Isuzu KB P190. Manual — part 754

Engine Mechanical – V6

Page 6A1–239

Page 6A1–239

4

Major Service Operations

A T T E N T I O N

The V6 engine is a combination of numerous components, containing machined, honed, polished and lapped

surfaces manufactured on the latest, high technology production equipment. Many of the components

contain tolerances measured in thousandths of a millimetre. Consequently, when any engine component is to

be serviced, care and cleanliness are extremely important.

Prior to re-assembly of the V6 engine, all components must be cleaned and inspected in accordance with the

relevant procedures throughout this section, and replaced or repaired where required.

In addition to cleaning and inspecting components, a liberal coating of engine oil should be applied to friction

surfaces during assembly to protect and lubricate the surfaces on initial operation.

When performing any service operation contained in this Section, it should be understood that correct

cleaning and protection of machined surfaces and friction areas is part of the repair procedure. This is

considered standard workshop practice, even if not specifically stated. Torque values must be used as

specified during reassembly to ensure correct retention of all components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

■

Fasteners must be replaced after loosening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

4.1 Engine

Removal

CAUTION

• Allow the engine to cool to at least 50° C,

before attempting fastener removal.

• As aluminium has a greater rate of thermal

expansion than that of cast iron,

aluminium bolt hole threads will change

dimension to a larger extent than cast iron

bolt threads.

• If a bolt or other threaded component is

removed before the engine is allowed to

cool to at least 50

° C, threads could be

pulled from the cylinder block or cylinder

head.

• Do not use impact tools to remove bolts

during engine disassembly. While this may

be common practice with cast iron engine

components, use of these tools is likely to

pull the aluminium threads in the cylinder

block or head of this engine.

Engine Mechanical – V6

Page 6A1–240

Page 6A1–240

Remove

1

Remove the skid plate.

2

Drain the radiator coolant, refer to

Section 6B1 Engine Cooling – V6

.

3

Disconnect the battery negative and positive terminal, refer to

Section 8A Electrical Body & Chassis

.

4

Remove the battery from the vehicle.

5

Depressurise the fuel system pressure, refer to

Section 6C Fuel System – V6

.

6

Make alignment marks on the bonnet and hinges in order to return the bonnet to the exact original position.

7

Remove the bonnet, refer to

Section 2B Sheet Metal

.

8

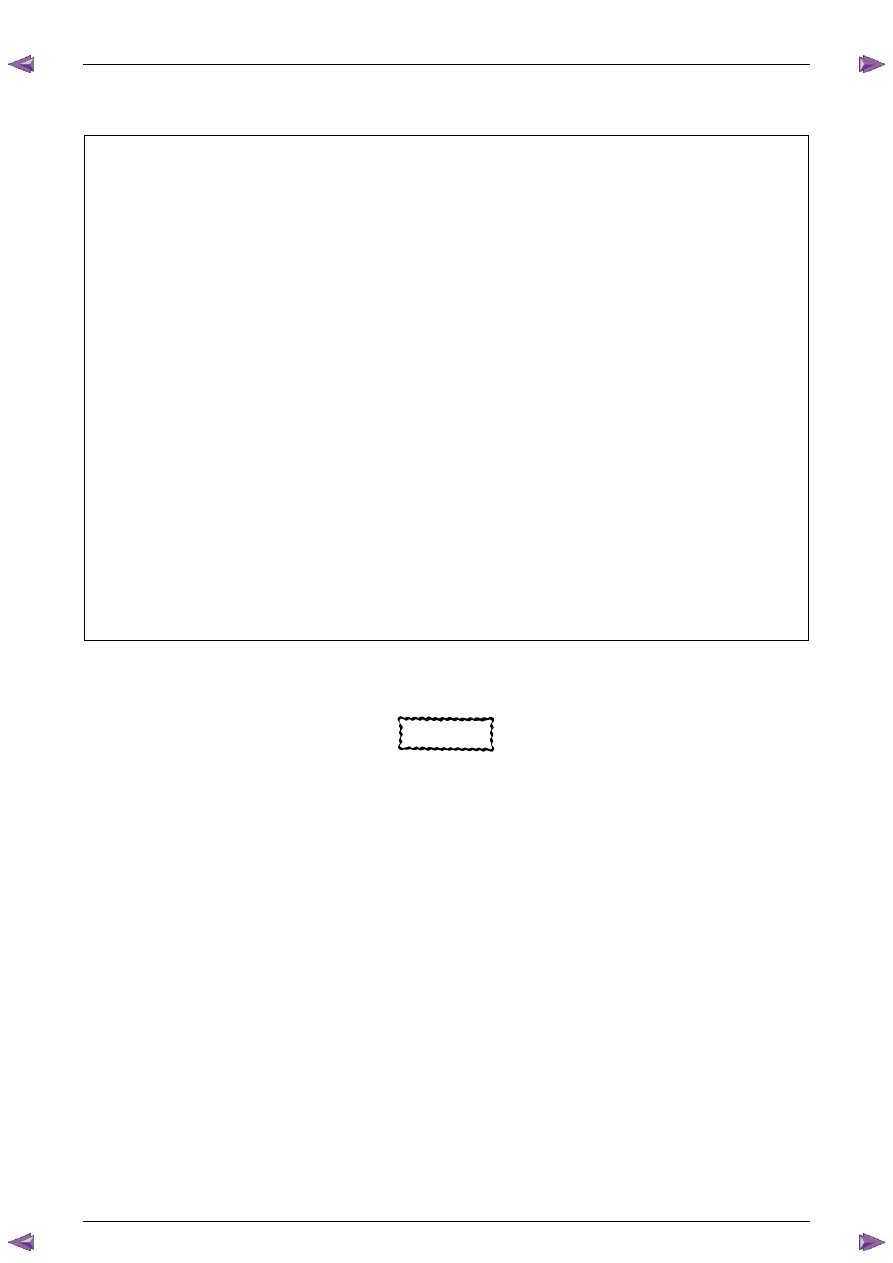

Remove the rubber hose (2) and air duct (1).

Figure 6A1 – 407

9

Disconnect the barometric sensor connector (1).

Figure 6A1 – 408

Engine Mechanical – V6

Page 6A1–241

Page 6A1–241

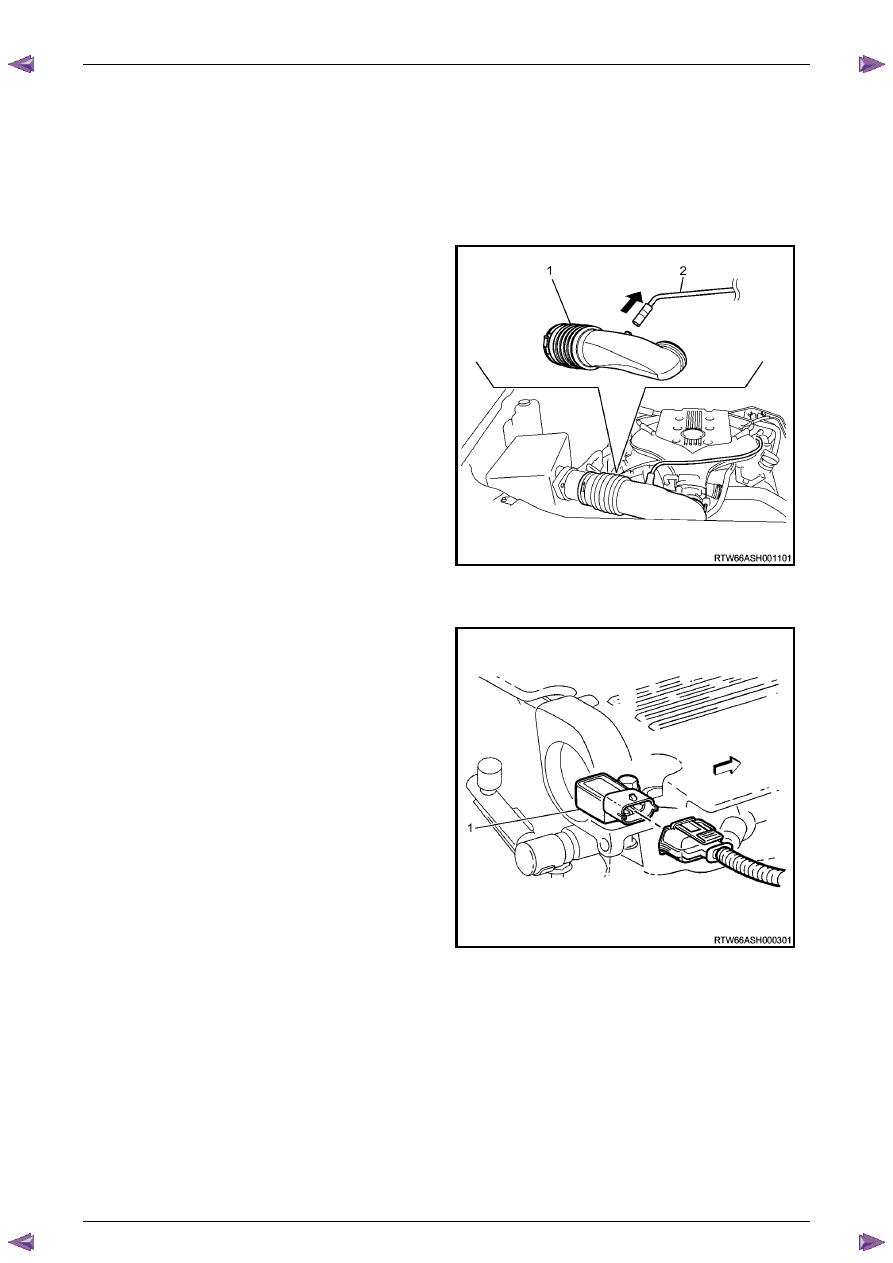

10

Disconnect the vacuum booster hose (1).

Figure 6A1 – 409

11

Disconnect the EVAP purge solenoid connector (1).

Figure 6A1 – 410

Engine Mechanical – V6

Page 6A1–242

Page 6A1–242

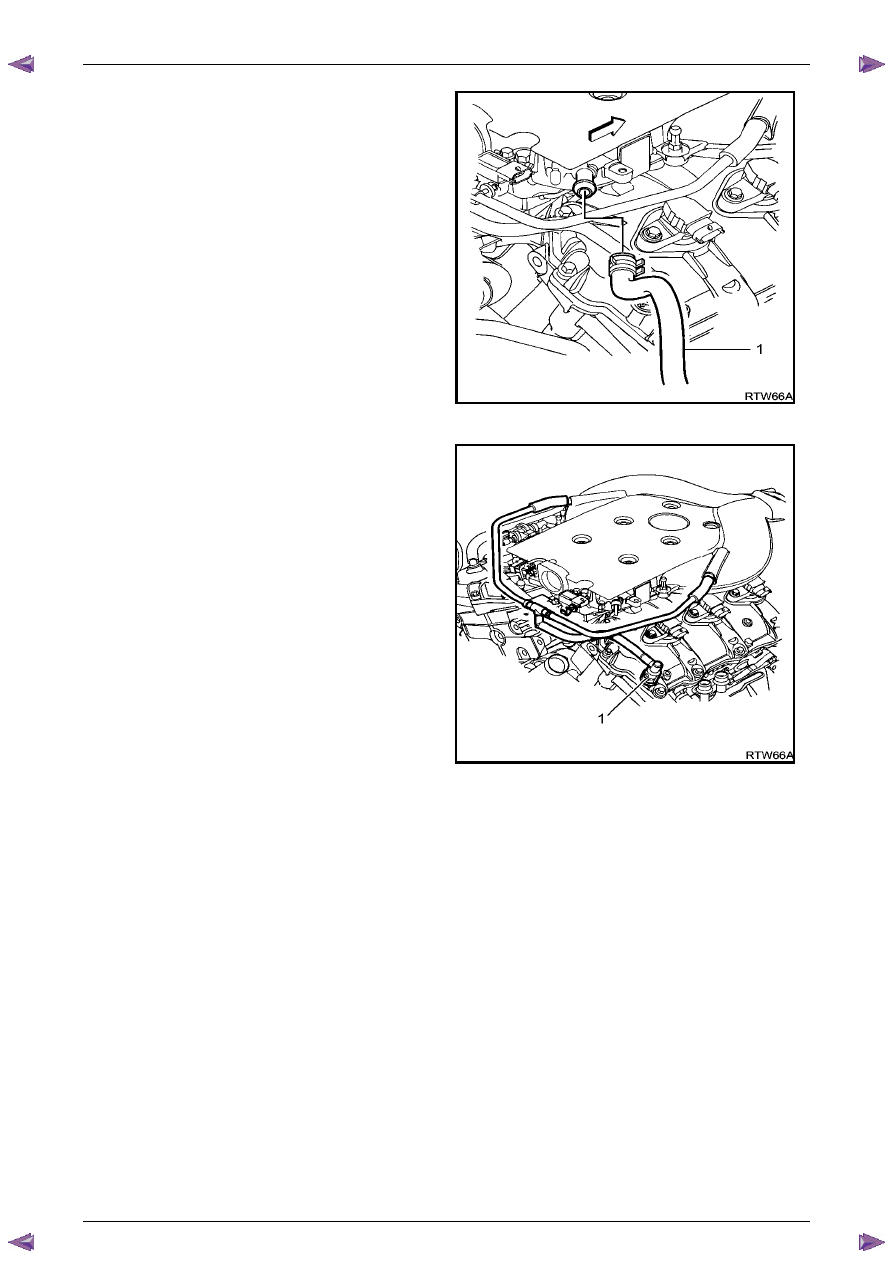

Plug the fuel feed hose after removal to

prevent dirt entering the pipe.

12

Disconnect the fuel pipe connector and injector

harness connector.

13

Disconnect the fuel feed hose from the fuel rail (1),

refer to

Section 6C Fuel system

.

14

Pull out release bar (2) of the fuel injector harness

wiring connector (3).

15

Disconnect the fuel injector harness wiring connector

from the fuel injector wiring harness (4).

Figure 6A1 – 411

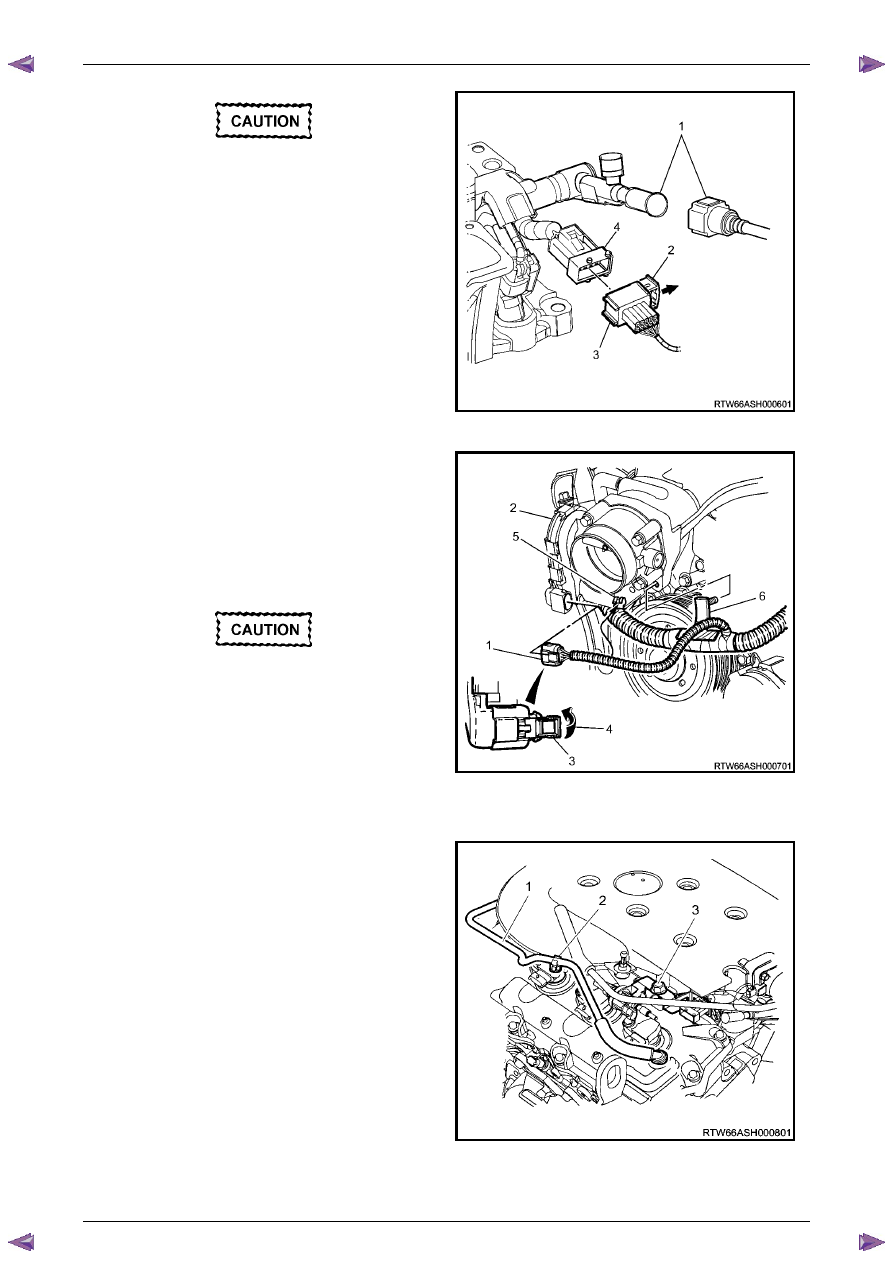

16

To disconnect the throttle body connector (1) the

following procedure must be followed.

17

Retract the throttle body wiring connector lock (3)

while pressing the connector latch in the direction of

the arrow (4).

18

Disconnect the throttle body wiring connector (1).

19

Release the throttle body connector wiring harness

from its retaining clip (5).

Take care not to break the barbed retainer

pin (6), when removing the harness. Should

the pin be damaged it is vital that a new

harness retainer be fitted.

20

Remove the main wiring harness retainer pin (6) from

the intake manifold by pushing from the front to the

rear using a suitable length of 5mm steel rod or an

allen key.

Figure 6A1 – 412

21

Disconnect the PCV fresh air tube (1) from the upper

intake manifold mounting clip (2) and remove the

fixing bolt (3).

Figure 6A1 – 413

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст