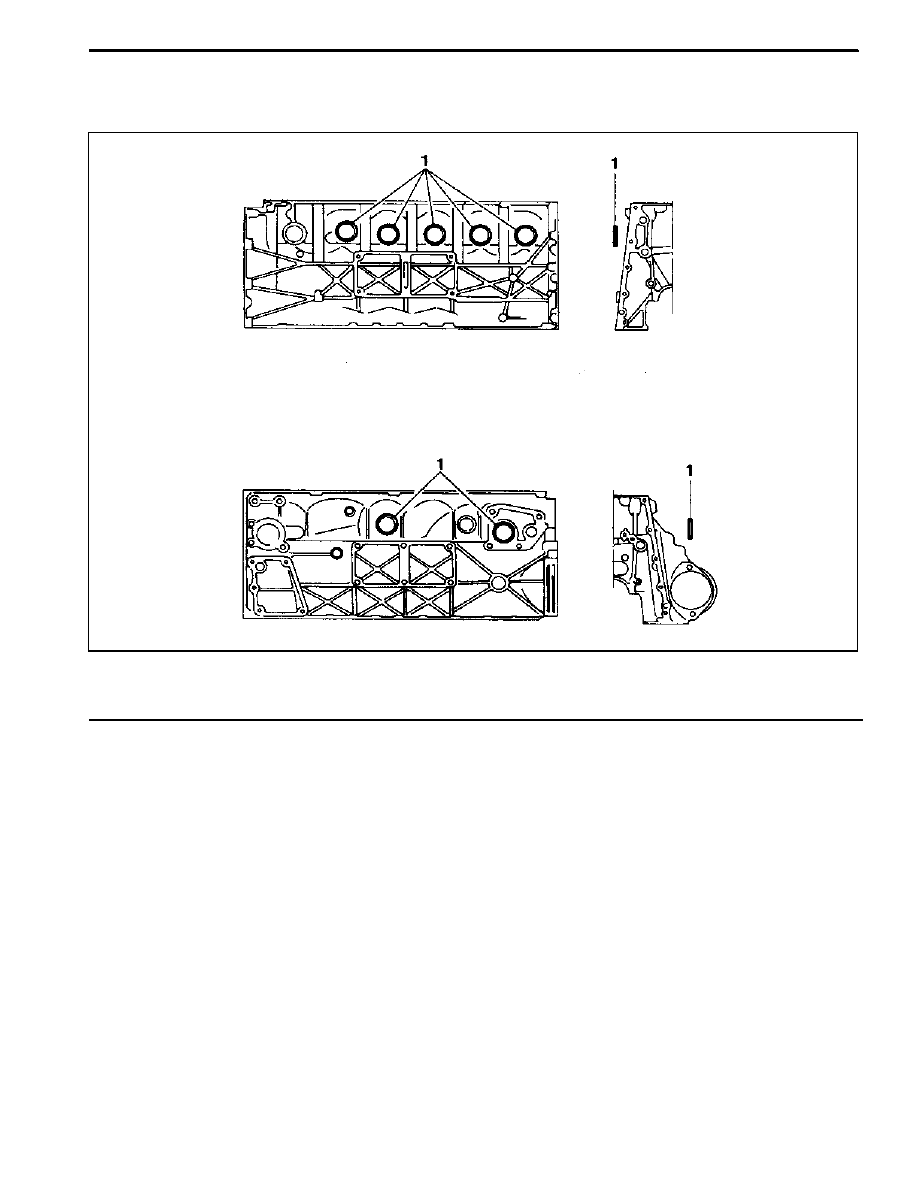

CORE PLUGS IN CRANKCASE

Preceding Work: Draining of the coolant

1 Core Plug

Replace

. . . . . . . . . . . . . . . . . . . . . . . . .

M162 ENGINE MECHANICAL 1B1 -- 105

DAEWOO MY_2000

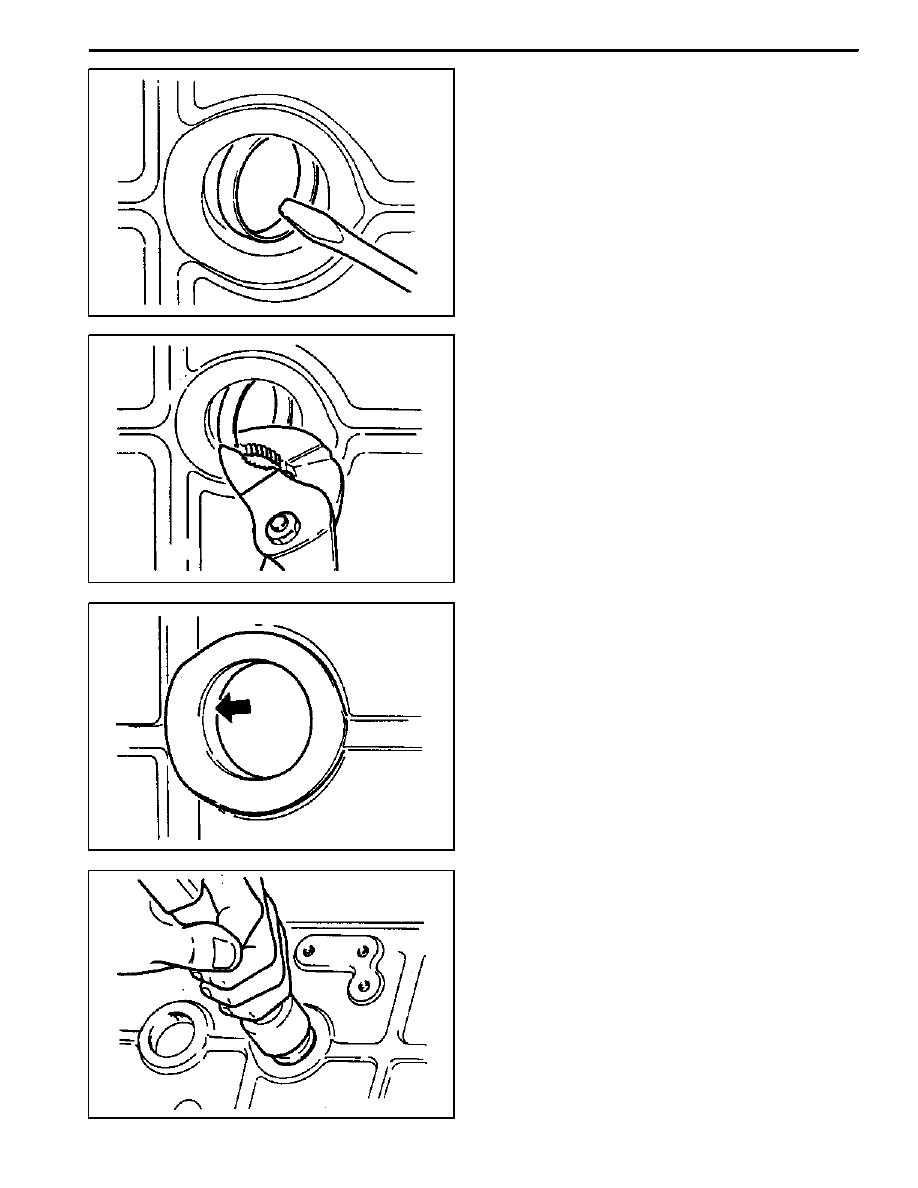

Replacement Procedure

1. Remove the intake and exhaust manifolds.

2. Pull back the core plug until the end of one side

comes out using the screw driver.

3. Pull out the plug carefully using a pliers.

4. Clean the sealing surface and apply Loctite 241.

5. Press in new plug using a drift.

Notice: Wait for about 45minutes before filling the cool-

ant so that the Loctite 240 hardens.

6. Warm up the engine and check the coolant for leaks.

1B1 -- 106 M162 ENGINE MECHANICAL

DAEWOO MY_2000

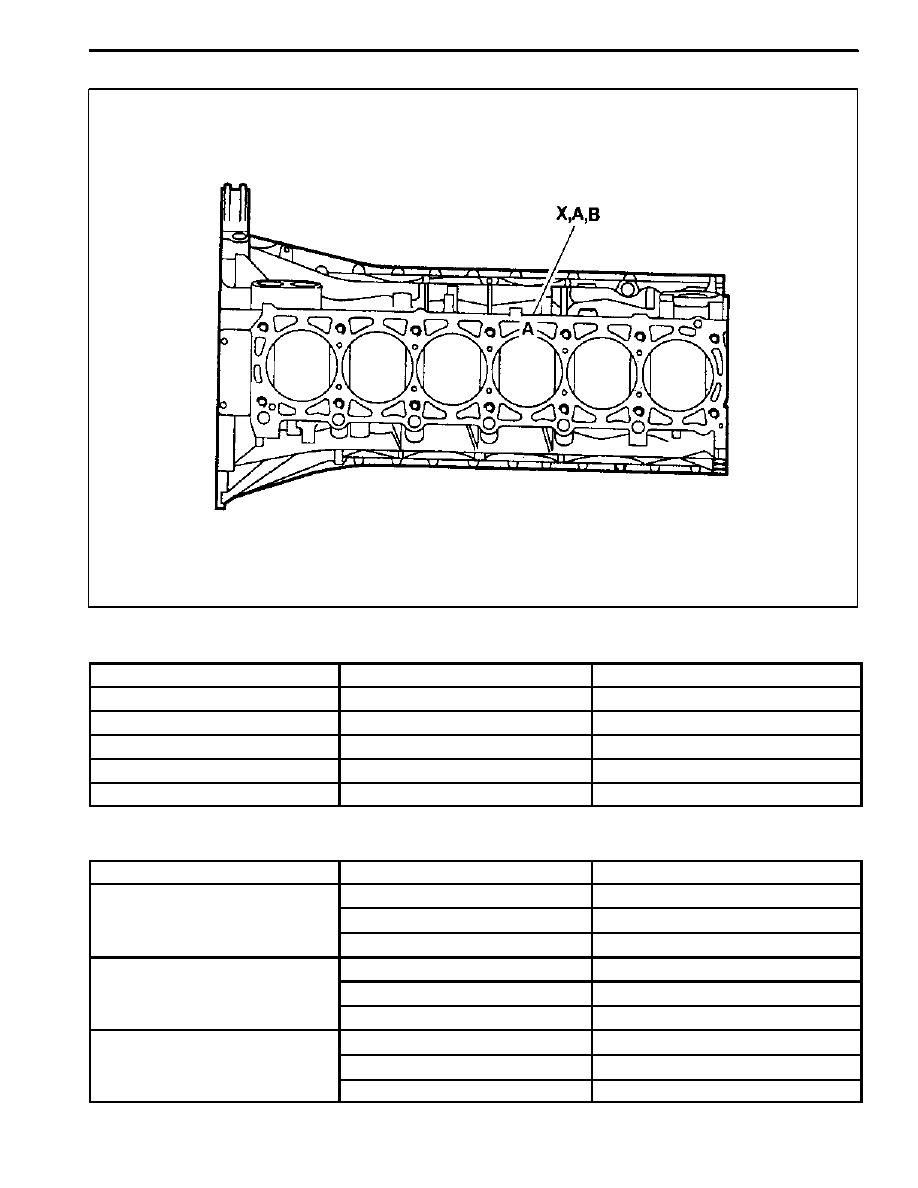

CYLINDER BORE

Group Code Letter and Cylinder Bore Size

Group Code Letter of Cylinder

Piston Type to be Used

Cylinder Bore Size (mm)

A

A or X

φ 89.900 -- φ 89.906

X

A, X or B

φ 89.906 -- φ 89.912

B

X or B

φ 89.912 -- φ 89.918

X + 5

X + 5

φ 89.950 -- φ 89.968

X + 10

X + 10

φ 90.000 -- φ 90.018

Repair Size

Type

Group Code Letter 1)

Cylinder Bore Size (mm)

Standard Size φ 89.9

A

φ 89.900 -- φ 89.906

φ

X

φ 89.906 -- φ 89.912

B

φ 89.912 -- φ 89.918

1st Repair Size

(St d d Si

0 25)

A

φ 90.150 -- φ 90.156

p

(Standard Size + 0.25)

X

φ 89.156 -- φ 90.162

B

φ 90.162 -- φ 90.168

2nd Repair Size

(St d d Si

0 5)

A

φ 90.400 -- φ 90.406

p

(Standard Size + 0.5)

X

φ 90.406 -- φ 90.412

B

φ 90.412 -- φ 90.418

1) The group code letters are carved on the surface of the piston crown and in the mating surface of the crankcase.

M162 ENGINE MECHANICAL 1B1 -- 107

DAEWOO MY_2000

Service Data Standard

Wear Limit in Longitudinal and Transverse Direction

0.1 mm

Permissible Deviation of Cylinder Out--of--round

When new

0.007 mm

y

Wear limit

0.05 mm

Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area)

0.05 mm

Basic Peak--to--valley Height After Final Honing and Brushing

0.003 -- 0.006 mm

Chamfer Angle

60°

Honing Angle

50° ± 10°

Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore

size in axial and transverse direction at three points

(1,2,3).

1,2,3. Measuring Points

A. Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c. Location of the Oil Ring at BDC

Chamfer Angle

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст