Isuzu KB P190. Manual — part 760

Engine Mechanical – V6

Page 6A1–263

Page 6A1–263

6

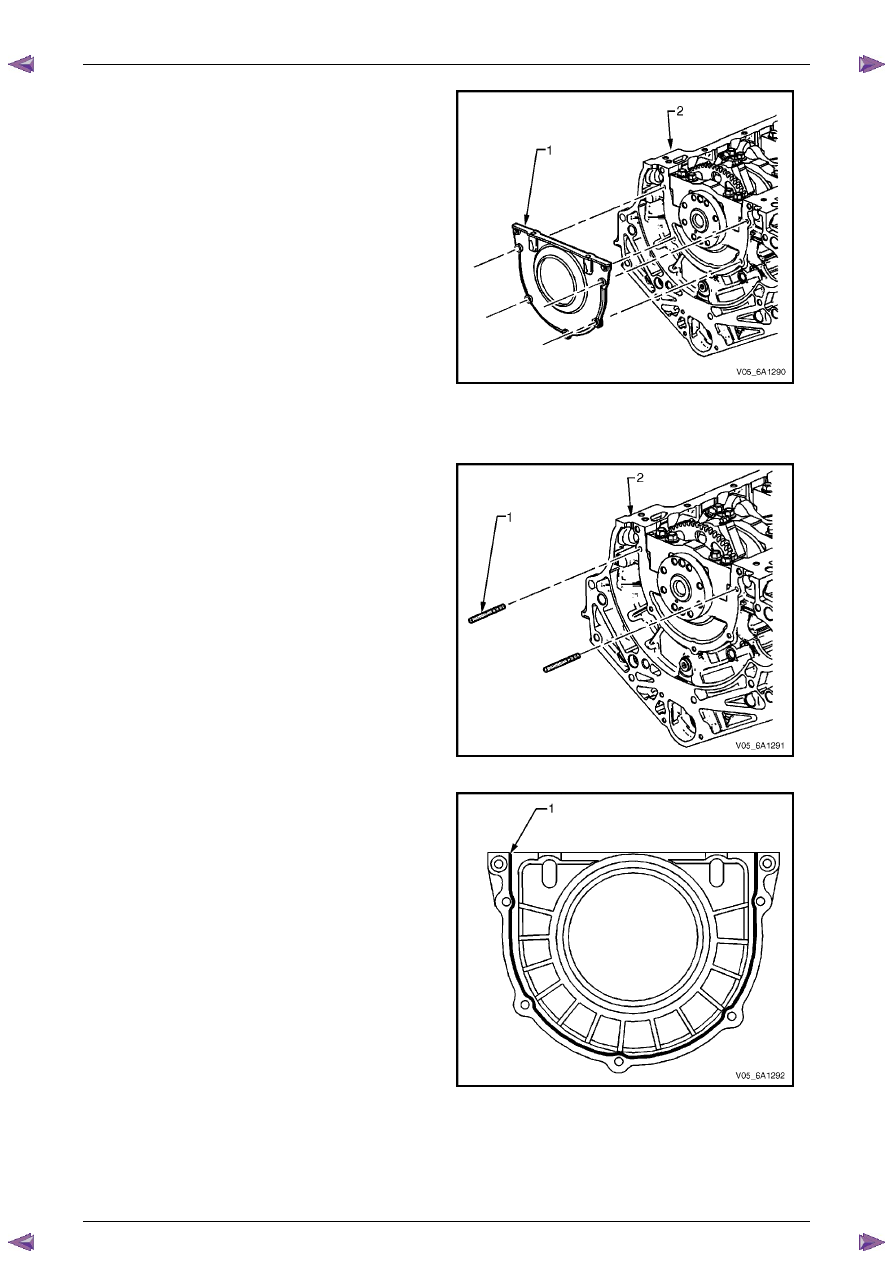

Remove the crankshaft rear oil seal housing (1) from

the cylinder block (2).

Figure 6A1 – 459

Reinstall

1

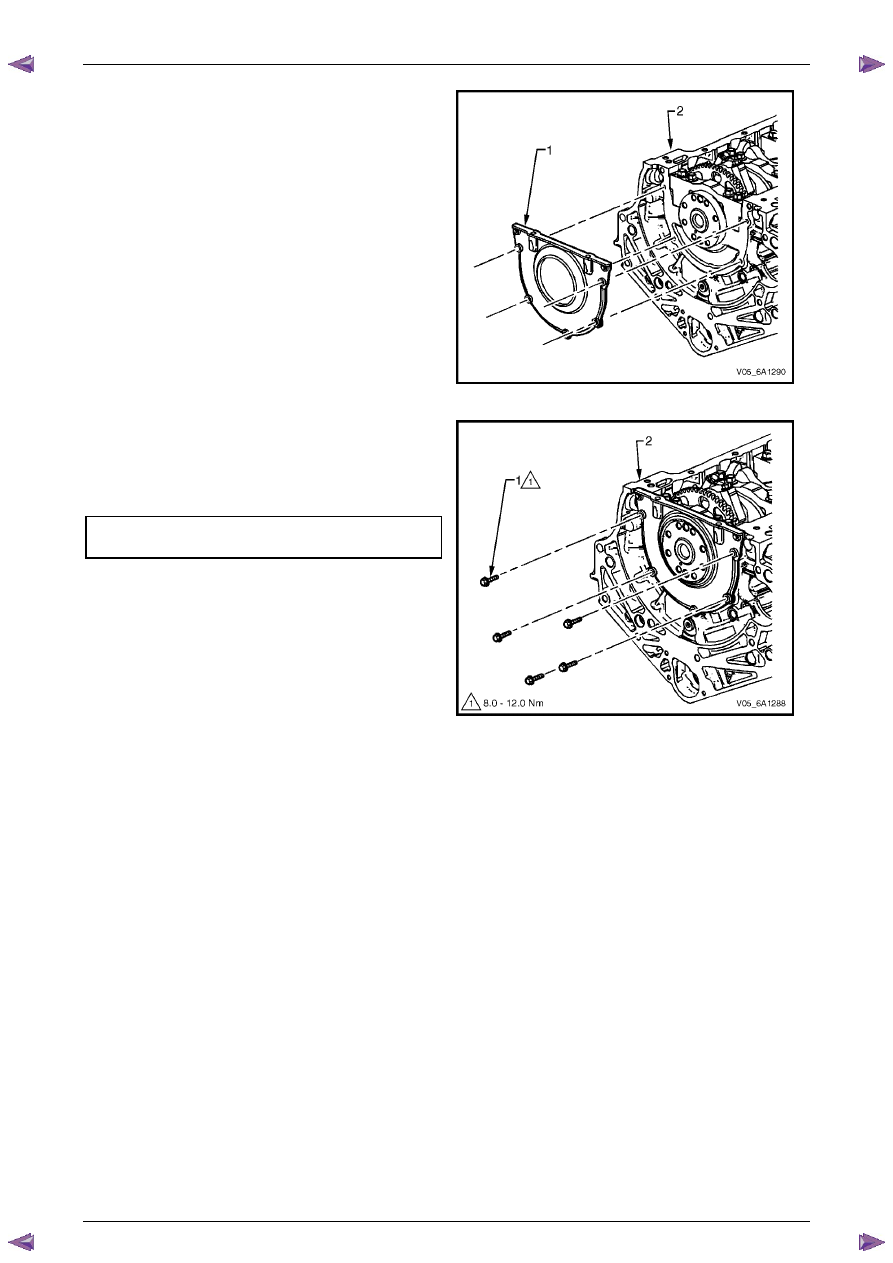

Install the guide pins, Tool No. EN-46109 (1) into the

two crankshaft rear oil seal housing bolt holes of the

cylinder block (2).

Figure 6A1 – 460

2

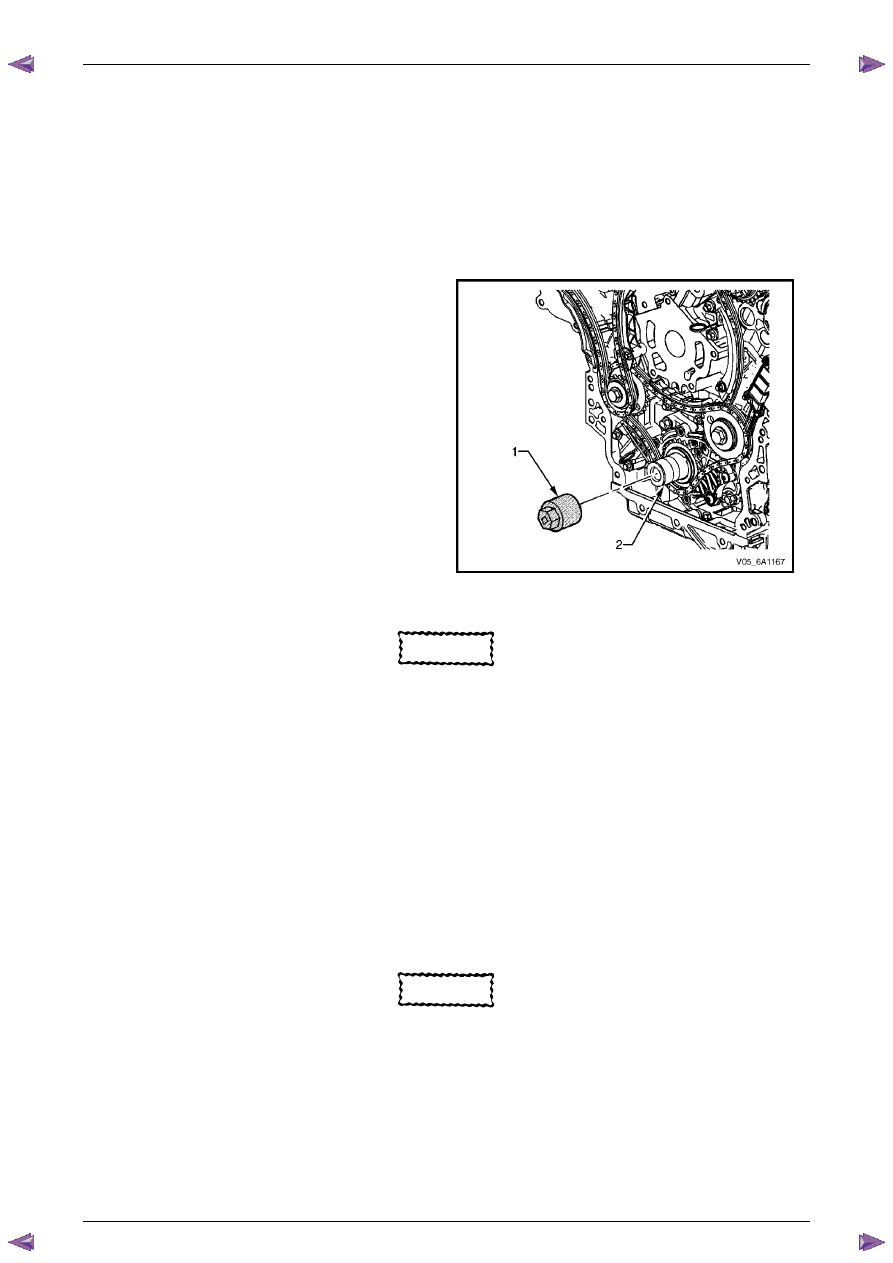

Apply a 3mm bead (1) of RTV sealant to the

crankshaft rear oil seal housing.

Figure 6A1 – 461

Engine Mechanical – V6

Page 6A1–264

Page 6A1–264

3

Install the crankshaft rear oil seal housing (1) to the

cylinder block (2).

N O T E

• Do not allow any engine oil onto the cylinder

block mating surface, where the crankshaft

rear oil seal housing is to be installed.

• A seal-protector is provided with the new

crankshaft rear seal and housing assembly.

Do not remove the seal protector from the

crankshaft rear oil seal housing until the

crankshaft rear oil seal housing is fully in

position.

4

Remove the guide pins from the cylinder block.

Figure 6A1 – 462

5

Install the crankshaft rear oil seal housing attaching

bolts (1) to the cylinder block (2) and tighten to the

correct torque specification.

Crankshaft rear oil seal housing

attaching bolt torque specification. . . .8.0 – 12.0 Nm

Figure 6A1 – 463

Engine Mechanical – V6

Page 6A1–265

Page 6A1–265

4.5

Pistons, Pins, Rings, Connecting Rods

and Big-end Bearings

Remove

1

Remove the engine assembly, refer to

4.1 Engine

.

2

Remove both cylinder head assemblies, refer to

3.22 Cylinder Head Assembly

.

3

Remove the oil pan assembly, refer to

4.2 Oil Pan and Oil Pump Suction Pipe Assembly

.

4

Mark the top of the piston being removed to identify its specific bore.

5

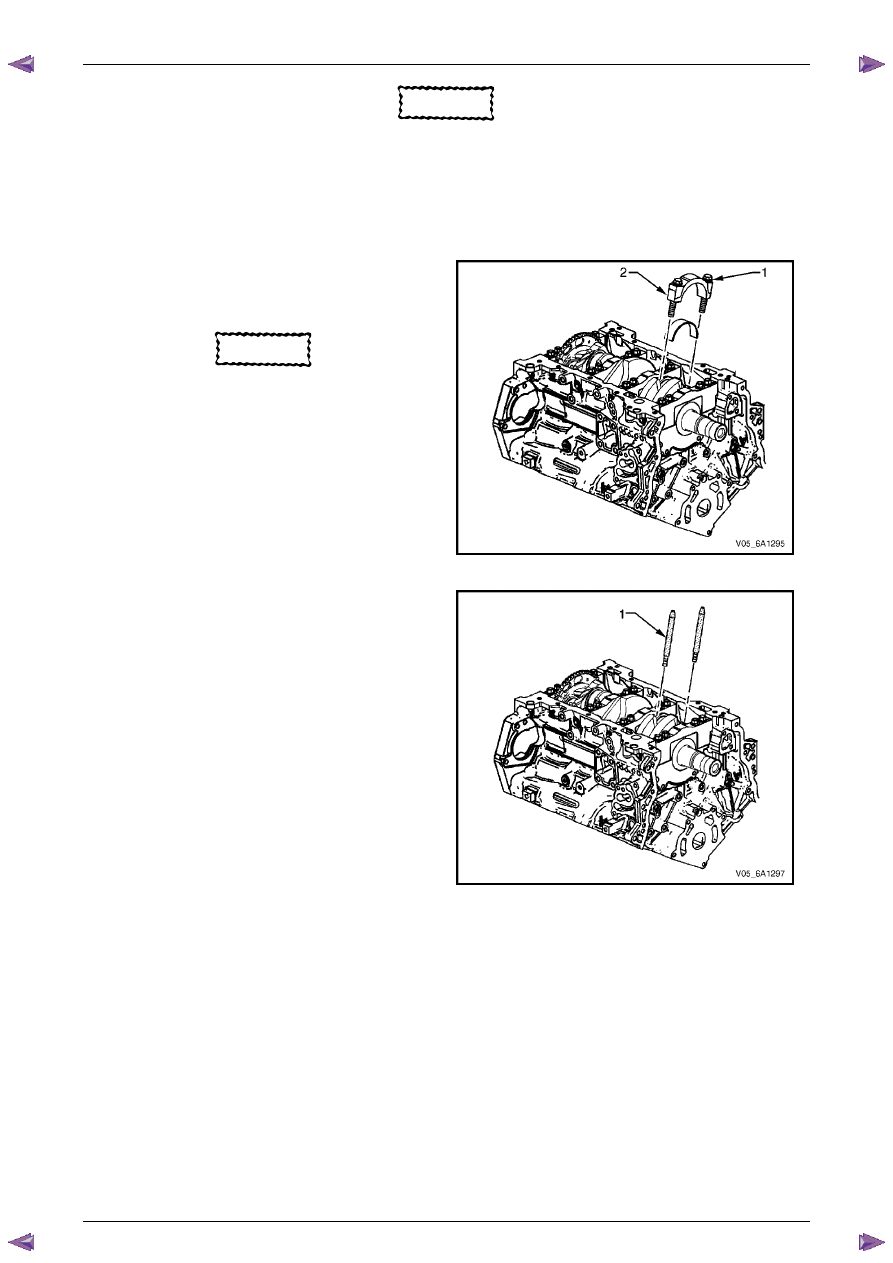

Install Tool No. EN-46111 (1) onto the crankshaft (2).

6

Rotate the crankshaft until the piston being removed

is at the bottom of its stroke; bottom dead centre

(BDC).

Figure 6A1 – 464

CAUTION

If the connecting rod bearings have been

used in a running engine, they must be

replaced with new connecting rod bearings

for reassembly.

7

Before removing the connecting rods, check the connecting rod side clearance using the following procedure:

a

Tap the connecting rod to one end of the crankshaft journal with a dead blow or wooden hammer.

b

Using feeler gauges, measure the clearance between the crankshaft counterweight and the connecting rod.

c

The connecting rod side clearance should not exceed specifications, refer to

5 Specifications

.

d

If the endplay exceeds the specified limits, measure the width of the crankpin end of the connecting rod, refer

to

5 Specifications

.

e

If the connecting rod width is significantly smaller than specified and severe wear is present on the side of the

connecting rod, replace the connecting rod.

f

If the connecting rod width is within specification and excessive scoring is present on the crankshaft journals,

replace the crankshaft.

CAUTION

Do not use a stamp, punch or any other

method that may distort or stress the

connecting rod and cap. Extensive engine

damage may result from a connecting rod that

is distorted or stressed.

8

Mark the cylinder number on the connecting rod and the connecting rod cap with a paint stick or permanent marker.

Engine Mechanical – V6

Page 6A1–266

Page 6A1–266

CAUTION

Powdered metal connecting rods have rod

bolts which yield when tighten to the

specified torque. If the bolts are loosened or

removed they must be replaced. Rod bolts

that are not replaced will not torque to the

correct clamp load and can lead to serious

engine damage.

9

Remove the connecting rod bolts (1), loosening

progressively from side to side.

CAUTION

The connecting rod caps must remain with

the original connecting rod.

10

Remove the connecting rod cap (2).

Figure 6A1 – 465

11

Install connecting rod guide pin set, Tool No.

EN-46121 (1) to the connecting rod bolt holes.

Figure 6A1 – 466

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст