Isuzu KB P190. Manual — part 248

6C – 28 FUEL SYSTEM

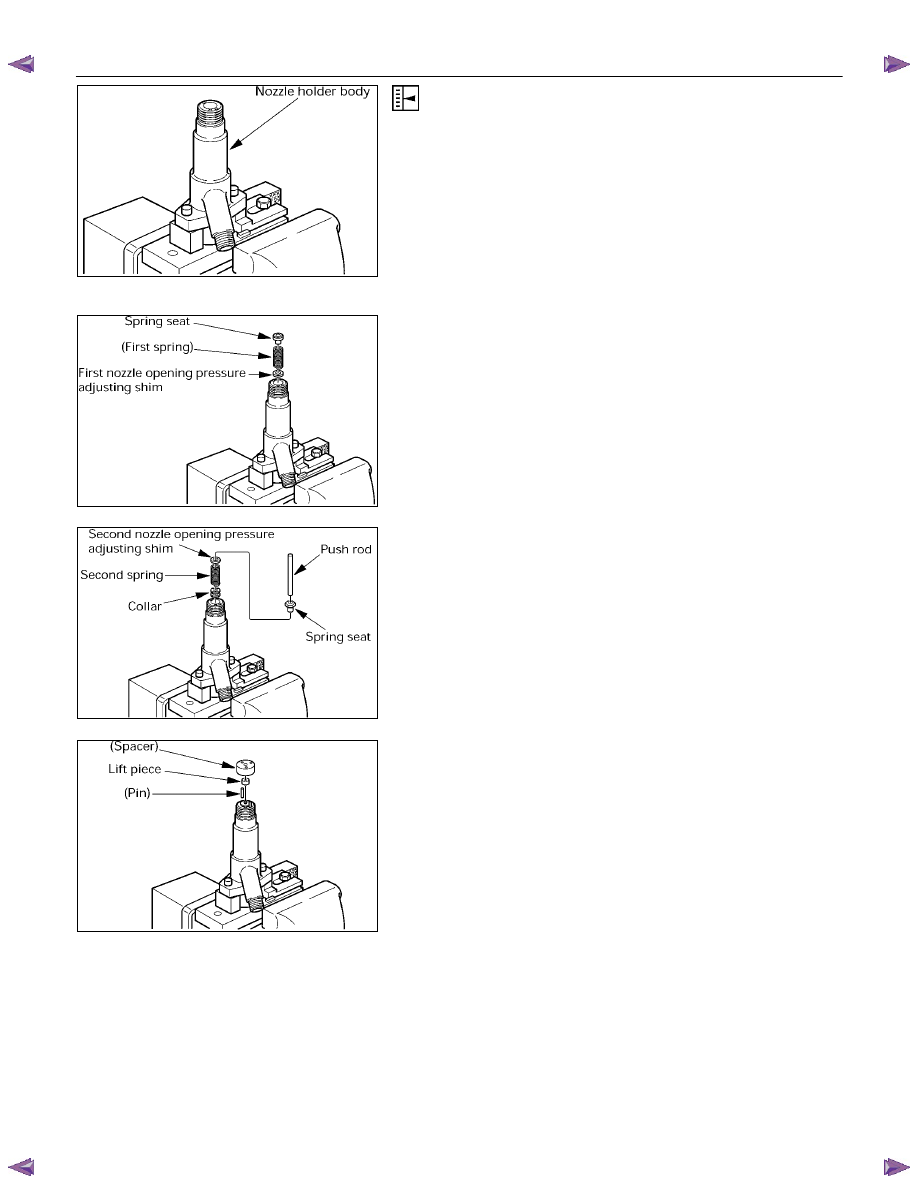

Injection Nozzle Adjustment

First nozzle opening pressure adjustment

1.Clamp the nozzle holder in a vise.

2. Install the shim, first spring and spring seat in the

nozzle holder.

3. Install the collar, second spring, shim, spring seat and

pushrod in the nozzle holder.

4. Install the pins, lift piece and spacer in the nozzle

holder.

040MV015.tif

040MV016.tif

040MV017.tif

040MV018.tif

FUEL SYSTEM 6C – 29

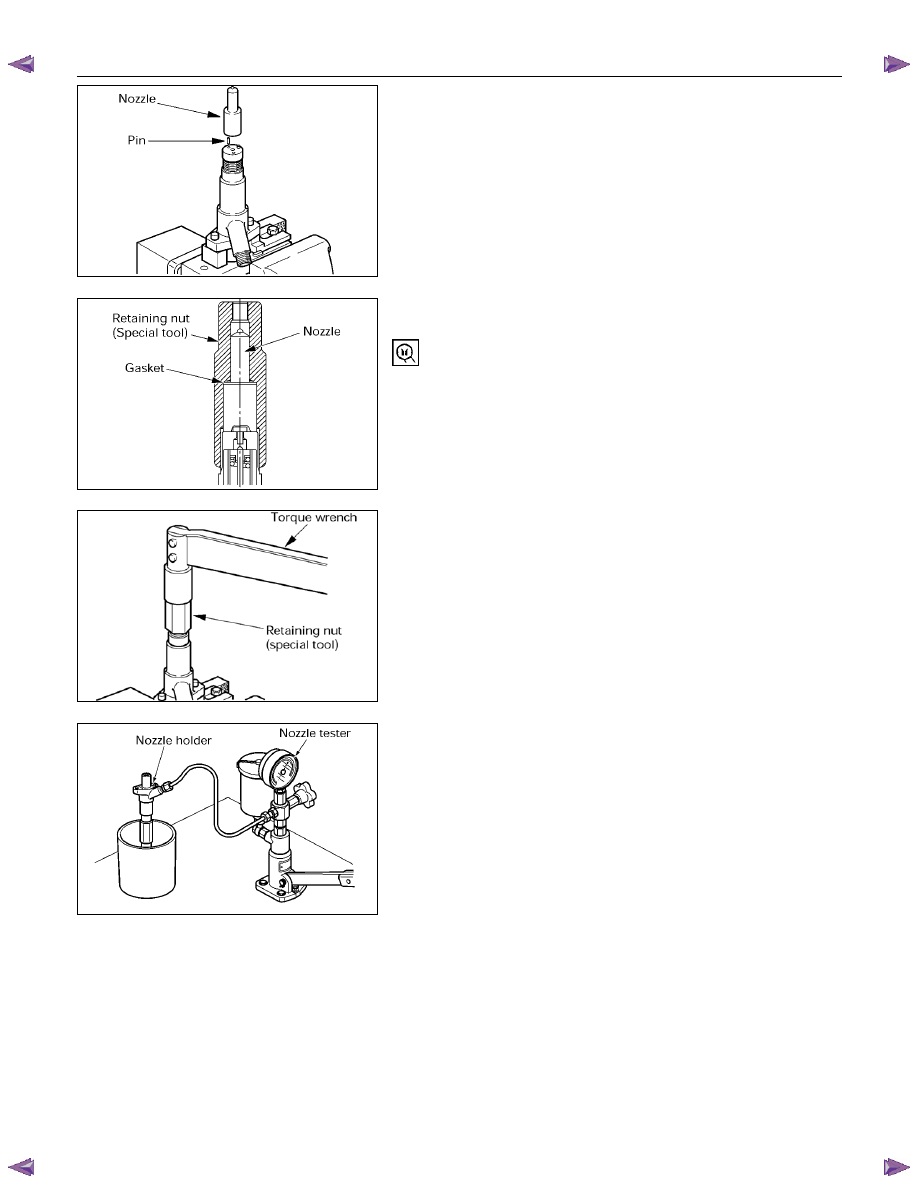

5. Install the pins in the spacer.

6. Install the nozzle on the spacer.

7. Hand-tighten the adjustment retaining nut together

with the gasket to the nozzle holder.

Retaining nut:

157892-3200 (Bosch AS)

Gasket:

157892-5100 (Bosch AS)

(Bosch AS = Bosch Automotive Systems Corporation)

8. Tighten the adjustment retaining nut to the specified

torque.

Torque: 5.1 kg·m (36.9 Ib·ft/50 N·m)

9. Set the nozzle holder to the nozzle tester.

10. Operate the nozzle tester and measure the first nozzle

opening pressure.

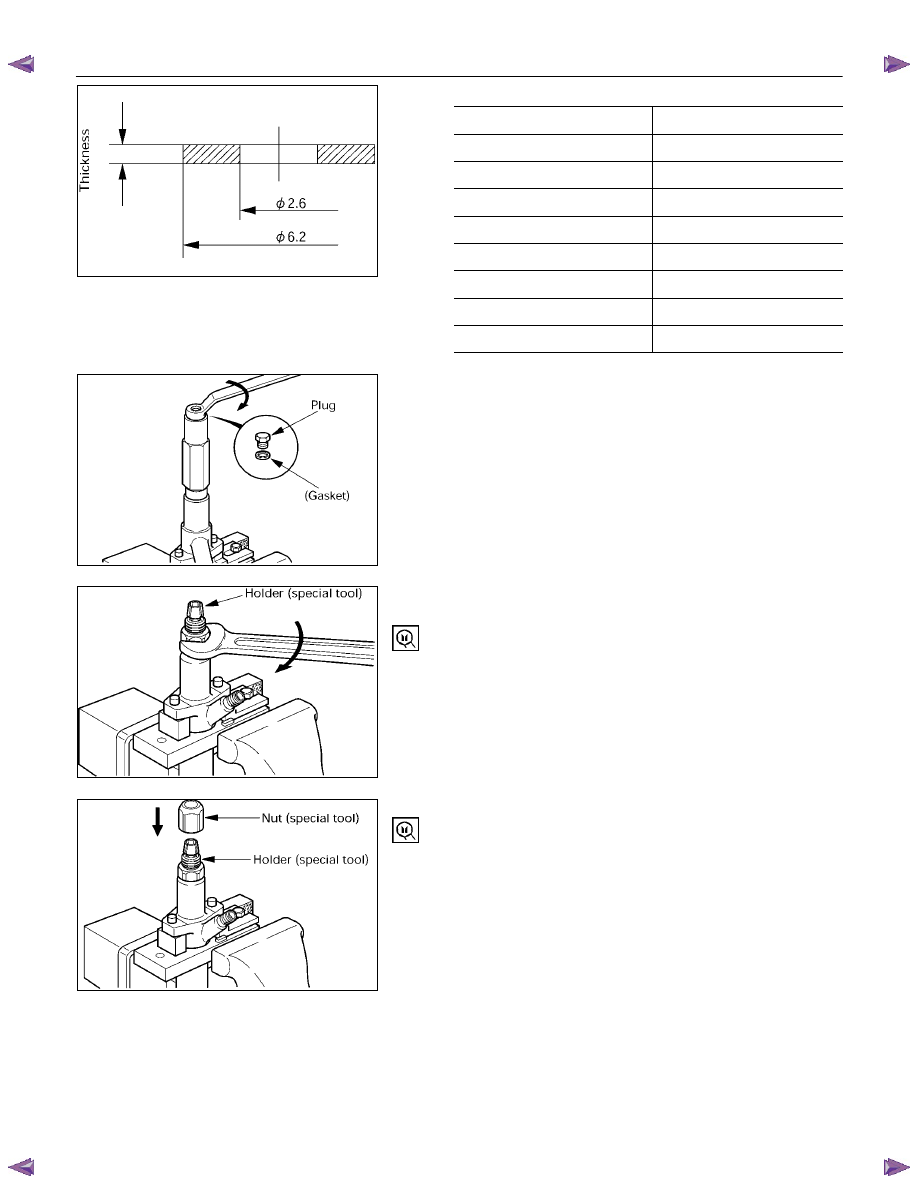

11. If the first nozzle opening pressure is not as specified,

disassemble the nozzle holder and replace the shim

until the pressure is as specified.

CAUTION:

•

Use a micrometer to measure shim thickness.

040MV019.tif

040MV010.tif

040MV014-1.tif

040MV030.tif

6C – 30 FUEL SYSTEM

•

First nozzle opening pressure adjusting shims

Parts No. (ISUZU)

Thickness (mm)

115349-0420 0.40

115349-0430 0.50

115349-0440 0.52

115349-0450 0.54

115349-0460 0.56

115349-0470 0.58

115349-0480 0.60

115349-0490 0.70

Full needle valve lift confirmation

1. Install the gasket and plug on the adjustment retaining

nut.

Gasket:

026508-1140 (Bosch AS)

8-9422-7602-0 (ISUZU)

Plug:

157892-1600 (Bosch AS)

2. Position the nozzle holder with the nozzle facing down

and install the dial gauge holder on the nozzle holder.

Dial gauge holder: 157892-5000 (Bosch AS)

3. Install the nut on the dial gauge holder.

Nut: 157892-1000 (Bosch AS)

040LX010.tif

040MV013.tif

040MV012.tif

040MV011.tif

FUEL SYSTEM 6C – 31

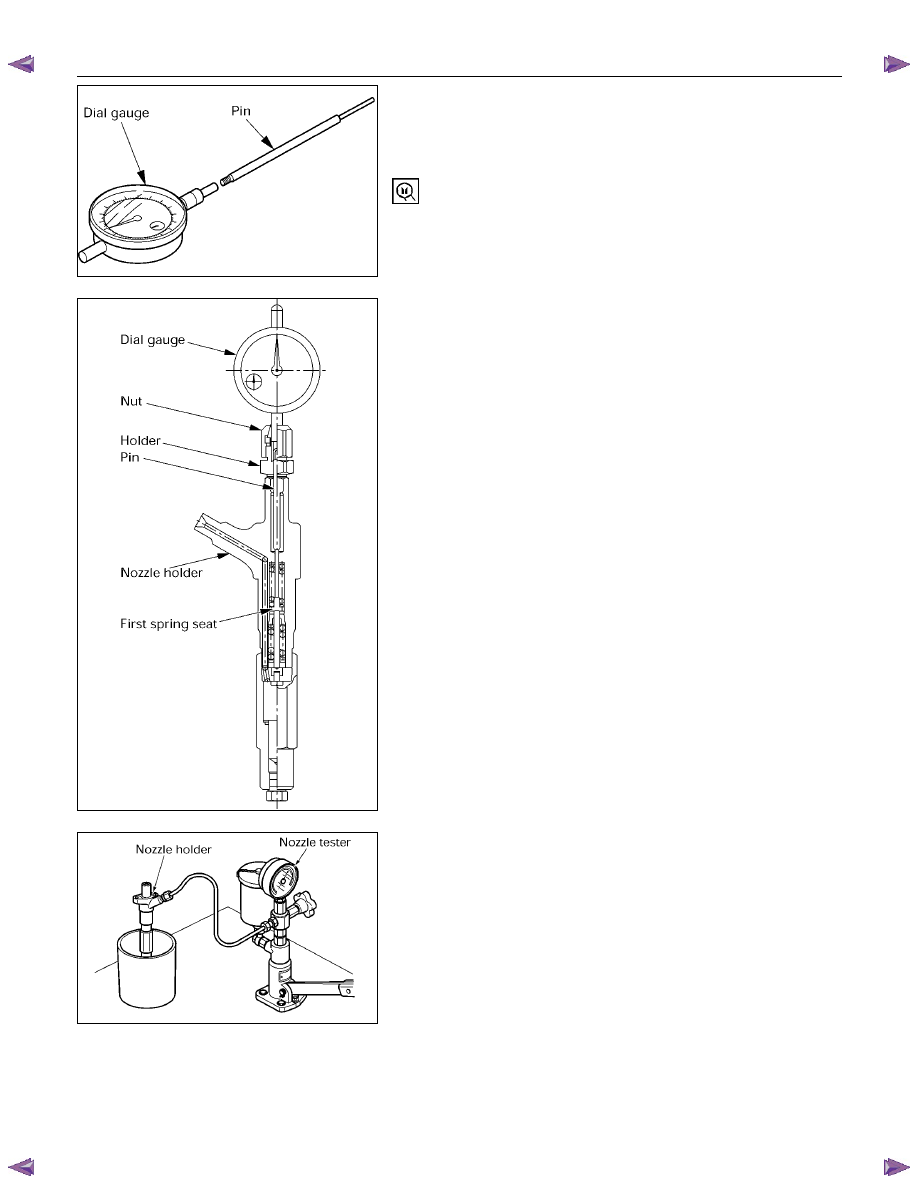

4. Install the pin to the dial gauge.

Note:

The lengths of the pins do not include the

threaded portions.

Pin (L=100 mm): 157892-5200 (Bosch AS)

Dial gauge:

157954-3800 (Bosch AS)

185317-0150 (ISUZU)

5. Secure the dial gauge to the nozzle holder using the

nut so that the pin contacts the tip of the first spring

seat.

CAUTION:

•

Secure the dial gauge so that a stroke of 2 mm can

be measured.

•

Do not over-tighten the nut as the dial gauge shaft

may jam. (Confirm from the dial gauge that the

shaft moves smoothly.)

6. Set the nozzle holder to the nozzle tester and put

needle to zero on the dial gauge.

7. Operate the nozzle tester to bleed any air from inside

the retaining nut and to confirm that no fuel leaks.

040MV029.tif

040MV009.tif

040MV030.tif

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст