Isuzu KB P190. Manual — part 886

Engine Management – V6 – Service Operations

Page 6C1-3–20

Reinstall

Reinstallation of the engine control module (ECM) is the reverse of the removal procedure, noting the following:

N O T E

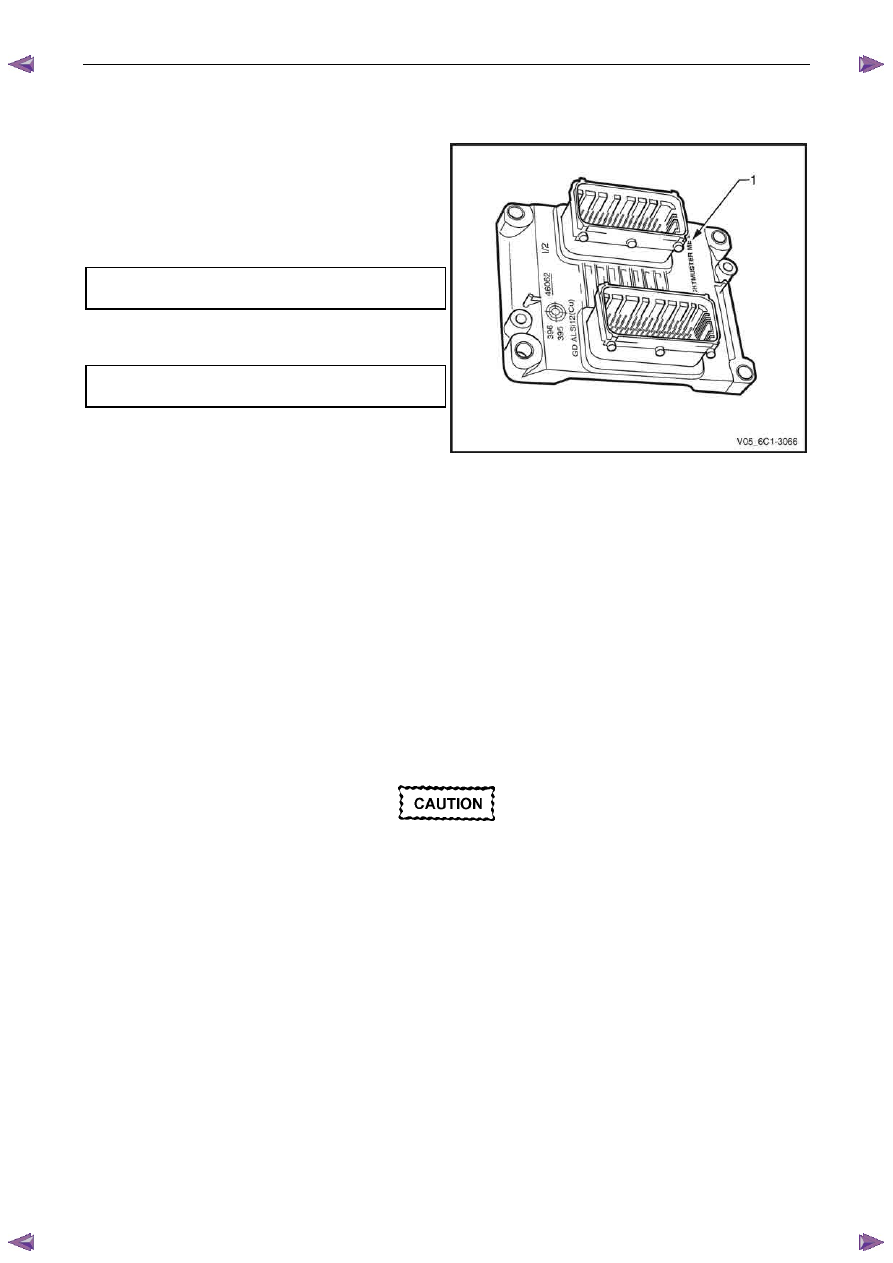

During installation of the ECM, the

SICHTMUSTER ME 9.6 label (1) is positioned at

the top right-hand corner.

1

Reinstall ECM attaching bolts and tighten to the

correct torque specification.

Engine control module attaching bolt

torque specification . . . . . . . . ...8.0 – 12.0 Nm

2

Reinstall the ground terminal screw and tighten to the

correct torque specification.

Ground terminal attaching screw

torque specification . . . . . . . . . . . ..4.5 Nm

Figure 6C1-3 – 17

3

Reinstall the main vehicle wiring harness connector, and engine wiring harness connector, ensuring the connector

locking lever is fully seated, refer to Figure 6C1-3 – 15.

4

If the ECM has been replaced, perform the following procedures:

•

ECM service programming, 6E1 Powertrain Interface Module – V6.

•

ECM / PIM / ICU security link, refer to 6E1 Powertrain Interface Module – V6.

•

Main diagnostic table functional check, refer to 6C1-2 Engine Management – V6 – Diagnostics.

5

If the ECM has been removed, but not replaced, perform the main diagnostic table functional check, refer to

6C1-2 Engine Management – V6 – Diagnostics.

6

Start the vehicle and allow to idle.

ECM Reset

Do not perform the reset procedure within

sixty seconds of turning the ignition on.

Failure to comply may result in the ECM

failing to reset.

When an ECM is installed onto a vehicle, it is security linked to the Immobiliser Control Unit (ICU) and powertrain

interface module (PIM). Once this linking has been performed, the ECM cannot be installed in any other vehicle unless

the security linking between the ICU and the PIM has been reset using the following procedure.

N O T E

Prior to resetting the ECM, obtain the Security

Code. This information is found on the vehicle

security card issued with the vehicle when new.

For further information on the vehicle security

card, refer to 6E1 Powertrain Interface Module –

V6.

1

Connect Tech 2 to the data link connector (DLC) and turn the ignition on.

2

On Tech 2 select Engine / V6 Engine / Programming / Reset ECU.

Engine Management – V6 – Service Operations

Page 6C1-3–21

N O T E

When Tech 2 requests programming approval,

obtain TIS approval.

3

When Tech 2 displays Enter Security Code, enter the security code, press the Enter key and then the Okay soft

key.

The engine will not start after the ECM has

been reset.

4

When Tech 2 displays Do you really want to Reset?, press the Reset soft key.

5

When Tech 2 displays Stop Engine - Turn Off Ignition, turn the ignition off and press the Confirm soft key.

6

When Tech 2 displays Turn Ignition On, turn the ignition on and press the Confirm soft key.

7

When Tech 2 displays Reset Completed Successfully, press the Confirm soft key to return to the Tech 2

Programming screen.

2.8

Engine Control Module Bracket

Assembly

Remove

1

Remove the engine control module (ECM), refer to 2.7

Engine Control Module.

2

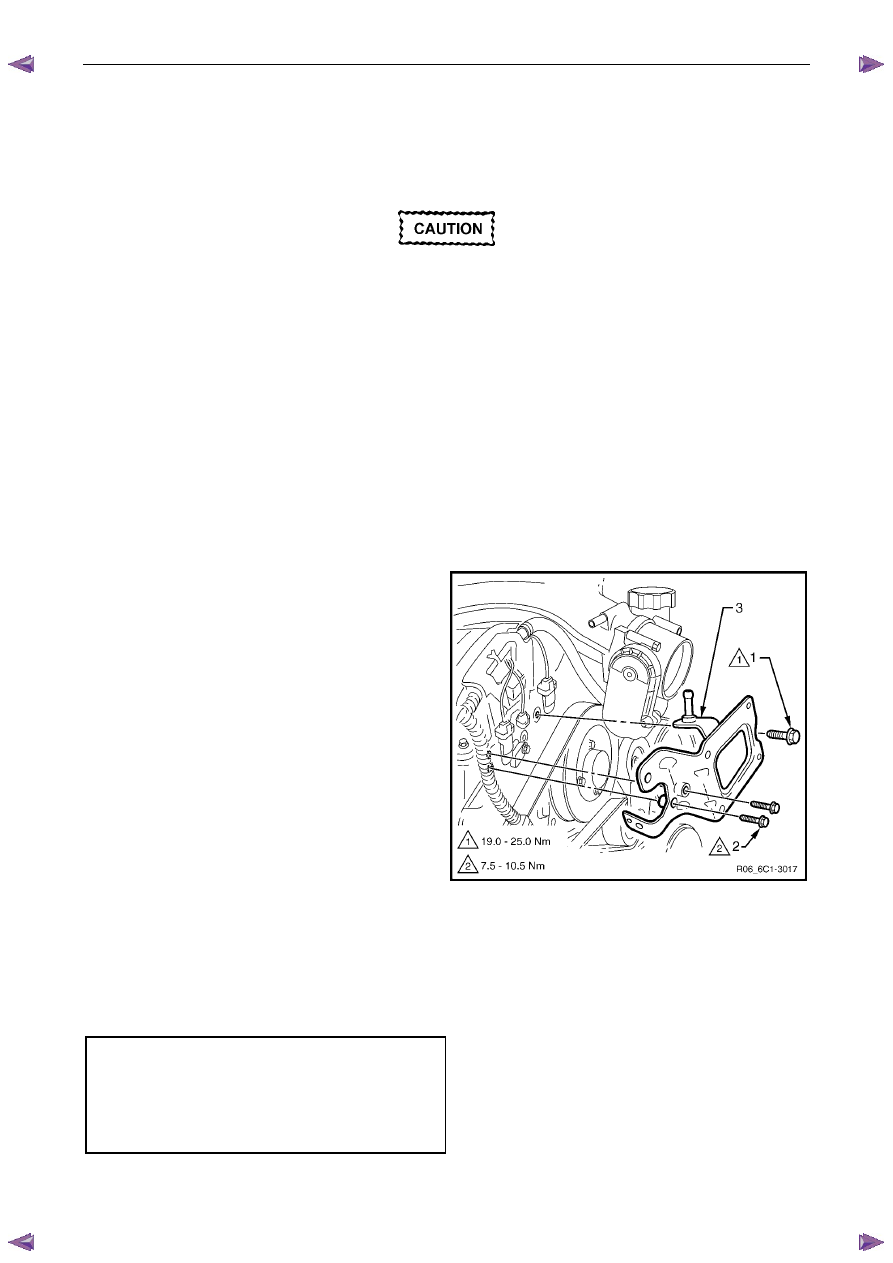

Remove the bolt (1) and the two bolts (2), attaching

the ECM bracket assembly (3) to the front engine

cover and remove.

Figure 6C1-3 – 18

Reinstall

Reinstallation of the engine control module (ECM) bracket assembly is the reverse of the removal procedure, noting the

following:

1

Tighten the ECM bracket assembly bolts to the correct torque specification.

Engine control module bracket

assembly attaching bolt

torque specification (6mm). . . . . . 7.5 – 10.5 Nm

Engine control module bracket

assembly attaching bolt

bolt torque specification (8mm) . . . ...19.0 – 25.0 Nm

2

Perform the main diagnostic table functional check, refer to 6C1-2 Engine Management – V6 – Diagnostics.

Engine Management – V6 – Service Operations

Page 6C1-3–22

3

Road test the vehicle and check for correct operation.

2.9

Engine Oil Level and Temperature

Sensor

To avoid personal injury, take care when

draining the engine oil or removing the engine

oil level and temperature sensor whilst the

engine is hot. Allow the engine to cool before

performing this procedure.

Remove

1

Turn the ignition switch off.

2

Raise the front and rear of the vehicle and support on safety stands, refer to 0A General Information for location of

the jacking points.

3

Drain the engine oil, refer to 6A1 Engine Mechanical – V6.

Clean the area around the engine oil level

and temperature sensor (1) before removal to

avoid debris from entering the engine.

4

Disconnect the wiring harness connector (2) from the

engine oil level and temperature sensor.

Figure 6C1-3 – 19

5

Using a 11/8" deep socket and socket bar, remove the

engine oil level and temperature sensor (1).

6

If required, test the Engine Oil Level and Temperature

sensor as follows, refer to the Test in this Section.

Figure 6C1-3 – 20

Engine Management – V6 – Service Operations

Page 6C1-3–23

Test

Engine Oil Level Sensor Check

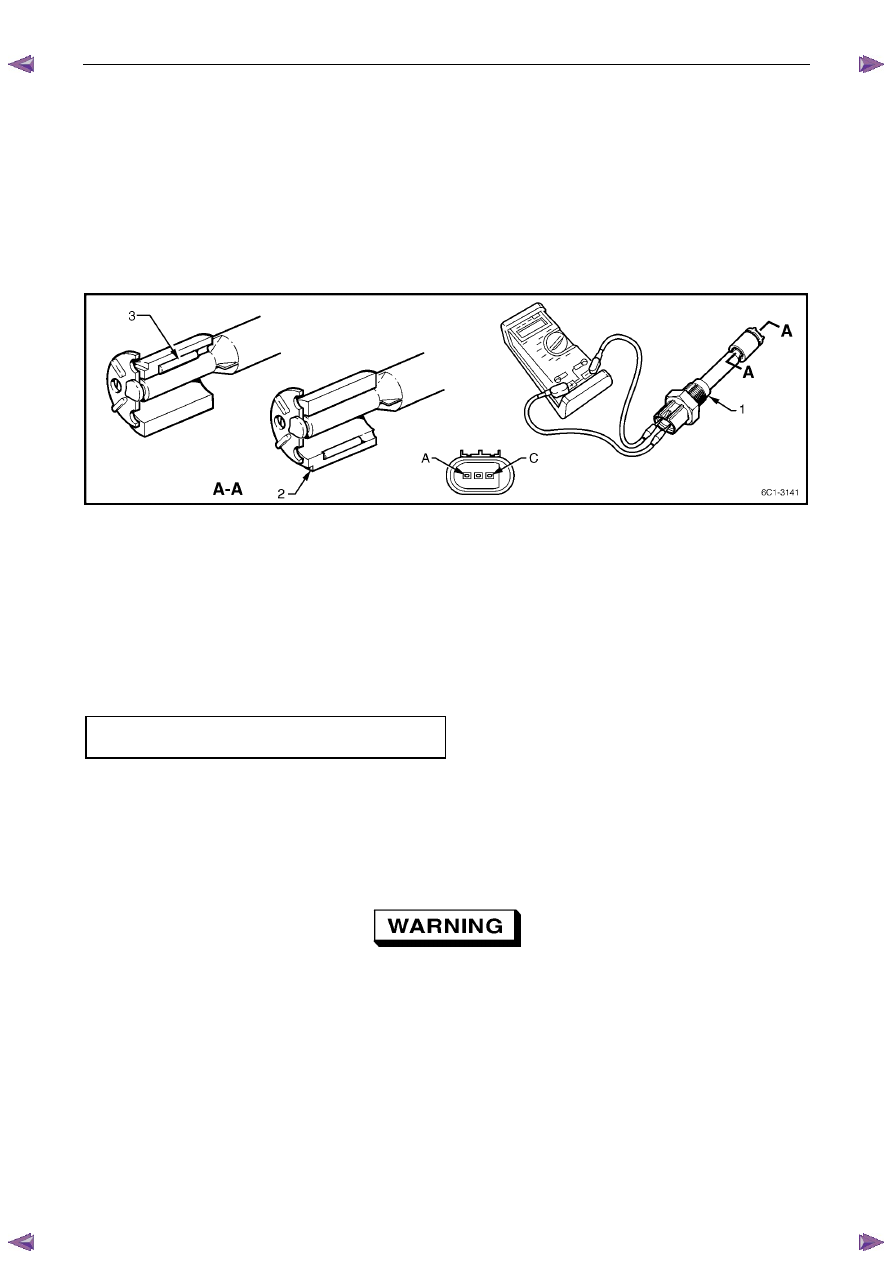

1

With the aid of an assistant, perform the following:

a

Whilst holding the engine oil level and temperature sensor (1) in a level position, connect a digital ohmmeter

using connector test adaptor kit J 35616-A to terminals A and C, refer to Figure 6C1-3 – 21.

b

With the flat surface of the float (2) positioned at the bottom, ensure continuity does not exist.

c

Push the float upwards so the magnetic pin (3), on the inside of the float (the side of the float with the flat

side) contacts the engine oil level sensor. Check for continuity whilst holding the float in this position.

Figure 6C1-3 – 21

2

If any of the above tests fail, replace the engine oil level sensor.

Reinstall

Reinstallation of the engine oil level and temperature sensor is the reverse of the removal procedure, noting the

following:

1

Lubricate the O-ring and threaded portion of the sensor with clean engine oil.

2

Tighten the engine oil level and temperature sensor to the correct torque specification.

Engine oil level and temperature sensor

torque specification – wet. . . . . . 11.0 – 15.0 Nm

3

Refill the engine with engine oil, refer to 6A1 Engine Mechanical – V6.

4

Road test the vehicle and check for correct operation, taking particular note there is no engine oil leakage from the

oil level and temperature sensor.

2.10 Engine Oil Pressure Sensor

To avoid personal injury, take care when

removing the engine oil pressure sensor

when the engine is hot. Allow the engine to

cool before performing this procedure.

Remove

1

Turn the ignition switch off.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст