Isuzu KB P190. Manual — part 332

6E-294 Engine Control System (4JH1)

Timing Control Device Description

RTW66ESH003001

Legend

1. Cam

Ring

2. Servo

Valve

3. Timer

Piston

4. Outlet

5. Feed

Pump

6. Inlet

7. Fuel

Suction

8. Ball

Pin

9. Annular

Chamber

10. Hydraulic Stopper

11. Return Passage

12. Timing Control Valve (TCV)

The timing device determines the optimum injection

timing against variations in engine speed. The pressure

of the fuel fed from the feed pump is adjusted in

accordance with speed by the regulating valve. This

delivery pressure acts on the hydraulic stopper's

annular chamber as control pressure. The chamber

pressure of the annular chamber is controlled by the

timing control valve (TCV). The timing plunger is

connected to the cam ring by a ball pin. Axial movement

of the timing plunger is transferred to the cam ring in the

form of rotational movement. Movement to the right of

the timing plunger (to the spring side) advances

injection timing. The main components are timing

plunger, the TCV and pump camshaft position (CMP)

sensor.

Beginning of Injection Staring

RTW66ESH003101

The engine control module (ECM) contains

characteristic maps of the beginning of injection,

corresponding to engine operating conditions

(engine load, engine speed and engine coolant

temperature). The fuel injection pump control unit

(PCU) is constantly comparing the set beginning of

injection timing and the actual beginning of injection

timing. If there is a difference, the timing control

valve (TCV) is controlled by the duty ratio. (The

actual beginning of injection timing is determined

from the pump camshaft position [CMP] sensor.)

Timing Control Valve

RTW66ESH003201

Legend

1. Coil

2. From Annular Chamber

3. To Feed Pump

4. Orifice

5. Valve

Needle

Engine Control System (4JH1) 6E-295

The timing control valve (TCV) acts as a variable

throttle, using the rapid opening and closing (cycling)

of the valve needle in the TCV. At normal operation,

the TCV controls the pressure acting on the annular

chamber so that the hydraulic stopper cam move to

any position, from the retard position to the advance

position. At this time, the duty ratio is set by the fuel

injection pump control unit (PCU).

When control current flows to the TCV coil, the valve

needle opens and the fuel annular chamber flows

through the orifice to the feed pump inlet.

Consequently, the pressure of the annular chamber

decreases and the hydraulic stopper is moved to the

retard side.

When control current to the TCV coil is cut, the valve

needle closes and the return passage is closed.

Consequently, the pressure of the annular chamber

increases and the hydraulic stopper is moved to the

advance side.

Pump Camshaft Position (CMP) Sensor

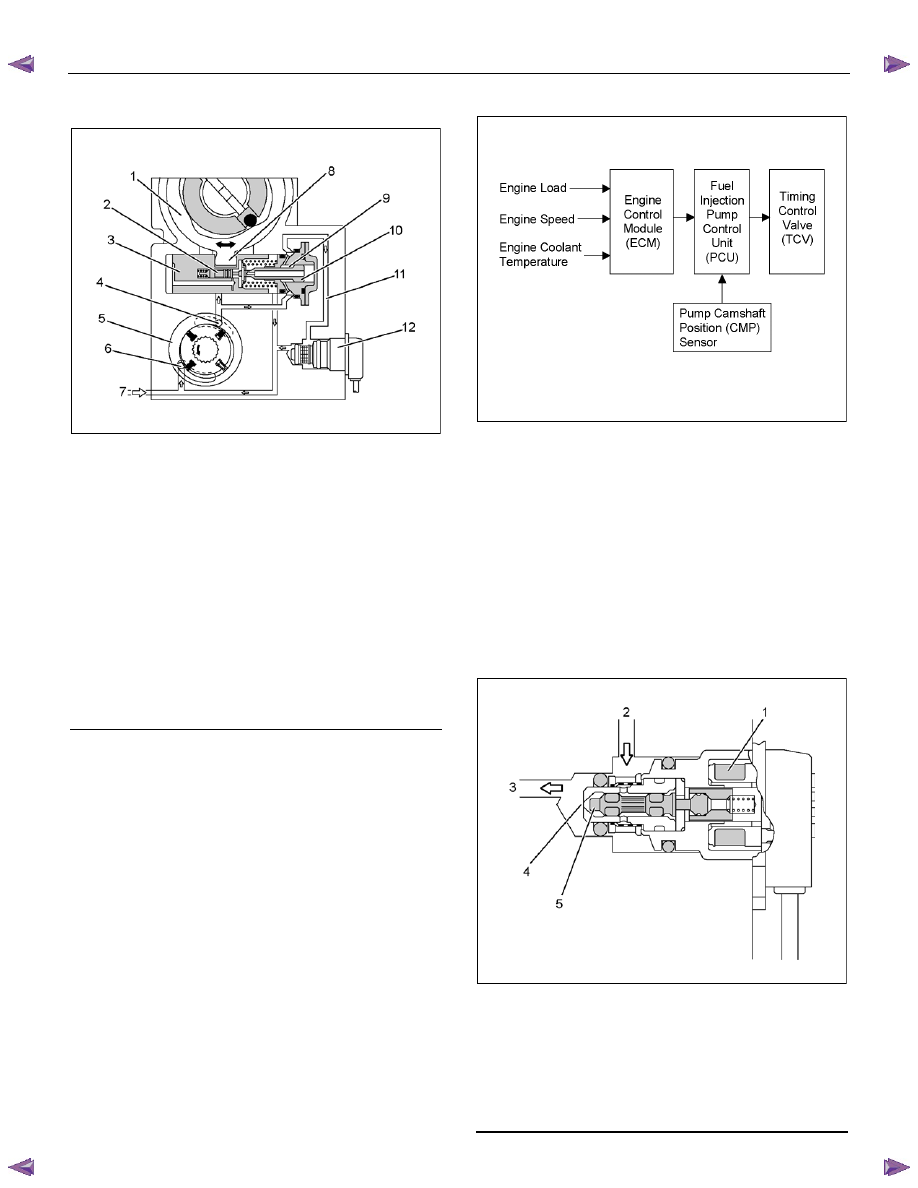

RTW66ESH003301

Legend

1. Pump Camshaft Position (CMP) Sensor

2. Flexible Connecting Harness

3. Drive

Shaft

4. Pump Camshaft Position (CMP) Sensor Retaining

Ring

5. Sensor

Wheel

When the drive shaft rotates, the pump camshaft

position (CMP) sensor receives signal form the sensor

wheel, and an electric pulse is sent through the flexible

connecting harness to the fuel injection pump control

unit (PCU). From these signals the PCU can determine

the average pump speed and the momentary pump

speed. The pump CMP sensor is mounted to the cam

ring. Thus, the relationship between the cam ring and

the pump CMP sensor signal is constant. The pump

CMP sensor signal is utilized for the following purposes:

• To determine the momentary angular position of

the cam ring.

• To calculate the actual speed of the fuel injection

pump.

• To determine the actual timing plunger position.

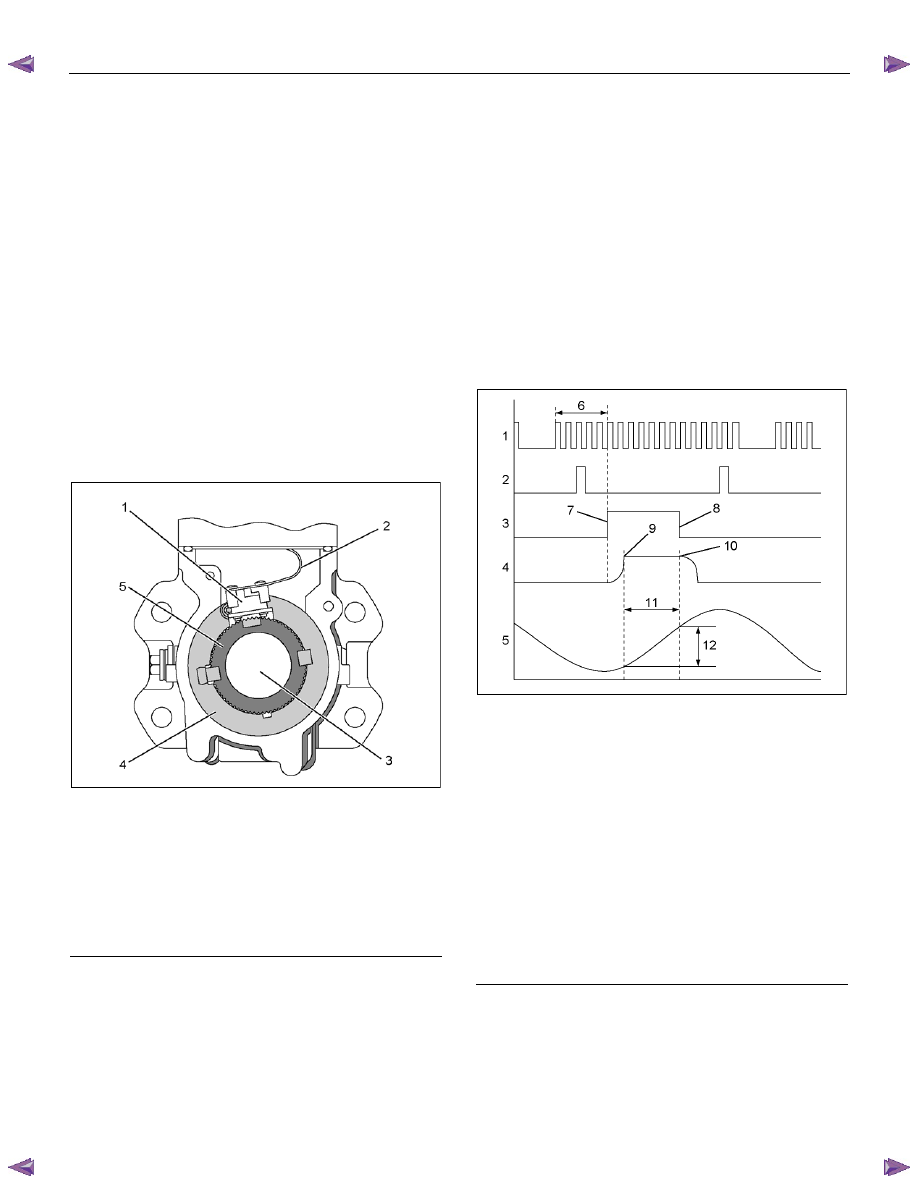

RTW66ESH003401

Legend

1. Pump Camshaft Position (CMP) Sensor Signal

2. Crankshaft Position (CKP) Sensor Signal

3. Fuel Injection Solenoid Valve Control Pulse

4. Fuel Injection Solenoid Needle Valve Lift

5. Cam Lift (Cam Profile)

6. Pulse

Count

7. Fuel Injection Solenoid Valve Close

8. Fuel Injection Solenoid Valve Open

9. Start of Pressure Delivery

10. End of Pressure Delivery

11. Pressure Delivery Angle

12. Effective Stroke

6E-296 Engine Control System (4JH1)

• Momentary Cam Ring Angular Position

The momentary angular position of the cam ring is

input into the fuel injection PCU as a fuel injection

solenoid valve control signal. From momentary

input of angular position for fluctuations in running

conditions, the fuel injection solenoid valve open

and close intervals corresponding to the cam ring's

cam lift can be accurately determined.

• Actual Injection Pump Speed

When the crankshaft position (CKP) sensor is

faulty, the engine control module (ECM) uses the

pump CMP signal as a replacement signal.

• Actual Timing Plunger Position

The actual timing plunger position can be

determined by comparing the CKP sensor signal

with the pump CMP sensor angle. This position is

used for timer control.

Engine Control System (4JH1) 6E-297

Exhaust Gas Recirculation (EGR) System Description

RTW66ELF000101

Legend

1. EGR

Cooler

2. Engine Coolant Outlet

3. Engine Coolant Inlet

4. EGR

Valve

5. ECM

6. MAF & IAT Sensor

7. Intake Throttle Valve

The EGR system recirculates a part of exhaust gas

back into the intake manifold, which results in reducing

nitrogen oxide (NOx) emissions. The EGR control

system uses an electronic control system solenoid valve

and vacuum control EGR valve to ensure both

driveability and low emission. The engine control

module (ECM) controls the EGR flow amount based on

the engine speed, engine coolant temperature, intake

air temperature, barometric pressure and fuel injection

quantity. The ECM controls the EGR valve opening by

controlling the EGR solenoid valve drive duty. The mass

air flow (MAF) sensor monitors EGR gas flow amount.

An expected MAF amount should be detected while the

engine running.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст