Suzuki Grand Vitara JB416 / JB420. Manual — part 79

1C-1 Engine Electrical Devices:

Engine

Engine Electrical Devices

Repair Instructions

Engine Control Module (ECM) Removal and

Installation

S5JB0A1306004

CAUTION

!

As ECM consists of precision parts, be

careful not to expose it to excessive shock.

Removal

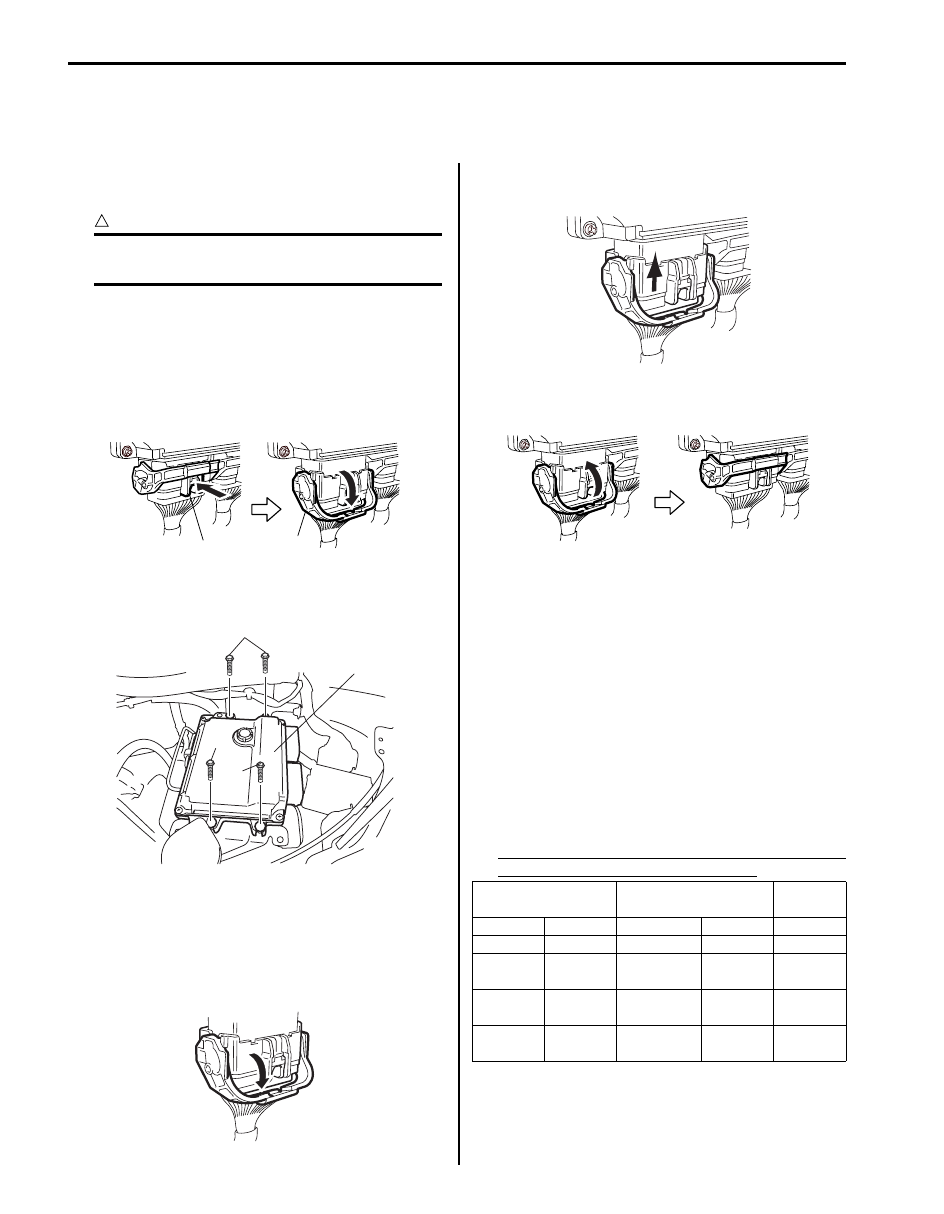

1) Disconnect negative cable at battery.

2) Remove ECM cover.

3) Disconnect connectors from ECM as follows.

a) Push lock (1) to release locking of lock lever (2).

b) Turn lock lever to arrow direction until it stops.

4) Remove ECM (1) from its bracket by removing its

mounting bolts (2).

Installation

Reverse removal procedure noting the following:

• Connect connectors to ECM as follows.

a. Make sure that lock lever of ECM connector is

unlock position.

b. Insert ECM connectors to ECM until it stops with

unlocked lock lever.

c. Lock ECM connectors securely by pulling its lock

lever up.

Manifold Absolute Pressure (MAP) Sensor

Inspection

S5JB0A1306005

1) Disconnect connector from MAP sensor.

2) Remove MAP sensor from intake manifold.

3) Arrange 3 new 1.5 V batteries (2) in series (check

that total voltage is 4.5 – 5.0 V) and connect its

positive terminal to “Vin” terminal of sensor and

negative terminal to “Ground” terminal. Then check

voltage between “Vout” and “Ground”. Also, check if

voltage reduces when vacuum is applied up to 400

mmHg by using vacuum pump (3).

If check result is not satisfactory, replace MAP

sensor (1).

Output voltage (When input voltage is 4.5 – 5.5 V,

ambient temp. 20 – 30

°C, 68 – 86 °F)

1

2

I4RS0A130003-01

1

2

2

2

I5JB0A130012-03

I4RS0B130021-01

Altitude

(Reference)

Barometric pressure

Output

voltage

(ft)

(m)

(mmHg)

(kPa)

(V)

0 – 2000

0 – 610

760 – 707 100 – 94 3.3 – 4.3

2001 –

5000

611 –

1524

Under 707

over 634

94 – 85

3.0 – 4.1

5001 –

8000

1525 –

2438

Under 634

over 567

85 – 76

2.7 – 3.7

8001 –

10000

2439 –

3048

Under 567

over 526

76 – 70

2.5 – 3.3

I4RS0B130022-01

I4RS0A130004-01

Engine Electrical Devices: 1C-2

4) Install MAP sensor securely.

5) Connect MAP sensor connector securely.

Electric Throttle Body Assembly On-Vehicle

Inspection

S5JB0A1306022

WARNING

!

Never touch throttle valve with finger while

ignition switch is turned ON and accelerator

pedal is depressed. Otherwise, injury may

result by pinching the finger between throttle

valve and throttle body housing.

CAUTION

!

• Do not disassemble electric throttle body

assembly.

• Do not expose electric throttle body

assembly to excessive shock like a

dropping it. If electric throttle body

assembly has been exposed to excessive

shock, it should be replaced.

• Be careful not to accrete a foreign material

(like dust and/or metallic particle) to the

throttle body housing and/or throttle valve.

Otherwise, the throttle body assembly is

breaking down by throttle valve accretion.

• Do not apply excessive moving force to

throttle valve for throttle valve operation

check and/or TP sensor performance

check.

Otherwise, the throttle body assembly is

breaking down by damaging the internal

resinous gear of throttle valve actuator.

Throttle Valve Visual Check

1) Remove air cleaner outlet hose (for J20 engine) or

air intake pipe (for M16 engine).

2) Check that there isn’t any foreign matter caught

between throttle valve and throttle body housing. If

there is, take it out after removing throttle body

referring to “Electric Throttle Body Assembly

Removal and Installation: For J20 Engine in Section

1D” or “Electric Throttle Body Assembly Removal

and Installation: For M16A Engine with VVT in

Section 1D”and clean inside of throttle body

thoroughly.

Throttle Valve Operation Check

1) Remove air cleaner outlet hose (for J20 engine) or

air intake pipe (for M16 engine).

2) Turn OFF ignition switch.

3) Move throttle valve with finger to its full open position

and check that it moves smoothly.

4) Move throttle valve with finger to its completely

closed position and check that it moves smoothly.

5) Take off finger from throttle valve (1) which is at full

open position and check that it moves smoothly by

its return spring and open spring force back to

default position (position where throttle valve is open

by 7

° (2) from completely closed position).

6) Take off finger from throttle valve (1) which is at

completely closed position and check that it moves

smoothly by its return spring and open spring force

back to default position.

If check result is not satisfactory, replace electric

throttle body assembly.

4. Voltmeter

I3RM0A130005-01

I5JB0A130013-01

1

2

I5JB0A130035-01

1C-3 Engine Electrical Devices:

Electric Throttle Body Assembly Operation Check

1) Remove air cleaner outlet hose (for J20 engine) or

air intake pipe (for M16 engine).

2) Turn ON ignition switch.

3) Depress accelerator pedal gradually and check that

throttle valve moves smoothly until it opens fully.

4) Release accelerator pedal depressed in Step 3) and

check that throttle valve (1) moves back to default

position (position where throttle valve is open by 7

°

(2) from its completely closed position).

If check result is satisfactory, electric throttle body

system is in good condition. If check result is not

satisfactory, proceed to next step.

5) Perform “Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection”, “Throttle Actuator

(Motor) Check” and “Throttle Position Sensor

Performance Check”.

If check results are not satisfactory, replace electric

throttle body assembly.

If check results are satisfactory, wire circuit and/or

ECM are faulty.

Throttle Actuator (Motor) Check

1) Turn OFF ignition switch.

2) Disconnect connector from electric throttle body

assembly.

3) Measure resistance between “M1” terminal (1) and

“M2” terminal (2) of electric throttle body assembly.

If measured resistance is out of specified value,

replace electric throttle body assembly.

Throttle actuator (motor) resistance

0.3 – 100

Ω at 20 °C, 68 °F

Throttle Position Sensor Performance Check

1) Remove air cleaner outlet hose (for J20 engine) or

air intake pipe (for M16 engine).

2) Turn OFF ignition switch.

3) Disconnect connector from electric throttle body

assembly.

4) Check throttle position sensor (main and sub) output

voltage as following steps.

a) For throttle position sensor (main), arrange 3

new 1.5 V batteries (1) in series (check that total

voltage is 4.5 – 5.0 V) and connect its positive

terminal to “Vin” terminal (2) and negative

terminal to “Ground” terminal (3) of sensor. Then

using voltmeter, connect positive terminal to

“Vout 1” terminal (4) of sensor and negative

terminal to battery.

[A]: For J20 engine

[B]: For M16 engine

1

2

I5JB0A130035-01

1

2

1

2

[B]

[A]

I5JB0A130014-01

[A]: For J20 engine

[B]: For M16 engine

1

4

2

3

1

4

2

3

[A]

[B]

I5JB0A130015-02

Engine Electrical Devices: 1C-4

b) For throttle position sensor (sub), arrange 3 new

1.5 V batteries (1) in series (check that total

voltage is 4.5 – 5.0 V) and connect its positive

terminal to “Vin” terminal (2) and negative

terminal to “Ground” terminal (3) of sensor. Then

using voltmeter, connect positive terminal to

“Vout 2” terminal (4) of sensor and negative

terminal to battery.

c) Measure output voltage variation while throttle

valve is opened and closed as following

specification.

If sensor voltage is out of specified value and linear

variation as the following graph, replace electric throttle

body assembly.

Throttle position sensor output voltage

Throttle position sensor (main) [A]: 0.45 – 4.88 V,

varying according to throttle valve opening by finger

(Voltage should vary by 0.04 V for each 1

° valve

opening)

Throttle position sensor (sub) [B]: 1.33 – 5.007 V,

varying according to throttle valve opening by finger

(Voltage should vary by about 0.032 V for each 1

°

valve opening)

Electric Throttle Body System Calibration

S5JB0A1306023

NOTE

If the service described under the

“Precautions of Electric Throttle Body

System Calibration in Section 1A” is

performed, calibrate electric throttle body

system as follows.

1) If electric throttle body assembly and/or accelerator

pedal position (APP) sensor assembly are replaced,

perform following steps.

a) Disconnect negative cable at battery for 20

seconds or more for the purpose of clearing

calibration data of closed throttle position from

memory in ECM.

b) Connect negative cable to battery.

2) Keep ignition switch at ON position for 5 seconds or

more without running engine.

[A]: For J20 engine

[B]: For M16 engine

1

3

2

4

1

3

2

4

[A]

[B]

I5JB0A130016-02

[C]: Throttle position sensor (main) output voltage

[D]: Throttle position sensor (sub) output voltage

[E]: Throttle valve opening

[F]: Position where throttle valve is open by 7

° from completely closed

position (default position)

[G]: Angle obtained when accelerator pedal is depressed fully (84

°)

[H]: Angle obtained when throttle valve is fully opened with finger (96

°)

[B]

[A]

[D]

(V)

[C]

(V)

[F]

[G]

[E]

0.45 - 0.75

0.724 - 1.036

3.675 - 4.245

4.000 - 4.880

1.33 - 1.63

1.604 - 1.916

3.883 - 4.453

4.097 - 5.007

[H]

[F]

[G]

[H]

I5JB0A130017-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст