Isuzu KB P190. Manual — part 254

ENGINE ELECTRICAL 6D – 15

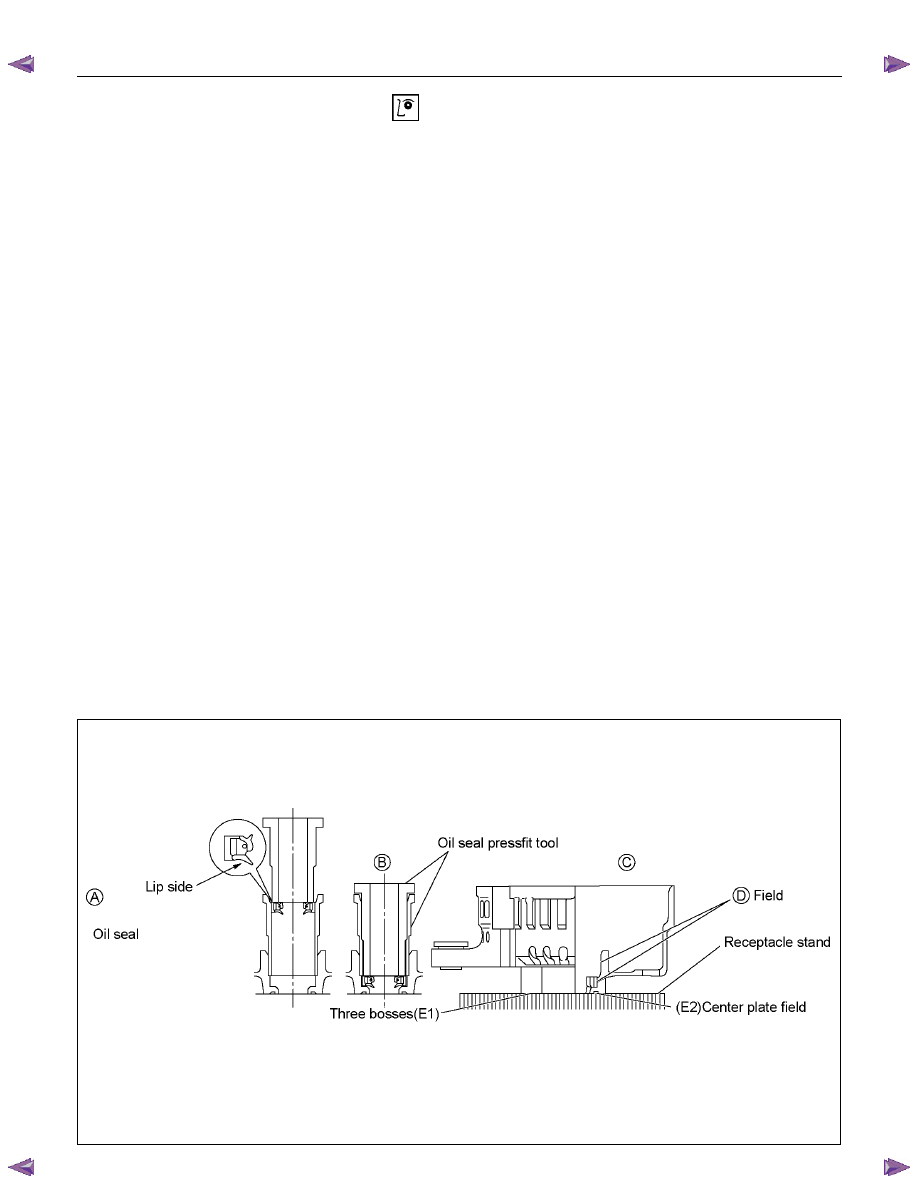

Oil seal

The oil seal must be replaced with a new one whenever

the alternator is disassembled.

Oil Seal Replacement

1. Push the old oil seal from the rear bracket outside

holes.

2. Use the insertion tool to press the new oil seal into

place. Follow the procedure shown in Figures A, B, C

and D.

Position the oil seal beneath the shaft and the

guide lip.

Position the cradle against the rear cover bosses

(3 points) so that the E1 and E2 surfaces fit into

the cradle. Take care not to damage the E1 and

E2 surfaces.

After completing the procedure, carefully check the

oil seal seating. Be absolutely sure that the seal is

evenly inserted (no warp) and level with the

surrounding surfaces.

Caution

Be sure that no foreign material enters the space

between the oil seal and the rotor shaft surfaces

during the installation procedure.

Take care not to damage the D surface.

Under no circumstances may the original oil seal

be reused.

The oil seal must be perfectly flat after being

pressed into place. If the oil seal is tilted, there will

be oil leakage.

RTW46DSF000101

6D – 16 ENGINE ELECTRICAL

RTW46DSH000901

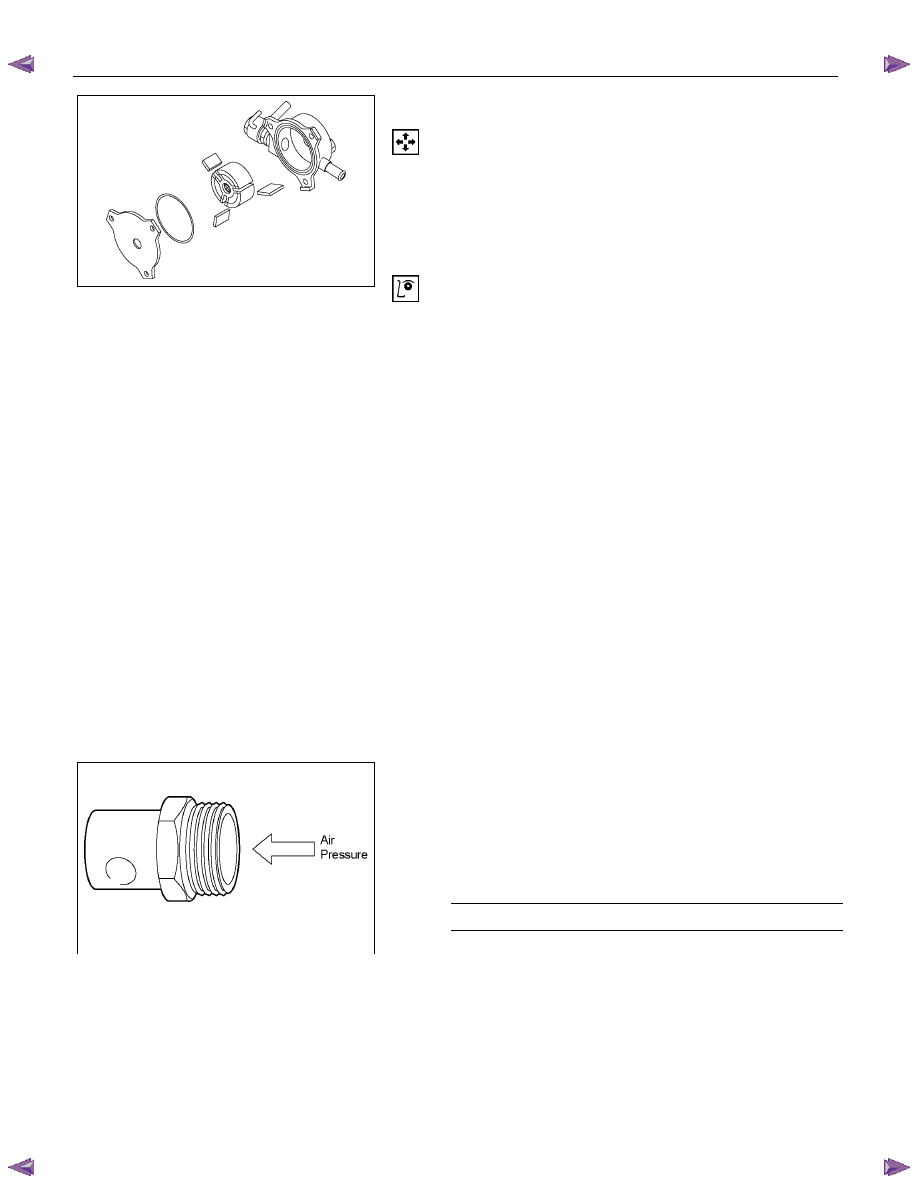

Vacuum Pump

Vacuum Pump Disassembly

1. Remove the center plate from the vacuum pump

housing.

2. Remove the vacuum pump rotor and the vanes from

the housing.

Inspection

Vacuum Pump Housing and Center Plate

Inspect the vacuum pump housing and the center plate for

excessive wear, abrasion, and scoring.

If any of these conditions are present, the vacuum pump

housing and center plate must be replaced.

Vane

Inspect the vanes for excessive wear and damage.

Replace all four vanes if either of these conditions are

present.

Never replace only one vane.

Rotor

1. Inspect the rotor for excessive wear, abrasion, and

scoring.

Pay particular attention to the internal spline.

Replace the rotor if any of these conditions are

present.

2. Inspect the generator rotor shaft splines for backlash.

Replace the rotor if backlash is present.

RTW46DSH005201

Check Value

1. Carefully force the valve from the “B” side as shown in

the illustration.

The valve must move smoothly.

If it does not, the check valve must be replaced.

2. Apply compressed air to the “A” side.

Air Pressure

kPa (kg/cm

2

/psi)

98 - 490 (1-5/14 – 71)

Check for air leakage from the check valve.

If there is air leakage, the valve must be replaced.

ENGINE ELECTRICAL 6D – 17

RTW46DSH001801

Vacuum Pump Reassembly

1. Install the vanes to the rotor slits.

The rounded side of the vanes must be facing the

rotor housing.

RTW46DSH001901

2. Install the rotor with the concave side facing the center

plate.

RTW46DSH002001

3. Install the center plate to the rotor housing.

Be sure to use a new O-ring.

6D – 18 ENGINE ELECTRICAL

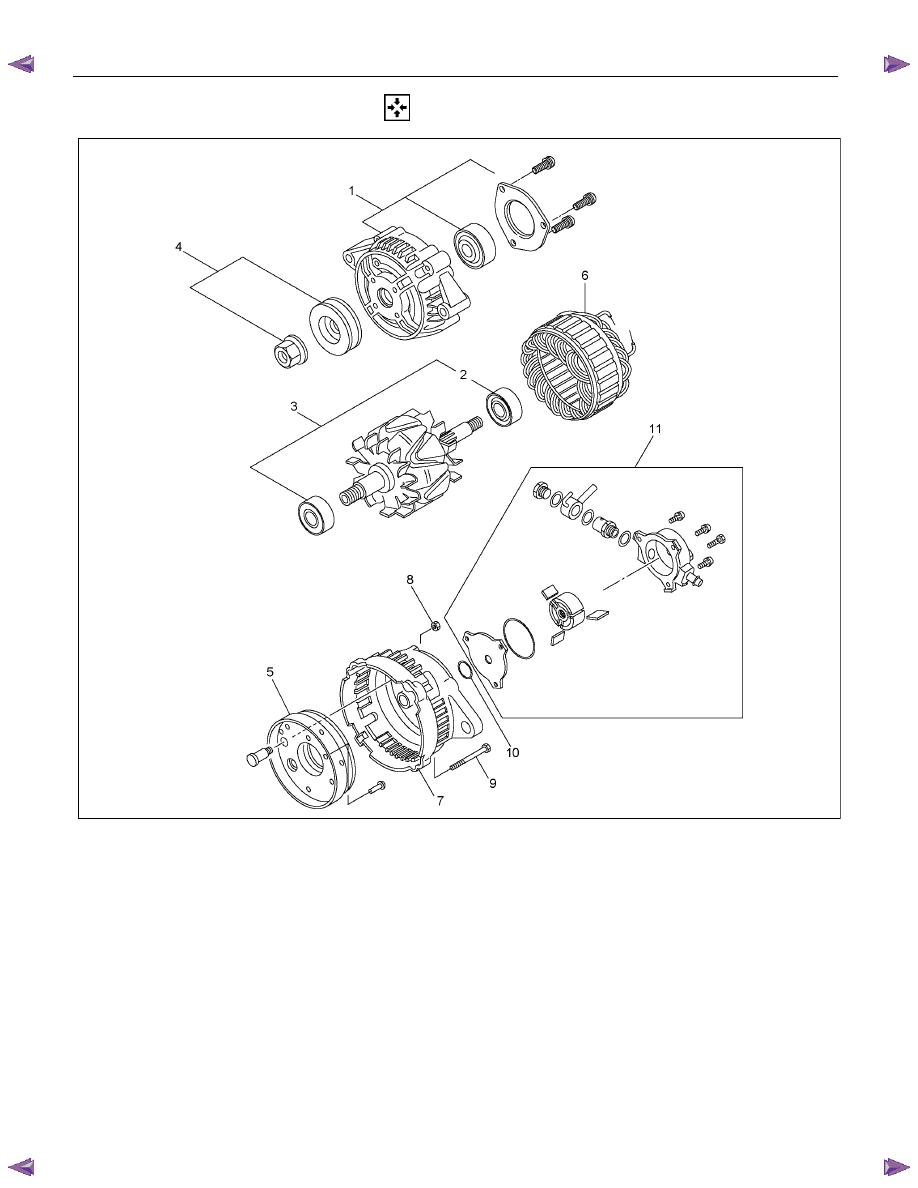

REASSEMBLY

RTW46DLF000501

Reassembly Step

1. Front cover

2. Rear rotor bearing

3. Rotor Assembly

4. Pulley

5. Rectifier Assembly

6. Stator Assembly

7. Rear cover

8. B Terminal nuts

9. Through bolt

10. O-ring

11. Vacuum pump

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст