Suzuki: Engine K6A-YH6. Manual — part 17

7-22

REPAIR

7

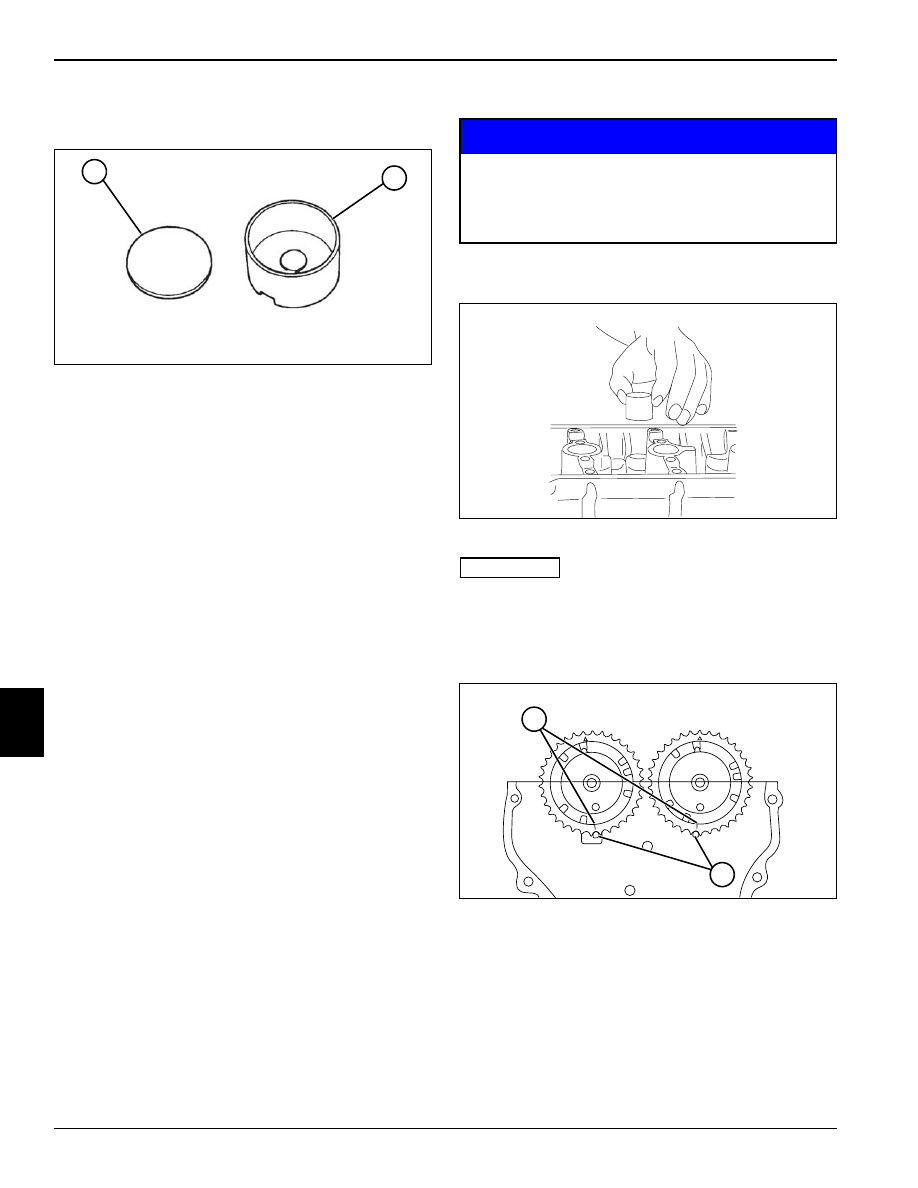

Tappets and Shims

Figure 7-55

1.

Inspect shim (1) and tappet (2) for any signs of wear.

If any abnormal condition is found, replace as

needed.

2.

Measure tappet outside diameter and tappet bore

inside diameter. Calculate clearance and compare to

specification. Replace as needed.

Tappet and Bore Clearance: 0.0009—0.0024 in.

(0.025—0.062 mm)

Tappet and Bore Clearance Limit: 0.003 in.

(0.10 mm)

Installation

NOTICE

See Figures 7-56 through 7-59.

Figure 7-56

IMPORTANT

Be sure tappets and shims are installed in correct

location.

1.

Apply engine oil to all surfaces of tappets and shims,

and install in proper locations.

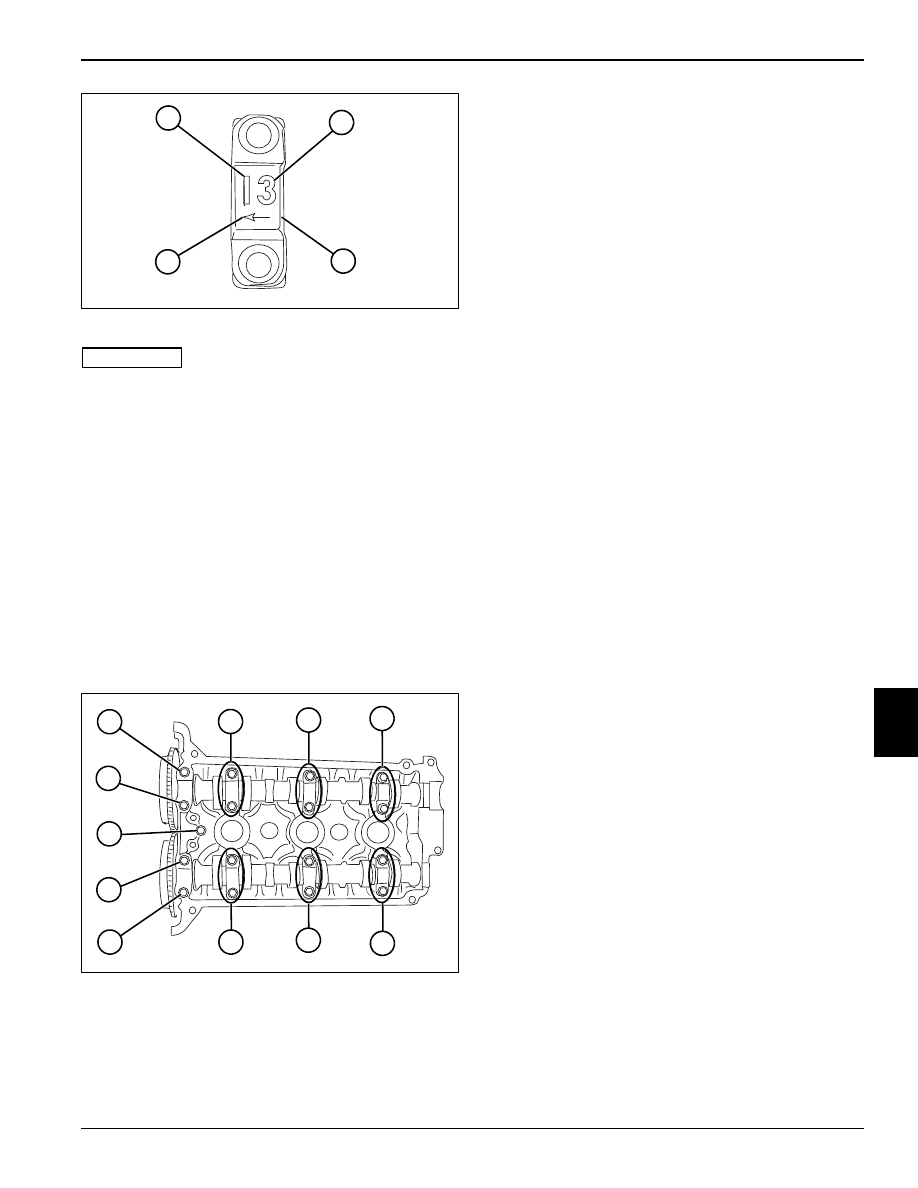

Figure 7-57

2.

Apply engine oil to camshaft journals, lobes, and

timing sprockets. Align timing gear dots (1) with the

index marks (2) on the cylinder head.

TN0412

1

2

Be sure to install tappets, shims, camshafts, and

camshaft housings at proper locations.

Failure to install parts properly can result in

engine damage and failure.

TN0414

TN0415

1

2

REPAIR

7-23

7

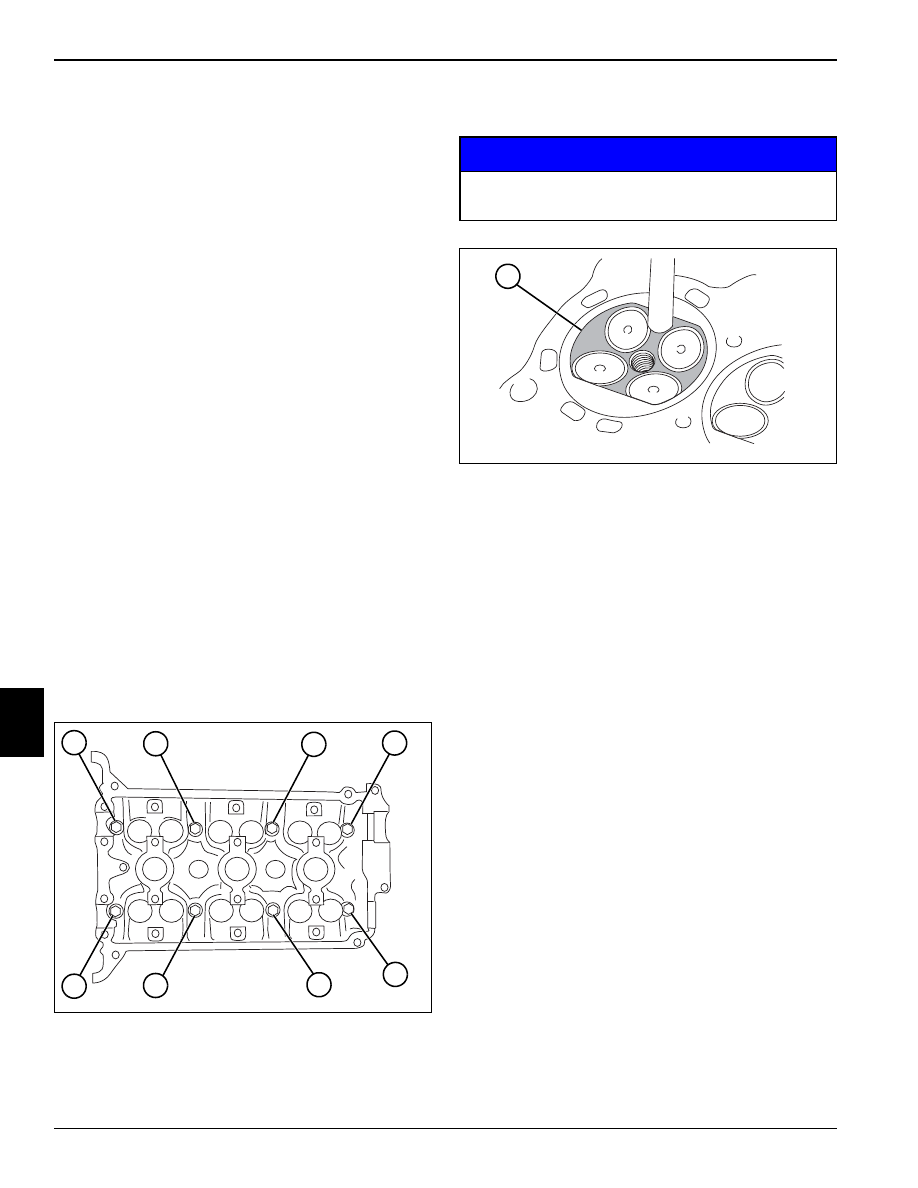

Figure 7-58

IMPORTANT

Be sure camshaft housings are properly located.

Be sure dowel pins are properly aligned before

installing camshaft housings.

3.

Check that the camshaft housing markings (3, 4, and

6) are located properly.

• The “I” or “E” markings (3) refer to intake or exhaust

side camshaft.

• The numerical markings (4) refer to the cylinder the

housing corresponds with. The cylinders are

numbered 1—3, starting from the timing chain

moving toward the rear of engine.

• The arrow marking (6) points toward the timing chain

(front of engine).

4.

Apply engine oil to cap screws and hand tighten the

camshaft housings (5) to the cylinder head.

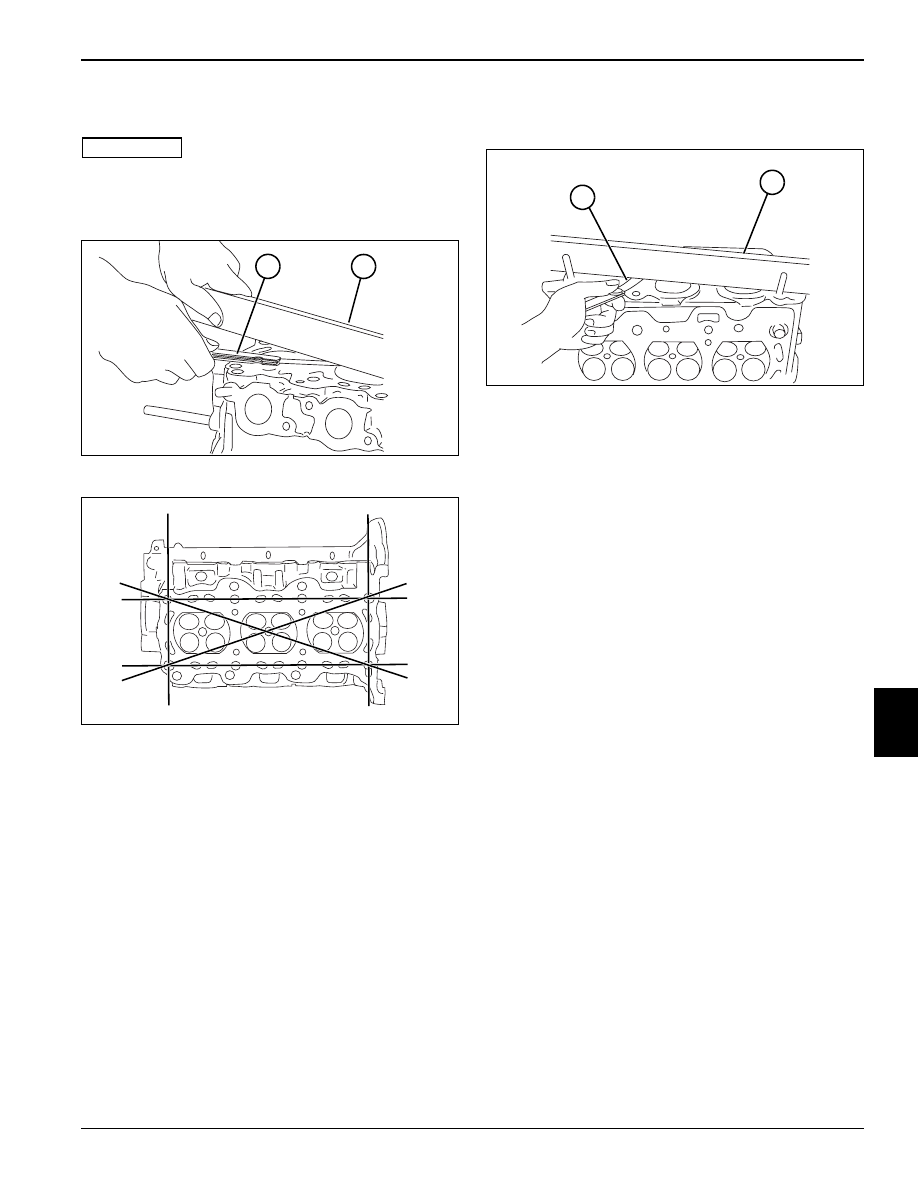

Figure 7-59

5.

Tighten camshaft housings, using sequence

(1 through 11) at increments of 32 lb-in. (3.6 N•m)

until specification is reached.

Camshaft Housing Torque: 97 lb-in. (11 N•m)

6.

Check valve clearance. (See “Valve Clearance Check

and Adjustment” on page 5-3.)

7.

Install timing chain. (See “Timing Chain” on

page 7-14.)

8.

Install front cover. (See “Front Cover” on page 7-12.)

9.

Install oil pan. (See “Oil Pan” on page 7-30.)

10. Install idler pulley. (See “Idler Pulley” on page 7-38.)

11. Install crankshaft pulley. (See “Crankshaft Pulley” on

12. Install cam cover. (See “Cam Cover” on page 7-17.)

13. Install PCV valve. (See “PCV Valve” on page 7-4.)

14. Install spark plugs. (See “Spark Plugs” on page 7-8.)

15. Install ignition coils. (See “Ignition Coils” on

TN0416

4

5

6

3

TN0409

11

10

9

8

7

6

5

4

3

2

1

7-24

REPAIR

7

Cylinder Head

Removal

1.

Remove throttle body. (See “Throttle Body” on

page 7-4.)

2.

Remove fuel rail and injectors. (See “Injectors” on

page 7-9.)

3.

Remove intake manifold. (See “Intake Manifold” on

page 7-4.)

4.

Remove exhaust manifold. (See “Exhaust Manifold”

on page 7-7.)

5.

Remove ignition coils. (See “Ignition Coils” on

page 7-8.)

6.

Remove spark plugs. (See “Spark Plugs” on

page 7-8.)

7.

Remove PCV valve. (See “PCV Valve” on page 7-4.)

8.

Remove cam cover. (See “Cam Cover” on

page 7-17.)

9.

Remove crankshaft pulley. (See “Crankshaft Pulley”

on page 7-37.)

10. Remove idler pulley. (See “Idler Pulley” on

11. Remove oil pan. (See “Oil Pan” on page 7-30.)

12. Remove front cover. (See “Front Cover” on

13. Remove timing chain. (See “Timing Chain” on

14. Remove camshafts and tappets. (See “Camshafts”

Figure 7-60

15. Loosen cap screws (1 through 8) sequentially as

shown, and remove cylinder head and gasket.

Inspection

NOTICE

Figure 7-61

Remove carbon deposits from the combustion chamber

(1). Check the intake port, exhaust port, combustion

chamber and entire cylinder head mating surface for

cracks.

TN0403

1

2

3

4

5

6

7

8

Do not scratch cylinder head surface when

removing carbon deposits.

TN0404

1

REPAIR

7-25

7

Cylinder Block Mating Face Distortion

IMPORTANT

A distorted cylinder head may cause combustion gas to

leak through the head gasket, resulting in overheating

and reduced power.

Figure 7-62

Figure 7-63

Using a straightedge (2) and a feeler gauge (1), inspect

the mating face for distortion. Place the straightedge

across bolt hole centers at the locations indicated.

Measure any gaps with the feeler gauge. If the

measurement exceeds the limit, repair or replace the

cylinder head.

Cylinder Block/Head Mating Face Distortion Limit:

0.001 in. (0.03 mm)

Intake and Exhaust Manifold Mating Face Distortion

Figure 7-64

Using a straightedge (2) and a feeler gauge (1), inspect

the manifold mating faces for distortion. Place the

straightedge across the mating face, and measure any

gaps with the feeler gauge. If the measurement exceeds

the limit, repair or replace the cylinder head.

Intake and Exhaust Manifold Mating Face Distortion

Limit: 0.000—0.002 in. (0.00—0.05 mm)

TN0405

1

2

TN0406

TN0407

1

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст