Isuzu KB P190. Manual — part 247

6C – 24 FUEL SYSTEM

13. Throttle Position Sensor Harness Connector

(4JA1TC/4JH1TC only)

Reconnect the harness connector to the throttle position

sensor.

14. Power Steering Pump Bracket

15. Fan

16. Vacuum Hose

Connect the vacuum hose to the EGR valve and the

intake throttle.

Euro under

Euro I

Euro II

Euro III

4JA1L without with with Not

used

4JA1TC

Not used

Not used

Not used

With cooler

(EGR cooler)

4JH1TC without

with

with

With

(EGR cooler)

17. Accelerator Control Cable

1) Connect the accelerator cable to the injection pump

(4JA1T) the intake throttle. (4JA1TC/4JH1TC only)

18. Power Steering Pump Assembly

19. Drive Belt

Install the drive belt and adjust the belt tension.

20. Battery

FUEL SYSTEM 6C – 25

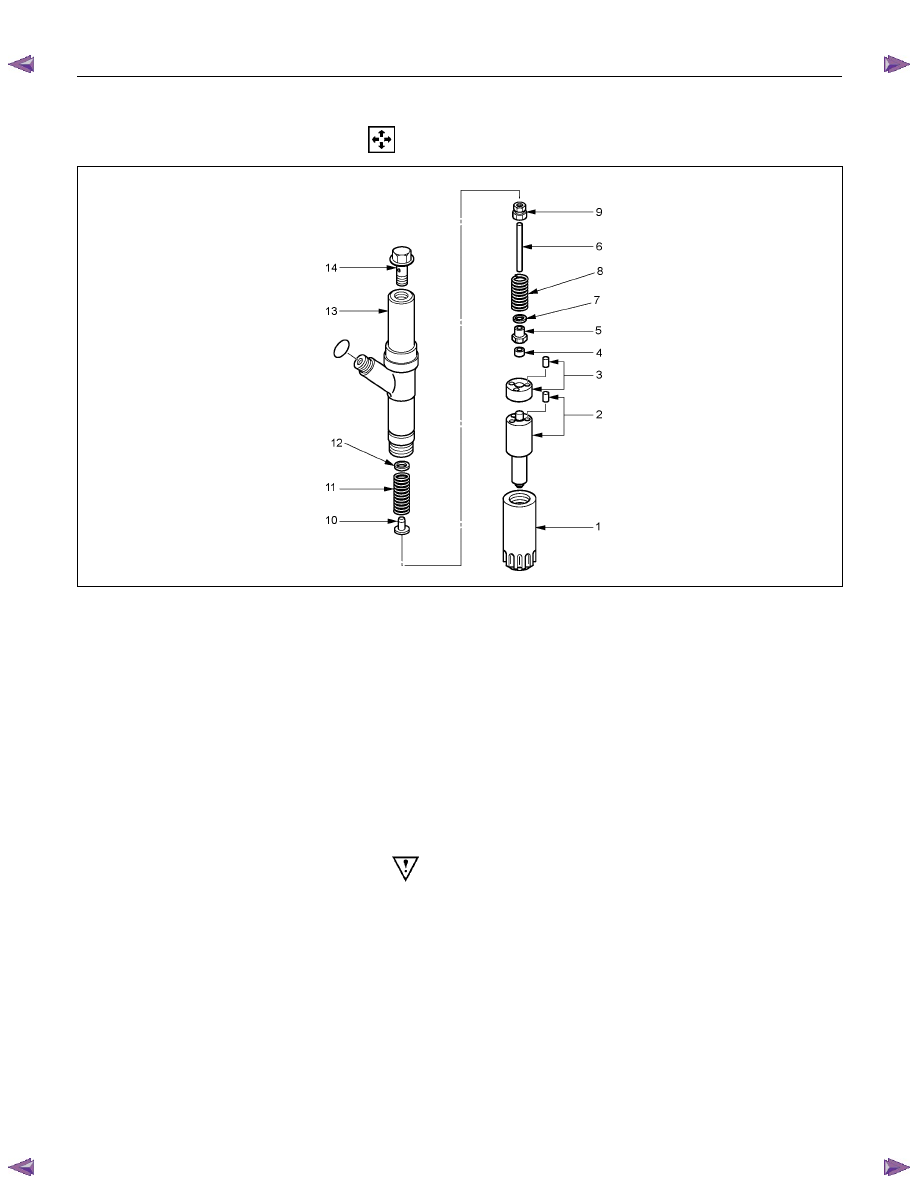

INJECTION NOZZLE (4JA1L)

DISASSEMBLY

RTW76CMF000401

Disassembly Steps

1.

Retaining

nut

2.

Nozzle & pin

3.

Spacer & pin

4.

Lift

Piece

5.

Spring

seat

6.

Push

rod

7.

Shim (Second nozzle opening

pressure adjustment)

8.

Second

spring

9.

Collar

10.

Spring

seat

11.

First

spring

12.

Shim (First nozzle opening

pressure adjustment)

13.

Nozzle holder body

14.

Eye

bolt

Important Operations

Injection nozzle adjustment is possible only on the 4JA1L

engine.

The two-spring nozzle holder has been developed to

reduce NOx (Nitrogen Oxides) and particulates from direct

injection diesel engine exhaust.

Before disassembly remove carbon deposit from nozzle

and nozzle holder using a wire brush and wash the outside

nozzle holder assembly.

Caution:

Do not touch nozzle holes with the wire brush during

cleaning it.

Disassemble the nozzle holder assembly to numerical

order.

6C – 26 FUEL SYSTEM

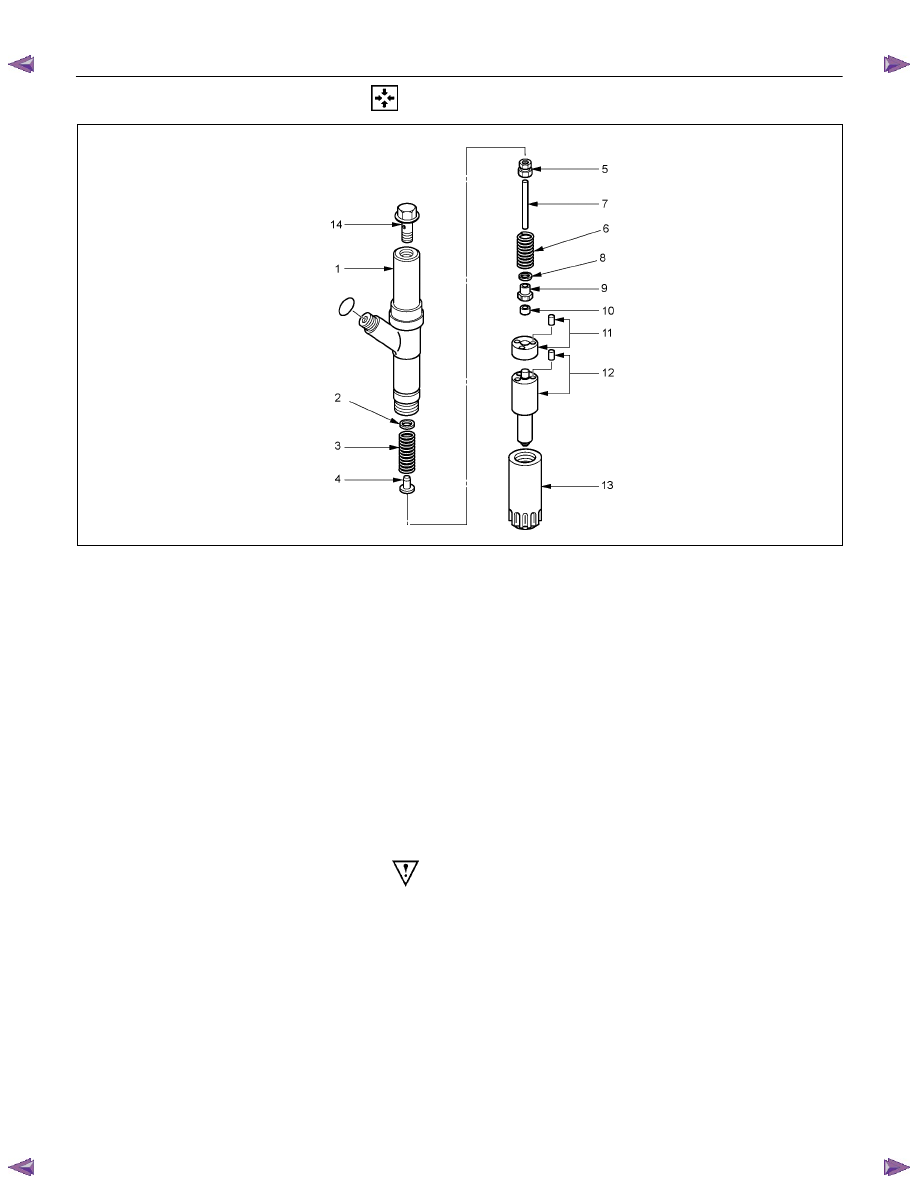

REASSEMBLY

RTW76CMF000501

Reassembly Steps

1.

Nozzle holder body

2.

Shim (First opening pressure

adjustment)

3.

First

spring

4.

Spring

seat

5.

Collar

6.

Second

spring

7.

Push

rod

8.

Shim (Second opening pressure

adjustment)

9.

Spring

seat

10.

Lift

Piece

11.

Spacer & pin

12.

Nozzle & pin

13.

Retaining

nut

14.

Eye

bolt

Important Operations

The nozzle holder is adjusted as the components are

reassembled in the sequence above.

As adjustment of the two-spring nozzle holder is made in

hundredths of a millimeter, clean the parts thoroughly in

light oil to completely remove any dirt or foreign matter.

FUEL SYSTEM 6C – 27

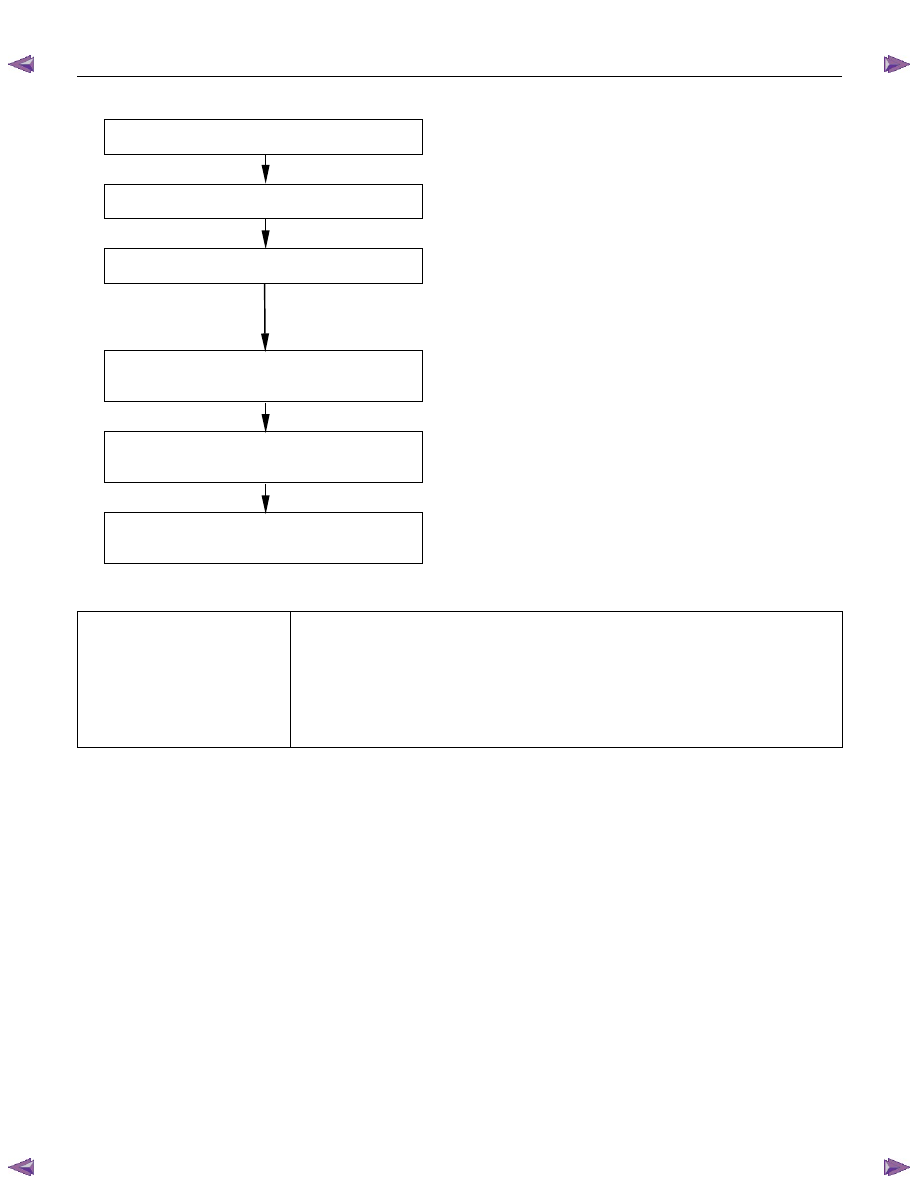

REASSEMBLY AND ADJUSTMENT PROCEDURE

1

First nozzle opening pressure adjustment

Adjust the first nozzle opening pressure using the shim.

2

Full needle valve lift confirmation

Confirm the full needle valve lift in accordance with the

closed method.

3

Pre-lift confirmation

Confirm pre-lift in accordance with the closed method.

CAUTION:

If not as specified, replace the nozzle assembly, lift

piece, pins and spacer using the nozzle service kit.

4

Second nozzle opening pressure

confirmation

Confirm the second nozzle opening pressure in accordance

with the closed method.

5

Second nozzle opening pressure

adjustment

Adjust the second nozzle opening pressure using the shim.

6

Final inspection

Confirm the condition of the fuel spray with the nozzle and

nozzle holder assembled.

First nozzle opening pressure adjustment

Nozzle needle valve full-lift

0.25 mm (0.0098 in)

Nozzle needle valve pre-lift

0.04 mm(0.0016 in) at 20,000 kPa (2901 psi, 204 kg/cm

2

)

Nozzle pressure

4JA1T(L)

1st Stage

19.1 MPa (2759 psi, 194 kg/cm

2

)

2nd Stage

25.5-27.0 MPa (3768-3911 psi, 260-275 kg/cm

2

)

NOTE: Only 4JA1L can perform adjustment of a nozzle.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст