Isuzu KB P190. Manual — part 761

Engine Mechanical – V6

Page 6A1–267

Page 6A1–267

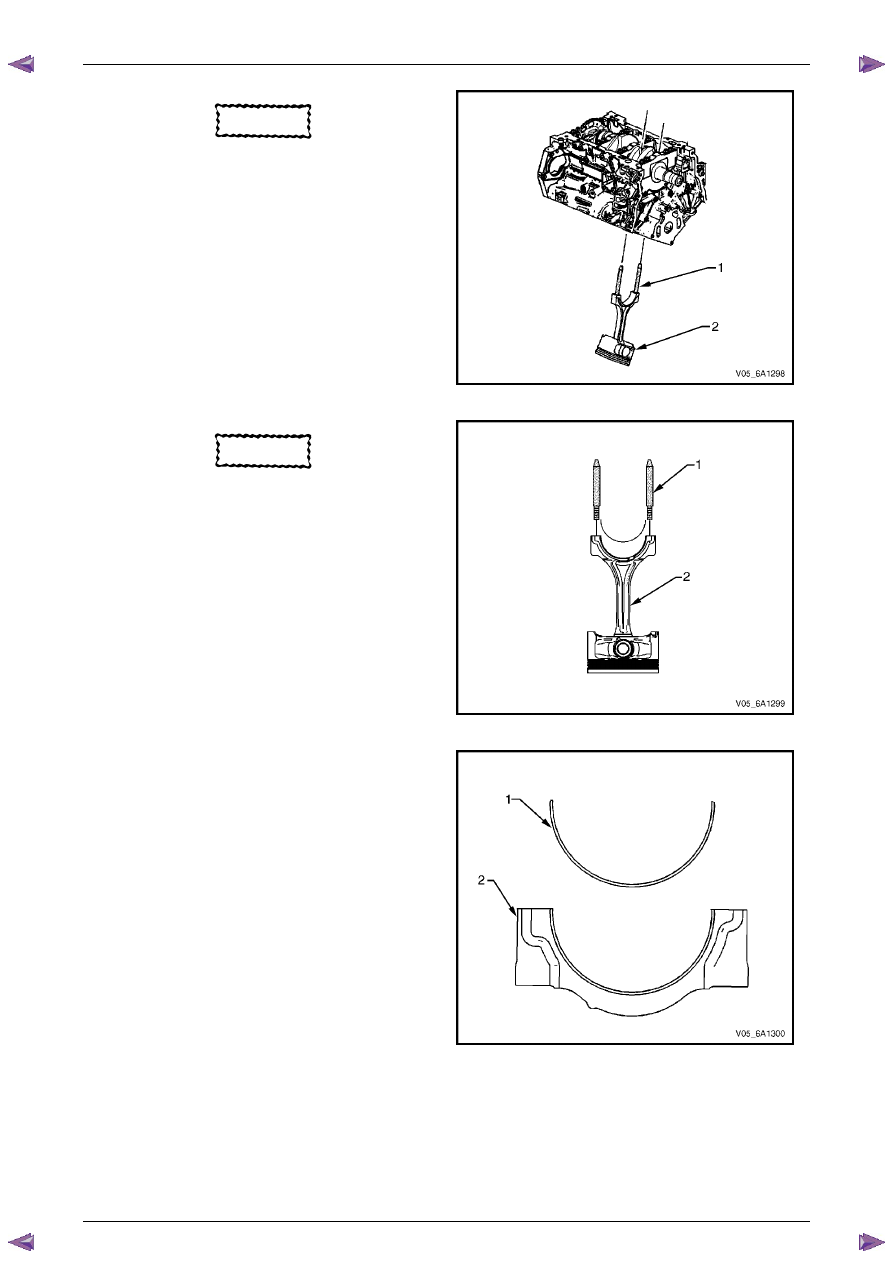

CAUTION

Do not damage the crankshaft journal,

cylinder wall and piston cooling jets when

removing the connecting rod and piston

assembly.

12

Using connecting rod guide pin set, Tool No.

EN-46121 (1), push the connecting rod and piston

assembly (2) through the top of the cylinder.

Figure 6A1 – 467

CAUTION

When dismantled, ensure the connecting

rod, connecting rod cap, piston and

bearings are organised in their original

position and location. This will also aid

engine mechanical diagnosis.

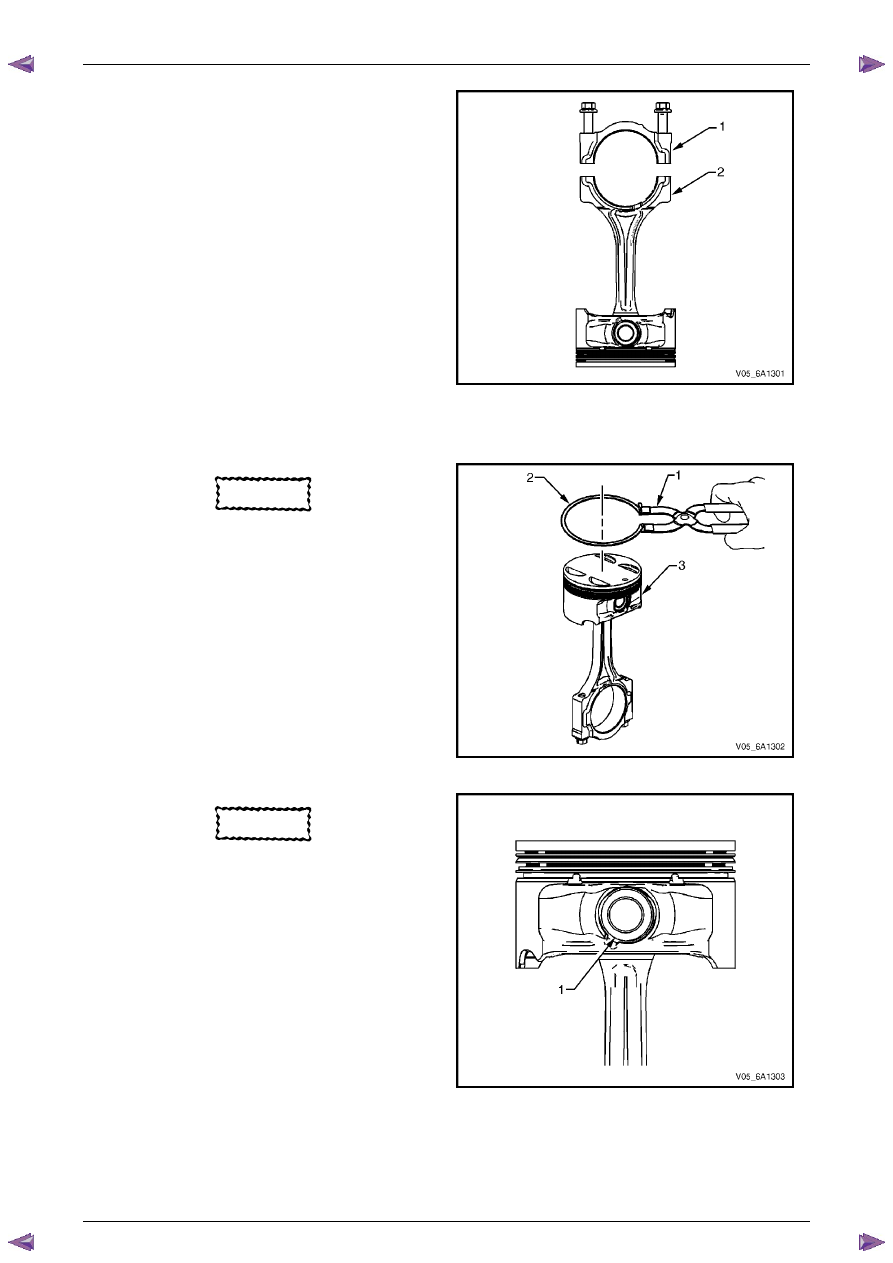

13

Remove connecting rod guide pin set, Tool No.

EN-46121 (1) from the connecting rod bolt holes.

14

Remove the upper connecting rod bearing from the

connecting rod (2).

Figure 6A1 – 468

15

Remove the lower connecting rod bearing (1) from

the connecting rod cap (2).

Figure 6A1 – 469

Engine Mechanical – V6

Page 6A1–268

Page 6A1–268

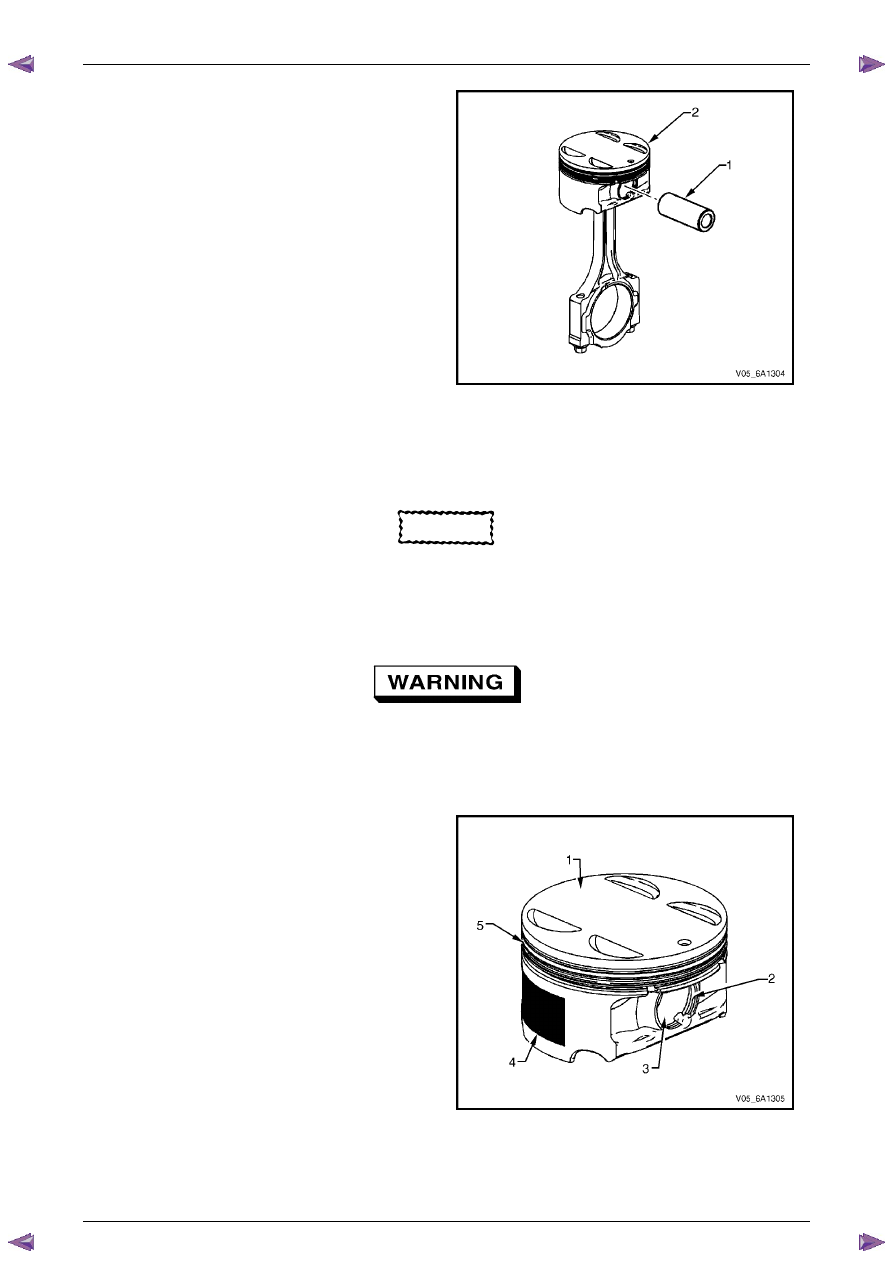

N O T E

The cap and rod are a matched set and must be

kept together.

16

Reattach the connecting rod cap (1) to the connecting

rod (2) to prevent damage to their mating surfaces.

17

Repeat steps 4 to 16 for the remaining piston and

connecting rod assemblies.

Figure 6A1 – 470

Disassemble

CAUTION

A piston ring expander must be used to

remove and install the piston rings. Only

expand the rings far enough to fit over the

piston lands. If the rings are overexpanded,

the top ring will shatter and the others will

distort.

1

Remove the piston rings (2) using a piston ring

expander (1). Place each ring in a clean shop towel

for storage.

Figure 6A1 – 471

CAUTION

Do not reuse the piston pin retainers.

2

Remove the piston pin retainers by using the removal

access notch (1) in the side of the piston. Discard the

piston pin retainers.

Figure 6A1 – 472

Engine Mechanical – V6

Page 6A1–269

Page 6A1–269

3

Slide the piston pin (1) out of the piston (2). The

piston will disconnect from the connecting rod.

Figure 6A1 – 473

Clean and Inspect

Piston Cleaning Procedure

CAUTION

Do not use a wire brush to clean any part of

the piston.

1

Clean the piston skirts and the pins with a suitable solvent.

2

Clean the piston ring grooves with a groove cleaner. Ensure the oil ring holes and slots are clean.

Safety glasses must be worn when using

compressed air.

3

Dry the piston with compressed air.

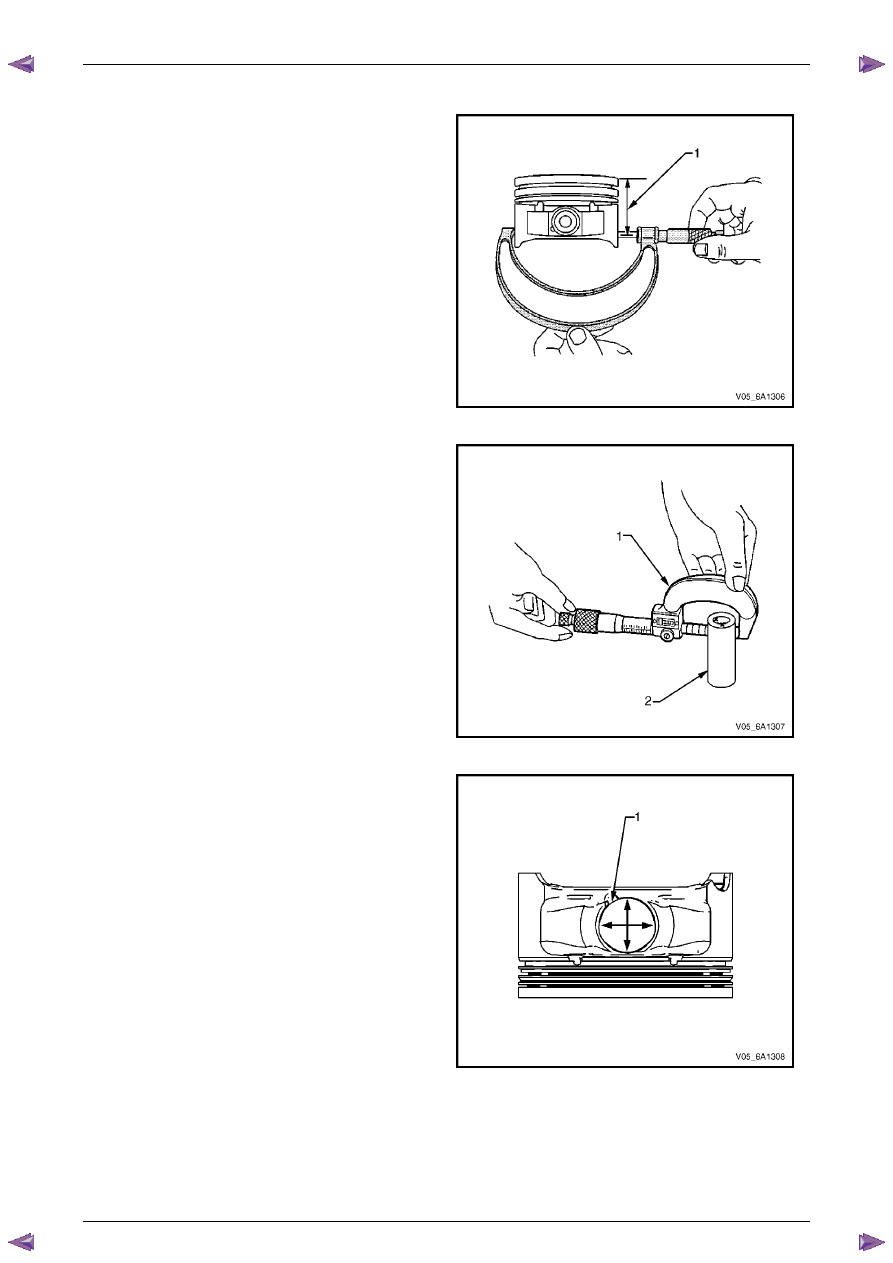

Piston Inspection Procedure

1

Inspect the pistons for the following conditions:

•

eroded areas at the top of the piston (1),

•

piston pin retainer grooves for burrs (2),

•

worn piston pin bores or worn piston pins (3),

•

scuffed or damaged skirt coating (4),

•

ring grooves for cracks, nicks or burrs that may

cause binding (5), and

•

warped or worn ring lands.

2

Replace pistons that show any signs of damage or

excessive wear.

Figure 6A1 – 474

Engine Mechanical – V6

Page 6A1–270

Page 6A1–270

Piston Measurement

1

Measure piston width using the following procedure:

a

Using an outside micrometer, measure the

width of the piston at 30 mm below the crown

top (1), at the thrust surfaces of the piston,

perpendicular to the piston pin centreline.

b

Compare the measurement of the piston to its

original cylinder by subtracting the piston width

from the cylinder diameter.

c

Check your measurements with specifications,

refer to

5 Specifications

.

d

If the clearance obtained through measurement

is greater than the provided specifications and

the cylinder bores are within specification,

replace the piston.

Figure 6A1 – 475

2

Measure the piston pin bore to piston pin (2)

clearances using the following procedure:

a

Piston pin bores and pins must be free of

varnish or scuffing.

b

Use an outside micrometer (1) to measure the

piston pin in the piston contact areas.

Figure 6A1 – 476

3

Using an inside micrometer, measure the piston pin

bore (1). Compare the result with the piston pin

diameter and piston pin to piston pin bore clearance

listed in the specifications, refer to

5 Specifications

.

4

If the clearance is excessive, determine which piece

is out of specification and replace as required.

5

Replace the piston if any of its dimensions are out of

specification.

6

If the new piston does not meet clearance

specifications, the cylinder block may need to be

oversized to 0.25 mm. There is only one size of

oversized pistons and rings available for service.

Figure 6A1 – 477

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст