Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 318

AUTOMATIC TRANSMISSION (AW30-40LE) 7A-121

242RW013

4. Measure the resistance between each terminals.

Resistance: 0.5 – 30 kΩ

Ω

Ω

Ω (at 0℃

℃

℃

℃ - 120℃

℃

℃

℃)

5. If either of the measured values exceeds the specified,

replace the ATF temperature sensor.

Torque: 15 N・・・・m (1.5 kg・・・・m/11 Ib・・・・ft)

THROTTLE POSITION SENSOR

INSPECTION (UBS and TFR/S)

1. Turn the starter switch to the “ON” position.

2. Measure the voltage between throttle position sensor

connector terminals 2 (output) and 1 (ground).

NOTE:

・ Do not remove the sensor connector.

・ Make sure that power source (4.75 – 5.25V) is

measured between terminals 1 and 3 before

measurement at step 2.

Standard voltage:

Idling −

−

−

− 0.25 – 0.45V

WOT −

−

−

− 3.74 – 4.56V

(LHD)

101R200007

(RHD)

101L200001

7A-122 AUTOMATIC TRANSMISSION (AW30-40LE)

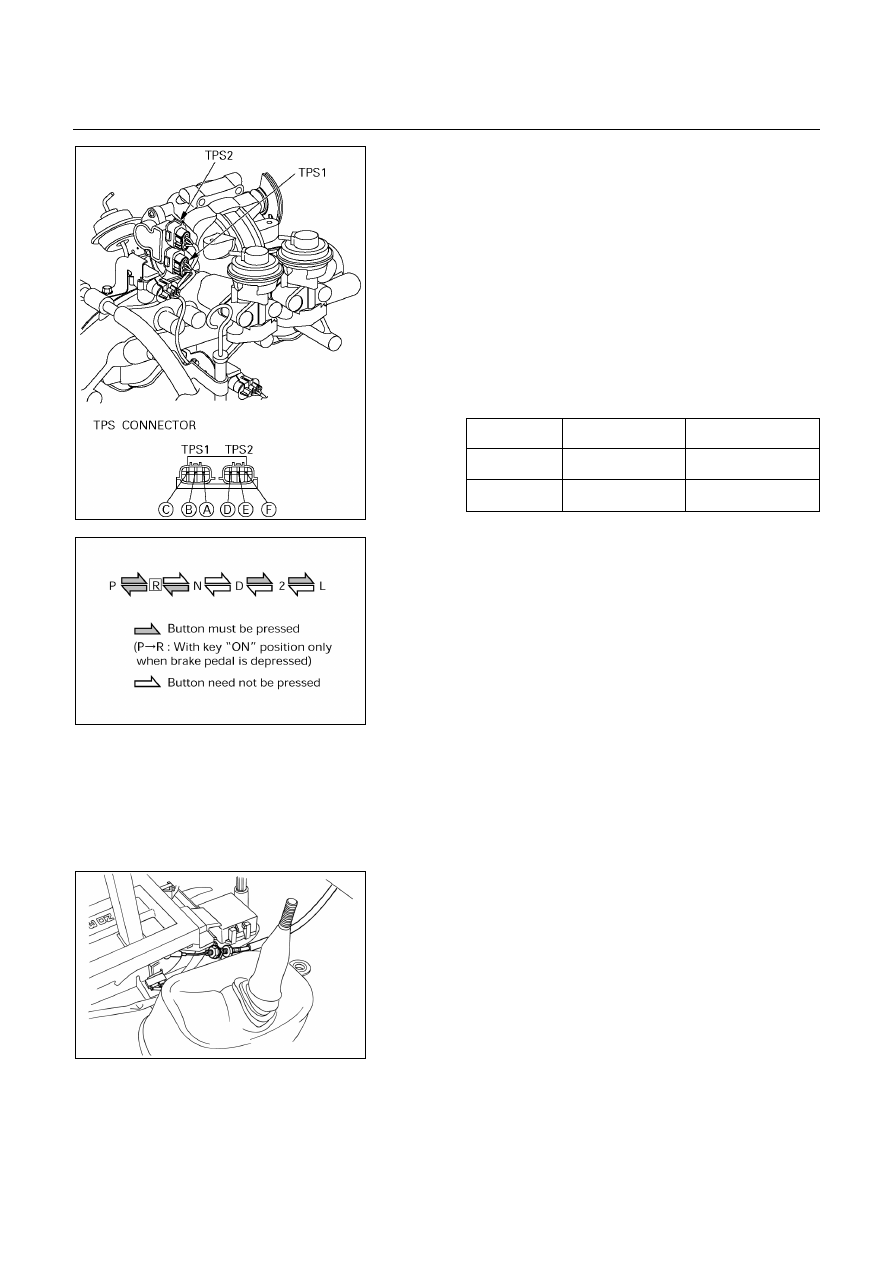

THROTTLE POSITION SENSOR

INSPECTION (’01 TFR)

1. Turn the starter switch to the “ON” position.

2. Measure the voltage between TPS1 connector

terminals (A) (output) and (C) (ground), and TPS2

connector terminals (D) (output) and (E) (ground).

NOTE:

・ Do not remove the sensor connector.

・ Make sure that power source (5.0±

±

±

±0.01V) is

measured between TPS1 connector terminals (B)

and (C), and TPS2 connector terminals (F) and (E)

before measurement at step 2.

Standard voltage:

TPS1 TPS2

Idling

0.55−0.65 V

0.2−0.4 V

WOT

3.1−3.3 V

1.5−1.6 V

035L100001

256RY00001

SELECTOR LEVER

Inspection

1. Make sure that when the selector lever is shifted from

"P" to "L", a "clicking" can be felt at each shift position.

Make sure that the gear corresponds to that of the

position plate indicator.

2. Check to see if the selector lever can be shifted as

shown.

REMOVAL

Preparation:

Disconnect negative (-) battery cable.

1. Transfer Control Lever Knob (4×4)

2. Front

Console

Disconnect wiring harness connectors.

UBS

256RW012

3. Selector Lever Assembly

1. Disconnect shift lock cable from the selector lever

assembly side (UBS).

2. Disconnect wiring harness connectors.

AUTOMATIC TRANSMISSION (AW30-40LE) 7A-123

256RW013

3. Disconnect shift control rod from the selector lever

assembly side.

’01 TFR

220L200001

256RW014

’01 TFR

256L200001

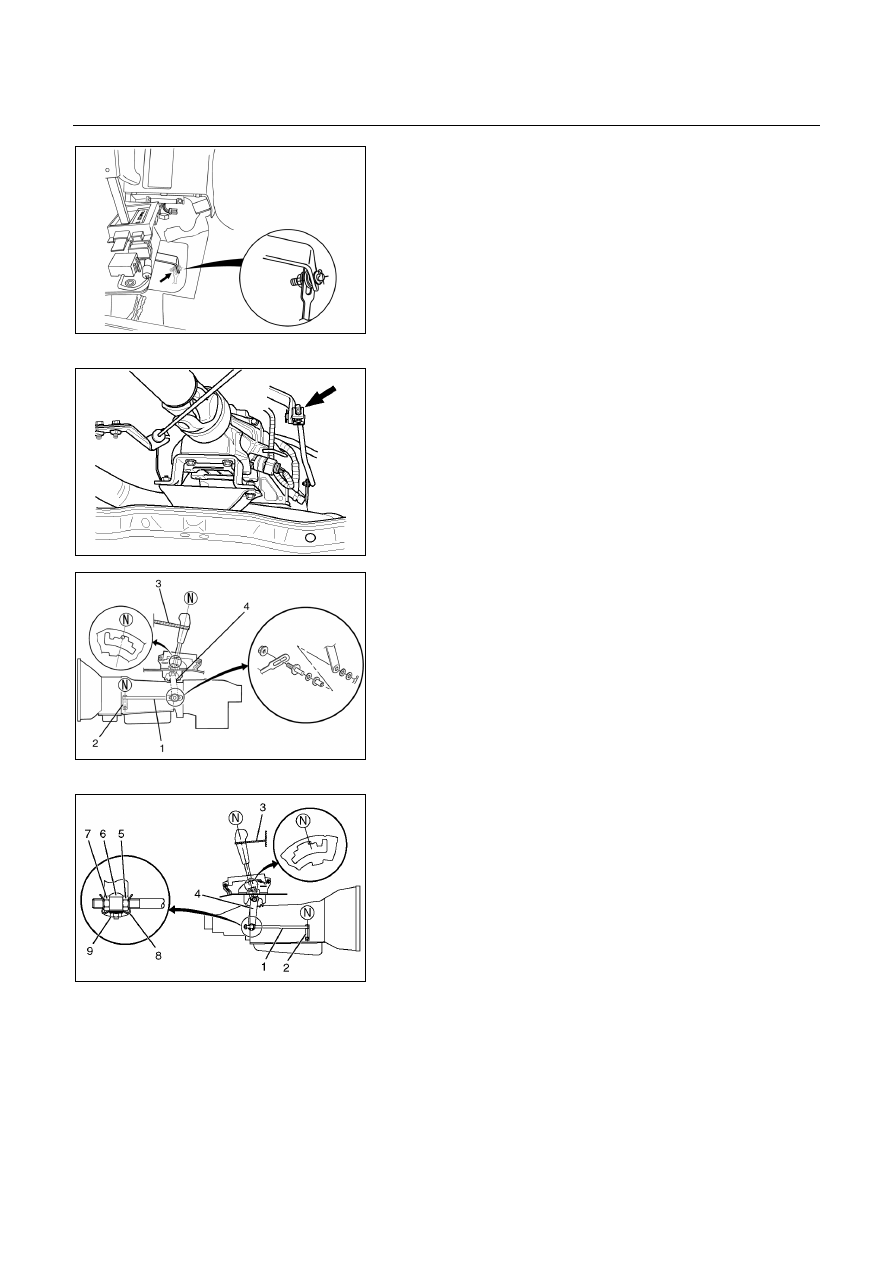

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points;

Adjustment of select lever and control rod

1. Place the vehicle on a level surface.

NOTE:

If the vehicle is not on a level surface, the shift

select cable set position will vary with the

movement of the engine. To prevent possible

misadjustment of the cable, the vehicle must be

placed on a level surface.

2. Install the shift control rod (1) to the transfmission

select lever (2), and then place the lever in the "N"

position.

3. Set select lever in the "N" position.

4. Push selector lever forward and secure it (using a

rubber band (3), etc.) so that pin comes into contact

with the wall of detent plate.

5. Install the shift control rod (1) to the selector lever arm

(4).

Nut torque: 27 N・・・・m (2.8 kg・・・・m/20 Ib・・・・ft)

NOTE:

Do not apply oil to threaded portions.

7A-124 AUTOMATIC TRANSMISSION (AW30-40LE)

6. (’01

TFR)

a. Turn nut (5) until it butts against boss (6).

b. Tighten nut (7) to lock boss while keeping nut (5)

stationary with a tool.

Nut torque: 27 N・・・・m (2.8 kg・・・・m/20 Ib・・・・ft)

c. Attach clip (8) and fix it with nut (9).

Nut torque: 7 N・・・・m (70 kg・・・・cm/61 Ib・・・・in)

7. After adjustment, operate select lever on a trial basis to

makes sure of its smooth operation and no abnormal

indication in each position.

256RW015

Adjustment of shift lock cable (UBS)

1. Set ignition key in "LOCK" position and selector lever in

"P" position.

2. Adjust cable screw cap on selector lever side to

provide a gap (slack for cable) of 1-2mm between rod

on steering lock side and stopper

Adjust cap as follows:

a. Pull screw cap (1) in arrow direction to put off slack of

inner cable.

b. With cable kept as (a), adjust gap between nut (2)

and bracket to 5mm (0.2in).

c. Lock inner cable by turning nut (3) while holding nut

(2) in place.

Lock nut torque: 3.7 N・・・・m (38 kg・・・・cm/33 Ib・・・・in)

NOTE:

Clean the rod threads and do not apply oil to the

threaded portions.

3. Make sure of proper operation of shift lock through

checks as follows:

a. Selector lever shall not be moved out of "P" position

with ingition key in "Lock" position.

b. Selector lever can be moved out of "P" position with

ignition key in "ON" position only when brake pedal is

depressed.

c. Ignition key can be turned to "LOCK" position only

when selector lever is in "P" position (key can be

pulled out).

If (a) and (c) fail, readjust cable. If (b) fails, readjust

connector wiring and brake pedal switch.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст