Suzuki: Engine K6A-YH6. Manual — part 16

7-18

REPAIR

7

Installation

Figure 7-44

1.

Clean cam cover and cylinder head gasket surfaces.

2.

Install new gasket (1) to cam cover (2).

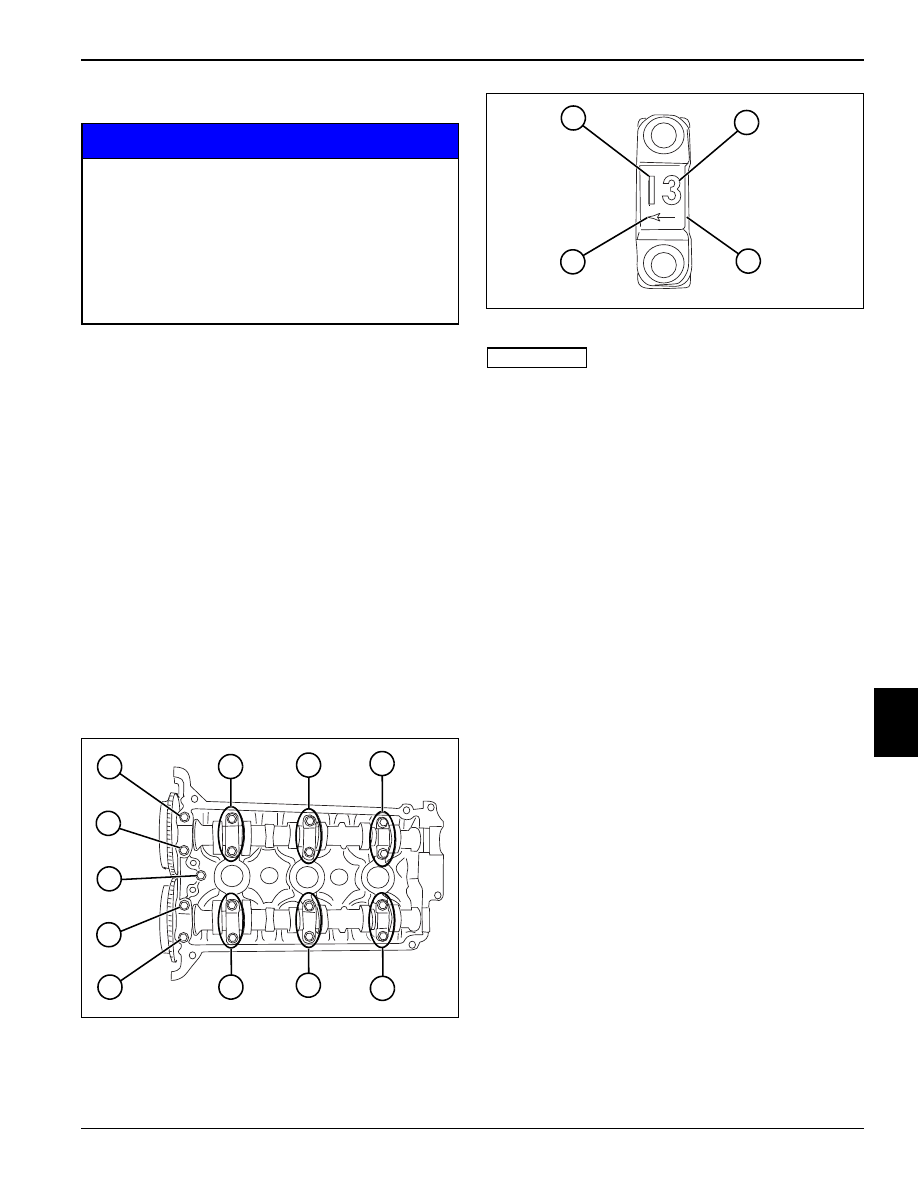

Figure 7-45

3.

Apply Three Bond™ 1215 to locations (3, 4, 5, and 6)

as shown.

4.

Install cam cover and cap screws. (See “Cam Cover

Torque Sequence” on page 7-18.)

Cam Cover Torque Sequence

Figure 7-46

1.

Tighten cap screws (1 through 6) in sequential order

as shown. Torque cam cover cap screws at

increments of 32 lb-in. (3.6 N•m), until specification is

reached.

Cam Cover Cap Screws Torque: 96 lb-in. (11 N•m)

2.

Install PCV valve. (See “PCV Valve” on page 7-4.)

3.

Install spark plugs. (See “Spark Plugs” on page 7-8.)

4.

Install ignition coils. (See “Ignition Coils” on

page 7-8.)

Required Materials

Three Bond™ 1215 (Suzuki PN 99000-1080-15A) or

equivalent

TN0725

1

2

TN0366

3

6

4

5

TN0554

3

4

5

6

1

2

REPAIR

7-19

7

Camshafts

NOTICE

Removal

1.

Remove ignition coils. (See “Ignition Coils” on

page 7-8.)

2.

Remove spark plugs. (See “Spark Plugs” on

page 7-8.)

3.

Remove PCV valve. (See “PCV Valve” on page 7-4.)

4.

Remove cam cover. (See “Cam Cover” on

page 7-17.)

5.

Remove crankshaft pulley. (See “Crankshaft Pulley”

on page 7-37.)

6.

Remove idler pulley. (See “Idler Pulley” on

page 7-38.)

7.

Remove oil pan. (See “Oil Pan” on page 7-30.)

8.

Remove front cover. (See “Front Cover” on

page 7-12.)

9.

Remove timing chain. (See “Timing Chain” on

page 7-14.)

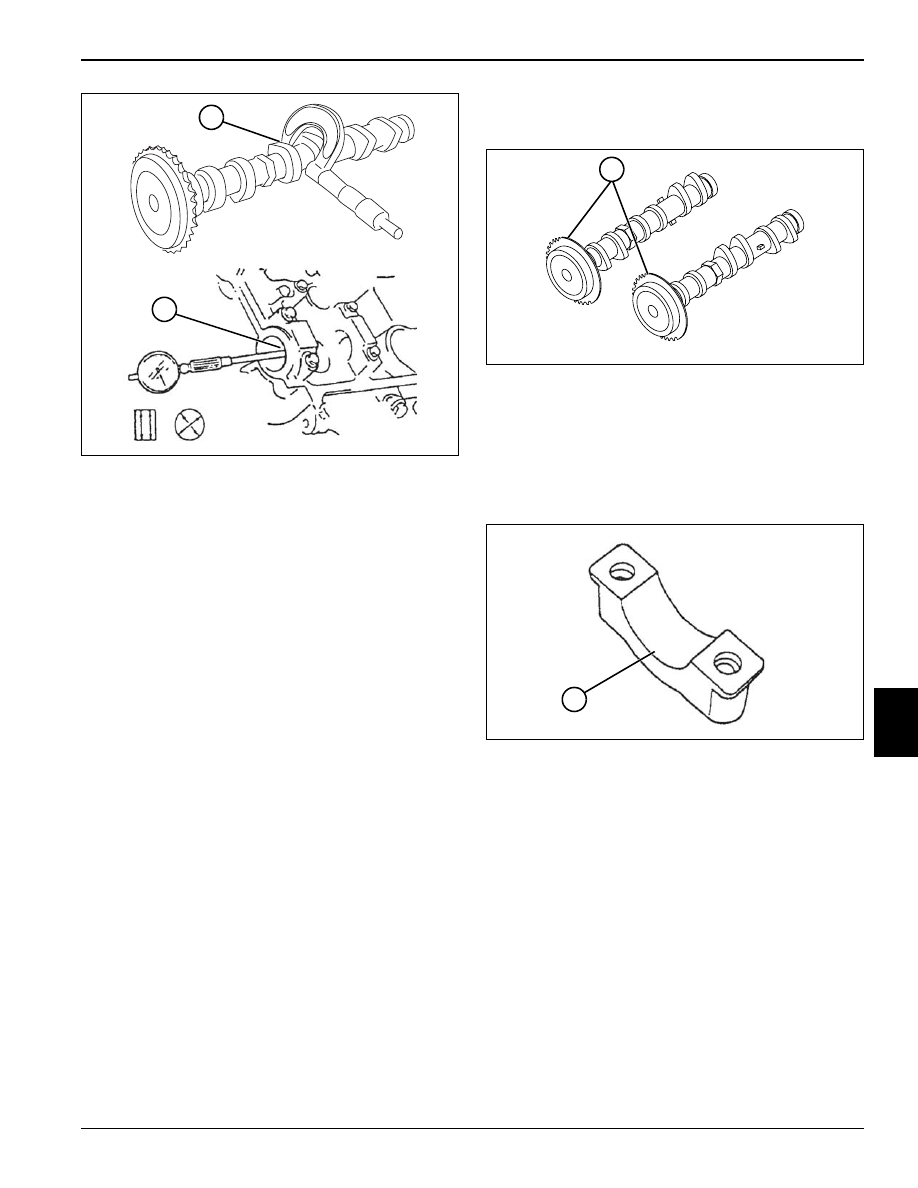

Figure 7-47

Figure 7-48

IMPORTANT

Mark the camshaft timing gear faces to easily

distinguish between intake and exhaust.

Take note of camshaft housings, location and

orientation to aid in assembly.

10. Loosen the camshaft housing bolts in sequence as

shown in figure 7-47.

11. Remove camshaft housings (14). Note the locations

and orientation using the stamped markings.

• The “I” or “E” markings (12) refer to intake or exhaust

side camshaft.

• The numerical markings (13) refer to the cylinder the

housing corresponds with. The cylinders are

numbered 1—3, starting from the timing chain

moving toward the rear of engine.

• The arrow marking (15) points toward the timing

chain (front of engine).

12. Remove the intake and exhaust camshafts. Inspect

camshafts for signs of wear or damage. Replace as

needed.

Remove camshaft housing cap screws using

illustrated sequence. Incorrect removal can result

in damaged camshafts.

When removing camshaft housings, camshafts,

shims, and tappets, be sure to note location and

orientation of all parts to aid in assembly.

Failure to install parts properly can result in

engine damage and failure.

TN0409

1

2

3

4

5

6

7

8

9

10

11

TN0416

13

14

15

12

7-20

REPAIR

7

Inspection

See Figures 7-49 through 7-52.

IMPORTANT

Tappets and shims must be removed before

measuring camshaft bearing clearance.

Be sure to note location and shim thickness of each

tappet.

Figure 7-49

1.

Remove twelve tappets with shims. Be sure to note

location and shim thickness of each tappet.

2.

Clean the camshaft journals and housings free of all

oil.

3.

Tear off a piece of Plastigage as long as the full

bearing width. (Tear through both the envelope and

plastic thread at the same time.) Lay the piece of

Plastigage across the full width of the lower bearing

shell about 1/4 in. (6.3 mm) off center.

Figure 7-50

IMPORTANT

Do not turn camshaft during oil clearance

measurement process.

Be sure dowel pins are properly aligned before

installing camshaft housings.

4.

Install the camshaft housings. Apply engine oil to cap

screws and tighten using sequence (1 through 11) at

increments of 32 lb-in. (3.6 N•m) until specification is

reached. Do not turn camshaft during measurement

process.

Cam Housing Cap Screw Torque: 97 lb-in. (11 N•m)

Figure 7-51

5.

Remove cap screws and camshaft housings in

opposite sequence of installation. The flattened

Plastigage (12) will adhere to either the bearing shell

or the camshaft.

6.

Using the supplied scale (13), take the measurement

at the widest point of gauging plastic.

Camshaft Oil Clearance Standard: 0.002—0.003 in.

(0.045—0.087 mm)

Camshaft Oil Clearance Limit: 0.004 in. (0.10 mm)

Required Tools and Materials

Plastigage™ Clearance Indicator

Micrometer

Inside Bore Gauge

TN0414

TN0409

11

10

9

8

7

6

5

4

3

2

1

TN0410

12

13

REPAIR

7-21

7

Figure 7-52

7.

If the oil clearance exceeds the limit, remove the

camshaft and retighten the camshaft housing to

specification.

Cam Housing Cap Screw Torque: 97 lb-in. (11 N•m)

8.

Using a micrometer and bore gauge, measure the

camshaft journal outside diameter (14) and the

journal bore diameter (15).

If the measurement is beyond the standard range,

either the camshaft or cylinder head must be

replaced.

Camshaft Journal Outside Diameter: 0.903—0.904

in. (22.934—22.955 mm)

Camshaft Journal Inside Diameter: 0.905—0.906 in.

(23.000—23.021 mm)

Cam Timing Sprocket

Figure 7-53

Inspect the camshaft timing sprockets (1) for wear and

damage. If any abnormal condition is noted, replace the

sprocket.

Camshaft Housing Bearing Face

Figure 7-54

Inspect the camshaft housing bearing face for pitting,

melting, and seizure. If any abnormal condition is found,

replace the cylinder head.

TN0411

14

15

TN0505

1

TN0408

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст