Isuzu KB P190. Manual — part 759

Engine Mechanical – V6

Page 6A1–259

Page 6A1–259

4.3 Flexplate

Assembly

Remove

1

Remove the transmission, refer to

Section 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing

.

2

Remove the starter motor, refer to

Section 6D1-2 Starting System – V6

.

3

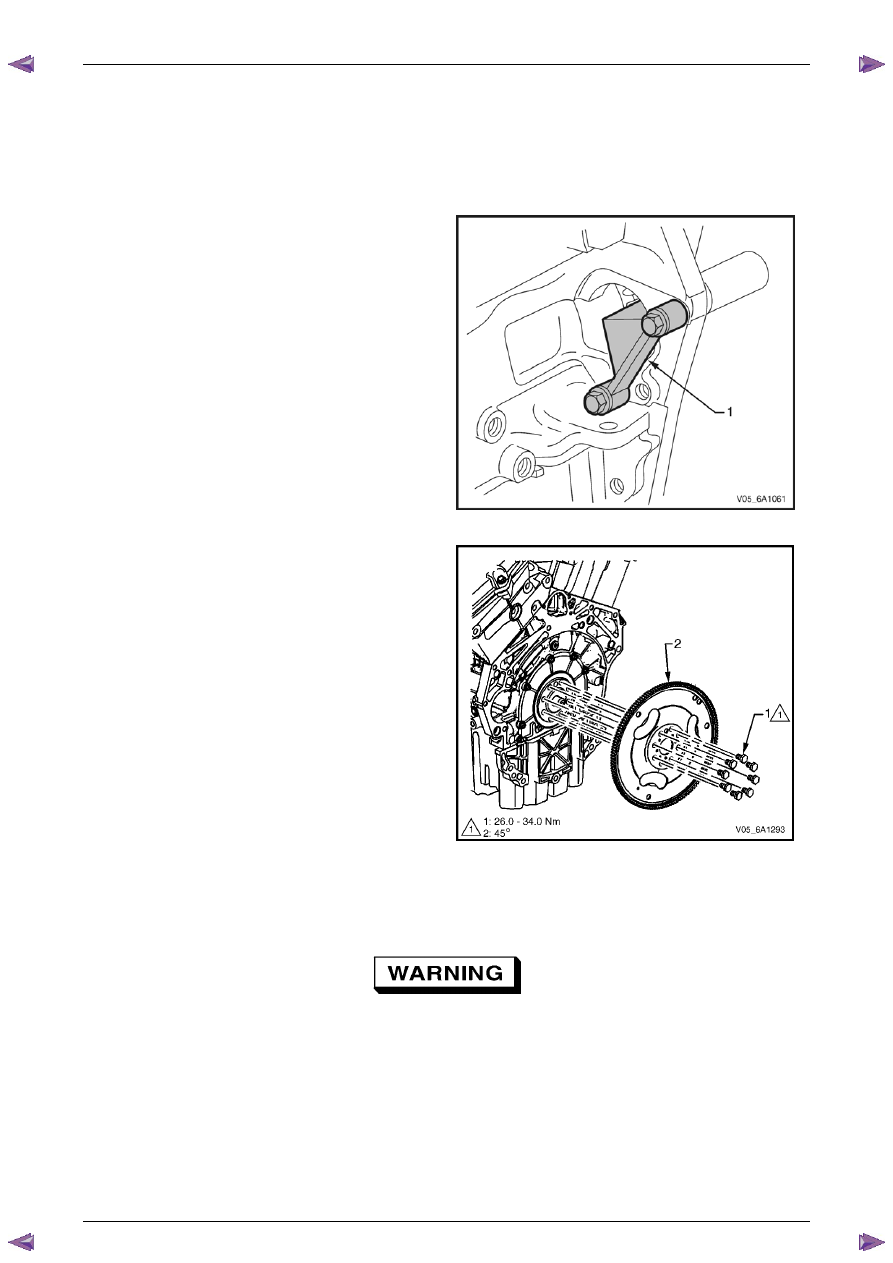

Install the flexplate holding tool, Tool No. EN-46106

(1) into the starter motor mounting location.

Figure 6A1 – 452

4

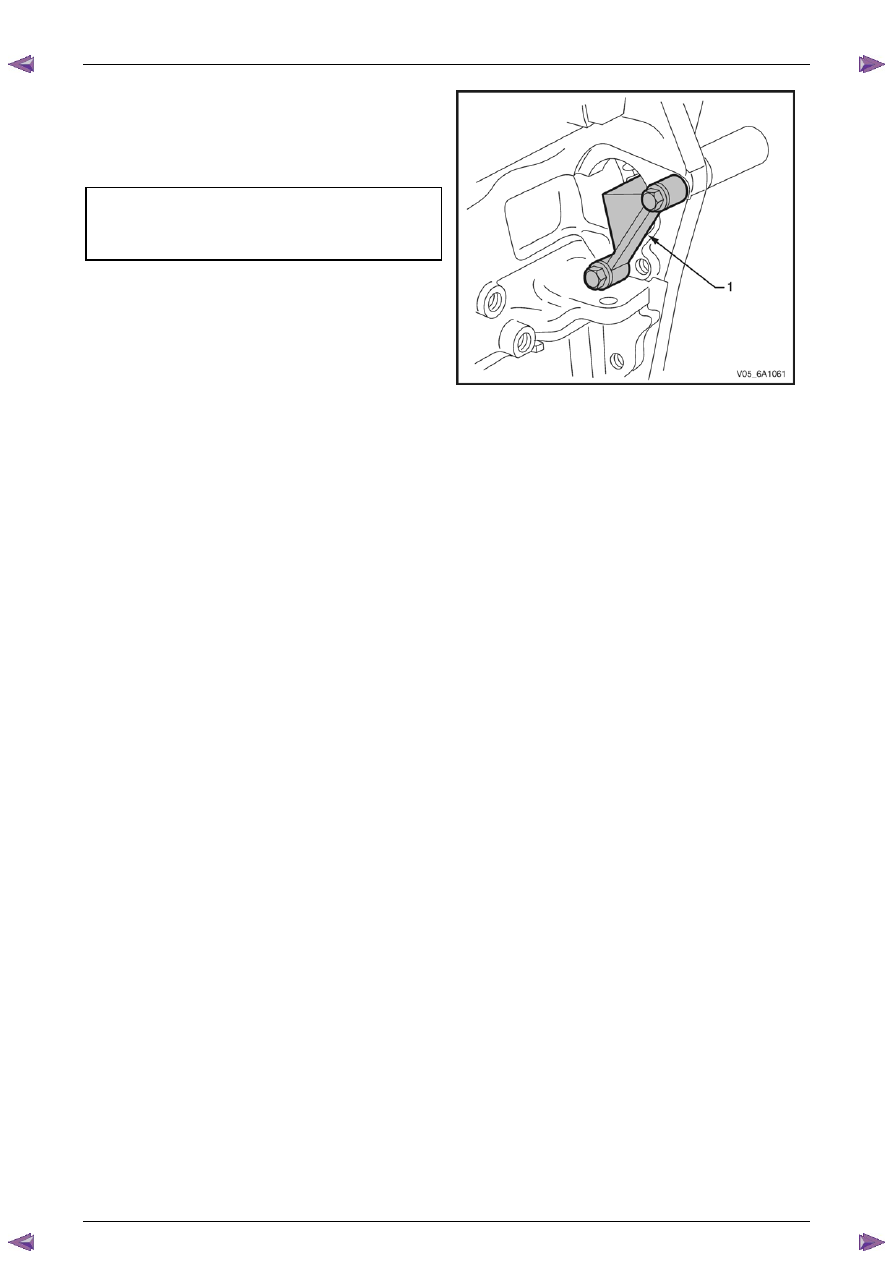

Loosen the eight flexplate attaching bolts (1).

5

Remove the flexplate holding tool.

6

Using a suitable permanent marker or paint pen, mark

the flexplate assembly (2) to crankshaft relationship.

7

Remove the eight flexplate attaching bolts and

discard.

8

Remove the flexplate assembly.

Figure 6A1 – 453

Clean

1

Clean the flexplate assembly in a suitable solvent.

Safety glasses must be worn when using

compressed air.

2

Dry the flexplate assembly with compressed air.

Engine Mechanical – V6

Page 6A1–260

Page 6A1–260

Inspect

1

Inspect the flexplate assembly for the following

conditions:

•

Stress cracks around the flexplate to torque

converter mounting bolt hole locations (1).

•

Stress cracks around the flexplate to crankshaft

mounting bolt hole locations (2 and 4).

•

Cracks at welded areas that retain the ring gear

onto the flexplate (3).

•

Damaged or missing ring gear teeth (5).

2

Replace the flexplate assembly as required.

N O T E

The flexplate ring gear is not serviced

separately and cannot be repaired. If found to

be faulty or damaged, the flexplate assembly

must be replaced.

CAUTION

Do not repair the welded areas that retain

the ring gear to the flexplate. The flexplate

must be replaced.

Figure 6A1 – 454

Reinstall

N O T E

The bolt holes are unevenly spaced to enable

flexplate fitment in the one position only.

1

Place the flexplate assembly (2) in position on the

crankshaft.

2

Install new flexplate attaching bolts (1) and hand

tighten.

Figure 6A1 – 455

Engine Mechanical – V6

Page 6A1–261

Page 6A1–261

3

Install the flexplate holding tool, Tool No. EN-46106

(1) into the starter motor mounting location.

4

Tighten the eight flexplate attaching bolts to the

correct torque specification.

Flexplate attaching bolt

torque specification:

Stage

1 . . . ..26.0 – 34.0 Nm

Stage

2 . . . . . . . . .45°

5

Remove the flexplate holding tool.

6

Install the starter motor, refer to

Section 6D1-2

Starting System – V6

.

7

Install the transmission, refer to

Section 7E4

Automatic Transmission – 4L60E – On-vehicle

Servicing

.

Figure 6A1 – 456

Engine Mechanical – V6

Page 6A1–262

Page 6A1–262

4.4

Crankshaft Rear Seal and Plate

Assembly

Remove

1

Remove the engine assembly, refer to

4.1 Engine

.

2

Remove the flexplate assembly, refer to

4.3 Flexplate Assembly

.

3

Remove the engine oil pan assembly, refer to

4.2 Oil Pan and Oil Pump Suction Pipe Assembly

.

4

Remove the five bolts (1) attaching the crankshaft

rear seal housing to the rear of the cylinder block (2).

Figure 6A1 – 457

5

Shear the RTV sealant using the prise points located

at the edge of the crankshaft rear oil seal housing,

Figure 6A1 – 458

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст