Isuzu KB P190. Manual — part 887

Engine Management – V6 – Service Operations

Page 6C1-3–24

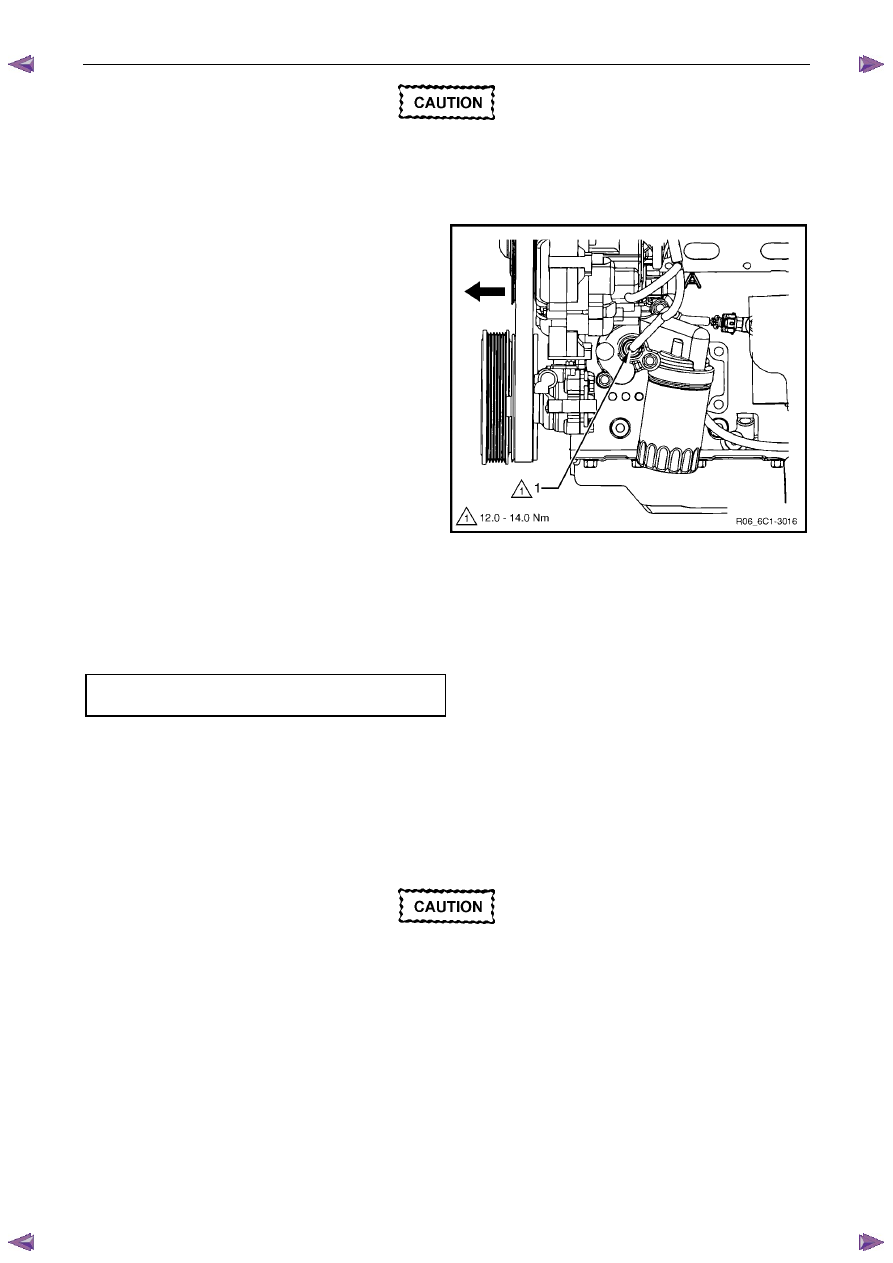

Clean the area around the engine oil pressure

sensor before removal to avoid debris from

entering the engine.

2

Disconnect the wiring harness connector (1) from the engine oil pressure sensor.

N O T E

A small amount of oil will drain from the oil filter

housing when the engine oil pressure sensor is

removed. Use a shop towel to absorb the oil.

3

Using special tool J 41712 or a 11/16" deep socket

and socket bar, remove the engine oil pressure

sensor (1).

Figure 6C1-3 – 22

Reinstall

Reinstallation of the engine oil pressure sensor is the reverse of the removal procedure, noting the following:

1

Tighten the engine oil pressure sensor to the correct torque specification.

Engine oil pressure sensor

torque specification . . . . . . . . .12.0 – 14.0 Nm

2

Check the engine oil level and top up if necessary, refer to 6A1 Engine Mechanical – V6.

2.11 Evaporative Emission (EVAP) Canister

Purge Valve Quick Connect Fittings

Disconnect

Clean the area around the evaporative

emission (EVAP) canister purge valve before

disconnecting the quick connect fitting to

avoid debris from entering EVAP canister

purge valve.

Engine Management – V6 – Service Operations

Page 6C1-3–25

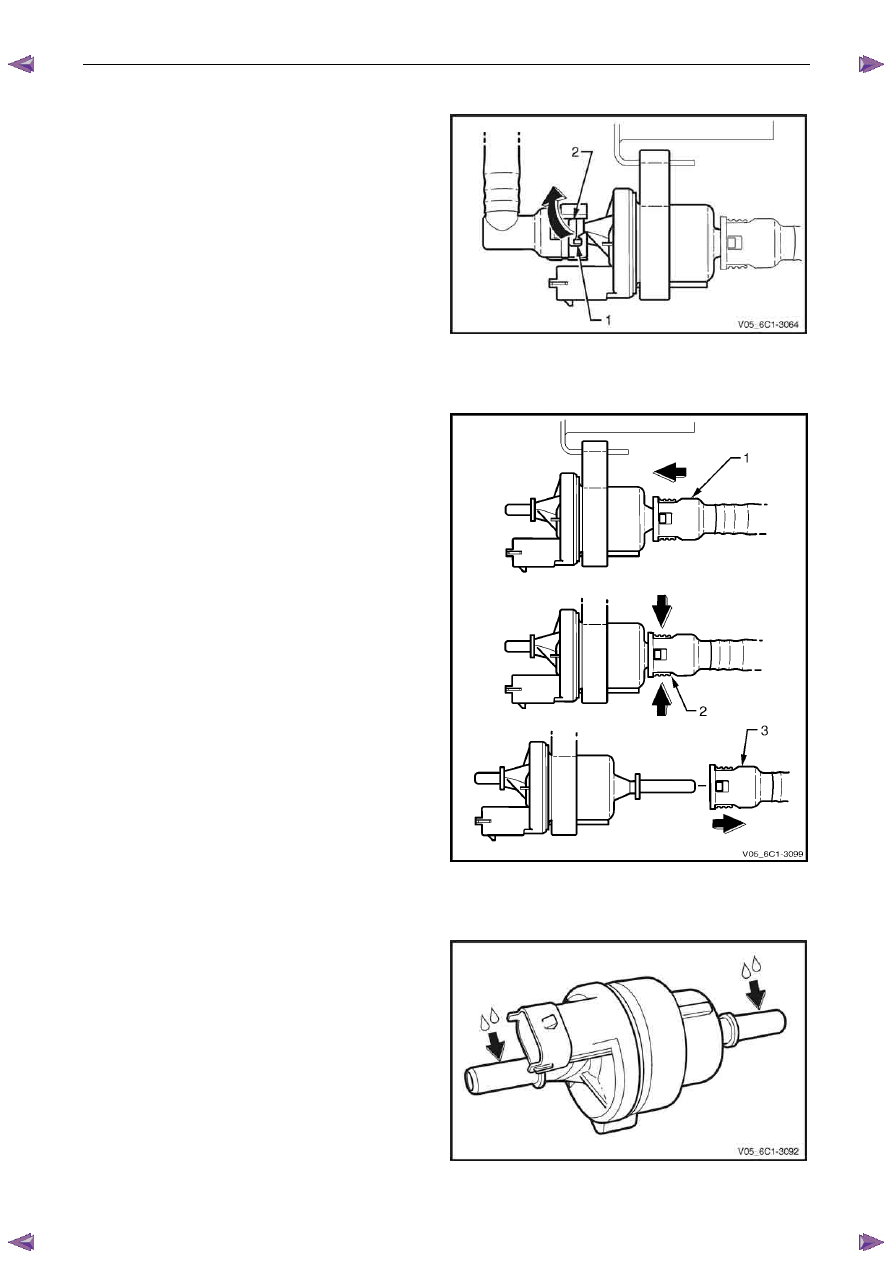

Locking Lever Type

1

Rotate the quick connect locking lever (1) in the

direction of the arrow.

2

Whilst holding the lever against its stop (2), pull the

hose away from the EVAP canister purge valve.

Figure 6C1-3 – 23

Latch Type

1

Push the quick connect fitting (1) in the direction of

arrow.

2

Whilst pressing the two latches (2) in the direction of

the arrows, pull the quick connect fitting (3) away from

the EVAP canister purge valve.

Figure 6C1-3 – 24

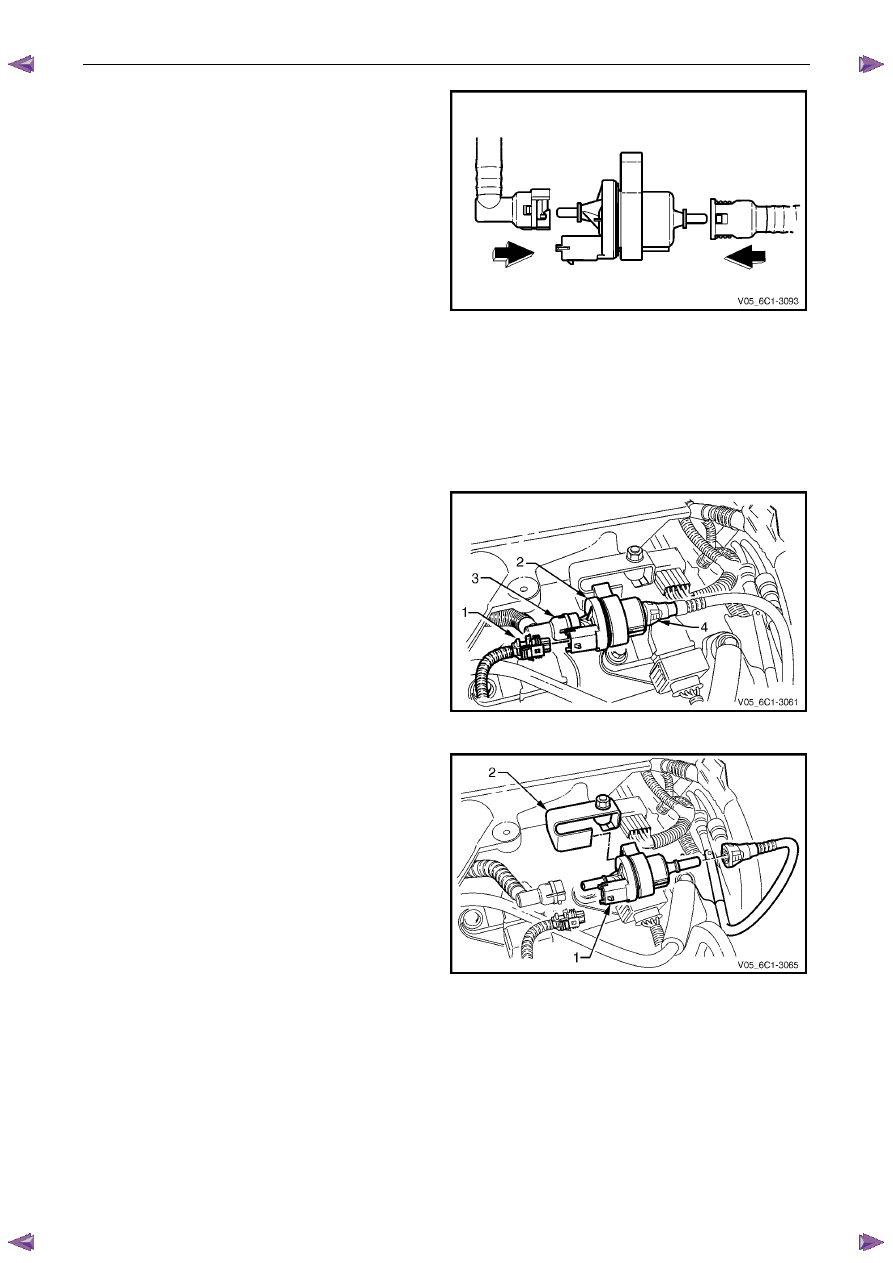

Connect

1

Lubricate the evaporative emission (EVAP) canister

purge valve with clean engine oil.

Figure 6C1-3 – 25

Engine Management – V6 – Service Operations

Page 6C1-3–26

2

Push the hose quick connect fitting onto the purge

valve fitting. There will be an audible click as the quick

connect fitting engages.

3

Check the locking lever has returned to its rest

position.

4

Check the quick connect fittings have fully engaged by

gently pulling the quick connect fitting away from the

purge valve.

Figure 6C1-3 – 26

2.12 Evaporative Emission Canister Purge

Valve

Remove

1

Turn the ignition switch off.

2

Disconnect the wiring harness connector (1) from the

evaporative emission (EVAP) canister purge valve (2).

3

Disconnect the two EVAP canister purge valve hoses

(3 and 4), refer to 2.11

Evaporative Emission

(EVAP) Canister Purge Valve Quick Connect Fittings.

Figure 6C1-3 – 27

4

Slide the EVAP canister purge valve (1) from the

purge valve mounting bracket (2).

5

If required, test the EVAP canister purge valve, refer to

the Test in this Section.

Figure 6C1-3 – 28

Engine Management – V6 – Service Operations

Page 6C1-3–27

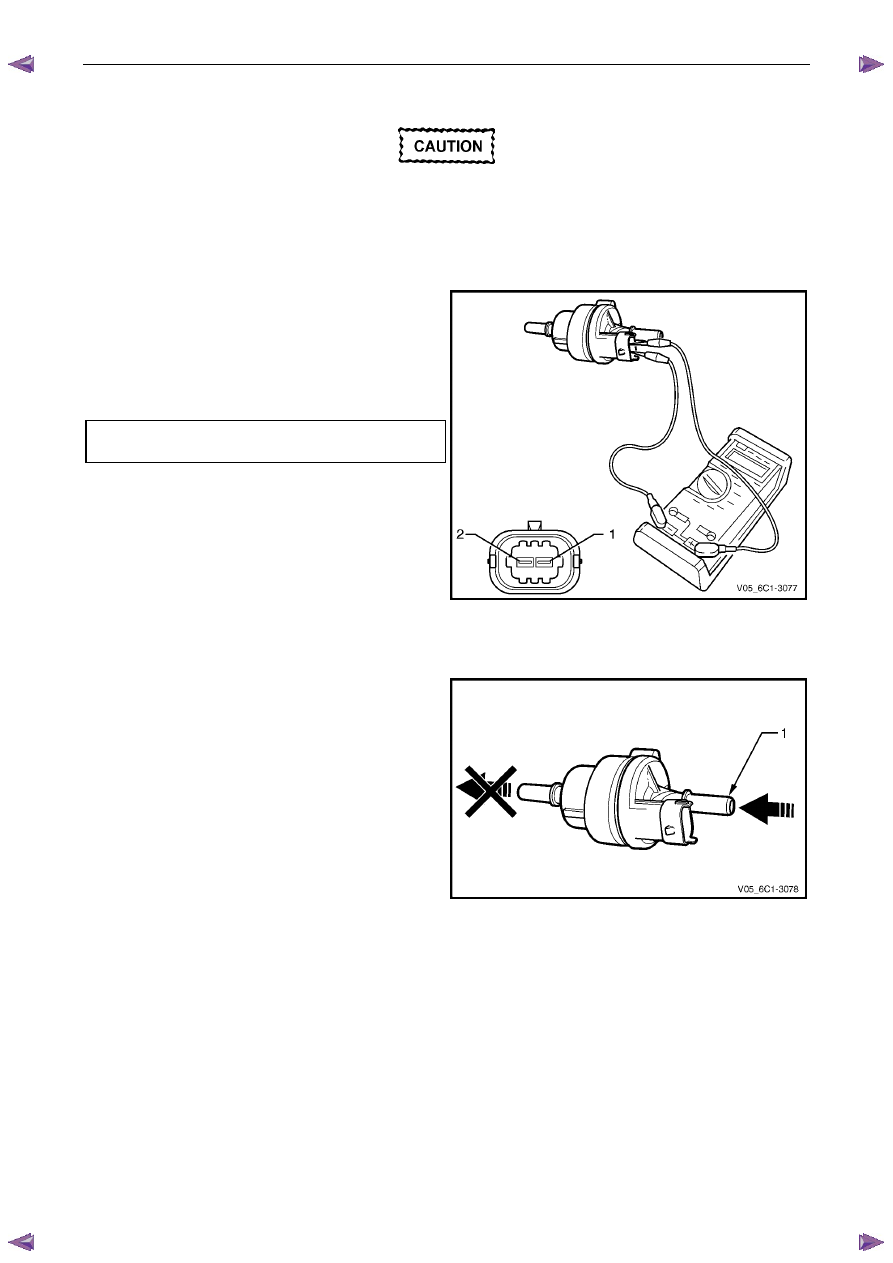

Test

To prevent component damage:

• Use connector test adaptor kit J 35616-A.

• When applying 12 V to a component,

always use a 3 A fused wire.

Resistance Check

1

Using a digital ohmmeter and connector test adaptor

kit J 35616-A, measure the resistance across

terminals 1 and 2.

2

Compare the reading against the specification.

3

If the resistance is not within specification, replace the

EVAP canister purge valve.

EVAP canister purge valve

resistance @ 20°C . . . . . . . . . 24.0 – 28.0

Ω

Figure 6C1-3 – 29

Functional Test

1

Attempt to blow air through the EVAP canister purge

valve inlet port (1). If air passes through the valve, the

valve is faulty and should be replaced.

Figure 6C1-3 – 30

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст