Isuzu KB P190. Manual — part 758

Engine Mechanical – V6

Page 6A1–255

Page 6A1–255

Disassemble

1

Remove the following:

2

Oil pan drain plug (7) and sleeve (8).

3

Oil level sensor (9).

4

Crankshaft oil deflector bolts (6) and remove the deflector.

5

Oil pump suction pipe bolts (5) and the suction pipe (3).

6

Oil pump suction pipe gasket (4) from the suction pipe and discard.

Figure 6A1 – 444

Clean

1

Remove any remaining thread sealant, gasket material or sealant using a commercially available wooden or plastic

scraper.

2

Clean the oil pan and oil pan components in solvent.

3

Clean out debris from the bolt holes.

Safety glasses must be worn when using

compressed air.

4

Dry the oil pan and oil pan components with compressed air.

Engine Mechanical – V6

Page 6A1–256

Page 6A1–256

Inspect

1

Inspect the exterior of the oil pan for the following

conditions:

•

Damage to the drain plug or drain plug hole,

•

Damage to the transmission mounting bosses,

•

Damage to the oil level sensor threads, and

•

Dents or damage to the exterior.

2

Inspect the interior of the oil pan for the following

conditions:

•

Gouges or damage to the oil pan sealing

surfaces,

•

Damage to the crankshaft oil deflector,

•

Damage to the bolt holes,

•

Damage to the oil suction tube mounting

bosses, and

•

Damage to the crankshaft oil deflector mounting

bosses.

Figure 6A1 – 445

3

Inspect the oil pan deflector for damage.

4

Repair or replace the oil pan deflector and/or oil pan

as required.

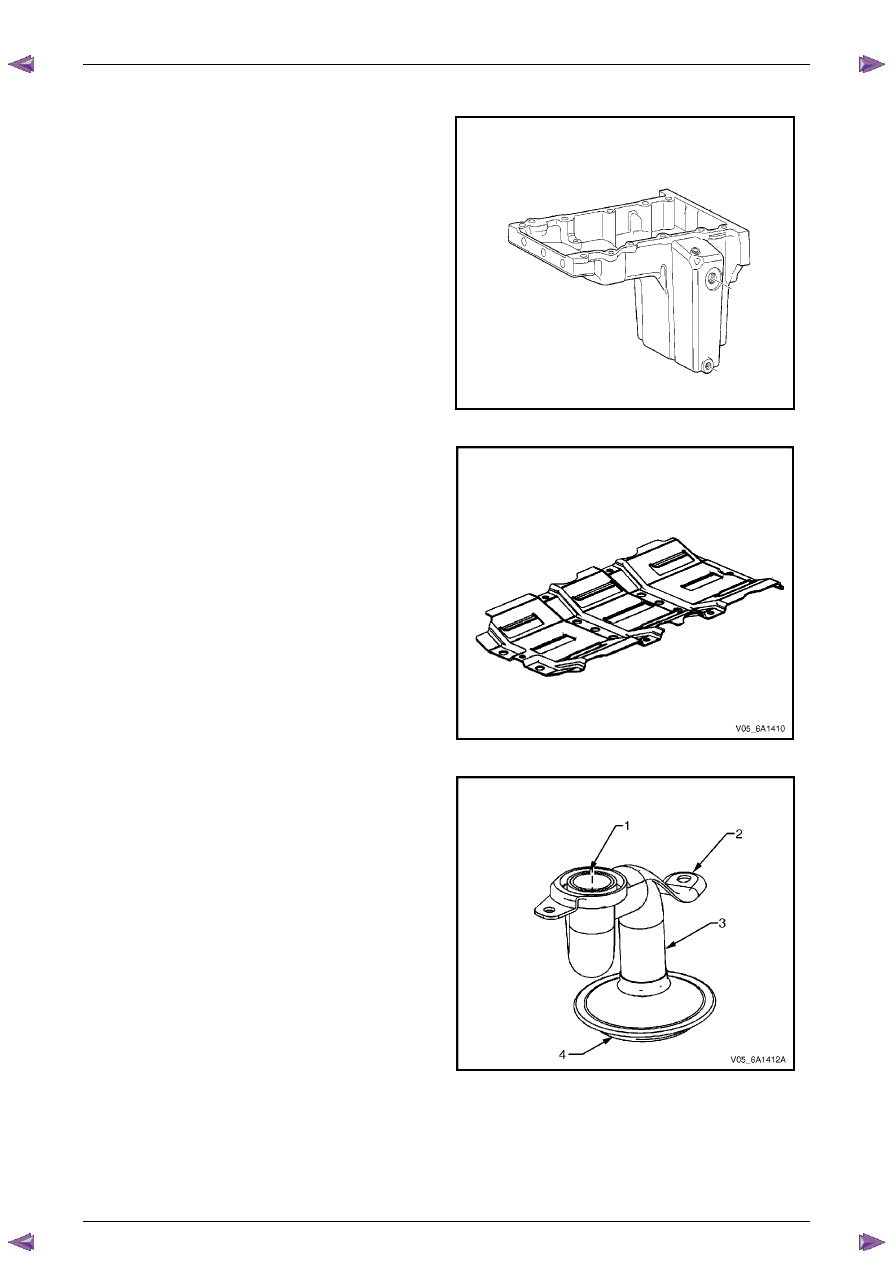

Figure 6A1 – 446

5

Inspect the following:

6

The mounting face (1) of the oil pump suction pipe for

possible leakage paths.

7

The oil pump pipe support bracket (2) for cracks or

damage.

8

The oil pump suction pipe tube (3) for cracks,

imperfections and/or damage.

9

The oil pump screen (4) for blockage, foreign

material, tears, cracks and/or damage.

10

Repair or replace the oil pan and/or oil pan

components as required.

Figure 6A1 – 447

Engine Mechanical – V6

Page 6A1–257

Page 6A1–257

Reassemble

Reassembly of the oil pan and oil suction pipe assembly is the reverse of the disassembly procedure, noting the

following:

1

Install a new oil suction tube seal onto the oil suction

tube.

2

Install the oil suction pipe and tighten the attaching

bolts to the correct torque specification.

Oil suction pipe attaching

bolt torque specification . . . . . . . . . .10.0 Nm

3

Install the crankshaft oil deflector into the oil pan

assembly and tighten the attaching bolts to the

correct torque specification.

Crankshaft oil deflector

attaching bolt torque specification. . . . . ..10.0 Nm

4

Install the oil level sensor into the oil pan assembly

and tighten to the correct torque specification.

Oil level sensor torque specification. . . . ...20.0 Nm

Figure 6A1 – 448

5

Install the oil pan drain plug into the oil pan assembly and tighten to the correct torque specification.

Oil pan drain plug

torque specification . . . . . . . . . . . 25.0 Nm

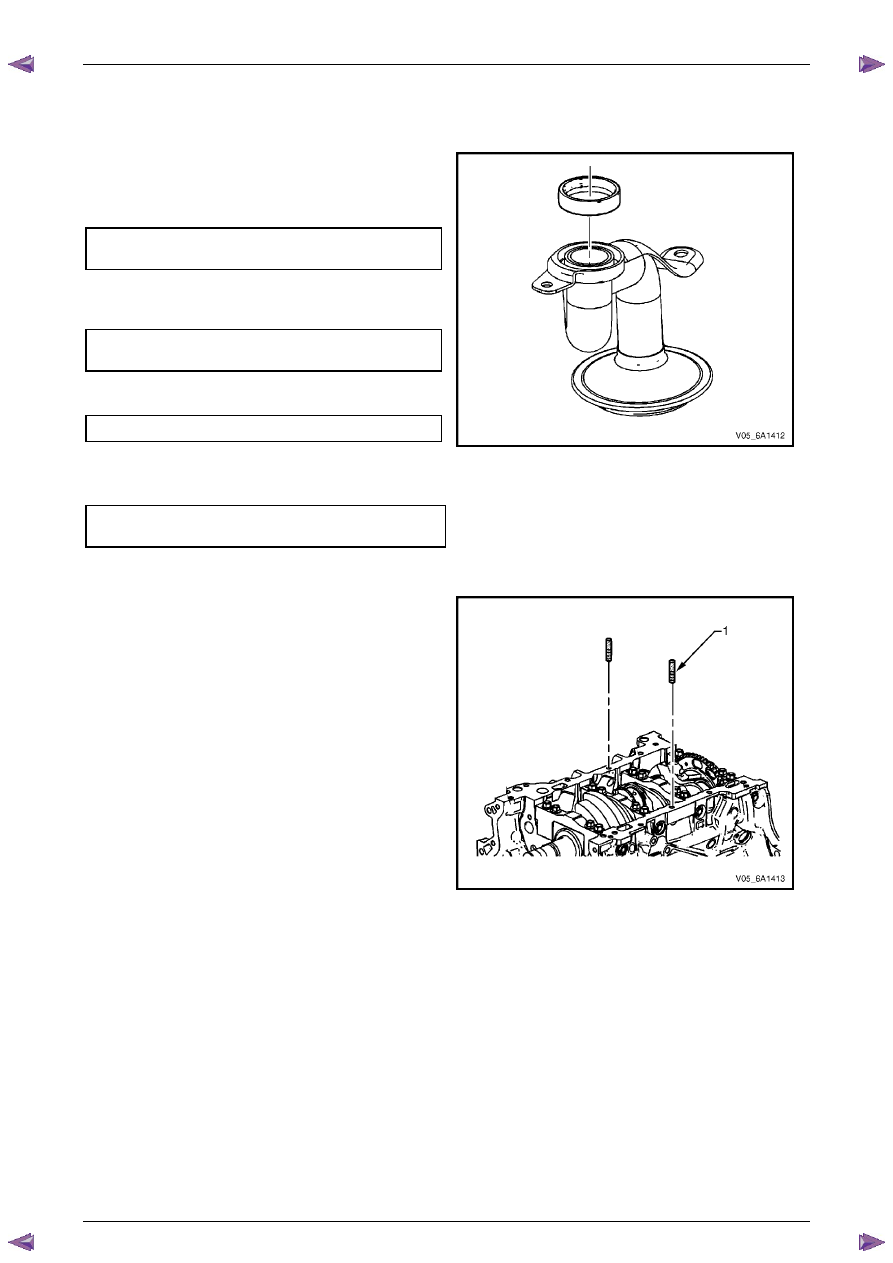

Reinstall

1

Install the guide pins, Tool No. EN-46109 (1) into the

oil pan rail bolt hole on each side of the engine block.

Figure 6A1 – 449

Engine Mechanical – V6

Page 6A1–258

Page 6A1–258

2

Place a 3mm bead (1) of RTV sealant on the cylinder

block pan rail and crankshaft rear oil seal housing to

oil pan mating surfaces.

3

Position the oil pan onto the cylinder block.

4

Remove the guide pins, Tool No. EN-46109 from the

cylinder block.

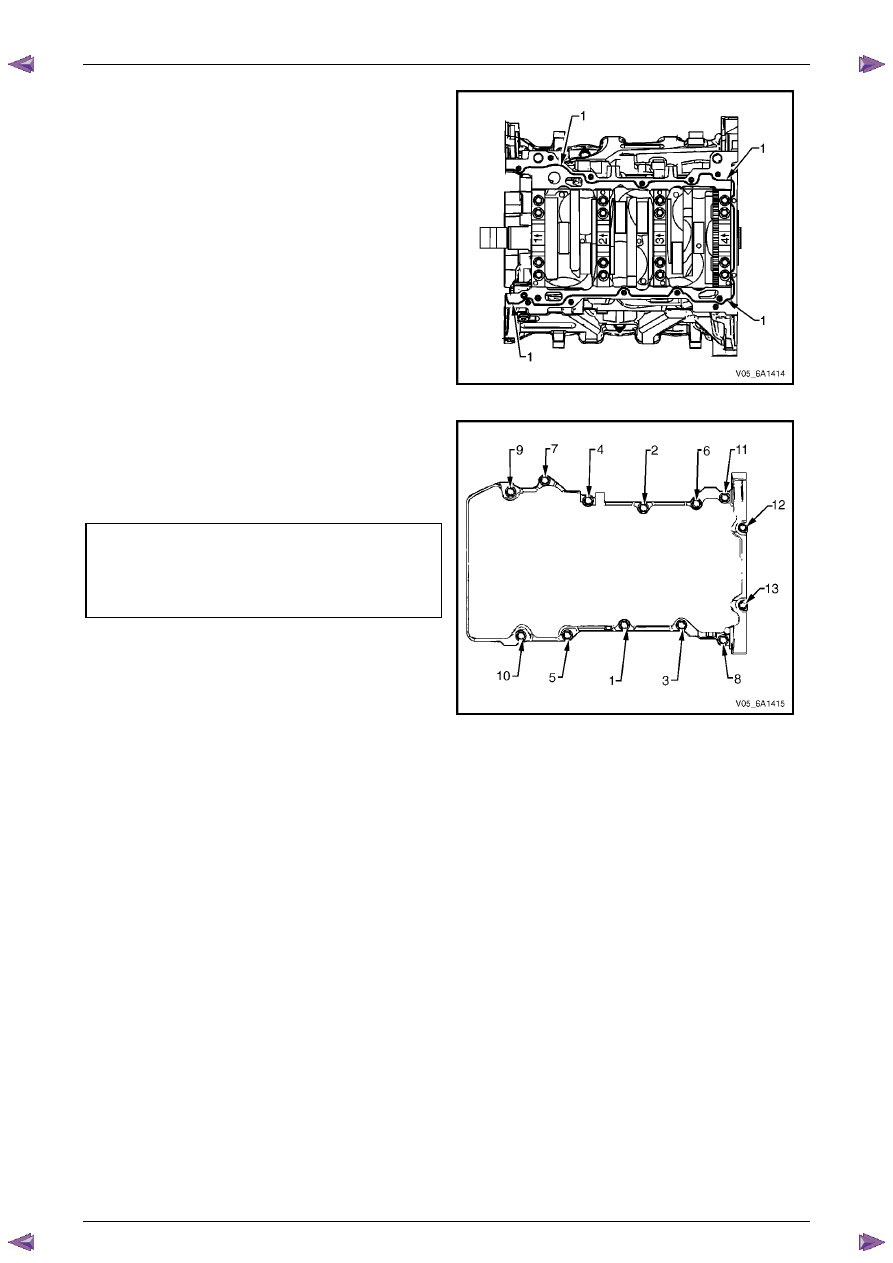

Figure 6A1 – 450

5

Loosely install the oil pan bolts.

6

Tighten the oil pan attaching bolts to the correct

torque specification and in the sequence shown.

Oil pan to cylinder block attaching

bolt (1 – 11) torque specification . . . .20.0 – 26.0 Nm

Oil pan to crankshaft rear oil

seal housing attaching bolt (12 – 13)

torque specification . . . . . . . . ...8.0 – 12.0 Nm

Figure 6A1 – 451

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст