Isuzu KB P190. Manual — part 984

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–23

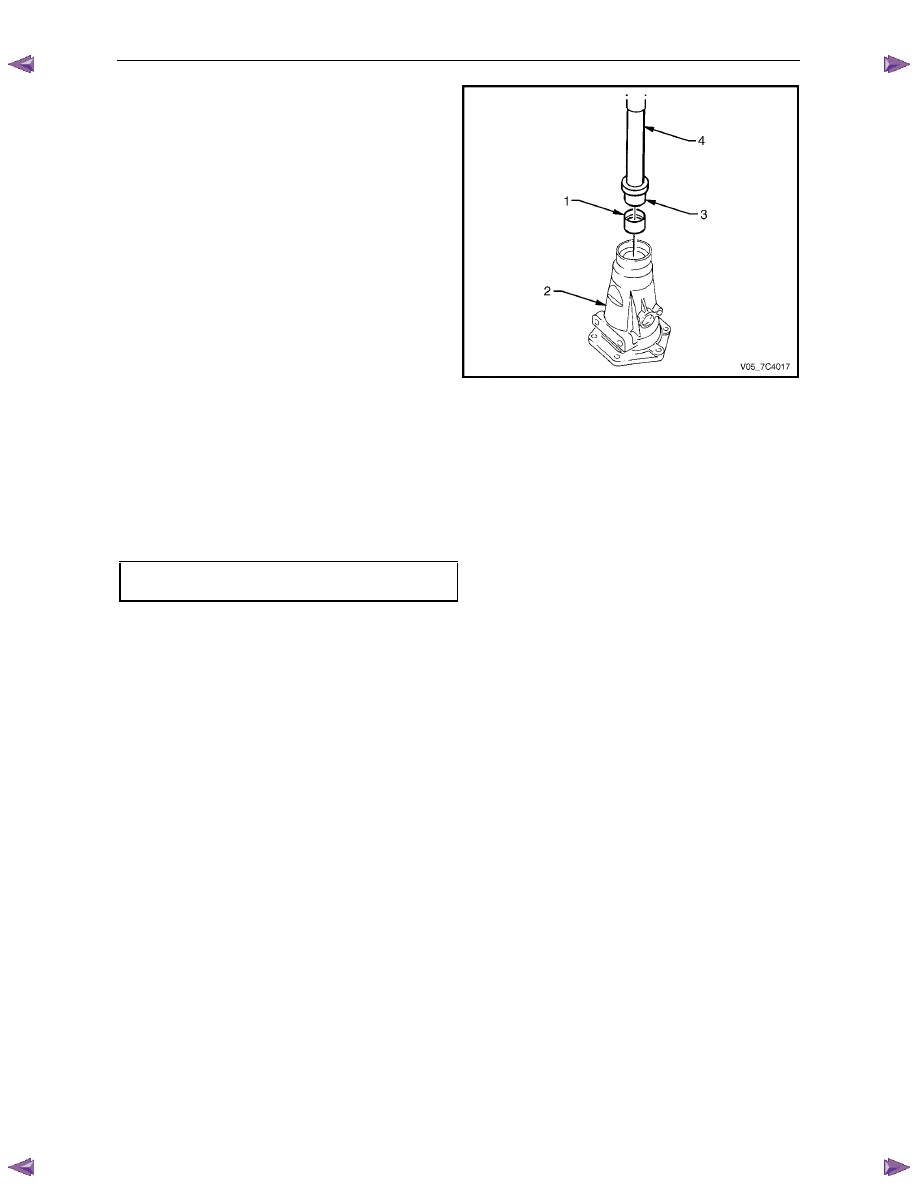

3

Remove the bolt (1), six places, attaching the

extension housing (2) to the transmission case.

4

Remove the extension housing and seal (3) from the

rear of the transmission case, discard the seal.

Figure 7C4 – 22

Take care not to scratch the machined seal

recess in the extension housing as

transmission fluid may weep past the outer

diameter of the installed seal.

5

If the extension housing rear bush is to be replaced,

remove the oil seal (1) from the extension housing (2),

using a suitable removing tool such as Tool No. E308

and discard the seal.

Figure 7C4 – 23

N O T E

Before removal, take note of the orientation of

the split in the bush to assist in the replacement

process.

6

If required, using the bush remover, Tool

No. J23062-14 (1) and driver handle, Tool

No. J8092 (2), press the bush (3) out of the extension

housing (4) and discard.

Figure 7C4 – 24

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–24

7

Lubricate the outside of a new bush with automatic

transmission fluid to reduce the chance of material

pick-up.

8

Ensure the split in the new bush (1) is in the same

orientation as noted previously and Install it into the

extension housing (2) using the installer tool, Tool

No. J34196-4 (3) and driver handle, Tool

No. J8092 (4).

Figure 7C4 – 25

Reinstall

Installation of the extension housing is the reverse of the removal procedure, noting the following:

1

If required, install a new oil seal in the extension housing, refer to 3.8

Extension Housing Oil Seal.

2

Lubricate a new seal with clean automatic transmission fluid and fit to the extension housing mounting flange.

3

Tighten the six bolts attaching the extension housing to the correct torque specification.

Extension housing attaching bolt

torque specification . . . . . . . . . 42.0 – 48.0 Nm

3.10 Adaptor Housing, 4WD

Remove and Reinstall

For service operation of the transmission adaptor housing for 4WD vehicles, refer to 7D Transfer Case and Adaptor

Housing.

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–25

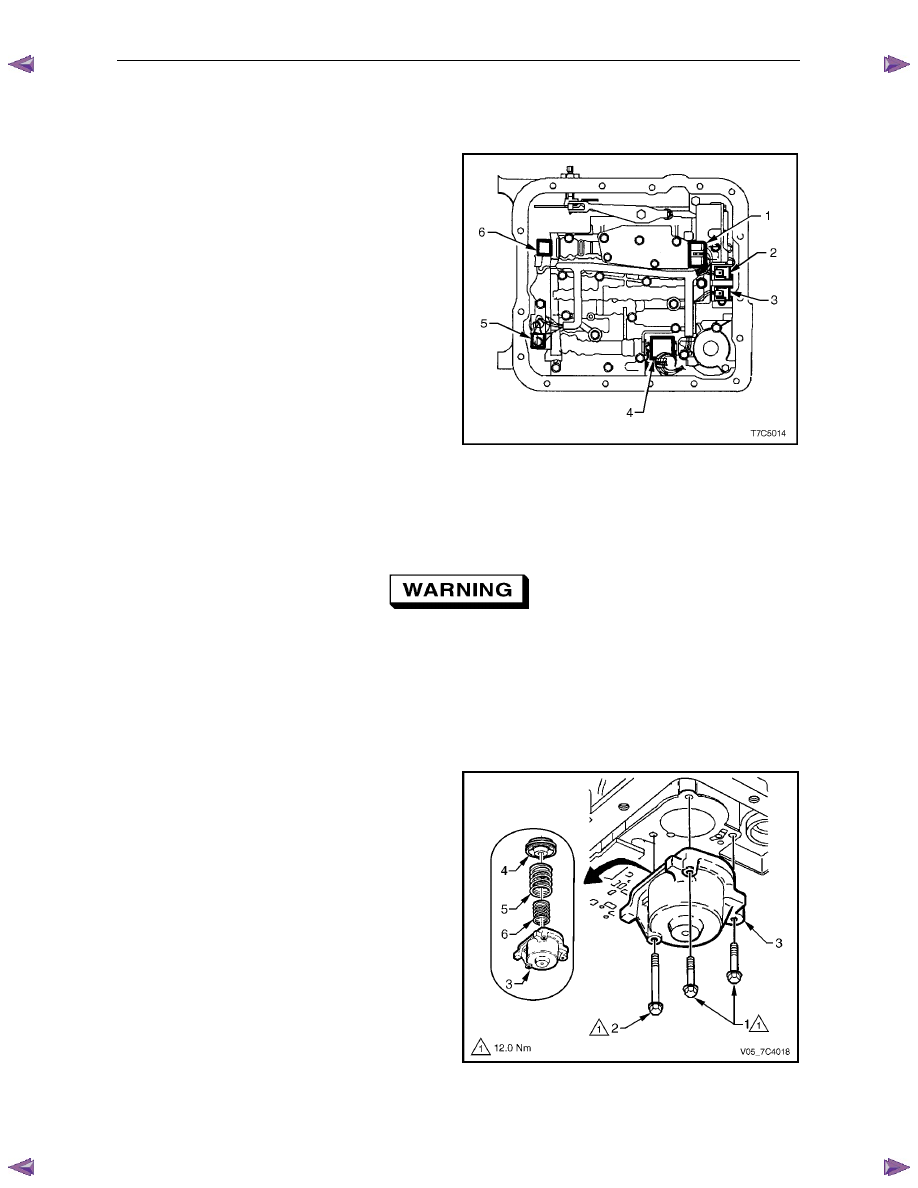

3.11 Shift Solenoid Locations

Location and Identification

Legend

1

Transmission Fluid Pressure (TFP) Manual

Valve Position Switch.

2

1 – 2 Shift Valve Solenoid A.

3

2 – 3 Shift Valve Solenoid B.

4

Pressure Control Solenoid (PCS).

5

Torque Converter Clutch Pulse Width Modulated

(TCC PWM) Solenoid.

6

3 – 2 Control Solenoid.

Figure 7C4 – 26

To service the TCC PWM solenoid, refer to 3.13

Control Valve Body Harness.

3.12 1 – 2 Accumulator Assembly

Throughout this Section when using

compressed air and cleaning fluids, wear

safety glasses and gloves to avoid personal

injury.

Remove

1

Remove the oil pan and filter, refer to 3.1

Fluid Change and Filter Replacement.

2

Remove the two short bolts (1) and one long bolt (2)

attaching the accumulator cover (3) and remove the

cover.

3

Using low pressure compressed air applied to the

drilling in the cover, remove the 1 – 2 accumulator

piston and seal assembly (4) and the two

springs (5 and 6).

4

Remove the seal from the piston and discard the seal.

Figure 7C4 – 27

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–26

Clean and Inspect

1

Clean all components in a commercially available cleaning fluid and blow dry using compressed air.

2

Inspect the springs and ensure they are not distorted or broken, replace as required.

3

Inspect all machined surfaces for damage, wear or burrs.

Reinstall

Reinstallation of the 1 – 2 accumulator assembly is the reverse of the removal procedure, noting the following:

1

Lubricate a new seal with petroleum jelly and install it to the piston. Ensure the piston seal does not bind in the

piston groove.

2

Tighten the three bolts attaching the accumulator cover to the correct torque specification.

1 – 2 Accumulator cover attaching

bolt torque specification . . . . . . . . . .12.0 Nm

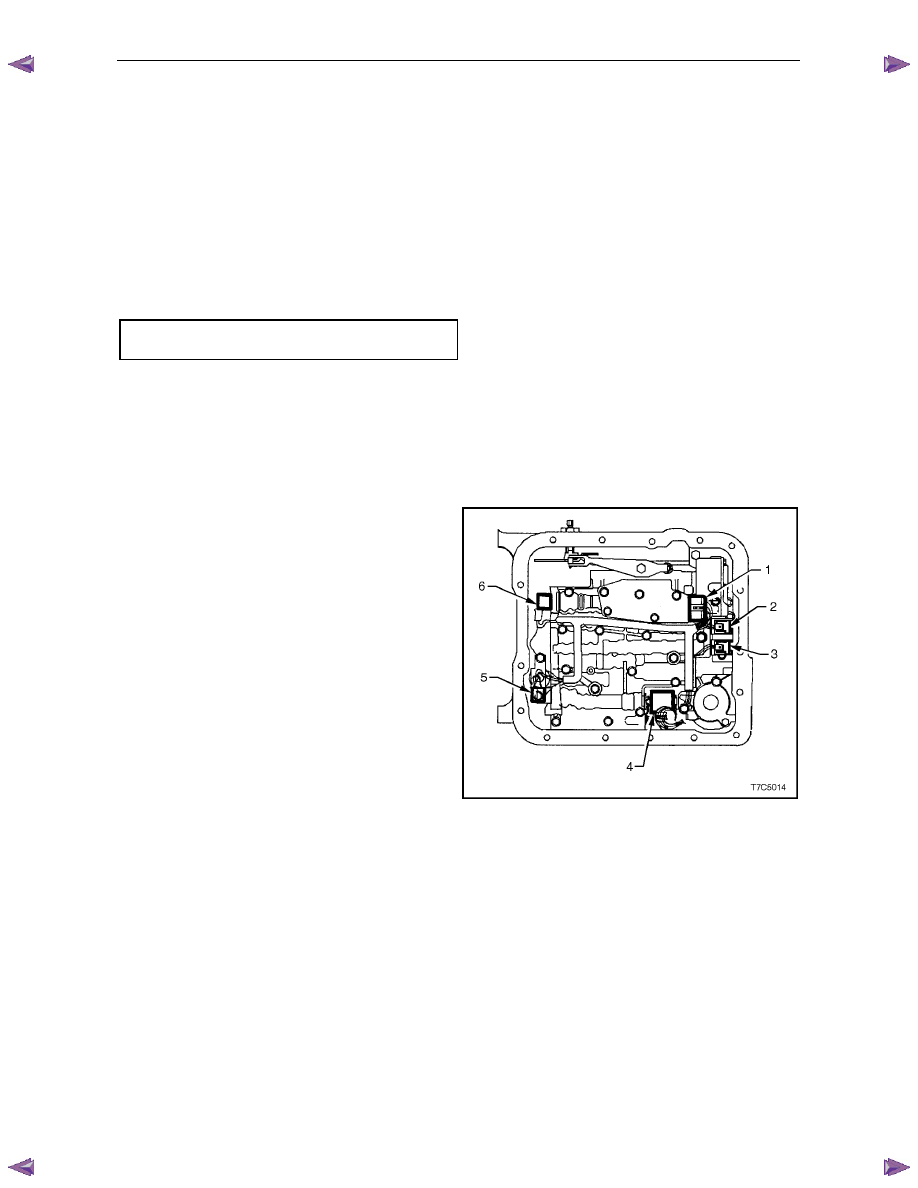

3.13 Control Valve Body Harness

Remove

1

Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

2

As required, remove the oil pan and filter, refer to 3.1

Fluid Change and Filter Replacement.

3

Disconnect the control valve body harness connectors

from all electrical components except the torque

converter clutch (TCC) solenoid, which is hard wired.

Connectors identification:

•

Transmission Fluid Pressure (TFP) Manual

Valve Position Switch (1)

•

1 – 2 Shift Valve Solenoid A (2)

•

2 – 3 Shift Valve Solenoid B (3)

•

Pressure Control Solenoid (PCS) (4)

•

Torque Converter Clutch Pulse Width Modulated

(TCC PWM) Solenoid (5)

•

3 – 2 Control Solenoid (6).

Figure 7C4 – 28

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст