Isuzu KB P190. Manual — part 21

1-50 HEATER AND AIR CONDITIONING

Important Operations - Installation

4. Bolt; Compressor to Bracket

N

⋅m (kgf⋅m/lb⋅ft)

Torque

44 (4.5/33)

3. Refrigerant Line

N

⋅m (kgf⋅m/lb⋅in)

Torque 11

∼19 (1.1/95∼1.9/168)

2. Drive Belt

Refer to SECTION 6A “V-BELT TENSION OF

ALTERNATER”.

HEATER AND AIR CONDITIONING 1-51

GENERAL REPAIR PROCEDURE

OIL SPECIFICATION

• The HFC-134a system requires a synthetic (PAG)

compressor oil.

• Compressor (PAG) oil varies according to compressor

model. Be sure to use oil specified for the model of

compressor.

Specified Compressor Oil

DH-PR

HANDLING OF OIL

• The oil should be free from moisture, dust, metal powder,

etc.

• Do not mix with other oil.

• The water content in the oil increases when exposed to the

air. After use, seal oil from air immediately.

• The compressor oil must be stored in steel containers, not

in plastic containers.

COMPRESSOR OIL CHECK

The Oil used to lubricate the compressor is circulating with the

refrigerant.

Whenever replacing any component of the system or a large

amount of gas leakage occurs, add oil to maintain the original

amount of. oil.

Oil Capacity

Capacity total in

system

CR-14 180

cm

3

(5.07 lmp fl oz)

Compressor

(Service parts)

charging amount

CR-14

180 cm

3

(5.07 lmp fl oz)

1-52 HEATER AND AIR CONDITIONING

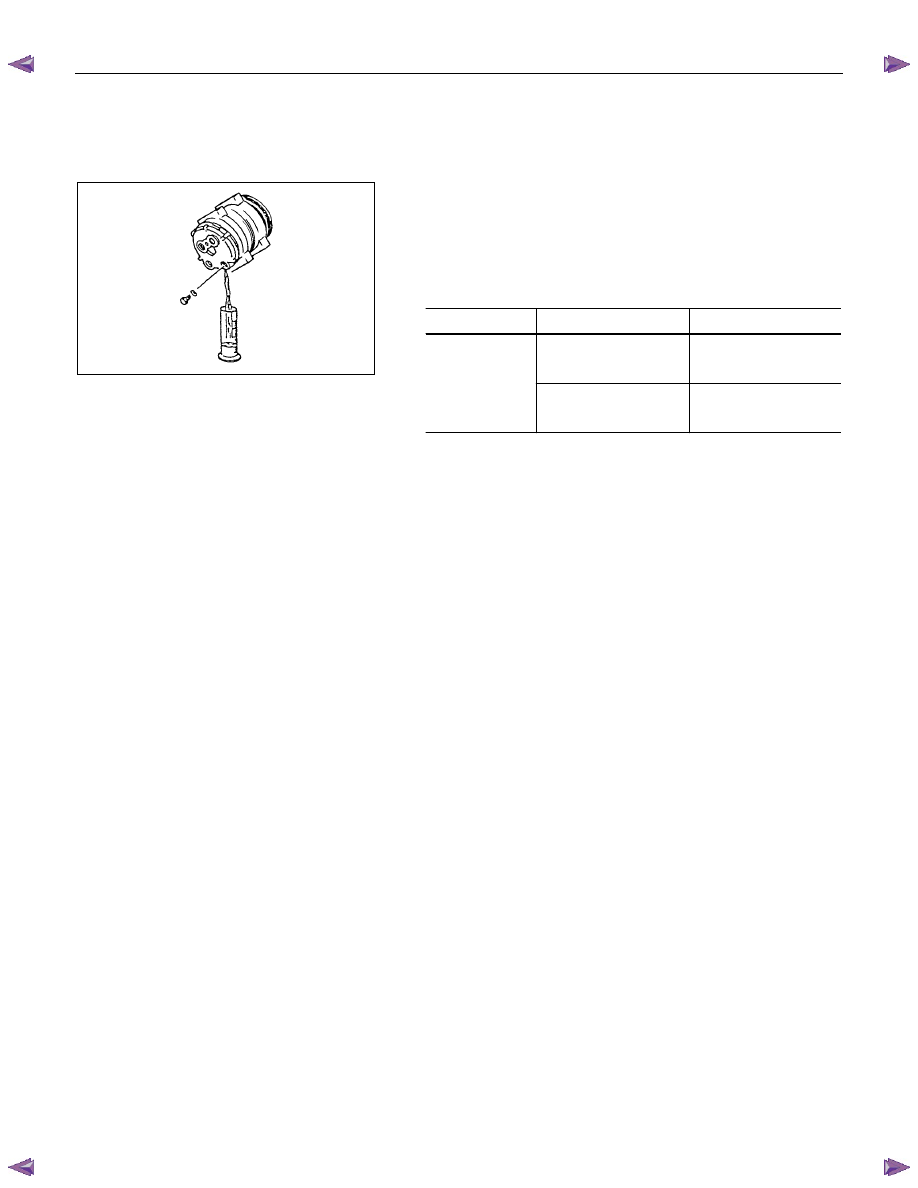

Checking and Adjusting for Used Compressor

(1) Perform Oil return operation.

(Refer to "Oil Return Operation" in this section.)

(2) Discharge refrigerant and remove the compressor.

(3) Drain the compressor oil and measure the extracted oil with

a measuring cylinder.

(4) Check the compressor oil for contamination.

(Refer to "Contamination of Compressor Oil" in this

section.)

(5) Adjust oil level following the procedure below.

Type

Collected Amount

Charging Amount

more than 90 cm

3

(2.53 lmp fl oz)

same as collected

amount

less than 90 cm

3

(2.53 lmp fl oz)

90 cm

3

(2.53 lmp fl oz)

CR-14

(6) Install the compressor, then evacuate, charge and perform

oil return operation.

(7) Check system operation.

When it is impossible to perform oil return operation, the

compressor oil should be checked in the following order:

(1) Discharge refrigerant and remove the compressor.

(2) Drain the compressor oil and measure the extracted oil with

a measuring cylinder.

(3) Check the oil for contamination.

(4) If more than 90 cm

3

(2.53 lmp fl oz) for CR-14 type is

extracted from the compressor, supply same amount of oil

to the compressor to be installed.

If the amount of oil extracted is less than 90 cm

3

(2.53 lmp

fl oz) for CR-14 type recheck the compressor oil in the

following order:

(5) Supply 90 cm

3

(2.53 lmp fl oz) for CR-14 type oil to the

compressor and install it onto the vehicle.

(6) Perform oil return operation.

(7) Remove the compressor and recheck the amount of oil.

(8) Adjust the compressor oil.

HEATER AND AIR CONDITIONING 1-53

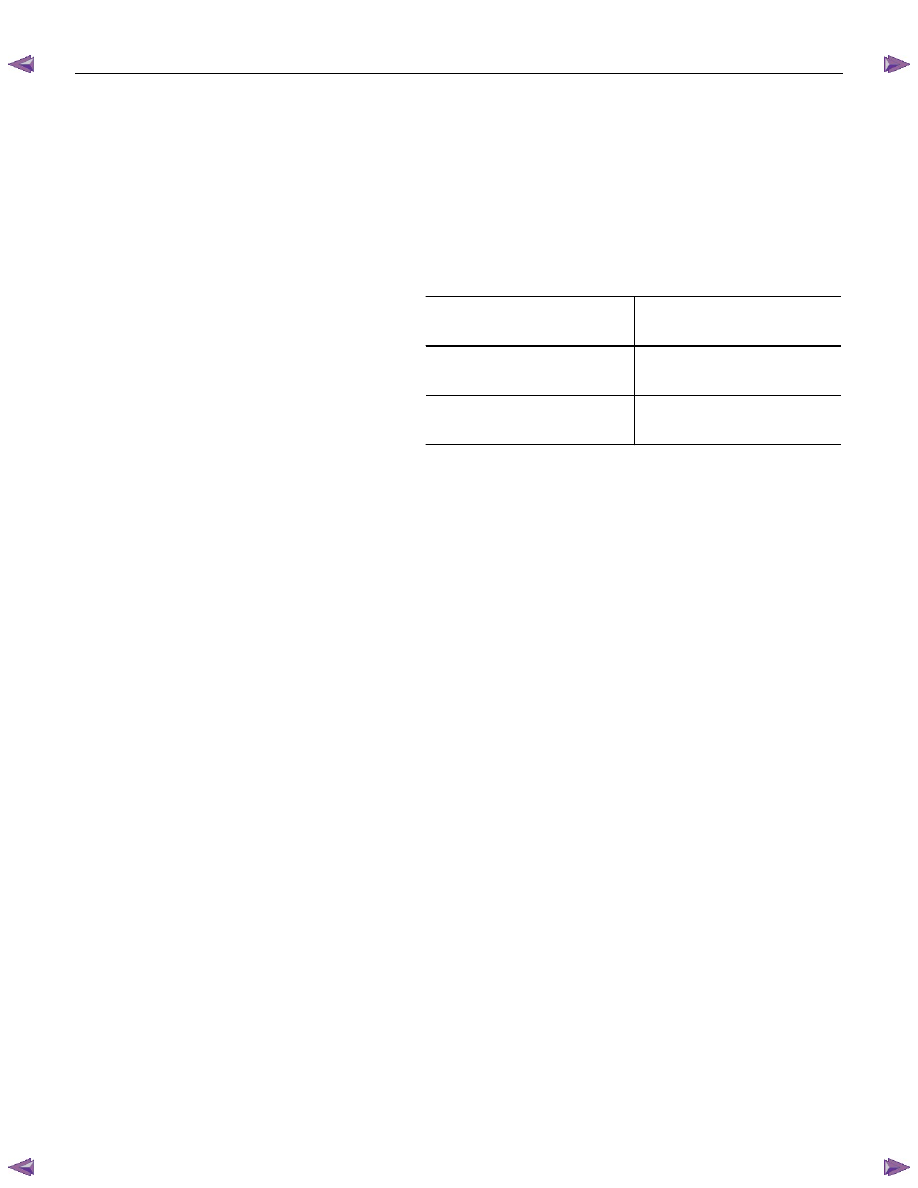

Checking and Adjusting for Compressor

Replacement

180 cm

3

(5.07 lmp fl oz) of oil is charged in compressor

(service parts). So it is necessary to drain the proper amount

of oil from the new compressor.

1) Perform oil return operation.

2) Discharge refrigerant and remove the compressor.

3) Drain the compressor oil and measure the extracted oil.

4) Check the compressor oil for contamination.

5) Adjust oil level as required.

Amount of oil drained

From used compressor

Draining amount of oil

From new compressor

less than

90 cm

3

(2.53 lmp fl oz)

Some as drained

amount

more than

90 cm

3

(2.53 lmp fl oz)

90 cm

3

(2.53 lmp fl oz)

6) Evacuate, charge and perform oil return operation.

7) Check system operation.

CONTAMINATION OF COMPRESSOR OIL

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even is the compressor runs for a long period

of time (approximately 1 season), the oil never becomes

contaminated as long as there is nothing wrong with the

compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

• The capacity of the oil has increased.

• The oil has changed color to red.

• Foreign substances, metal powder, etc., are present in the

oil.

If any of these conditions exists, compressor oil is

contaminated. Whenever contaminated compressor oil is

discovered, the receiver/drier must be replaced.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст