Isuzu KB P190. Manual — part 331

6E-290 Engine Control System (4JH1)

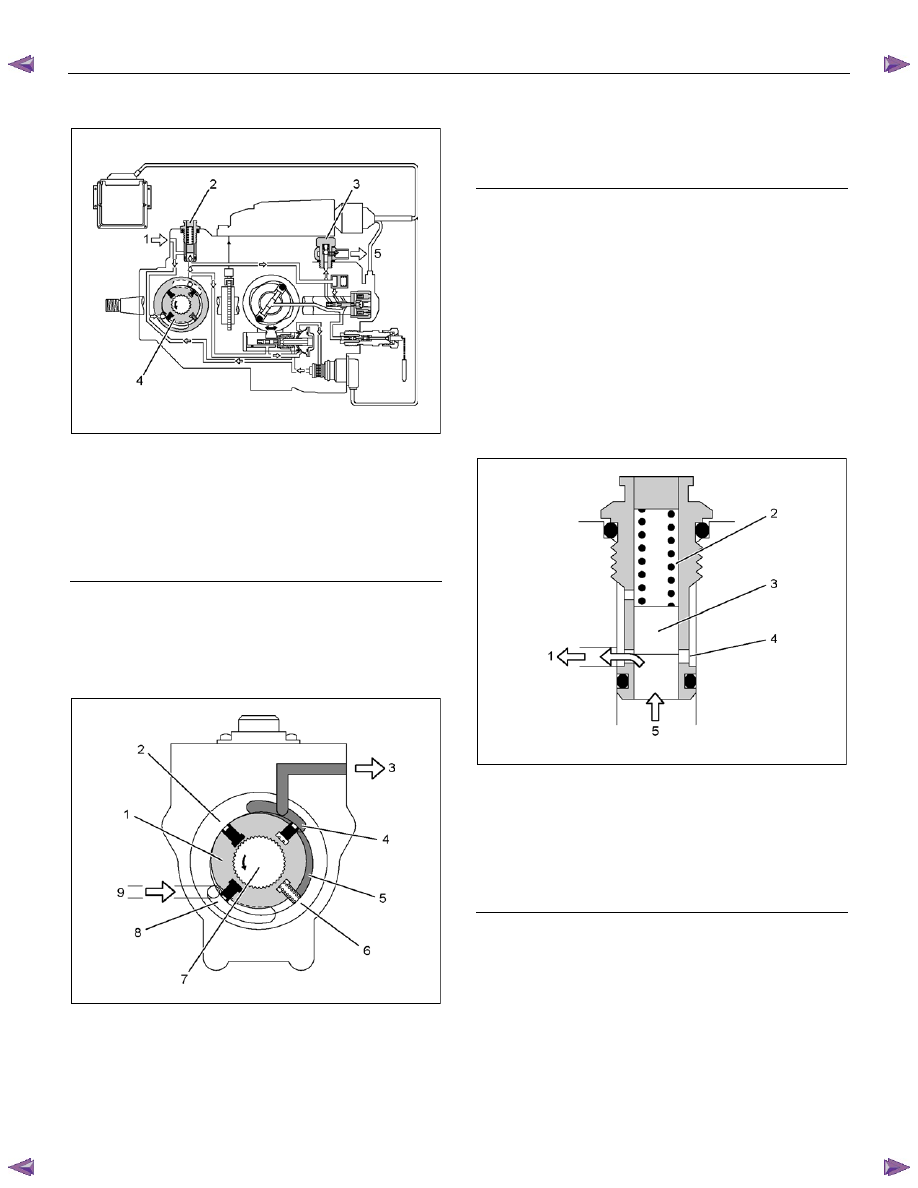

Low Pressure Fuel Circuit Description

RTW66ESH002101

Legend

1. Fuel

Suction

2. Regulating

Valve

3. Overflow

Valve

4. Feed

Pump

5. To Fuel Tank

The low pressure fuel circuit must supply sufficient fuel

to the high pressure fuel circuit. The main components

are the feed pump, the regulating valve and the

overflow valve.

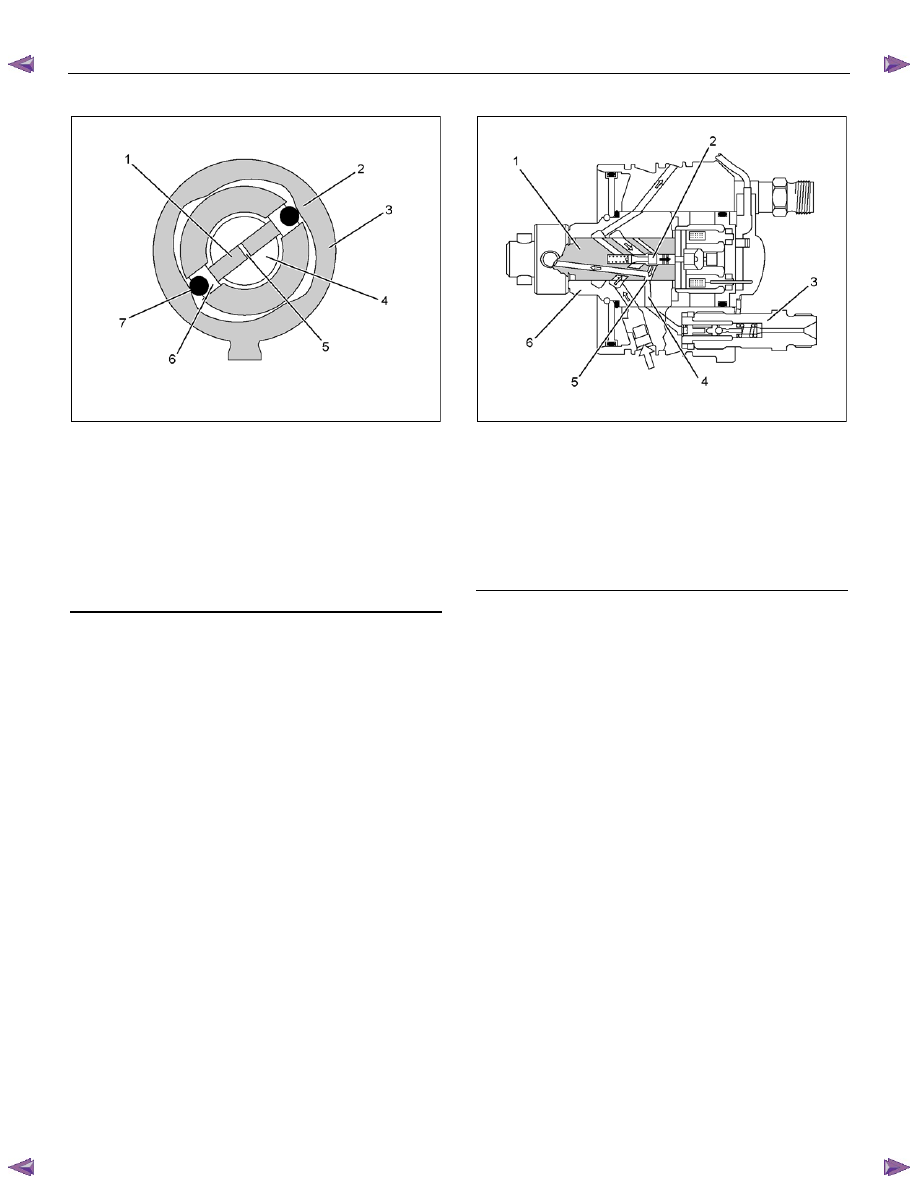

Feed Pump

RTW66ESH002201

Legend

1. Rotor

2. Casing

Ring

3. Fuel

Supply

4. Outlet

5. Chamber

6. Vane

7. Driveshaft

8. Inlet

9. Fuel

Suction

The feed pump is driven by the drive shaft, performs

suction and supply of fuel. The vanes assembled in the

rotor are pressed against the inside of the casing ring

by spring forces and centrifugal force during rotation to

form chambers. When the vanes rotate, the volume of

these chambers increase when they reach recesses the

casing ring connected to the inlet port. Pressure then

decreases and fuel is drawn in. When the chambers

have passed the inlets and recesses, the volume

decreases and the fuel is compressed. Fuel pressure

increases until the chamber reaches the outlet, where

the fuel passes through the regulating valve to the high

pressure fuel circuit.

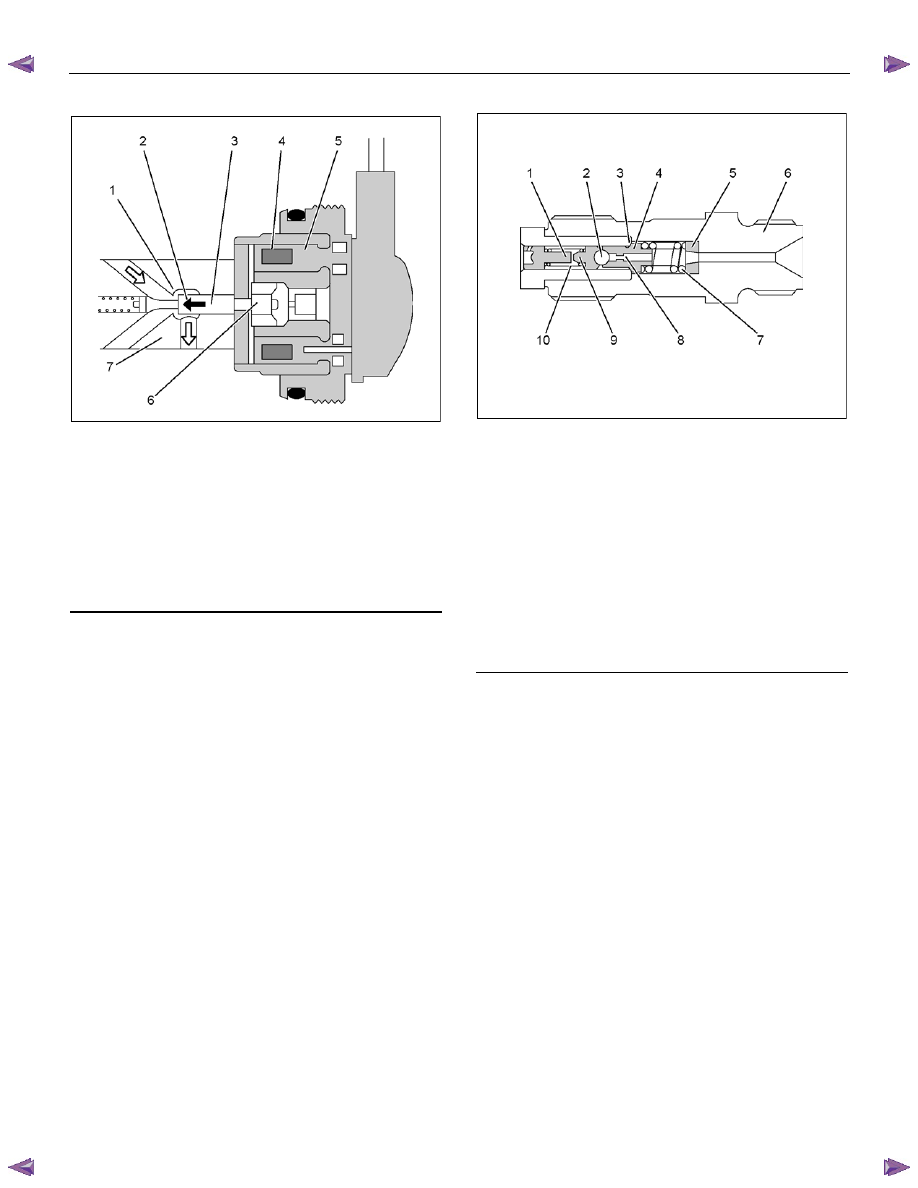

Regulating Valve

RTW66ESH002301

Legend

1. To

Inlet

2. Spring

3. Valve

Piston

4. Port

5. From

Outlet

When feed pump speed increases so that the delivery

pressure of the fuel delivered from the outlet exceeds

the regulating valve spring force, the plunger is pushed

upwards. Excess fuel passes through the ports and

returns to the inlet side, and the delivery pressure is

maintained within a specified range. When feed pump

speed decreases so that the delivery pressure

decreases, the plunger is pushed downwards by spring

force to close the port.

Engine Control System (4JH1) 6E-291

Overflow Valve

RTW66ESH002401

Legend

1. Valve

Holder

2. Port

3. To Fuel Tank

4. Orifice

Port

5. From Fuel Tank

6. Ball

Valve

7. Spring

When the pressure of the fuel, returned from the

distributor head, exceeds the spring force, the overflow

valve's ball valve is pushed up. Excess fuel presses

through the port and returns to the tank, and fuel

pressure inside the pump chamber does not exceed a

specified pressure. The flow of excess fuel serves

cooling and automatic bleeding of the fuel pump during

operation. Also the orifice port is installed to assist in

automatic air bleeding.

High Pressure Fuel Circuit Description

RTW66ESH002501

Legend

1. Fuel Injection Pump Control Unit (PCU)

2. Distributor

Head

3. Fuel Injection Solenoid Valve

4. Constant Pressure Valve (CPV)

5. Radial

Plunger

In addition high pressure generating device, the high

pressure circuit also consists of fuel piping, and devices

to set the beginning of injection and fuel injection

quantity. The main components are as follows:

• High pressure generation: Radial Plunger

• Fuel distribution: Distributor Head

• Beginning of injection timing: Timing Device

• Prevention of secondary injection: Constant

Pressure Valve (CPV)

6E-292 Engine Control System (4JH1)

Radial Plunger

RTW66ESH002601

Legend

1. Radial

Plunger

2. Internal

Cam

3. Cam

Ring

4. Rotor

Shaft

5. Plunger

Chamber

6. Roller

Shoe

7. Roller

While the radial plungers assembled to the rotor shaft

rotate, they are held against the inside of the cam ring

(via the roller shoes and rollers) by fuel delivery

pressure from the feed pump and centrifugal force. The

radial plungers perform rotational movement as well as

internal cam induced reciprocating movement to suck in

and compress the fuel in the plunger chamber.

Distributor Head

RTW66ESH002701

Legend

1. Rotor

Shaft

2. Valve

Needle

3. Constant Pressure Valve (CPV) Holder

4. High Pressure Outlet

5. Distributor

Shaft

6. Barrel

The distributor head distribute the high pressure fuel

that has flowed through the rotating rotor shaft's

distributor slits and the barrel's high pressure outlets (4

cylinders: 4) to the engine cylinders via the constant

pressure valve (CPV) and the nozzle holder

assemblies. The fuel injection solenoid valve needle

changes the passage to the radial plunger high

pressure pump between fuel suction and fuel

compression.

Engine Control System (4JH1) 6E-293

Fuel Injection Solenoid Valve

RTW66ESH002801

Legend

1. Valve

Seat

2. Valve Closing Direction

3. Valve

Needle

4. Coil

5. Magnet

6. Magnet

Anchor

7. Rotor

Shaft

The fuel injection solenoid valve consists of a valve

seat, a valve needle, and a magnet anchor (a movable

iron core), a coil and a magnet. The valve needle

rotates together with the rotor shaft. When current

controlled by the fuel injection pump control unit (PCU)

flows to the coil, the magnet anchor and the valve

needle are pushed towards the valve seat. When the

valve seat is completely closed by the valve needle, the

fuel in the high pressure passage is isolated from the

low pressure passage, is compressed by the radial

plunger high pressure pump, and injected into the

engine cylinder through the nozzle holder assembly.

When the required injection quantity is reached, the

current to the coil is cut, the valve seat opens and

injection of fuel is completed.

Constant Pressure Valve (CPV)

RTW66ESH002901

Legend

1. Plug

2. Ball

3. Seat

4. Valve

5. Spacer

6. Holder

7. Valve

Spring

8. Oriffice

9. Ball

Support

10. Spring

The constant pressure valve (CPV) consists of a holder,

a spacer, a valve spring, a valve, a seat, a ball, a ball

support, a spring and a plug. The valve is equipped with

an orifice to suppress the reflected pressure wave (the

cause of secondary injection) caused by nozzle closing

at the end of the injection and maintains a stable

pressure in the injection pipe (residual pressure) to

ensure stabilized injection timing for subsequent

injection. The valve is opened by pressurized fuel and

this high pressure fuel is delivered to the nozzle holder

assembly.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст