Suzuki Grand Vitara JB627. Manual — part 45

1A-129 Engine General Information and Diagnosis:

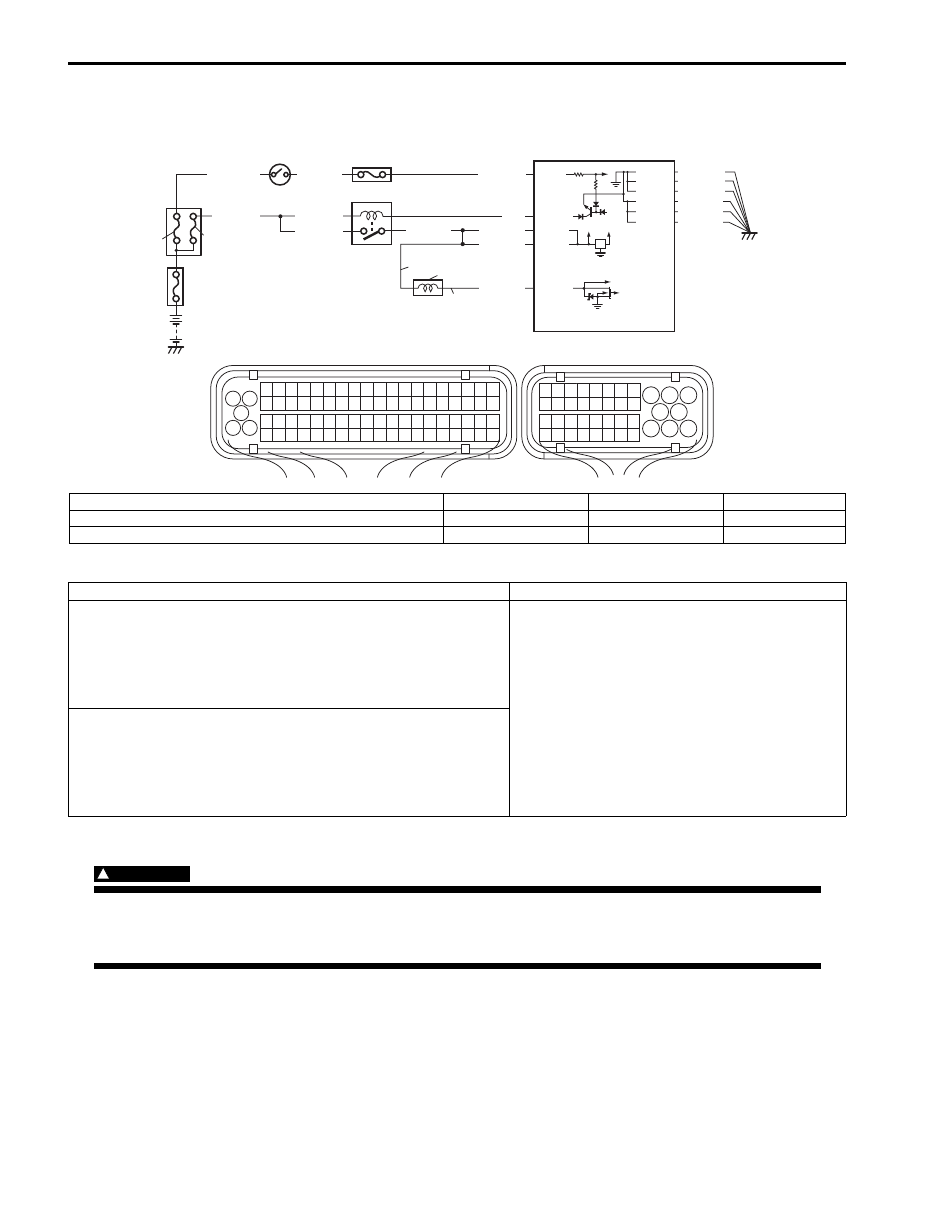

DTC P0444 / P0445: EVAP Emission System Purge Control Valve Circuit Open / Shorted

S6JB0B1104046

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING

!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC by using scan tool if any.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle in 4000 r/min. or less of engine speed for 10 seconds or longer.

5) Stop vehicle and check DTC by using scan tool.

BLU/BLK

BLU/BLK

BLU/BLK

BLK/RED

BLK/RED

BLK/RED

BLU

12V 5V

E23-8

E23-16

E23-2

E23-3

WHT/GRN

C37-59

C37-58

C37-39

C37-73

C37-80

BLK/YEL

BLK/ORN

BLK/ORN

BLK/YEL

BLK/YEL

1

3 2

4

5

6

7

8

9

1110

12

13

14

15

16

17

18

19

20

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

33

34

35

36

37

38

39

40

32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

E23

C37

BLK/ORN

C37-81

BLK/YEL

BLK/WHT

C37-10

GRN/BLK

7

8

4

5

3

2

P

1

C

6

I6JB01110040-03

P: EVAP canister purge valve power supply circuit

2. Main relay

5. Ignition switch

8. “IGN” fuse

C: EVAP canister purge valve control circuit

3. “IG COIL” fuse

6. ECM

1. EVAP canister purge valve

4. Fuse box No.2

7. “FI” fuse

DTC detecting condition

Trouble area

DTC P0444: EVAP Emission System Purge Control Valve

Circuit Open

EVAP canister purge valve control duty (on 48% ON duty or less)

is continuous 240 pulses or more and purge valve circuit voltage is

3.0 V or less during OFF duty pulse condition.

(1 driving cycle detection logic)

• EVAP canister purge valve and its circuit

• ECM

DTC P0445: EVAP Emission System Purge Control Valve

Circuit Shorted

EVAP canister purge valve control duty (on 50% ON duty or less)

is continuous 240 pulses or more and purge valve circuit voltage is

8.4 V or more during OFF duty pulse condition.

(1 driving cycle detection logic)

Engine General Information and Diagnosis: 1A-130

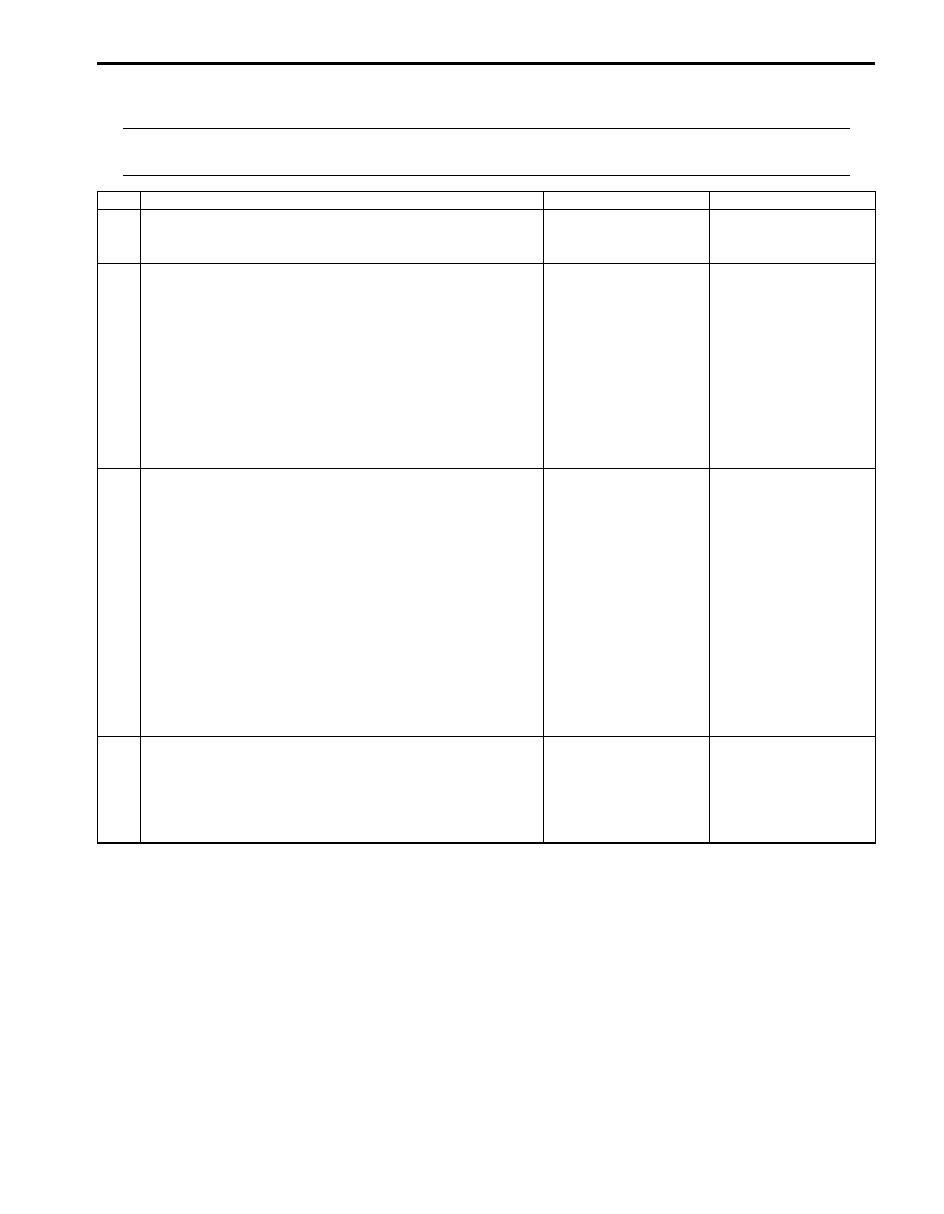

DTC Troubleshooting

NOTE

Before this trouble shooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step

Action

Yes

No

1

Was “Engine and Emission Control System Check”

performed?

Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2

EVAP canister purge valve power supply voltage check

1) Disconnect connector from EVAP canister purge valve

with ignition switch turned OFF.

2) Check for proper terminal connection to EVAP canister

purge valve and ECM connectors.

3) If connections are OK, check that EVAP canister purge

valve power supply voltage is battery voltage between

EVAP canister purge valve connector and vehicle body

ground with ignition switch turned ON.

Is it in good condition?

Go to Step 3.

Repair or replace EVAP

canister purge valve

power supply circuit.

3

Wire harness check

1) Disconnect connector from ECM with ignition switch

turned OFF.

2) Check that EVAP canister purge valve circuit is as

follows.

• Wiring harness resistance of EVAP canister purge

valve control circuit is less than 3

Ω.

• Insulation resistance of EVAP canister purge valve

control circuit is infinity between EVAP canister purge

valve connector and vehicle body ground.

• Circuit voltage of EVAP canister purge valve control

circuit is 0 – 1 V with ignition switch turned ON.

Are they in good condition?

Go to Step 4.

Repair or replace

defective wire harness.

4

EVAP canister purge valve check

1) Check EVAP canister purge valve coil resistance

referring to “EVAP Canister Purge Valve Inspection in

Section 1B”.

Is it in good condition?

Substitute a known

good ECM and recheck.

Replace EVAP canister

purge valve.

1A-131 Engine General Information and Diagnosis:

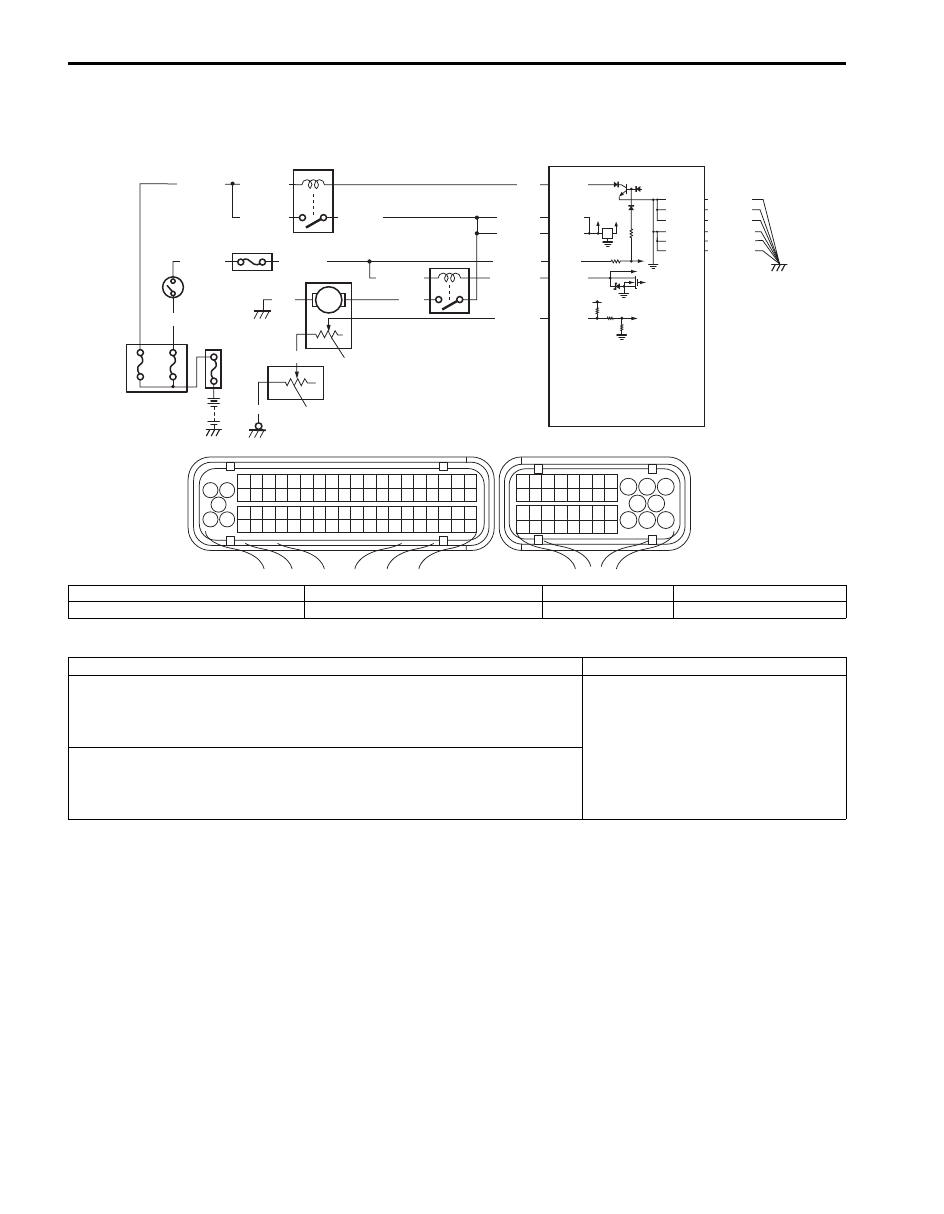

DTC P0462 / P0463: Fuel Level Sensor Circuit Low / High

S6JB0B1104047

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC by using scan tool if any.

3) Start engine and run it for 10 sec.

4) Check DTC and pending DTC by using scan tool.

1

3 2

4

5

6

7

8

9

1110

12

13

14

15

16

17

18

19

20

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

33

34

35

36

37

38

39

40

32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

E23

C37

12 V

E23-28

YEL/RED

BLK/YEL

YEL/GRN

BLU/BLK

WHT/GRN

BLU/BLK

BLU/BLK

BLK/RED

BLK/RED

BLK/RED

BLU

12V 5V

E23-8

E23-24

E23-16

E23-2

E23-3

WHT/GRN

C37-59

C37-58

C37-39

C37-73

C37-80

BLK/YEL

BLK/ORN

BLK/ORN

BLK/YEL

BLK/YEL

BLK/ORN

C37-81

BLK/YEL

BLK/WHT

BLK/WHT

BLK/WHT

BLK

PNK

5

6

7

1

2

3

4

I6JB01110060-03

1. Fuel pump assembly

3. Main fuel level sensor

5. ECM

7. Fuel pump relay

2. Fuel pump

4. Sub fuel level sensor

6. Main relay

DTC detecting condition

Trouble area

DTC P0462: Fuel Level Sensor Circuit Low Input

Circuit voltage of fuel level sensor is less than voltage specification calculated

from battery voltage.

(2 driving cycle detection logic)

• Fuel level sensor and/or its circuit

• ECM

DTC P0463: Fuel Level Sensor Circuit High Input

Circuit voltage of fuel level sensor is more than voltage specification

calculated from battery voltage.

(2 driving cycle detection logic)

Engine General Information and Diagnosis: 1A-132

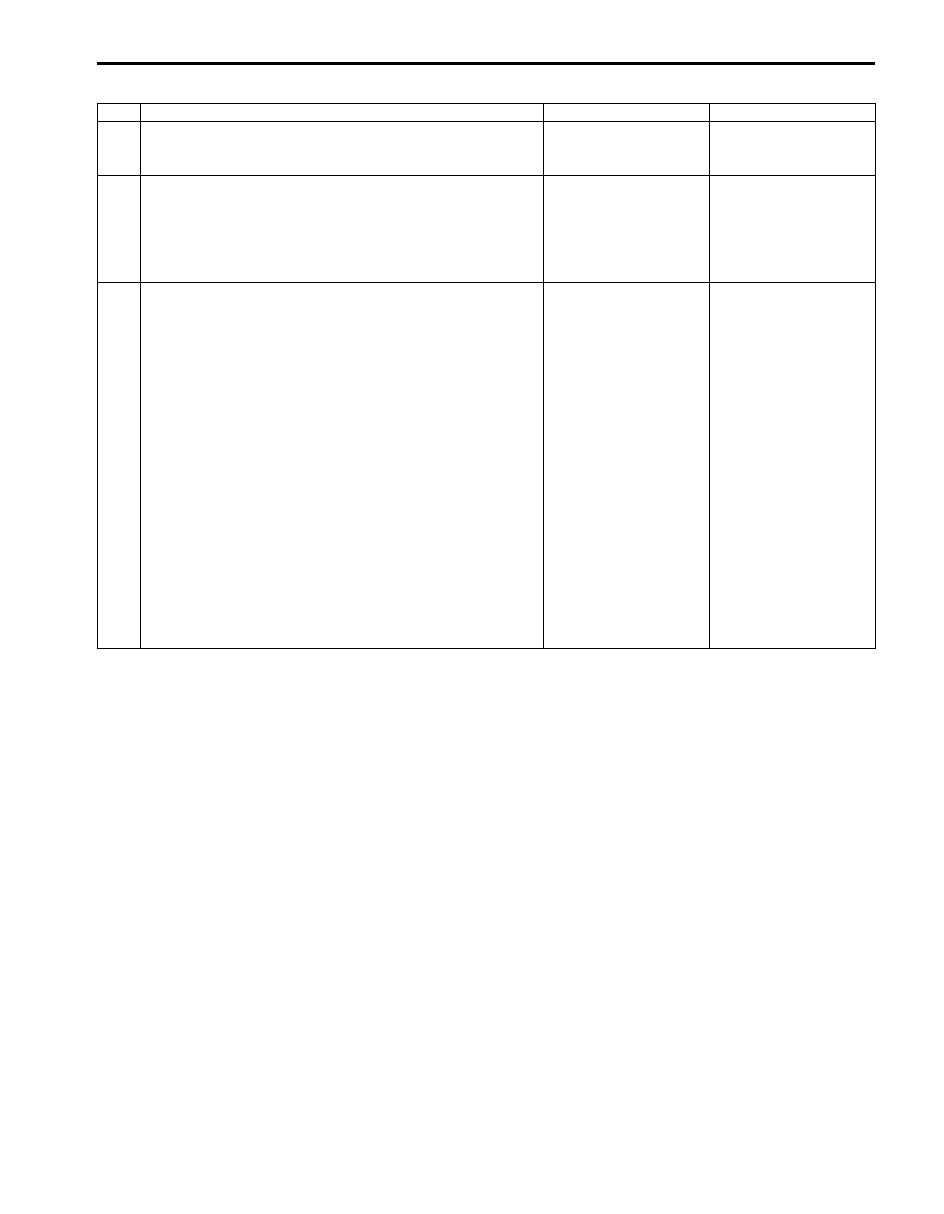

DTC Troubleshooting

Step

Action

Yes

No

1

Was “Engine and Emission Control System Check”

performed?

Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2

Fuel level sensor performance check

1) Check fuel level sensor (main and sub) for performance

referring to “Fuel Level Sensor Inspection in Section

9C”.

Is it in good condition?

Go to Step 3.

Replace main and/or

sub fuel level sensor.

3

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper terminal connection to fuel level sensor

(main and sub) and ECM connectors.

3) If connections are OK, check that fuel level sensor circuit

is as follows.

• Wiring harness resistance of fuel level sensor (main

and sub) circuit is less than 3

Ω.

• Insulation resistance of fuel level sensor (main and

sub) circuit is infinity between fuel level sensor (main

and sub) connector and vehicle body ground.

• Insulation resistance of wire harness is infinity

between fuel level sensor (main and sub) terminal and

each other terminal at fuel level sensor connector.

• Circuit voltage of fuel level sensor (main and sub)

circuit is 0 – 1 V with ignition switch turned ON.

Are they in good condition?

Substitute a known

good ECM and recheck.

Repair or replace

defective wire harness.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст