Isuzu KB P190. Manual — part 930

Powertrain Interface Module – V6

Page 6E1–59

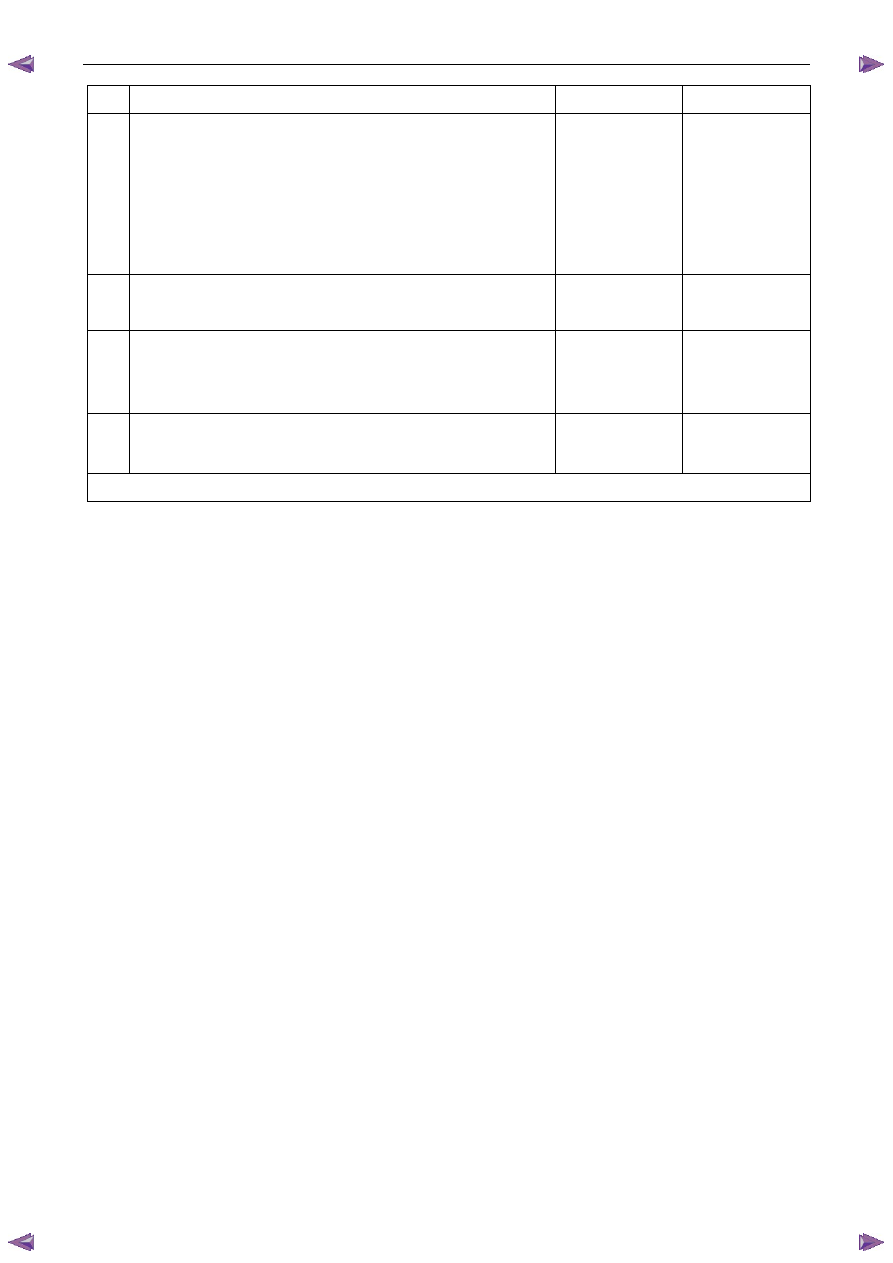

Step Action

Yes

No

4

1

Test all ground circuits of the PIM for a high resistance or an

open circuit fault condition. Refer to 8A Electrical - Body and

Chassis for information on electrical fault diagnosis.

2

Test the PIM ignition supply voltage circuit for a high resistance,

open circuit or short to ground fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

Has any fault been found and rectified?

Go to Step 6

Go to Step 5

5

Replace the PIM. Refer to 11.2

Powertrain Interface Module.

Has the repair been completed?

Go to Step 6

—

6

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

Does DTC P1611 fail this ignition cycle?

Go to Step 2

Go to Step 7

7

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table

System OK

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

9.16 DTC B0981 – 3

rd

Start Switch Signal

Malfunction

DTC Description

This diagnostic procedure supports DTC B0981 – 3

rd

Start Switch Signal Malfunction.

Circuit Description

The 3

rd

start mode switch is a normally open switch that closes when the switch is activated. When activated, the switch

supplies signal ground to the 3

rd

start ground signal circuit. The powertrain interface module (PIM) converts the signal

ground input into serial data, which is used by the automatic transmission control module (TCM) to enable or disable the

3

rd

start mode, and by the instrument cluster to display power mode status.

Additional Information

•

For the 4L60E automatic transmission, refer to 7C1 Automatic Transmission – 4L60E – General Information:

•

Power mode switch description, operation and inspection procedure, and

•

TCM wiring diagram.

•

Refer to 6 Wiring Diagram and Connector for the following information:

•

PIM connector illustration and terminal assignment, and

•

PIM wiring diagram.

•

For intermittent fault conditions, refer to

Intermittent Fault Conditions.

•

Since fault conditions in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

Conditions for Running the DTC

Conditions for running the DTC are:

•

The ignition is switched on.

•

The ignition voltage is 10.0 – 16.0 V.

Powertrain Interface Module – V6

Page 6E1–60

Conditions for Setting the DTC

The PIM detects the power mode switch is activated for 120 seconds or more.

Action Taken When the DTC Sets

When the DTC sets, there is no warning lamp displayed on the instrument cluster.

Conditions for Clearing the DTC

Refer to 4.1

Diagnostic General Descriptions for information on the conditions for clearing DTCs.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2

This step tests the power mode switch using Tech 2.

6

This step tests the power mode switch signal circuit.

DTC B0980 Diagnostic Table

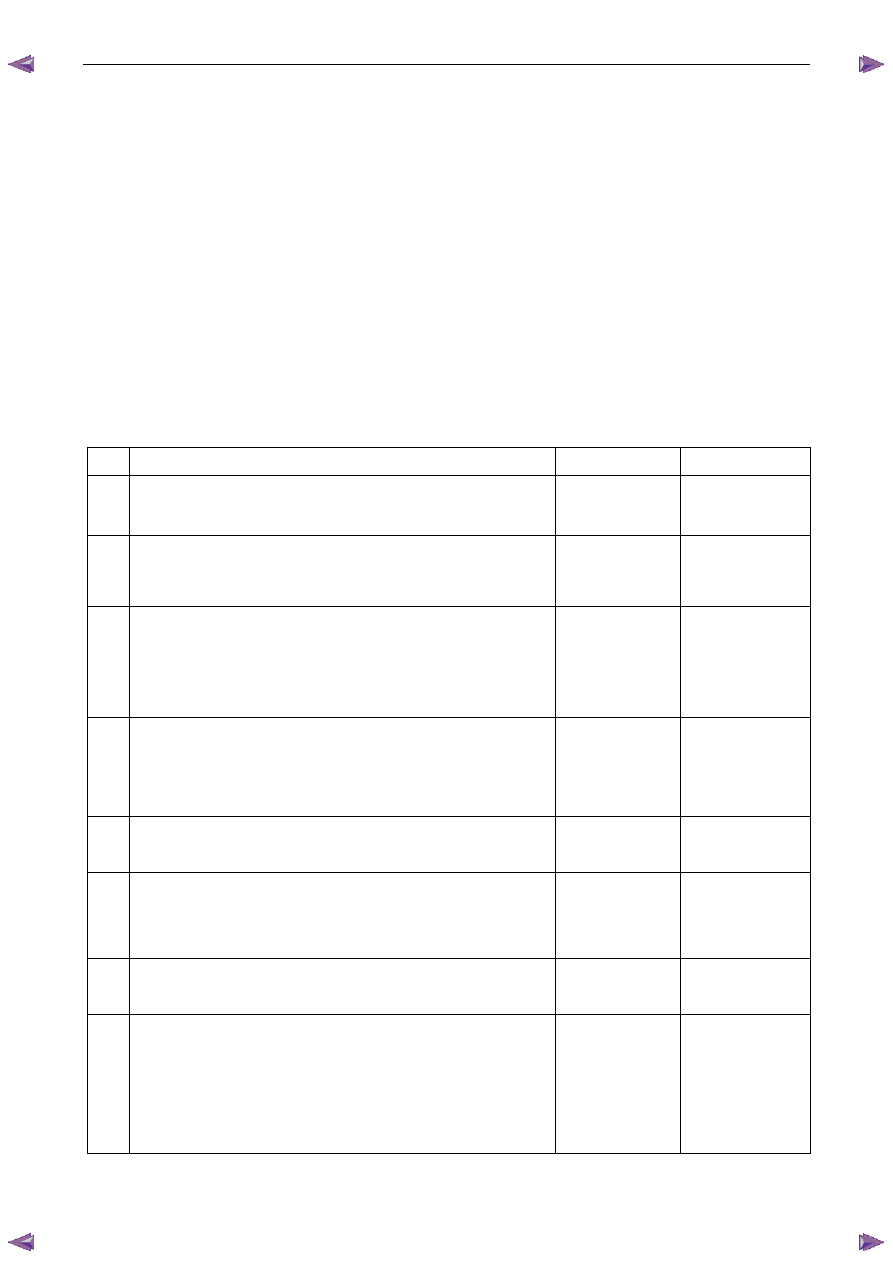

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

7.2 Diagnostic

System Check

2

Using Tech 2, view the power mode switch status parameter in the

PIM data list.

Does Tech 2 display Power?

Go to Step 4

Go to Step 3

3

1

Switch off the ignition for 10 seconds.

2

Operate the vehicle within the conditions for setting DTC B0980.

3

Using Tech 2, select the DTC display function.

Does DTC B0980 fail this ignition cycle?

Go to Step 4

Refer to

Additional

Information in this

Section

4

1

Disconnect connector S22 – X1 from the power mode switch.

2

Using Tech 2, view the power mode switch status parameter in

the PIM data list.

Does Tech 2 display Power?

Go to Step 6

Go to Step 5

5

Replace the power mode switch. Refer to 10 Cab.

Has the repair been completed?

Go to Step 8

—

6

Test the power mode switch ground signal circuit for a short to ground.

Refer to 8A Electrical - Body and Chassis for information on electrical

fault diagnosis.

Has any fault been found and rectified?

Go to Step 8

Go to Step 7

7

Replace the PIM. Refer to 11.2

Powertrain Interface Module.

Has the repair been completed?

Go to Step 8

—

8

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does DTC B0980 fail this ignition cycle?

Go to Step 2

Go to Step 9

Powertrain Interface Module – V6

Page 6E1–61

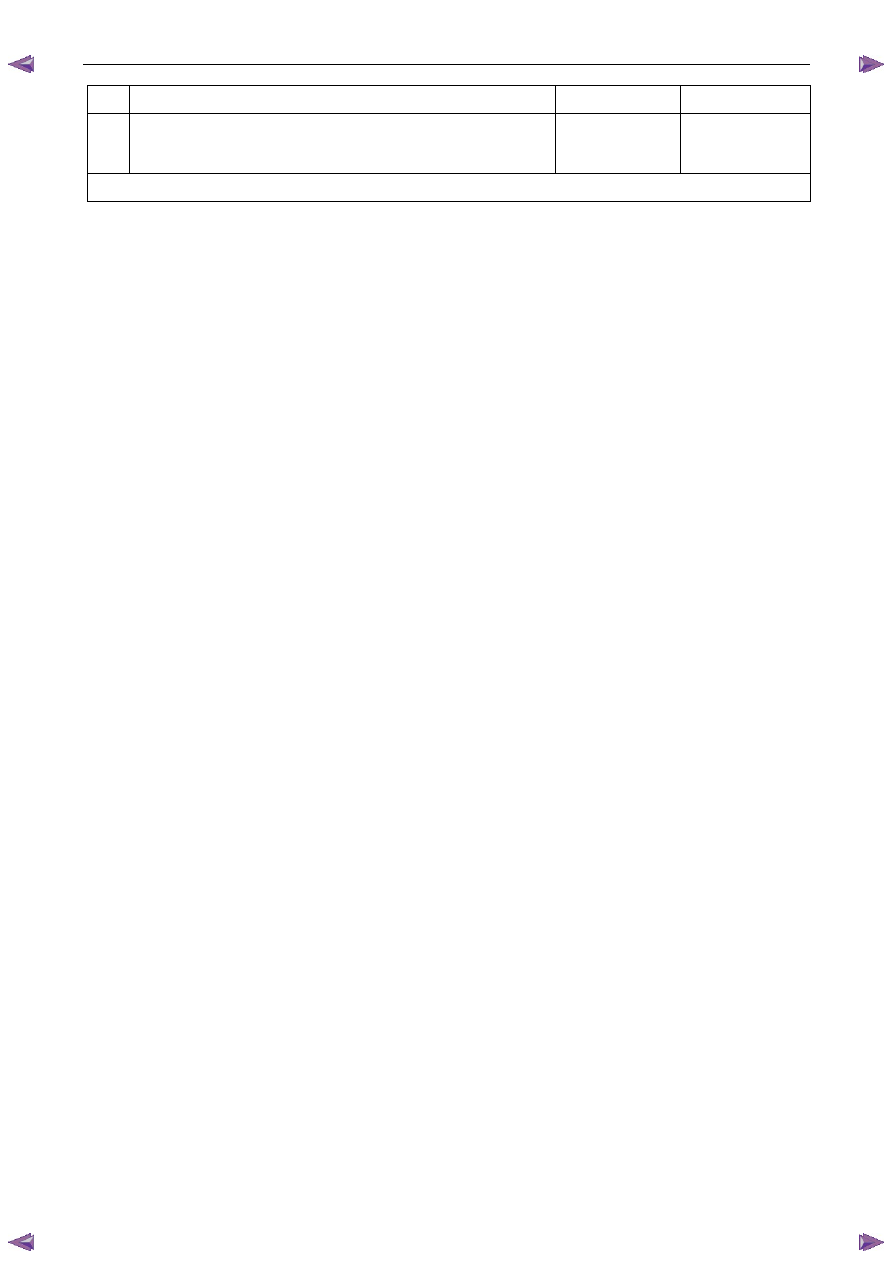

Step Action

Yes

No

9

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table

System OK

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

Powertrain Interface Module – V6

Page 6E1–62

10

Diagnostics For Non DTC Faults

10.1 PRND32L Display Diagnostics

Circuit Description

The powertrain interface module (PIM) receives transmission gear status via the GM Lan serial data bus from the

transmission control module (TCM) it is then sent to the instrument cluster by the PIM via a series of hard wired

connections to illuminate the appropriate gear position indicator within the instrument cluster. Some of these components

do not set a DTC, in the event of a component failure. The following diagnostic procedures are devised to assist in these

cases.

Additional Information

•

Refer to 7.2 Diagnostic System Check to monitor DTC’s.

•

Refer to 8A Electrical Body and Chassis for the following information:

•

Automatic transmission Neutral Start and Back-up Lamp Switch and wiring,

•

TCM wiring diagram.

•

Refer to 6 Wiring Diagram and Connector Chart for the following information:

•

PIM connector illustration and terminal assignment, and

•

PIM wiring diagram.

•

For intermittent faults, refer to Intermittent Fault Conditions.

•

Check for an intermittent fault in the wiring harness or connectors, if a fault cannot be found the system is

serviceable.

Since fault conditions in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1

This step tests for DTC’s in the overall system.

2

This step manually tests the PRND32L display.

4

This step uses Tech 2 to drive each indicator on.

7

This step tests for shorts to voltage.

8

This step tests neutral start and back-up lamp switch and automatic transmission.

12

This step tests the instrument cluster circuits.

15

This step manually tests the PRND32L display.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст