Isuzu KB P190. Manual — part 885

Engine Management – V6 – Service Operations

Page 6C1-3–16

2.6

Engine Coolant Temperature Sensor

Remove

To avoid serious personal injury, never

remove the engine coolant temperature (ECT)

sensor when the engine is hot. Allow the

engine to cool to ambient temperature (less

than 50

°°°°C) before performing this procedure.

1

Turn the ignition switch off.

To avoid serious personal injury, never

remove the coolant filler cap when the engine

is hot. Allow the engine to cool to ambient

temperature (less than 50

°°°°C) before

performing this procedure.

2

Allow the engine to cool to ambient temperature less than 50

°C, and slowly remove coolant filler cap located on the

coolant outlet housing.

3

Drain approximately two litres of coolant into a suitable container, refer to 6B1 – Engine Cooling – V6.

4

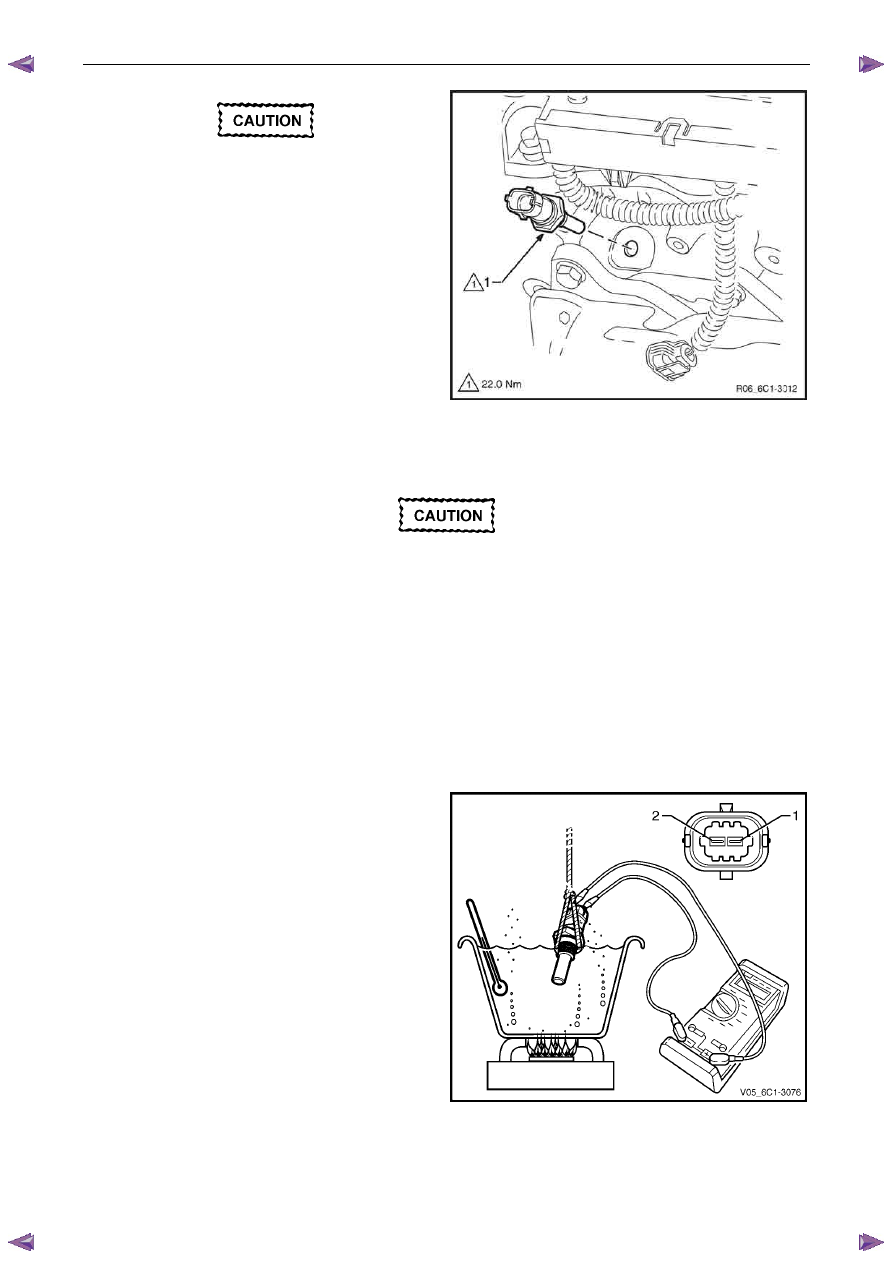

Disconnect the wiring harness connector (1) from the

ECT sensor (2).

Figure 6C1-3 – 12

Engine Management – V6 – Service Operations

Page 6C1-3–17

Clean the area around the ECT before

removal to avoid debris from entering the

engine.

5

Remove the ECT sensor (1).

N O T E

If coolant leaks from the cylinder head as the

sensor is removed, screw the sensor back into

the cylinder head and drain more coolant from

the cooling system.

6

If required, test the ECT sensor, refer to the Test in

this Section.

Figure 6C1-3 – 13

Test

To prevent component damage, use

connector test adaptor kit J 35616-A.

Resistance Check

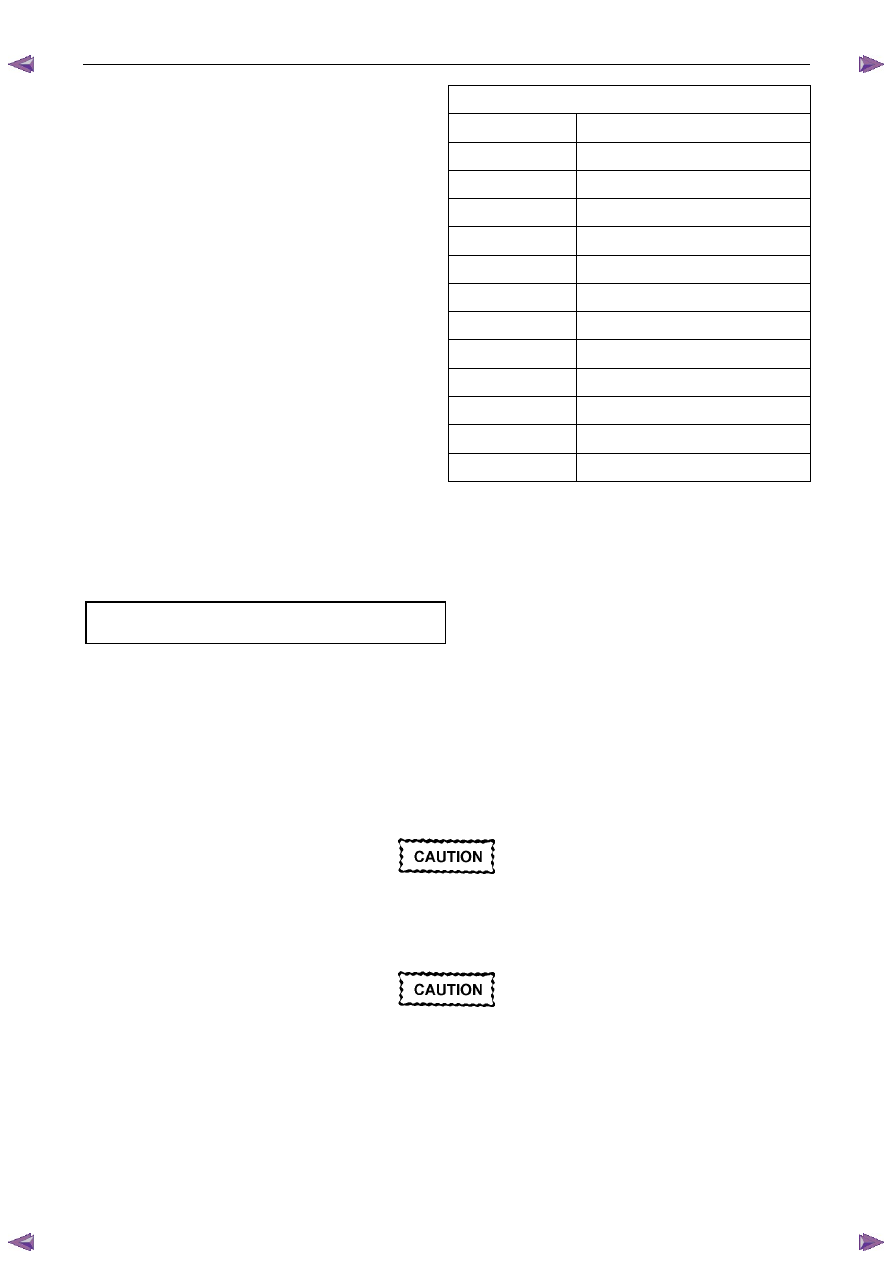

1

Suspend the engine coolant temperature (ECT) sensor and a suitable thermometer in a container of 50/50 DEX-

COOL® long life coolant or equivalent and water.

N O T E

Neither the ECT sensor or thermometer should

rest on the bottom of the container due to an

uneven concentration of heat at this point when

the container is heated.

2

Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the ECT sensor.

3

Measure the resistance across terminals 1 and 2.

4

Whilst heating the container, observe the resistance

values as the temperature increases and compare the

temperature / resistance change to the specifications.

Figure 6C1-3 – 14

Engine Management – V6 – Service Operations

Page 6C1-3–18

5

If the resistance is not within specifications, replace

the ECT sensor.

Engine Coolant Temperature Vs Resistance

Temperature °C

Resistance – Ohms (

Ω)

-40

40490 – 50136

-20

14096 – 16827

-10

8642 – 10152

0

5466 – 6326

20

2351 – 2649

25

1941 – 2173

40

1118 – 1231

60

573 – 618

80

313 – 332

100

182 – 191

120

109 – 116

140

68 – 74

Reinstall

Reinstallation of the engine coolant temperature (ECT) sensor is the reverse of the removal procedure, noting the

following:

1

Tighten the ECT sensor to the correct torque specification.

Engine coolant temperature sensor

torque specification . . . . . . . . . . . 22.0 Nm

2

Refill the cooling system, refer to 6B1 Engine Cooling – V6.

3

Road test the vehicle and check for correct operation, taking particular note there is no coolant leakage.

2.7

Engine Control Module

Service of the engine control module (ECM) should normally consist of either replacement or ECM programming. If the

diagnostic procedures call for the ECM to be replaced, it should be first checked to ensure it is the correct part. If it is,

replace the faulty ECM.

Do not touch the ECM connector pins as

electrostatic discharge (ESD) damage may

result.

When removing or reinstalling the ECM wiring

harness connector/s, ensure the ignition

switch is in the OFF position and the battery

has been disconnected. Failure to do so may

result in damage to the ECM and / or

associated componentry.

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery - V6 before disconnecting the battery.

Engine Management – V6 – Service Operations

Page 6C1-3–19

Remove

If replacing the ECM, it must be reset prior to

removal. Failure to perform this procedure

will result in the inability to test the ECM for

warranty purposes, refer to ECM Reset in this

Section.

1

Turn the ignition switch off.

2

Disconnect the battery.

3

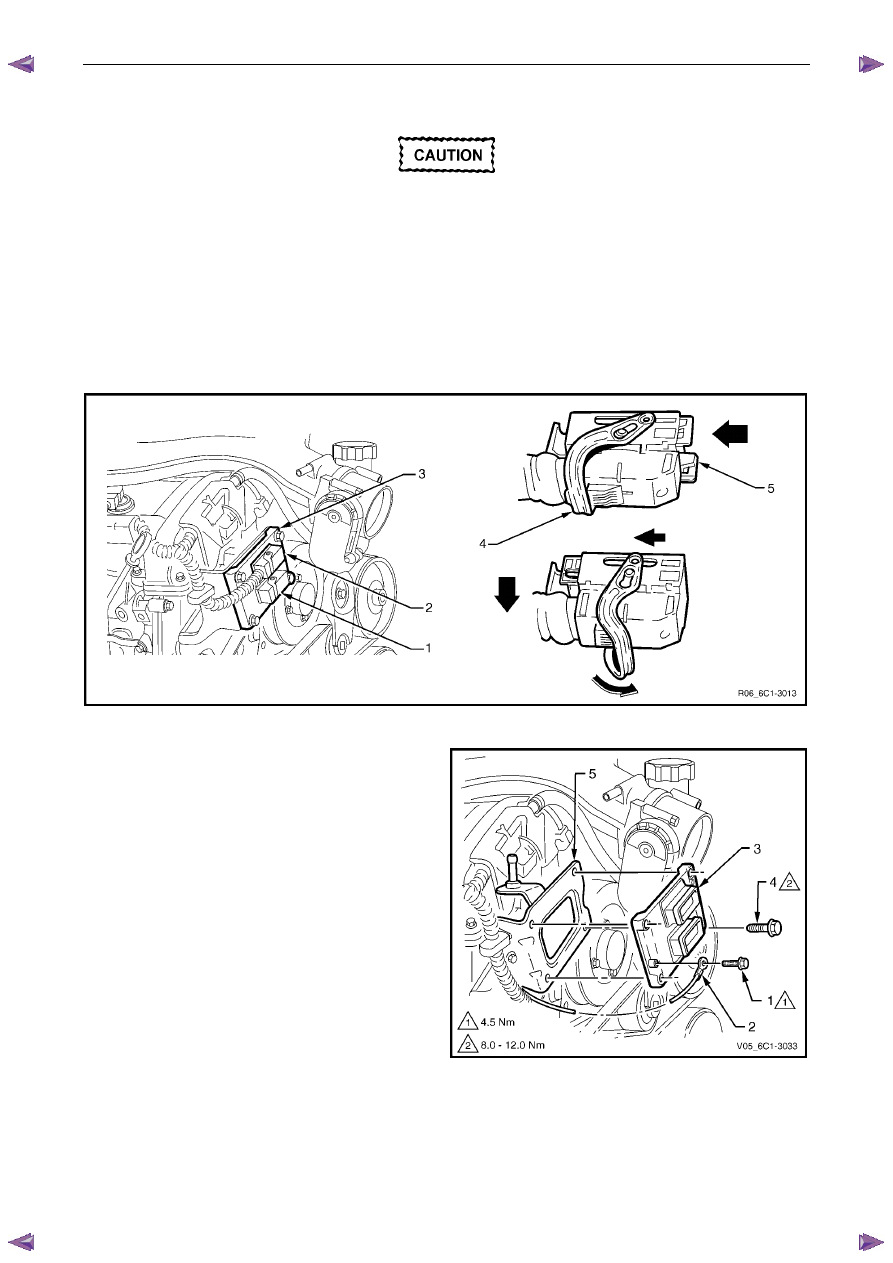

Disconnect the engine harness connector (1) and the front body harness connector (2) from the ECM (3). To

release each connector, lift the connector locking lever (4) whilst simultaneously pushing the connector locking

slide (5), refer to Figure 6C1-3 – 15.

Figure 6C1-3 – 15

4

Remove the screw (1) attaching the ground

terminal (2) to the ECM (3).

5

Remove the bolt (4), four places, attaching the ECM to

the mounting bracket (5) and remove the ECM.

Figure 6C1-3 – 16

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст