Isuzu KB P190. Manual — part 211

ENGINE MECHANICAL 6A – 39

18. Radiator

1) Drain the engine coolant.

2) Remove the reservoir hose.

3) Remove the upper and lower hose.

4) Remove the fan guide.

5) Remove the radiator.

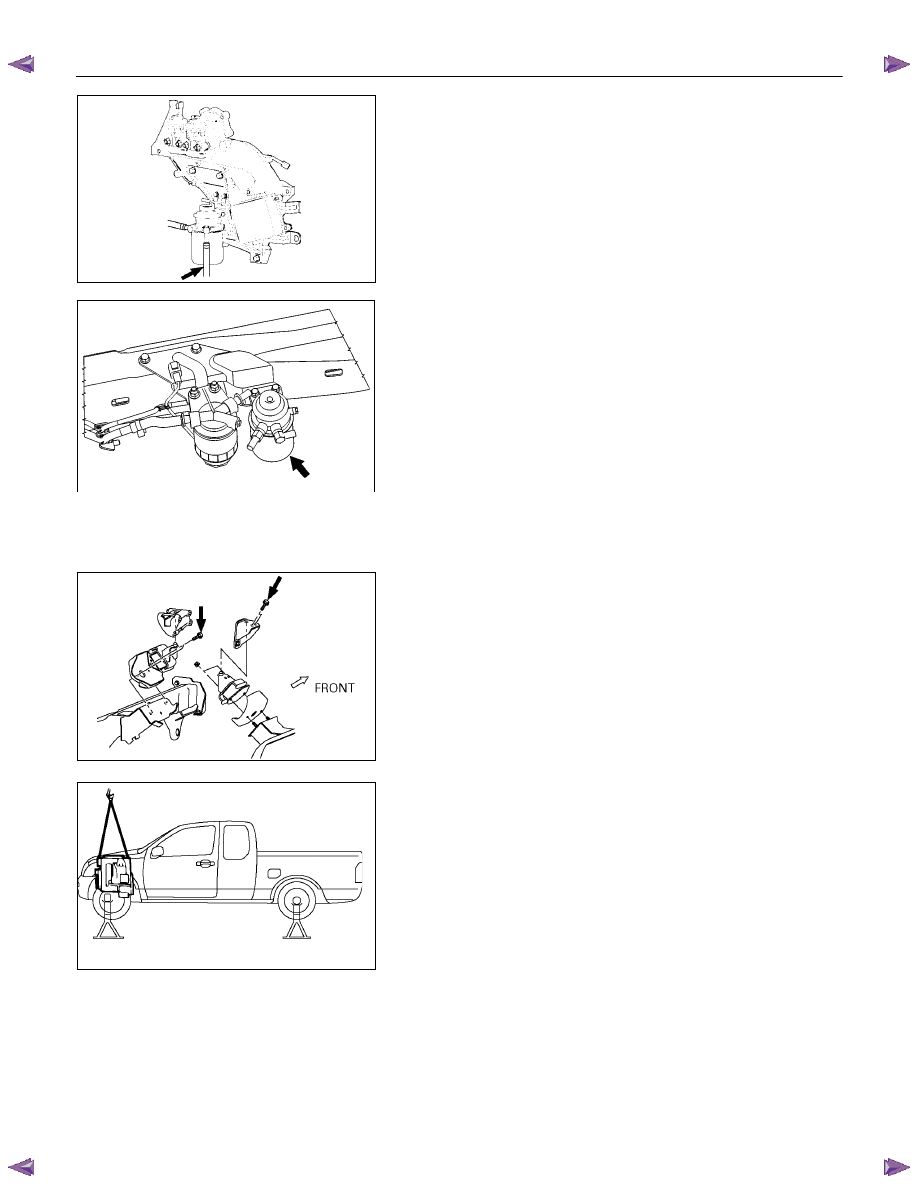

19. Fan

P1010034

20. Air cleaner

1) Remove the MAF sensor connector (4JA1TC/4JH1TC)

from air cleaner duct.

2) Remove the air cleaner duct and the air cleaner box

from engine room.

3) Remove the two air ducts from inter cooler

(4JA1TC/4JH1TC).

21. Power Steering Pump

Loosen the power steering pump adjust plate bolt, then

remove the power steering pump assembly. Place the

power steering pump assembly along with piping on the

body side.

22. Air conditioner compressor

1) Remove air compressor magnet connector.

2) Remove the air conditioner compressor. Place the air

conditioner compressor along with piping on the body

side.

23. Engine Control Cable

Remove the engine control cable from its bracket

(4JA1TC/4JH1TC) or the injection pump (4JA1T(L)).

24. Vacuum Piping

Remove the vacuum pipe from the vacuum pump, the

EGR valve, injection pump FICD (4JA1T(L)).

25. Engine Harness

1) Remove following connectors from engine.

• TPS

connector

• Oil pressure switch connector

• Thermo switch connector

• Injection pump connector

• Engine

earth

• Thermometer unit connector

• TDC

sensor

2) Remove the clips fixing engine harness.

P1010009

6A – 40 ENGINE MECHANICAL

140R300001

26. Fuel Hose

Remove the fuel hose from the fuel filter (Except EURO

III).

RTW46ASH000501

Remove the fuel hose from injection pump (EURO III

only).

27. Exhaust Pipe

Remove the front exhaust pipe bolts and separate the

exhaust manifold and the front exhaust pipe.

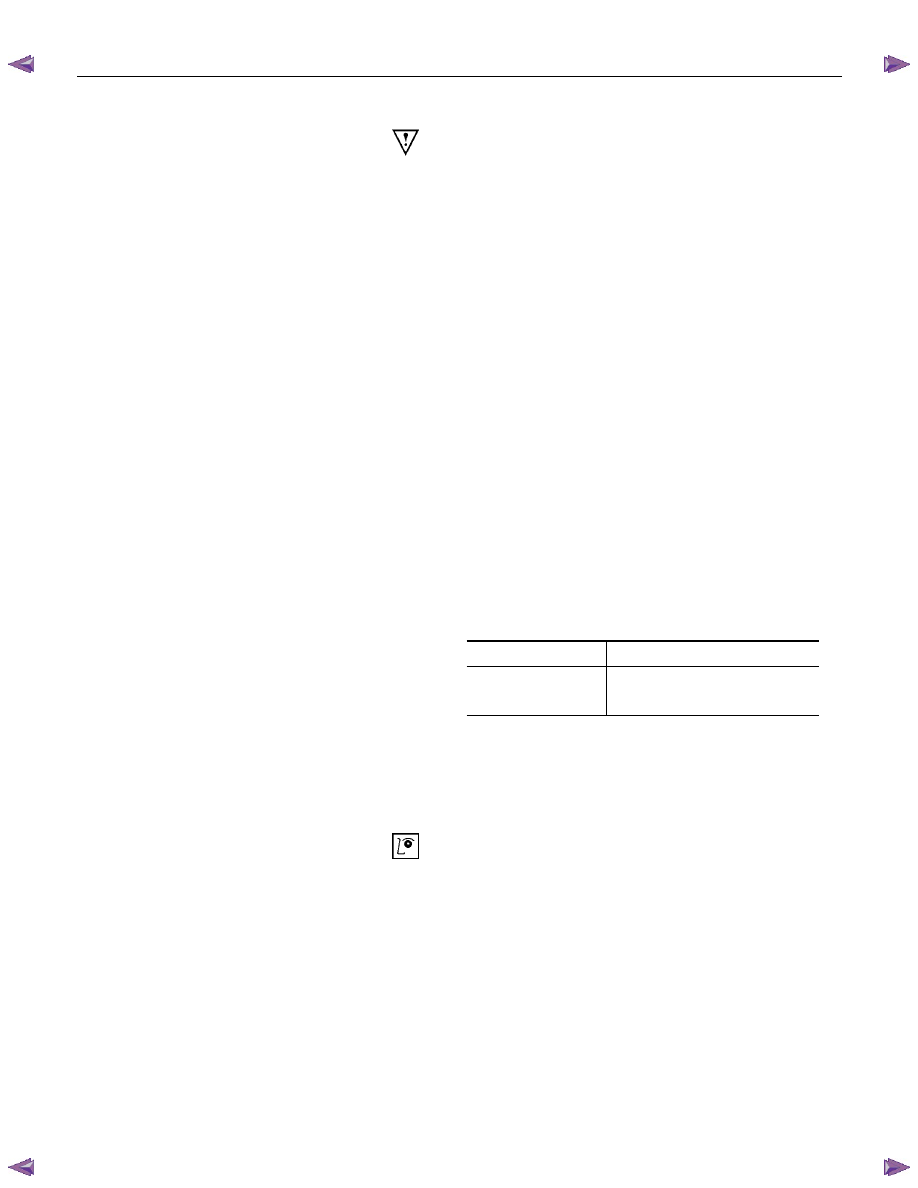

28. Engine Assembly

1) Remove two right side engine foot bolts.

2) Remove two left side engine mount bolts.

3) Use the hoist to lift the engine from the engine

compartment.

Installation

To reassemble, follow the removal steps in the reverse

order.

022R300002

F06R300008

ENGINE MECHANICAL 6A – 41

Coolant Replenishment

Warning:

When the coolant is heated to a high temperature, be

sure not to loosen or remove the rediator cap.

Otherwise you might get scalded by hot vapor or

boiling water.

To open the radiator cap, put a piece of thick cloth on

the cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

1. Open rediator cap pour coolant up to filler neck

2. Pour coolant into reservoir tank up to "MAX" line

3. Tighten radiator cap and start the engine. After idling

for 2 to 3 minutes, stop the engine and reopen radiator

cap. If the water level is lower, replenish.

4. After replenish the coolant tighten radiator cap, warm

up the engine at about 2000 rpm. Set heater

adjustment to the highest temperature position, and let

the coolant circulate also into heater water system.

5. Check to see the thermometer, continuously idling 5

minutes and stop the engine.

6. When the engine has been cooled, check filler neck for

water level and replenish if required. Should extreme

shortage of coolant is found, check the coolant system

and reservoir tank hose for leakage.

7. Pour coolant into the reservoir tank up to "MAX" line.

Coolant Capacity

lit (US/UK gal)

4JA1 / TC

9.4 (2.5 / 2.1)

4JH1TC

M/T: 10.1 (2.7 / 2.2)

A/T: 10.0 (2.6 / 2.2)

Engine Warm-Up

After completing the required maintenance procedures,

start the engine and allow it to idle until it is warm.

Check the following:

1. Engine idling speed.

2. Engine noise level.

3. Engine lubricating system and cooling system.

Carefully check for oil and coolant leakage.

4. Clutch

engagement.

5. Transmission

operation.

6. Indicator warning light operation.

6A – 42 ENGINE MECHANICAL

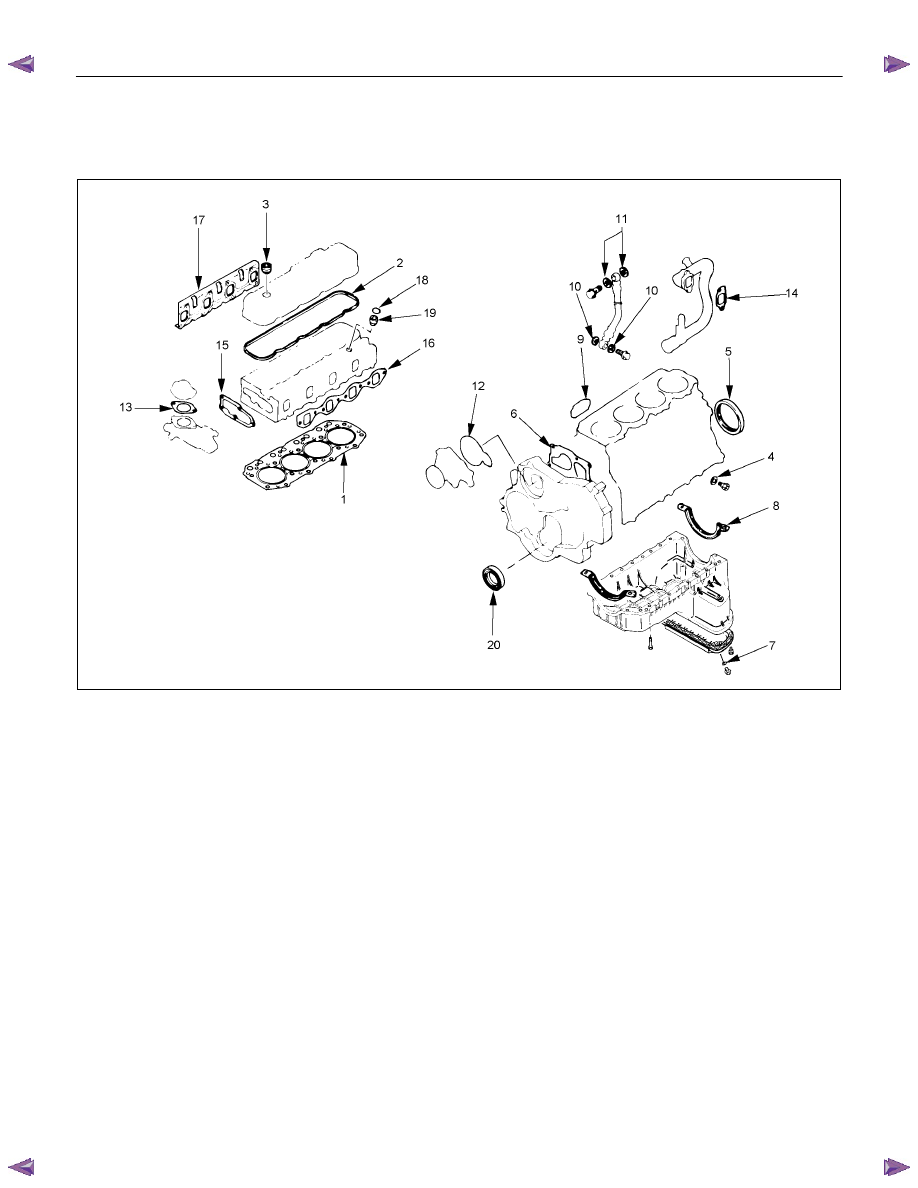

ENGINE REPAIR KIT

RTW36ALF000601

Removal Steps

1. Cylinder head gasket

2. Head cover gasket

3. Head cover cap nut gasket

4. Drain cock gasket

5. Crankshaft rear oil seal

6. Gear case gasket

7. Oil pan drain plug gasket

8. Oil pan gasket

9. Oil filter gasket

10. Joint bolt gasket

11. Vacuum pump gasket

12. Water pump O-ring

13. Water outlet pipe gasket

14. Intake pipe gasket

15. Thermostat housing gasket

16. Intake manifold gasket

17. Exhaust manifold gasket

18. Nozzle holder O-ring

19. Nozzle holder gasket

20. Crankshaft front oil seal

NOTE

Discard all O-rings, gaskets, and seals removed at disassembly and replace them with new ones. Reuse of

these parts will result in oil, water, and gas leakage.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст