Isuzu KB P190. Manual — part 846

Engine Management – V6 – Diagnostics

Page 6C1-2–106

−

Damaged accessory drive belt

•

For an intermittent condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

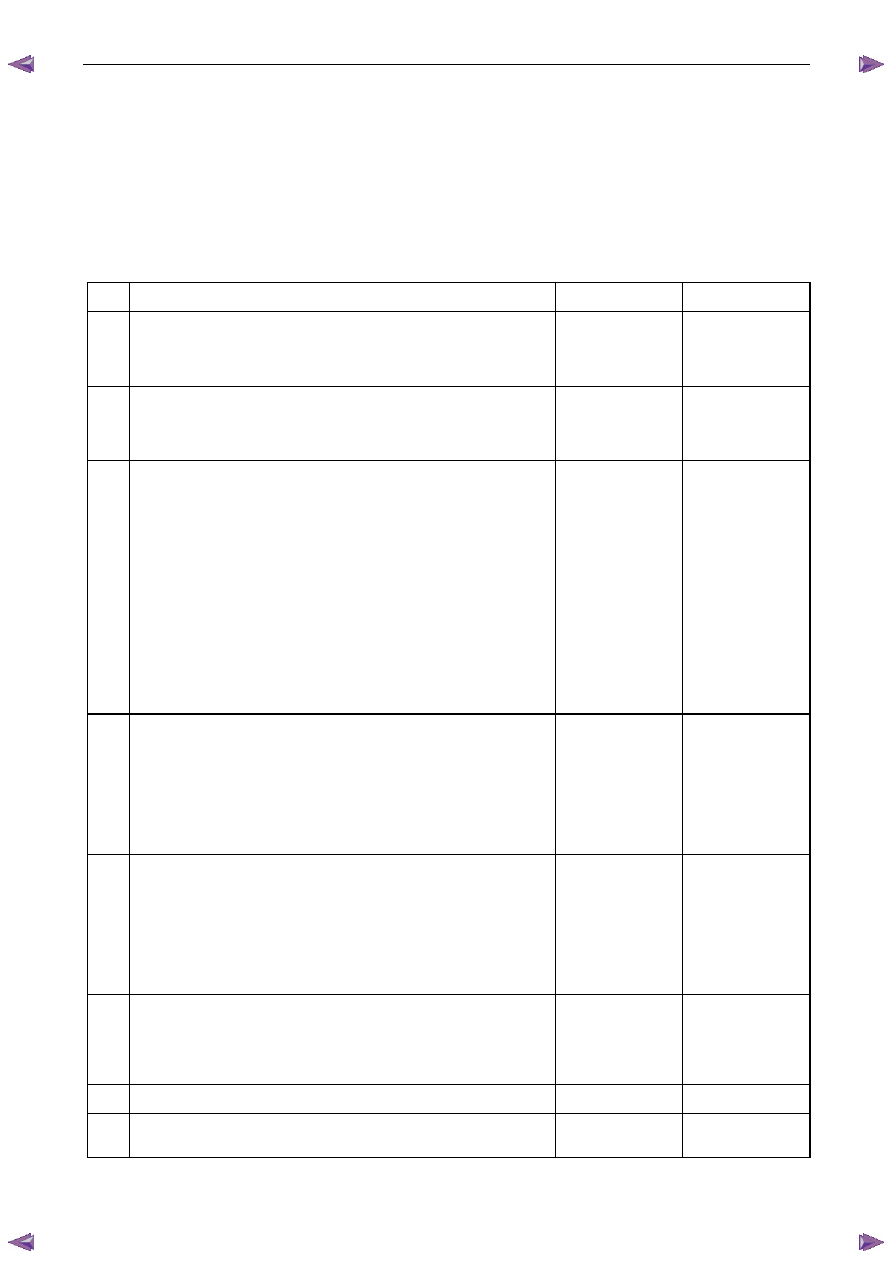

DTC P0301, P0302, P0303, P0304, P0305 or P0306 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been completed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

Were you sent here from DTC P0300?

Go to Step 3

Go to 7.16

DTC

P0300 in this

Section

3

1 Ignition

OFF.

2

Remove the ignition coil of the misfiring cylinder, but leave the

electrical connector connected. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

3

Inspect the ignition coil boot for the following conditions:

−

Holes.

−

Tears.

−

Carbon tracking.

−

Oil contamination or water intrusion.

Did you find a condition with the ignition coil boot?

Go to Step 12

Go to Step 4

4

1

Remove the fuel pump fuse from the under-hood fuse and relay

centre.

2

Install the J 26792 Spark Tester to the ignition coil boot and a

good ground.

3

Crank the engine while observing J 26792.

Does the spark tester spark and is the spark consistent?

Go to Step 5

Go to Electronic

Ignition System

Diagnosis

5

1 Ignition

OFF.

2

Remove the spark plug from the cylinder that indicated a

misfire.

3

Inspect the spark plug. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

Does the spark plug appear to be OK?

Go to Step 9

Go to Step 6

6

Is the spark plug oil or coolant fouled?

Inspect the spark

plugs. Go to 6C1-3

Engine

Management – V6 –

Service Operations

Go to Step 7

7

Is the spark plug gas fouled?

Go to Step 10

Go to Step 9

8

Does the spark plug show any signs of being cracked, worn, or

incorrectly gap?

Go to Step 11

Go to Step 9

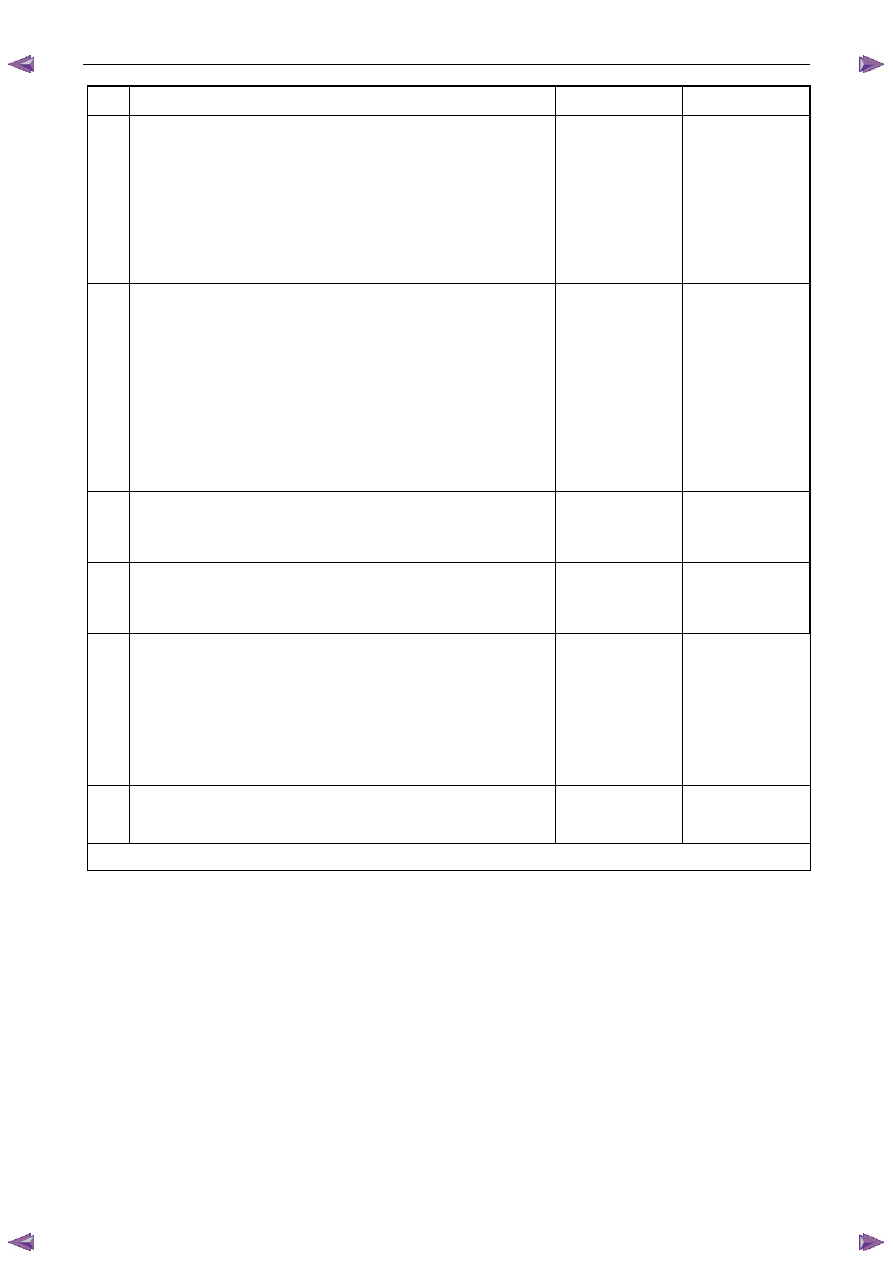

Engine Management – V6 – Diagnostics

Page 6C1-2–107

Step Action

Yes

No

9

1

Swap the suspected spark plug with another cylinder that is

operating correctly.

2

Start the engine.

3

Operate the engine within the conditions that the misfire

occurred.

4

Use Tech 2 to monitor the Misfire Current Counters.

Did the misfire move with the spark plug?

Go to Step 11

Go to Step 10

10

N O T E

• Make sure all the fuel injectors operate. High

resistance in a fuel injector circuit causes the fuel

injector to be inoperative without setting a fuel injector

DTC.

• Return to this diagnostic after you complete the Fuel

Injector Coil Test.

1

Perform the fuel injector coil test. Refer to 6.2

Fuel Injector

Coil Test in this Section.

Did you find and correct the condition?

Go to Step 13

Go to 5 Symptoms

Diagnostics in this

Section

11

1

Replace the spark plug. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

Did you complete the replacement?

Go to Step 13

—

12

1

Replace the ignition coil. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

Did you complete the replacement?

Go to Step 13

—

13 1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running DTC P0301

to P0306.

Do any Cylinder Engine Misfire DTCs fail this ignition cycle?

Go to Step 2

Go to Step 14

14 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.18 DTC

P0324

DTC Descriptor

This diagnostic procedure supports DTC P0324 – Knock Sensor Module Performance

Circuit Description

The ECM supplies the ground to the knock sensor (KS) low reference circuit. The KS produces a signal voltage, which is

proportional to the level of the engine vibration or spark knock.

When the ECM detects an excessive spark knock, it retards the ignition timing until the spark knock stops.

The KS circuitry within the ECM receives, amplifies, filters and evaluates the KS signal voltage. The ECM performs the

following tests to determine if the ECM internal KS circuitry is functioning correctly.

Engine Management – V6 – Diagnostics

Page 6C1-2–108

Test One

The ECM performs the following:

1

Turns off the knock sensor signal circuits.

2

Applies different test signals to the ECM internal KS circuitry.

3

Verifies each test signal output response is within range.

4

If the ECM detects any of the tested signals are not within the normal range, DTC P0324 sets.

Test Two

The ECM performs the following:

1

Turns off the knock sensor signal circuits.

2

Tests for any output response when no test signals are applied.

3

If the ECM detects an output response, DTC P0324 sets.

Test Three

1

Turns off the knock sensor signal circuits.

2

Generates an internal test pulse then monitors the return signal.

3

If the return test pulse is less than a calibrated threshold, DTC P0324 sets.

DTC P0324 sets if the ECM detects an incorrect response to the ECM internal KS circuitry tests.

Conditions for Running the DTC

Condition One

Runs continuously once the following conditions are met:

•

The ECM is controlling the ignition spark.

•

The engine speed is less than 2,300 rpm and steady.

•

The volumetric efficiency is steady.

Condition Two

Runs continuously once the following conditions are met:

•

The ECM is controlling the ignition spark.

•

The engine speed is 1,000 – 4,000 rpm

•

The engine coolant temperature is greater than 60

° C.

•

The volumetric efficiency is steady.

Condition Three

Runs continuously once the following conditions are met:

•

The ECM is controlling the ignition spark.

•

The engine speed is less than 2,300 rpm and steady.

•

The engine coolant temperature is greater than 40

° C.

•

The volumetric efficiency is steady.

Conditions for Setting the DTC

The ECM detects an incorrect response to an internal ECM KS circuitry test.

Engine Management – V6 – Diagnostics

Page 6C1-2–109

Conditions for Clearing the DTC

DTC P0324 – Knock Sensor (KS) Module Performance is a Type B DTC. Refer to 1.4

Diagnostic Trouble Codes in

this Section, for action taken when a Type B DTC sets and conditions for clearing Type B DTC.

Additional Information

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the knock sensor (KS) system

operation.

•

The ECM turns off the KS signal circuits when performing the ECM internal KS circuitry tests. DTC P0324 sets if

there is a fault condition in the internal ECM KS circuitry. Therefore, the KS and the KS signal circuits are not

tested in DTC P0324 Diagnostic Table.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step number in the diagnostic table:

3

A crankshaft sensor DTC may trigger DTC P0324.

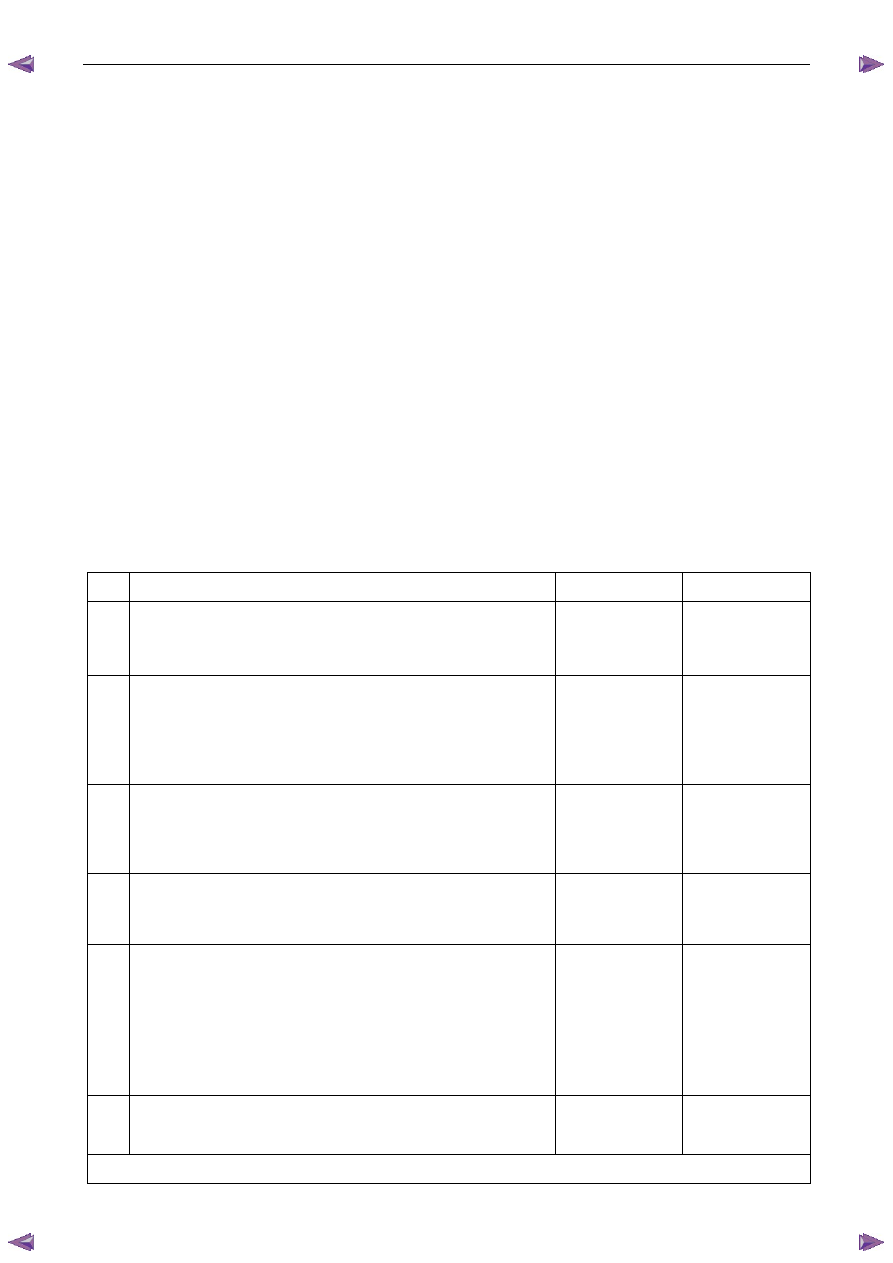

DTC P0324 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P0324 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

Are DTCs relating to the CKP Sensor Circuit also set?

Refer to

7.20 DTC

P0335,

P0336, P0337 or

P0338 in this

Section

Go to Step 4

4

Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 5

—

5

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running DTC

P0324.

Does DTC P0324 fail this ignition cycle?

Go to Step 2

Go to Step 6

6

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст