Suzuki Grand Vitara JB416 / JB420. Manual — part 88

1D-20 Engine Mechanical: For M16A Engine with VVT

Installation

1) Clean sealing surface on timing chain cover, cylinder

block and cylinder head.

Remove oil, old sealant and dust from sealing

surface.

2) Install oil seal (1) to timing chain cover, if removed.

NOTE

When installing new oil seal, press fit to

timing chain cover (2) by using special tool

(bearing installer) as shown in the figure.

Drive in dimension

“a”: 1.5 mm (0.06 in.)

Special tool

(A): 09913–75810

3) Install oil control valve to timing chain cover referring

to “Oil Control Valve Removal and Installation: For

M16A Engine with VVT”.

4) Apply sealant “A” to mating surface of cylinder and

cylinder head and “B” to mating surface of timing

chain cover as shown in the figure.

“A”: Water tight sealant 99000–31140 (SUZUKI

Bond No.1207B)

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for timing chain cover

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

5) Apply engine oil to oil seal lip, then install timing

chain cover (1). Tighten bolts and nut to specified

torque.

NOTE

Before installing timing chain cover, check

that pin is securely fitted.

Tightening torque

Timing chain cover bolt and nut (a): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

6) Apply engine oil to new O-rings and install them to

water outlet pipe (2).

7) Install water outlet pipe (2) to timing chain cover (1).

8) Install new O-ring (1) to oil gallery pipes No.2 (2) and

No.3 (3).

I2RH0B140058-01

I5RS0D140018-01

I5JB0A141023-02

Engine Mechanical: For M16A Engine with VVT 1D-21

9) Install oil gallery pipes No.2 and No.3 to cylinder

head (4) and timing chain cover (5).

Tighten bolts to specified torque.

Tightening torque

Oil gallery pipe No.2 and No.3 bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft)

10) Install water pump pulley.

11) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation: For M16A Engine

with VVT in Section 1E”.

12) Install cylinder head cover referring to “Cylinder

Head Cover Removal and Installation: For M16A

Engine with VVT”.

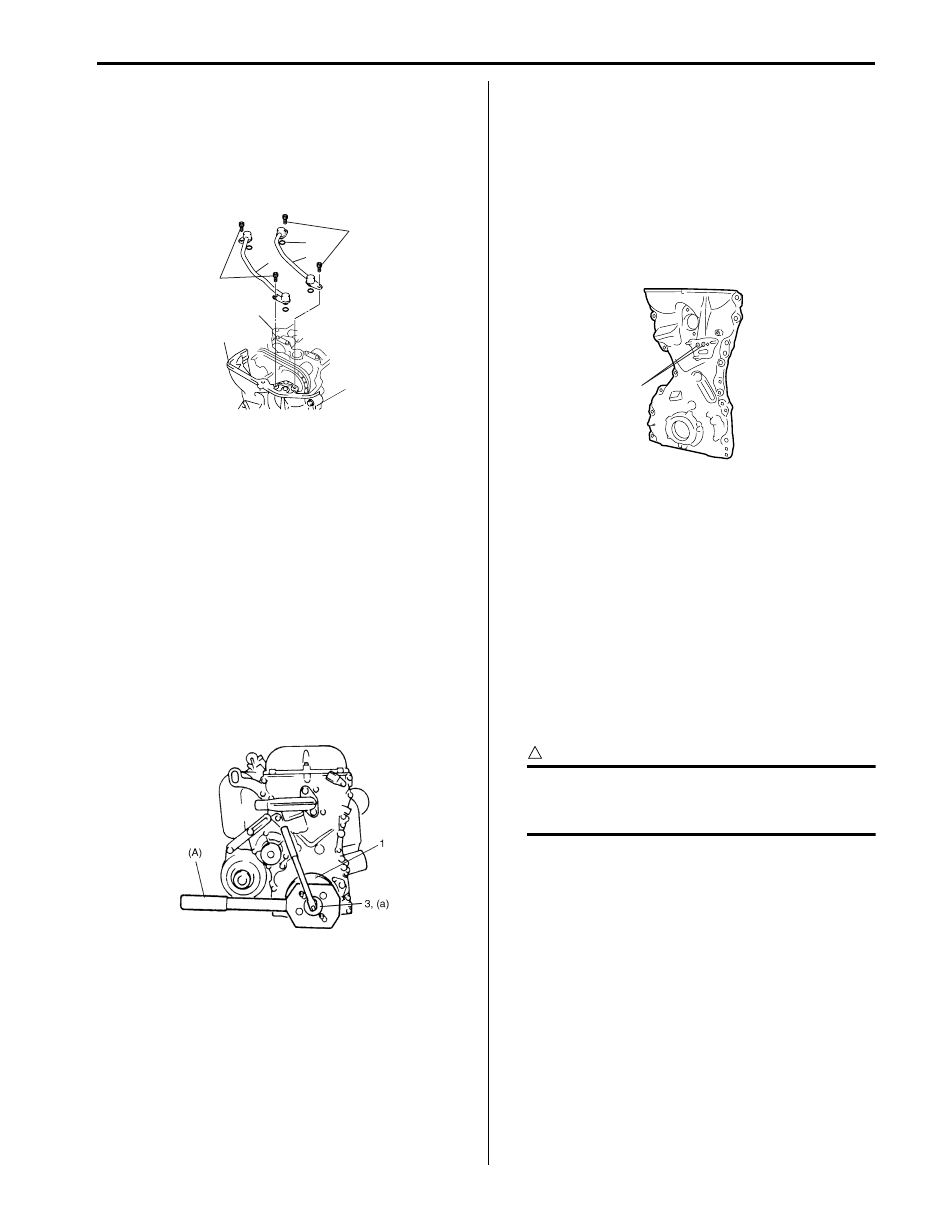

13) Install crankshaft pulley (1). Tighten bolt (2) to

specified torque. To lock crankshaft pulley, use

special tool with it as shown in the figure.

Special tool

(A): 09917–68221

Tightening torque

Crankshaft pulley bolt (a): 150 N·m (15.0 kgf-m,

108.5 lb-ft)

14) Install water pump and generator drive belt referring

to “Water Pump and Generator Drive Belt Removal

and Installation (For M16 Engine) in Section 1J”.

15) Install P/S pump and A/C compressor drive belt

referring to “P/S Pump and A/C Compressor (If

Equipped) Drive Belt Removal and Installation for

M16 Engine Model in Section 6C”.

16) Install engine assembly to vehicle referring to

“Engine Assembly Removal and Installation: For

M16A Engine with VVT”.

Timing Chain Cover Inspection

S5JB0A1416016

Oil Seal

Check oil seal lip for fault or other damage. Replace as

necessary.

Timing Chain Cover

Inspect strainer (1) of oil passage for driving intake cam

timing sprocket assembly (VVT actuator).

If clog or foreign matter exists, clean strainer.

Oil Control Valve Removal and Installation

S5JB0A1416043

Removal

1) Drain engine oil referring to “Engine Oil and Filter

2) Remove P/S pump and A/C compressor drive belt

referring to “P/S Pump and A/C Compressor (If

Equipped) Drive Belt Removal and Installation for

M16 Engine Model in Section 6C”.

3) With hose connected, detach P/S pump from its

bracket referring to “P/S Pump Removal and

Installation for M16 Engine Model in Section 6C”.

CAUTION

!

Suspend removed P/S pump at a place where

no damage will be caused during removal

and installation of engine assembly.

4) Remove P/S pump bracket.

5) Remove oil gallery pipe No.1 (1) and oil control valve

(2) from timing chain cover (3).

(a)

(a)

1

2

3

4

5

I3RH0B140027-01

I5JB0A141024-01

1

I3RH0B140028-01

1D-22 Engine Mechanical: For M16A Engine with VVT

Installation

1) Install new O-ring (4) to oil control valve.

2) Install oil control valve to timing chain cover.

Tighten nuts to specification.

Tightening torque

Oil control valve mounting nut (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

3) Install oil gallery pipe No.1 with new copper washers

(5) to timing chain cover.

Tighten bolts to specification.

Tightening torque

Oil gallery pipe No.1 bolt (b): 30 N·m (3.0 kgf-m,

21.5 lb-ft)

4) Install P/S pump bracket.

5) Install P/S pump to its bracket referring to “P/S Pump

Removal and Installation for M16 Engine Model in

Section 6C”.

6) Install P/S pump and A/C compressor drive belt

referring to “P/S Pump and A/C Compressor (If

Equipped) Drive Belt Removal and Installation for

M16 Engine Model in Section 6C”.

7) Adjust P/S pump and A/C compressor drive belt

tension referring to “P/S Pump and A/C Compressor

(If Equipped) Drive Belt Inspection and Adjustment

for M16 Engine Model in Section 6C”.

8) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

Oil Control Valve Inspection

S5JB0A1416044

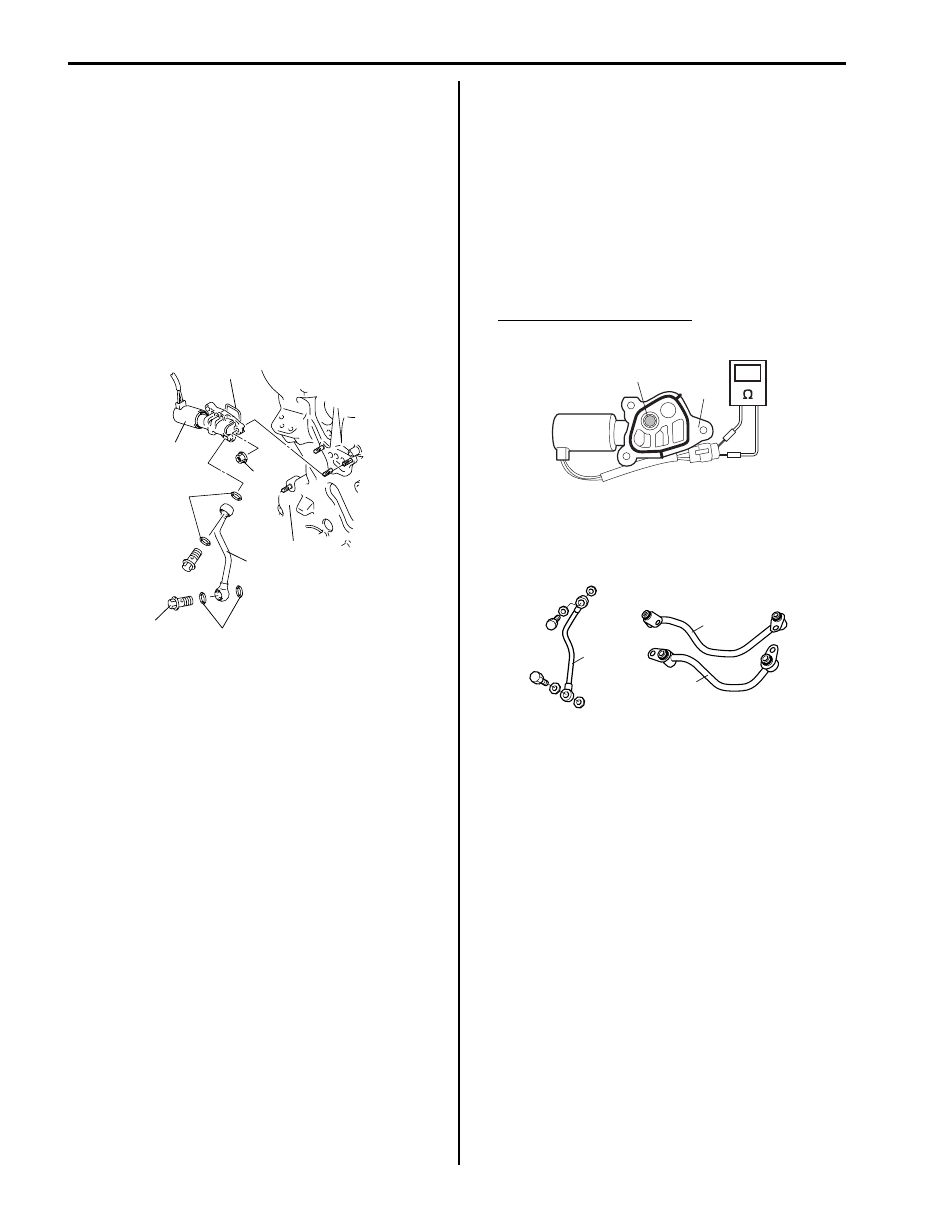

Oil Control Valve

1) Inspect strainer (1) and mating surface (2) of oil

control valve for clog or damage. Clean oil control

valve if clog or foreign matter is present on strainer

or mating surface of oil control valve.

Replace oil control valve if its mating surface is

damaged.

2) Check resistance between terminals of oil control

valve.

Oil control valve resistance

6.7 – 7.7

Ω (at 20 °C (68 °F))

Oil Gallery Pipe

Inspect oil gallery pipe No.1 (1), No.2 (2) and No.3 (3).

Replace if crack, deformation or clog exists.

1

5

(b)

3

(a)

2

4

5

I3RM0A140027-01

1

2

I3RM0A140028-01

1

3

2

I3RH0B140030-01

Engine Mechanical: For M16A Engine with VVT 1D-23

Timing Chain and Chain Tensioner Components

S5JB0A1416017

Timing Chain and Chain Tensioner Removal

and Installation

S5JB0A1416018

Removal

CAUTION

!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than its allowable turning range

described in “Installation”.

If turned, interference may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Remove timing chain cover referring to “Timing

Chain Cover Removal and Installation: For M16A

Engine with VVT”.

2) By turning crankshaft, align both intake and exhaust

camshaft timing sprocket marks (1) with notches (2)

of cylinder head respectively and align crankshaft

sprocket key (3) with notch of cylinder block (4).

3) Remove timing chain tensioner adjuster assembly

(5).

4) Remove timing chain tensioner (6).

5) Remove timing chain No.1 guide (7).

6) Remove timing chain (8) with crankshaft timing

sprocket (9).

I5RS0D140019-01

1. Crankshaft timing sprocket

5. Timing chain tensioner adjuster assembly

: 25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

2. Timing chain

: Apply engine oil.

6. Chain tensioner adjuster mounting bolt

: 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

3. Timing chain No.1 guide

: Apply engine oil to sliding surface.

7. Timing chain tensioner bolt

4. Timing chain tensioner

: Apply engine oil to sliding surface.

8. Timing chain No.1 guide bolt

3

4

1

1

2

5

6

7

8

9

I3RH0B140032-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст