Isuzu KB P190. Manual — part 884

Engine Management – V6 – Service Operations

Page 6C1-3–12

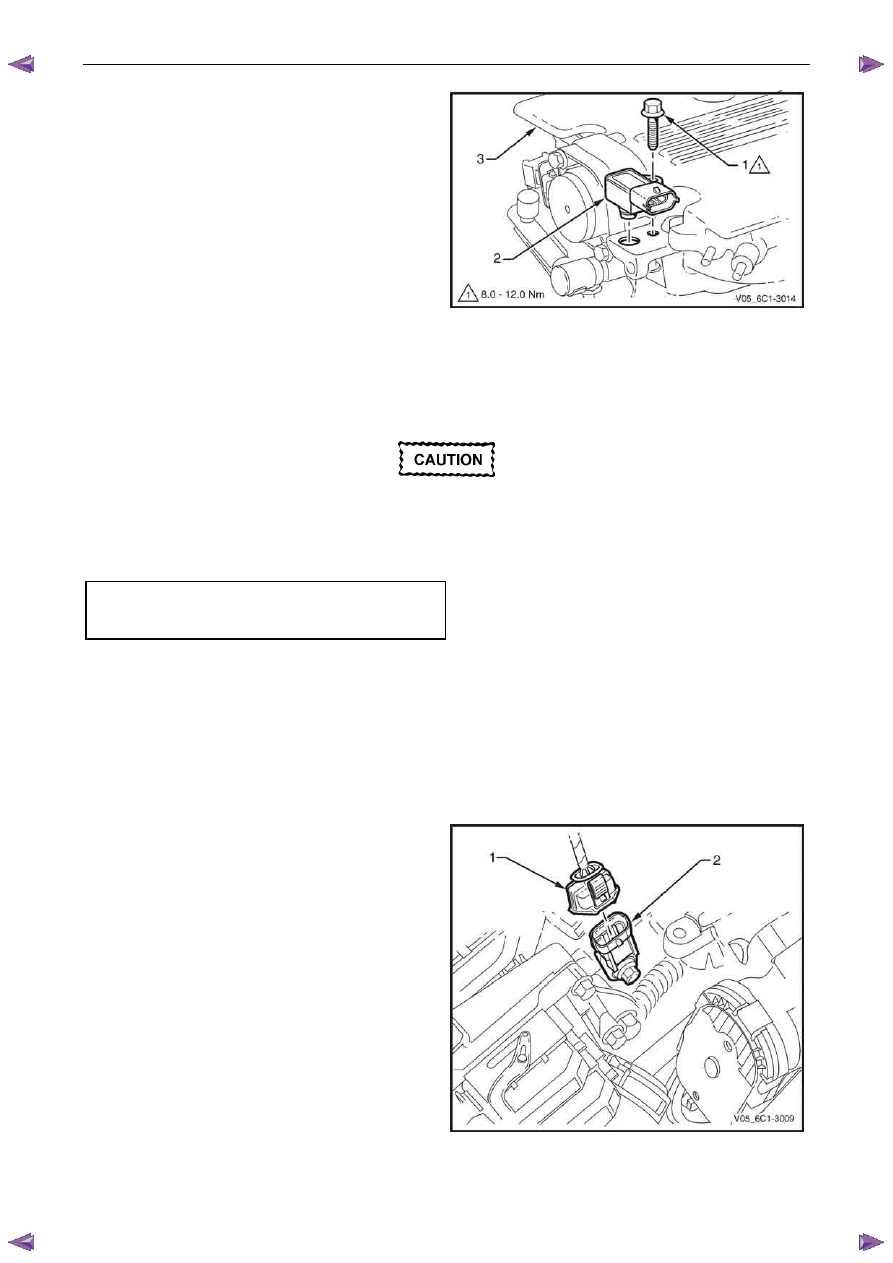

3

Remove the bolt (1) attaching the BARO sensor (2) to

the upper intake manifold (3).

4

Remove the BARO sensor from the manifold by first,

twisting the sensor to release it, and then pulling it

upwards to remove it.

Figure 6C1-3 – 6

Reinstall

Reinstallation of the barometric pressure (BARO) sensor is the reverse of the removal procedure, noting the following:

Ensure the BARO sensor is fully seated

before tightening the attaching bolt to the

specified torque.

1

Reinstall the BARO sensor bolt and tighten to the correct torque specification.

Barometric pressure sensor

attaching bolt

torque specification . . . . . . . . ...8.0 – 12.0 Nm

2

Road test the vehicle and check for correct operation.

2.4

Camshaft Position Sensor

Remove

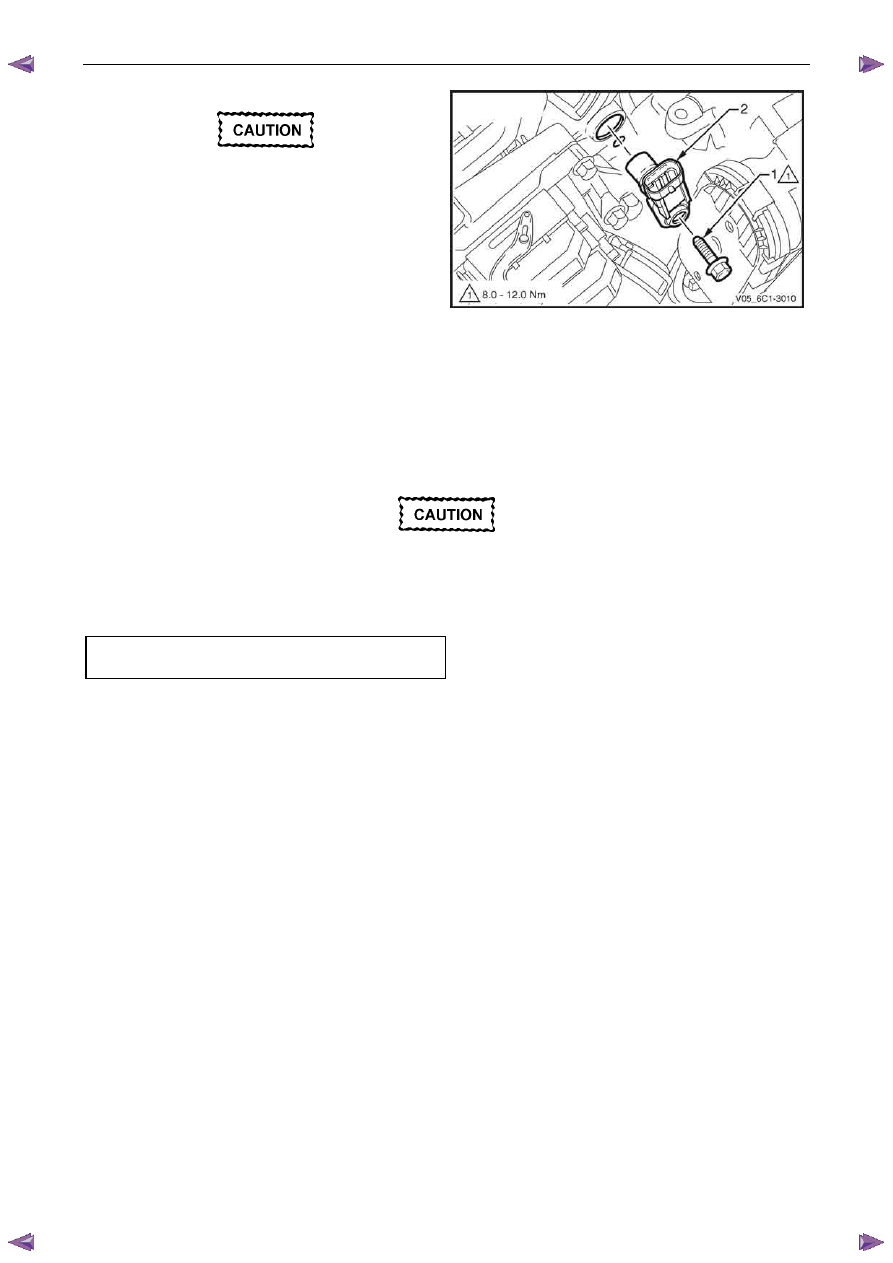

1

Turn the ignition switch off.

2

Disconnect the wiring harness connector (1) from the

CMP sensor (2).

Figure 6C1-3 – 7

Engine Management – V6 – Service Operations

Page 6C1-3–13

Clean the area around the CMP sensor before

removal to avoid debris from entering the

engine.

3

Remove the CMP sensor attaching bolt (1).

4

Remove the CMP sensor (2) by first twisting the

sensor to release it, and then pulling it away from the

front engine cover to remove it.

Figure 6C1-3 – 8

Reinstall

Reinstallation of the camshaft position (CMP) sensor is the reverse of the removal procedure, noting the following:

1

Lubricate the CMP sensor O-ring with clean engine oil.

2

Reinstall the CMP sensor by pushing in on the sensor to engage the sensor O-ring in the front engine cover.

Ensure the CMP sensor is fully seated before

tightening the attaching bolt to the specified

torque.

3

Reinstall the CMP sensor bolt and tighten to the correct torque specification.

Camshaft position sensor attaching bolt

torque specification . . . . . . . . ...8.0 – 12.0 Nm

4

Road test the vehicle and check for correct operation, taking particular note there is no engine oil leak from the

CMP sensor.

2.5

Crankshaft Position Sensor

Remove

1

Turn the ignition switch off.

2

Raise the front of the vehicle and support on safety stands, refer to 0A General Information for location of the

jacking points.

Engine Management – V6 – Service Operations

Page 6C1-3–14

3

Disconnect the wiring harness connector (1) from the

crankshaft position (CKP) sensor (2).

Figure 6C1-3 – 9

Clean the area around the CKP sensor before

removal to avoid debris from entering the

engine.

4

Remove the CKP sensor attaching bolt (1).

5

Remove the CKP sensor (2), by first twisting the

sensor to release it, and then pulling it away from the

engine block to remove it.

6

If required, test the CKP sensor, refer to the Test in

this Section.

Figure 6C1-3 – 10

Engine Management – V6 – Service Operations

Page 6C1-3–15

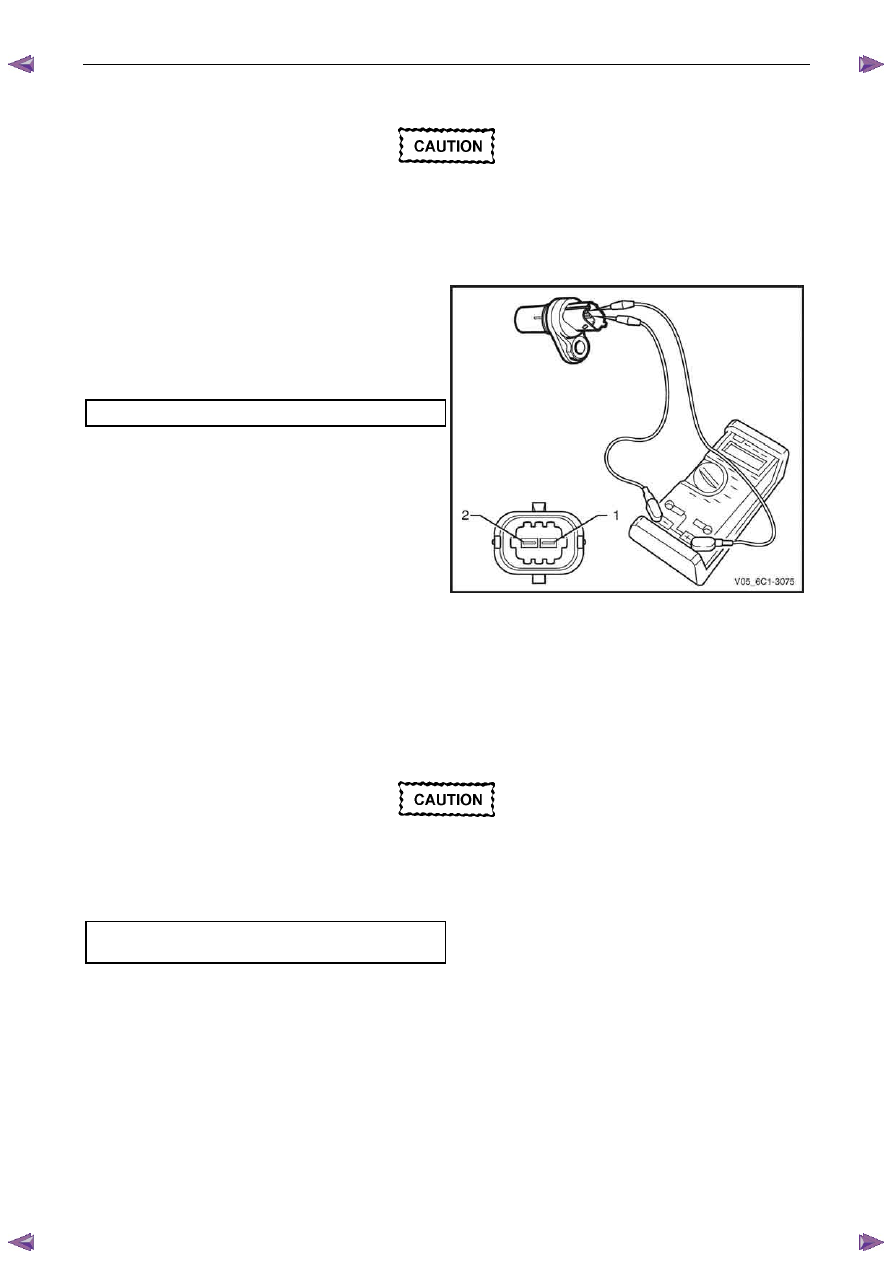

Test

To prevent component and damage use

connector test adaptor kit J 35616-A.

Resistance Check

1

Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the crankshaft position (CKP)

sensor.

2

Measure the resistance across terminals 1 and 2.

3

Compare the reading against the specification.

CKP sensor resistance @ 20°C . . . . 850 – 1040

Ω

4

If the resistance is not within specification, replace the

CKP sensor.

Figure 6C1-3 – 11

Reinstall

Reinstallation of the crankshaft position (CKP) sensor is the reverse of the removal procedure, noting the following:

1

Lubricate the CKP sensor O-ring with clean engine oil.

2

Reinstall the CKP sensor by pushing down on the sensor to engage the sensor O-ring in the engine block.

Ensure the CKP sensor is fully seated before

tightening the attaching bolt to the specified

torque.

3

Reinstall the CKP sensor bolt and tighten to the correct torque specification.

Crankshaft position sensor attaching bolt

torque specification . . . . . . . . ...8.0 – 12.0 Nm

4

Road test the vehicle and check for correct operation, taking particular note there is no engine oil leak from the

CKP sensor.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст