Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 556

6A – 62 ENGINE MECHANICAL

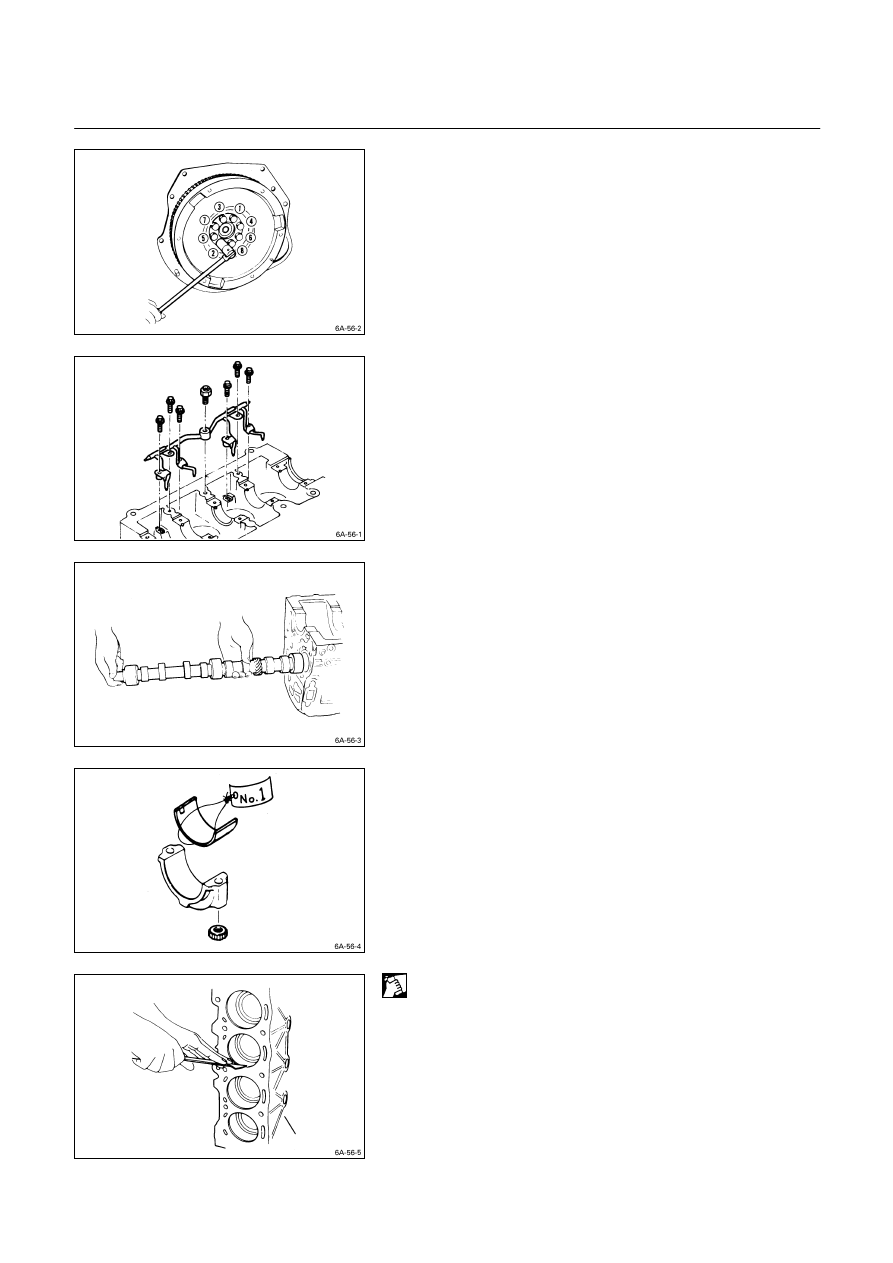

23. Flywheel

Block the crankshaft with a piece of hard wood to prevent

the flywheel from turning.

Loosen the flywheel bolts in numerical order a little at a

time.

27. Piston Cooling Oil Pipe

The oiling jet uses thin steel tubing which is easily bent.

Accidental contact between the oiling jet and the cylinder

body, piston, or a tool will damage the oiling jet.

Never attempt to repair a damaged oiling jet. Replace it

with a new one.

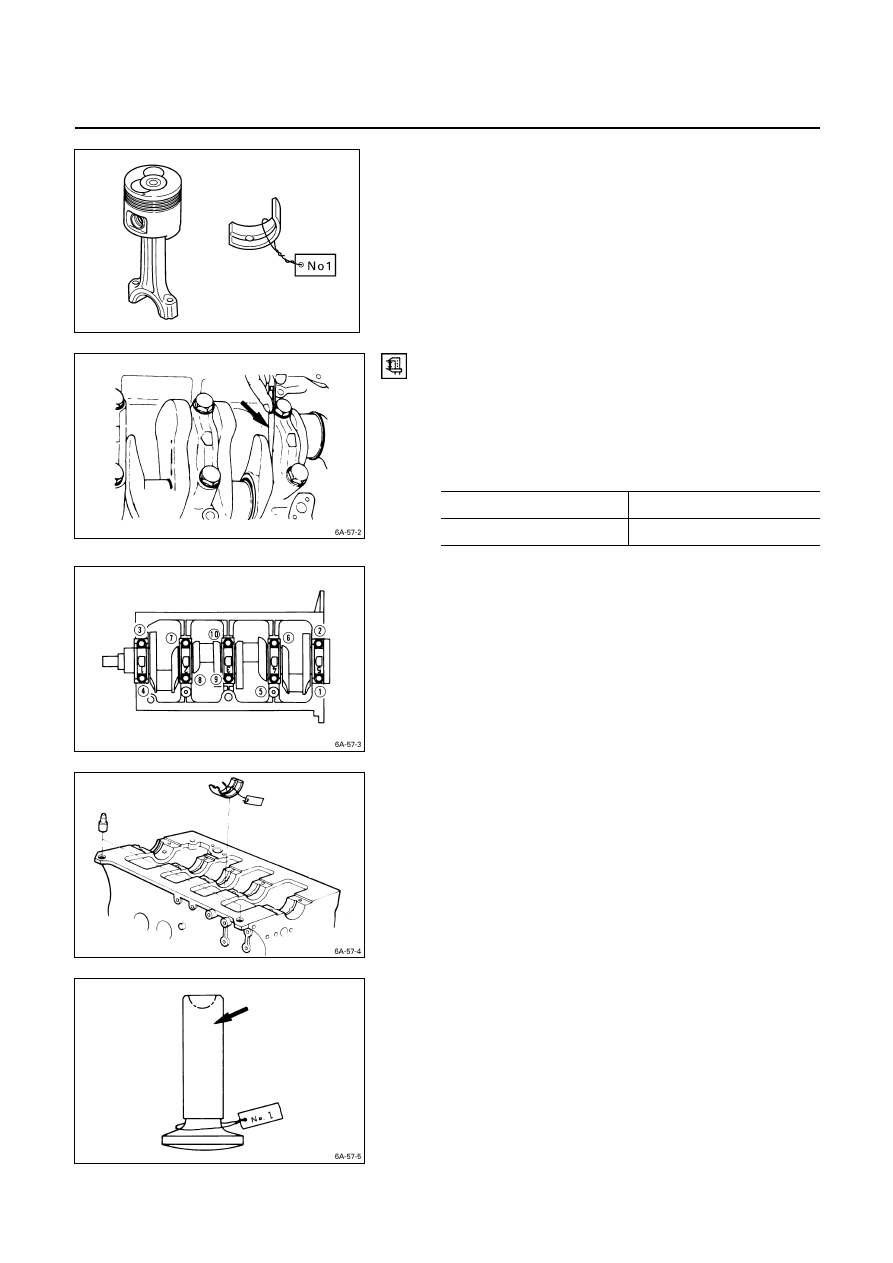

30. Camshaft

Jiggle the camshaft with your hand as you pull it free from

the front of the engine.

32. Connecting Rod Bearing Cap with Lower Bearing

If the connecting rod lower bearings are to be reinstalled,

mark their fitting positions by tagging each bearing with the

cylinder number from which it was removed.

33. Piston and Connecting Rod with Upper Bearing

1) Remove carbon deposits from the upper portion of the

cylinder wall with a scraper before removing the piston

and connecting rod.

2) Move the piston to the top of the cylinder and tap it

with a hammer grip or a similar object from the

connecting rod lower side to drive it out.

ENGINE MECHANICAL 6A – 63

If the connecting rod upper bearings are to be reinstalled,

mark their fitting positions by tagging each bearing with the

cylinder number from which it was removed.

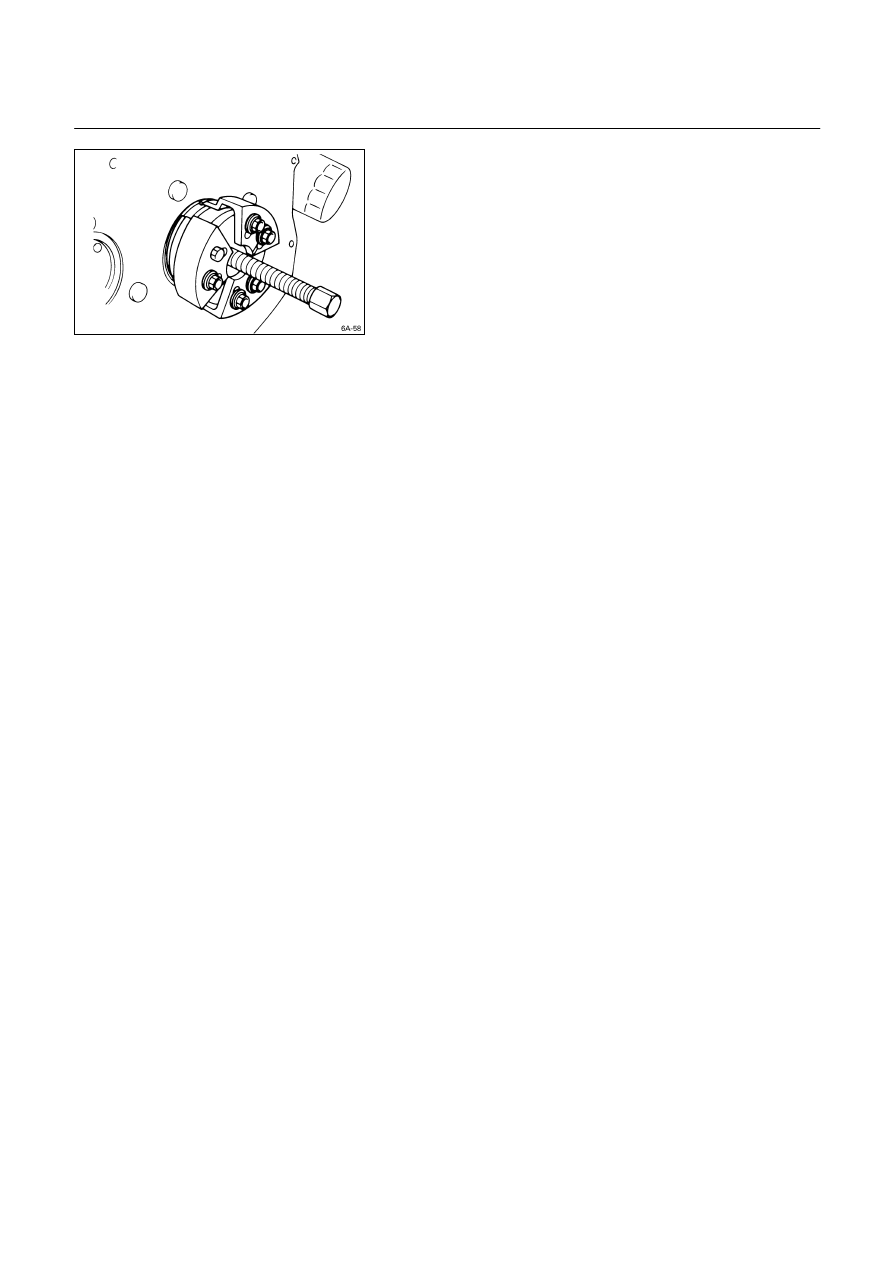

34. Crankshaft Bearing Cap with Lower Bearing

1) Measure the crankshaft end play at the center journal

of the crankshaft.

Do this before removing the crankshaft bearing caps.

If the measured value exceeds the specified limit, the

crankshaft thrust bearing must be replaced.

Crankshaft End Play

mm (in)

Standard

Limit

0.10 (0.004)

0.30 (0.012)

2) Loosen the crankshaft bearing cap bolts in numerical

order a little at a time.

If the crankshaft bearings are to be reinstalled, mark

their fitting positions by tagging each bearing with the

cylinder number from which it was removed.

37. Crankshaft Upper Bearing

If the crankshaft upper bearings are to be reinstalled, mark

their fitting positions by tagging each bearing with the

cylinder number from which it was removed.

38. Tappet

If the tappets are to be reinstalled, mark their fitting

positions by tagging each tappet with the cylinder number

from which it was removed.

015R100020

6A – 64 ENGINE MECHANICAL

39. Crankshaft Rear Oil Seal

• With the oil seal pushed in deep, install the special tool

as shown in the illustration and remove the oil seal.

Oil Seal Remover: 5-8840-2362-0

ENGINE MECHANICAL 6A – 65

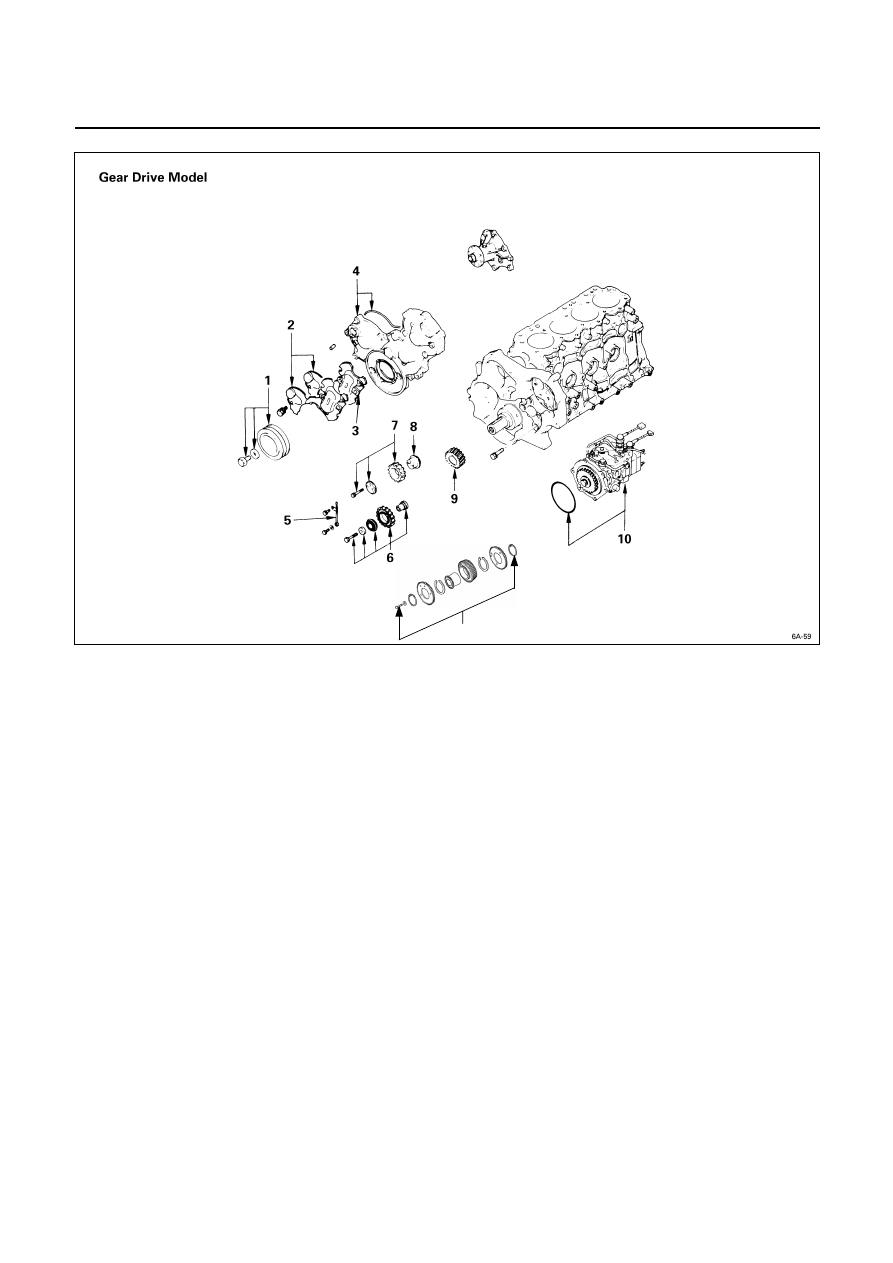

Disassembly Steps-2 (Gear Drive Model)

J

1.

Crankshaft damper pulley

2.

Gear case upper cover and

lower

cover

3.

Space rubber

J

4.

Timing gear case cover

5.

Timing gear oil pipe (Except

4JA1TC, 4JH1TC)

6.

Idler gear “B” and shaft

J

6a.

Idler gear “B” and shaft (scissor

gear) (4JA1TC, 4JH1TC only)

J

7. Idler gear “A”

8.

Idler gear shaft

9.

Crankshaft

timing

gear

J

10. Injection pump

6a

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст