Suzuki Grand Vitara JB627. Manual — part 180

4E-1 ABS:

Brakes

ABS

Precautions

Precautions in Diagnosing Troubles

S6JB0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• If the vehicles was operated in any of the following

ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked

up.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as

described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS (ESP

®) control module during inspection.)

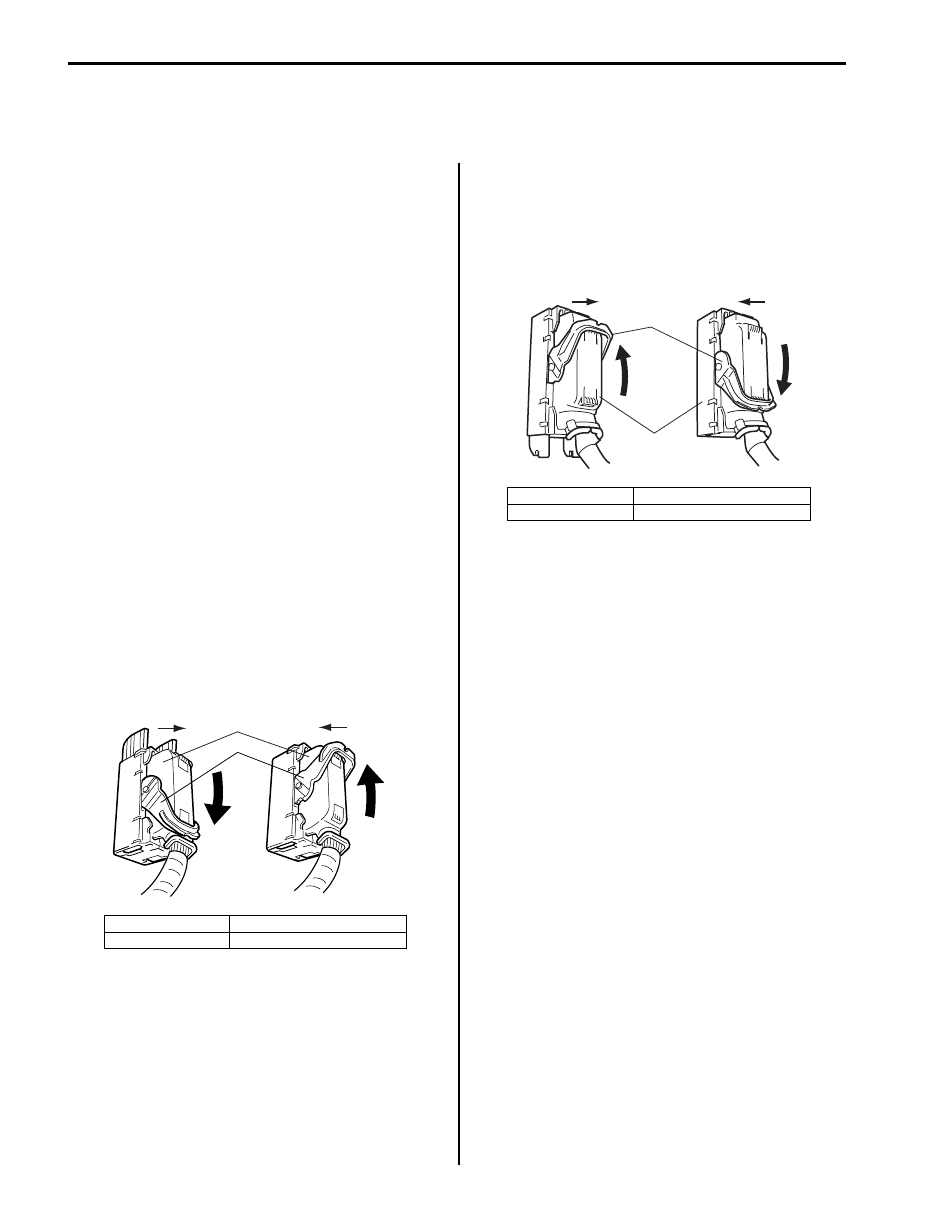

• When disconnecting ABS (ESP

®) hydraulic unit /

control module connector (1), pull down lock lever (2)

of connector.

When connecting, set the connector on ABS (ESP

®)

hydraulic unit / control module assembly and pull up

the lock lever (2) until it locks.

• When disconnecting ESP

® hydraulic unit / control

module connector (1), pull up lock lever (2) of

connector.

When connecting, set the connector on ESP

®

hydraulic unit / control module assembly and pull

down the lock lever (2) until it locks.

• Communication of ECM, TCM (A/T model), BCM,

ABS (ESP

®) control module, 4WD control module (if

equipped), keyless start control module (if equipped)

and combination meter is established by CAN

(Controller Area Network).

Therefore, be sure to read “Precaution for CAN

Communication System in Section 00” before

inspection and handle CAN communication line.

Precautions in On-Vehicle Service

S6JB0B4500002

When connector is connected to ABS (ESP

®) hydraulic

unit / control module assembly, do not disconnect

connectors of sensors with ignition switch ON.

Otherwise, DTC will be set in ABS (ESP

®) control

module.

Precautions in Hydraulic Unit Operation Check

S6JB0B4500003

ABS (ESP

®) hydraulic unit / control module assembly

function is checked by correct wheel release condition

when brake pressure is depressurized using SUZUKI

scan tool. The hydraulic unit operation check referring to

“Hydraulic Unit Operation Check” should be performed

to confirm the correct brake pipe connection in the

following cases.

• ABS (ESP

®) hydraulic unit / control module ABS

(ESP

®) hydraulic unit / control module assembly was

replaced.

• Brake pipe and/or hose were replaced.

[A]: Disconnect

C: Pull down to disconnect

[B]: Connect

D: Pull up to connect

2

1

C

D

[A]

[B]

I4RH01450001-01

[A]: Disconnect

C: Pull up to disconnect

[B]: Connect

D: Pull down to connect

2

1

[A]

[B]

C

D

I6JB01450001-02

ABS: 4E-2

General Description

ABS Description

S6JB0B4501001

The ABS (Antilock Brake System) controls the fluid

pressure applied to the wheel cylinder of each brake

from the master cylinder so that each wheel is not locked

even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control

becomes effective, braking force is distributed between

the front and rear so as to prevent the rear wheels from

being locked too early for better stability of the vehicle.

The main component parts of this ABS include the

following parts in addition to those of the conventional

brake system.

• Wheel speed sensor which senses revolution speed

of each wheel and outputs its signal.

• ABS warning light which lights to inform abnormality

when system fails to operate properly.

• ABS (ESP

®) hydraulic unit / control module assembly

is incorporated ABS (ESP

®) control module, ABS

hydraulic unit (actuator assembly), solenoid valve

power supply driver (transistor), solenoid valve driver

(transistor), pump motor driver (transistor).

– ABS (ESP

®) control module which sends operation

signal to ABS hydraulic unit to control fluid pressure

applied to each wheel cylinder based on signal

from each wheel speed sensor so as to prevent

wheel from locking.

– ABS hydraulic unit which operates according to

signal from ABS (ESP

®) control module to control

fluid pressure applied to wheel cylinder of each 4

wheels.

– Solenoid valve power supply driver (transistor)

which supplies power to solenoid valve in ABS

hydraulic unit.

– Solenoid valve driver (transistor) which controls

each solenoid valves in ABS hydraulic unit.

– Pump motor driver (transistor) which supplies

power to pump motor in ABS hydraulic unit.

This ABS is equipped with Electronic Brake force

Distribution (EBD) system that controls a fluid pressure

of rear wheels to best condition, which is the same

function as that of proportioning valve, by the signal from

wheel sensor independently of change of load due to

load capacity and so on. And if the EBD system fails to

operate properly, the brake warning light lights to inform

abnormality.

ABS (ESP

®) hydraulic unit / control module

Assembly Description

S6JB0B4501002

ABS (ESP

®) control module is a component of ABS

(ESP

®) hydraulic unit / control module assembly and

has the following functions.

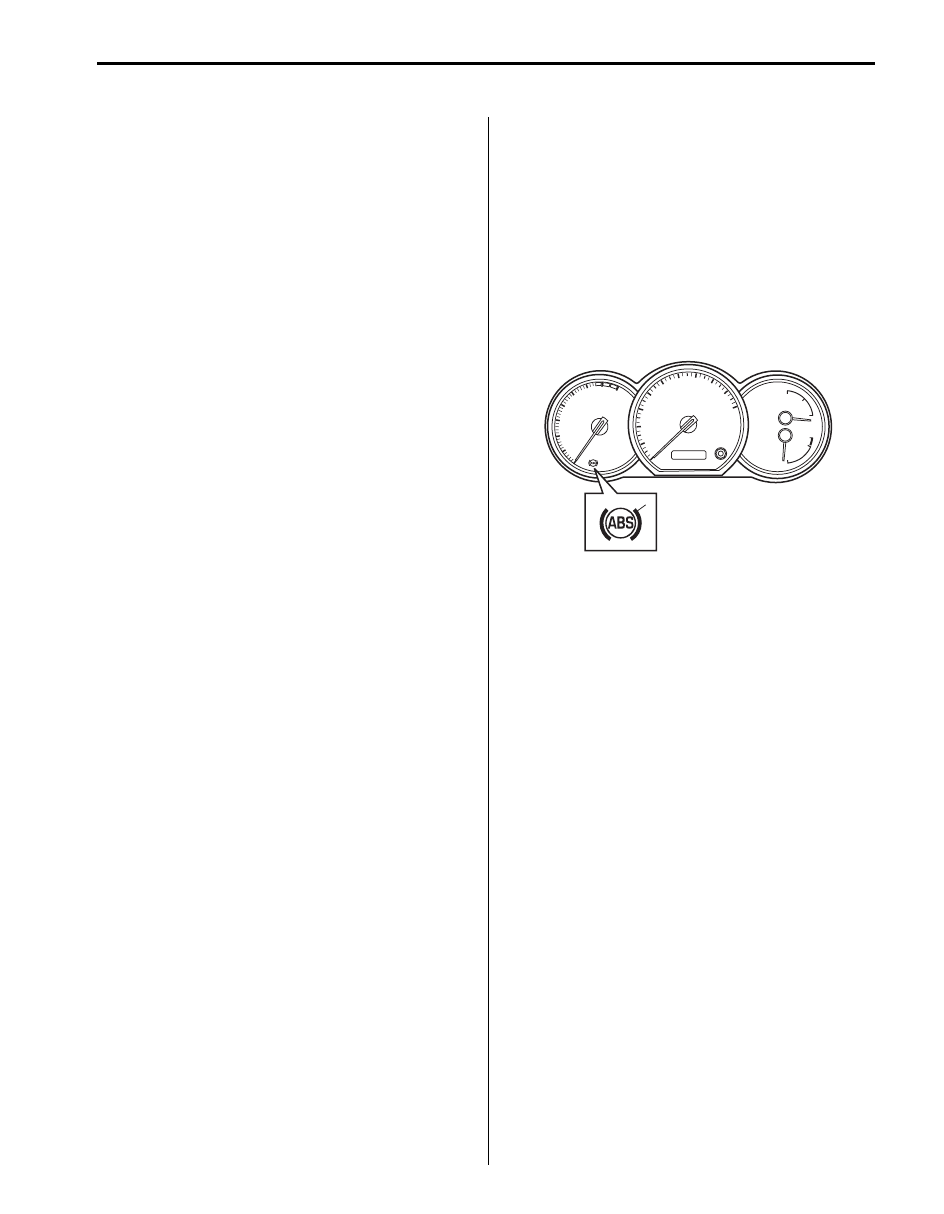

Self-Diagnosis Function

ABS (ESP

®) control module diagnoses conditions of the

system component parts (whether or not there is any

abnormality) all the time and indicates the results

(warning of abnormality occurrence and DTC) through

the ABS warning light (1) as described.

• When ignition switch is turned ON, ABS warning light

lights for 2 seconds to check its circuit.

• When no abnormality has been detected (the system

is in good condition), ABS warning light turns OFF

after 2 seconds.

• When an abnormality in the system is detected, ABS

warning light lights and the area where that

abnormality lies is stored in the memory of EEPROM

in ABS (ESP

®) control module.

1

I5JB0A450001-01

4E-3 ABS:

CAN Communication System Description

S6JB0B4501003

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

ABS communicates control data with each control module as follows.

ABS Transmission Data

ABS Reception Data

Torque request signal

Wheel speed signal

ABS active

ABS indication on

EBD indication on

ABS diagnostic trouble codes

Combination Meter

Transmit

DATA

ABS hydraulic

unit / control module

assembly

ECM

4WD control module

(if equiped)

I5JB0A450002-03

Brake pedal switch active

Receive

DATA

ABS hydraulic unit / control module assembly

ECM

I5JB0A450003-03

ABS: 4E-4

Schematic and Routing Diagram

ABS Schematic

S6JB0B4502001

INPUT

OUTPUT

ABS control module

Wheel speed sensor (LF)

Wheel speed sensor (LR)

Wheel speed sensor (RF)

Battery Voltage

Ignition Voltage

Pump motor

driver (transistor)

Solenoid valve power

supply driver (transistor)

Solenoid valve

driver (transistor)

Hydraulic unit

Pump motor

LF inlet solenoid valve

LF outlet solenoid valve

LR inlet solenoid valve

LR outlet solenoid valve

RF inlet solenoid valve

RF outlet solenoid valve

RR inlet solenoid valve

RR outlet solenoid valve

ABS warning

EBD warning

(Brake warning)

Data link connector

ABS hydraulic unit/control

module assembly

Wheel speed sensor (RR)

Stop lamp switch

3

7

2

6

4

5

8

12

13

ECM

G sensor (4WD model)

21

20

14

15

1

22

17

16

18

19

11

10

9

I6JB0B450001-02

1. ABS (ESP

®) hydraulic unit / control module

assembly

9. Brake light switch

17. Wheel speed sensor (Left-rear)

2. ABS (ESP

®) control module

10. ABS warning light

18. Battery

3. ABS (ESP

®) hydraulic unit

11. EBD warning light (Brake warning light)

19. Ignition switch

4. Solenoid valve power supply driver (transistor)

12. Light driver module

20. G sensor (4WD model)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст