Isuzu KB P190. Manual — part 753

Engine Mechanical – V6

Page 6A1–235

Page 6A1–235

5

Align the cylinder head with the locating pins.

6

Place the cylinder head in position on the deck face.

N O T E

Do not allow oil on the cylinder head bolt

bosses.

CAUTION

Do not reuse the old M11 cylinder head bolts

(1 to 8 inclusive).

7

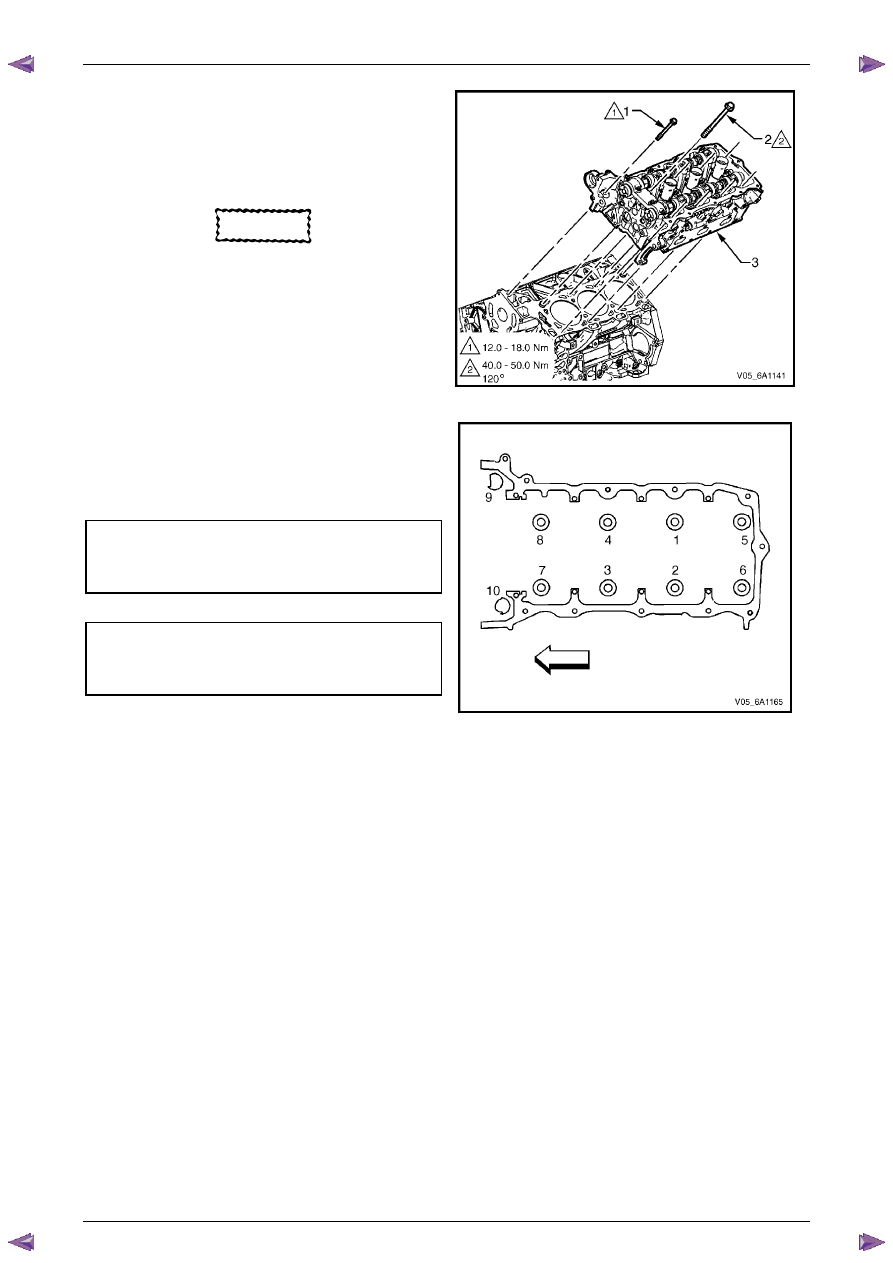

Install new M11 cylinder head bolt (1), eight places,

and tighten in the sequence shown and to the correct

torque specification.

Figure 6A1 – 402

8

Install the front M8 cylinder head bolt (2), two places,

and tighten in the sequence (9 and 10) and to the

correct torque.

Cylinder head M11 attaching bolt

torque specification:

Stage

1: . . . .40.0 – 50.0 Nm

Stage

2: . . . . . . . ..120°

M8 cylinder head bolt

torque specification

Stage

1: . . . .12.0 – 18.0 Nm

Stage

2: . . . . . . . . 60°

Figure 6A1 – 403

Engine Mechanical – V6

Page 6A1–236

Page 6A1–236

3.24 Engine Mounts and Brackets

Remove

1

Remove the exhaust manifold assembly from the side of the engine where the engine mount is to be removed,

refer to

3.11 Exhaust Manifold Assembly

.

2

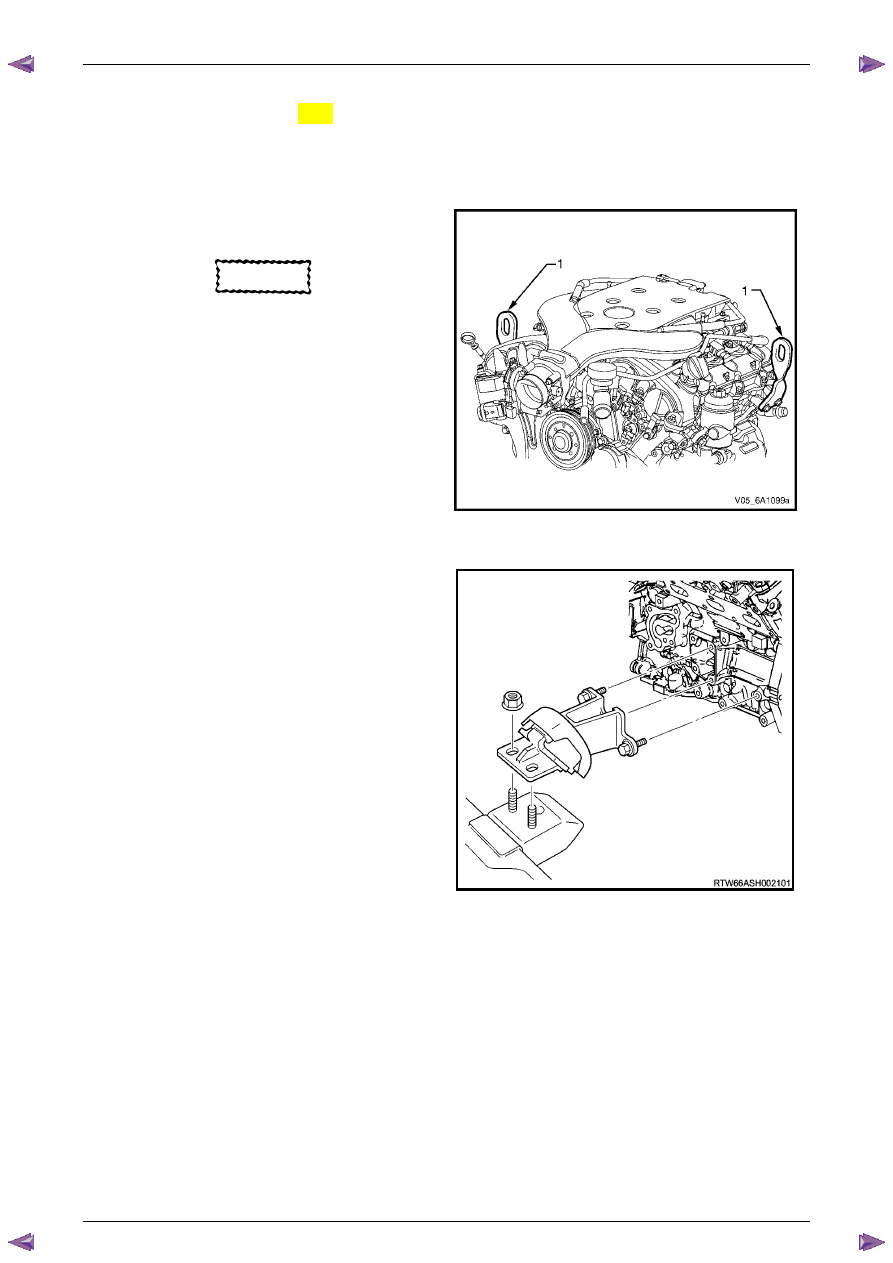

Fit the engine lift brackets, Tool No. EN-46114 (1) to

the cylinder heads.

CAUTION

Only lift the engine far enough to take the

weight off the engine mount, or damage to

the mount and lifting equipment failure may

occur.

3

Using an engine lifting crane, raise the side of the

engine where the mount is to be removed enough to

remove the weight from the engine mounts, and

create a slight tension in the lifting equipment.

Figure 6A1 – 404

4

Remove the left-hand or right-hand side engine

mount and bracket as required.

Figure 6A1 – 405

Engine Mechanical – V6

Page 6A1–237

Page 6A1–237

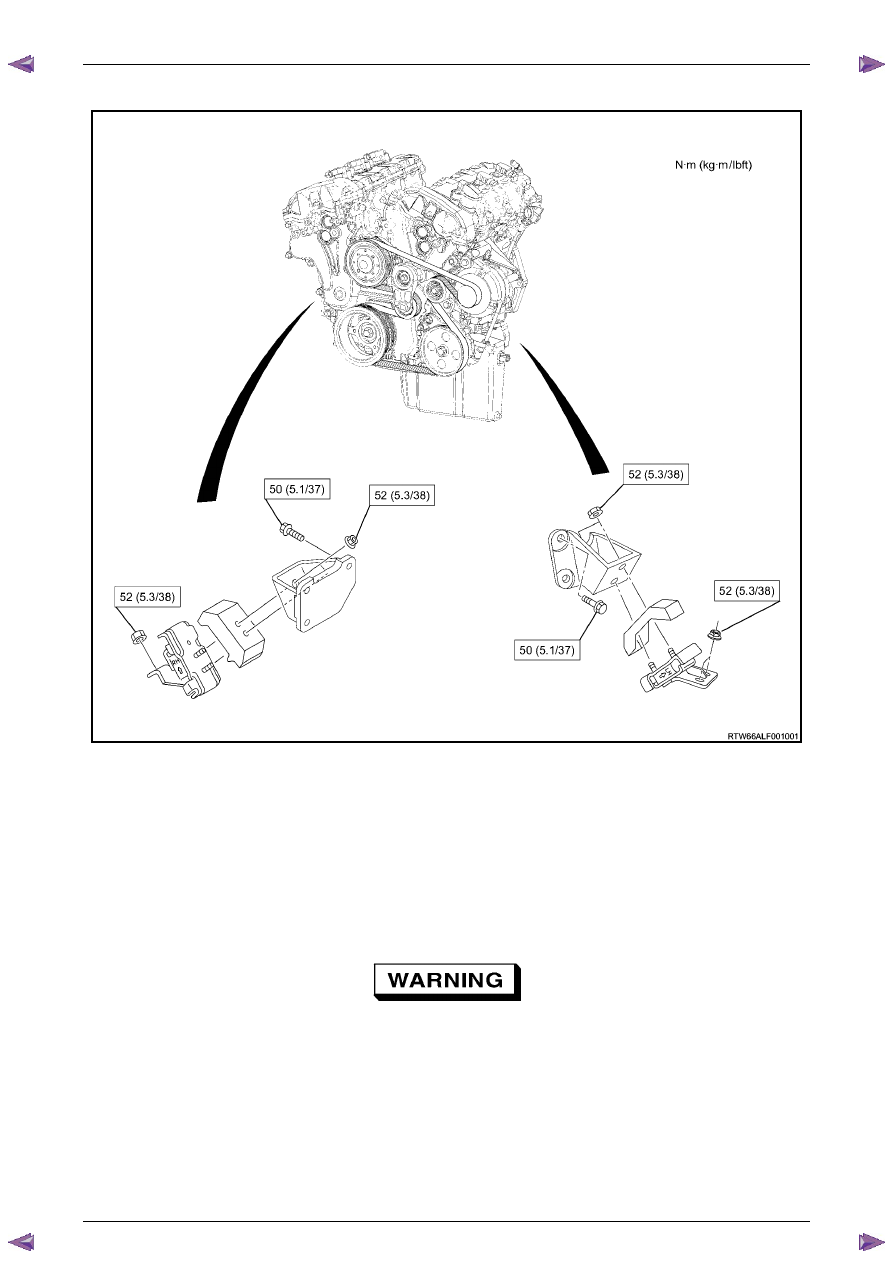

Engine Mount Location

Figure 6A1 – 406

Inspect

N O T E

Although the following procedure provides

information regarding on-vehicle engine mount

inspections, it is preferable to inspect the engine

mounts once removed from the vehicle.

1

Fit the engine lift brackets, Tool No. EN-4611 to the cylinder heads.

Only lift the engine enough to take the weight

off the engine mounts, or damage to the

mounts and lifting equipment failure may

occur.

2

Using a commercially available engine lifting crane, have an assistant raise the engine far enough to remove the

weight on the engine mounts and create a slight tension in the rubber.

3

Observe the engine mount while raising the engine.

Engine Mechanical – V6

Page 6A1–238

Page 6A1–238

4

Replace the engine mount if any of the following conditions are found:

•

The hard rubber surface is covered with heat check cracks,

•

The rubber is split through the centre of the engine mount, or

•

The rubber is separated from the metal plate portion of the engine mount.

5

Remove the engine lift brackets, Tool No. EN-46114 from the engine.

Reinstall

The reinstallation procedure for the engine mounts is the reverse of the removal procedure, noting the following:

Ensure all fasteners are tightened to the correct torque specification.

Engine mount bracket to

cylinder block attaching bolt

torque specification

. . . . . . . . . . . . . . . . 43.0 – 57.0 Nm

Engine mount to bracket attaching nut

torque specification

. . . . . . . . . . . . . . . . 70.0 – 90.0 Nm

Engine mount to frame attaching nut

torque specification

. . . . . . . . . . . . . . . . 44.0 – 60.0 Nm

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст