Suzuki Grand Vitara JB416 / JB420. Manual — part 137

1J-6 Charging System:

Repair Instructions

Jump Starting in Case of Emergency

S5JB0A1A06004

With Auxiliary (Booster) Battery

CAUTION

!

If vehicle is manual transmission model and

has a catalytic converter, do not push or tow

it to start. Damage to its emission system

and/or to other parts may result.

Both booster and discharged battery should be treated

carefully when using jumper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING

!

• Departure from these conditions or

procedure described as follows could

result in:

a. Serious personal injury (particularly to

eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

b. Damage to electronic components of

either vehicle.

• Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Remove rings, watches, and other jewelry.

Wear approved eye protection.

• Do not allow battery fluid to contact eyes,

skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Be careful so that metal tools or jumper

cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur.

• Batteries should always be kept out of

reach of children.

1) Set parking brake and place automatic transmission

in PARK (NEUTRAL on manual transmission).

2) Turn OFF ignition switch, turn OFF lights and all

other electrical loads.

3) Check built-in indicator (if equipped). If it is clear or

light yellow, replace the battery.

4) Attach end of one jumper cable to positive terminal

of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

5) Attach one end of the remaining negative cable to

negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

WARNING

!

Do not connect negative cable directly to

negative terminal of dead battery.

6) Start engine of vehicle with booster battery and turn

off electrical accessories. Then start engine of the

vehicle with discharged battery.

7) Disconnect jumper cable in the exact reverse order.

With Charging Equipment

CAUTION

!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

Charging System: 1J-7

Battery Dismounting and Remounting

S5JB0A1A06005

WARNING

!

When handling battery, following safety

precautions should be followed:

• Hydrogen gas is produced by battery. A

flame or spark near battery may cause the

gas to ignite.

• Battery fluid is highly acidic. Avoid spilling

on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

Dismounting

1) Disconnect negative cable.

2) Disconnect positive cable.

3) Remove retainer.

4) Remove battery.

Handling

When handling battery, the following safety precautions

should be followed:

• Hydrogen gas is produced by battery. A flame or

spark near battery may cause the gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing

or other fabric. Any spilled electrolyte should be

flushed with large quantity of water and cleaned

immediately.

Remounting

1) Reverse removal procedure.

2) Tighten battery cables securely.

NOTE

Check to be sure that ground cable has

enough clearance to hood panel by terminal.

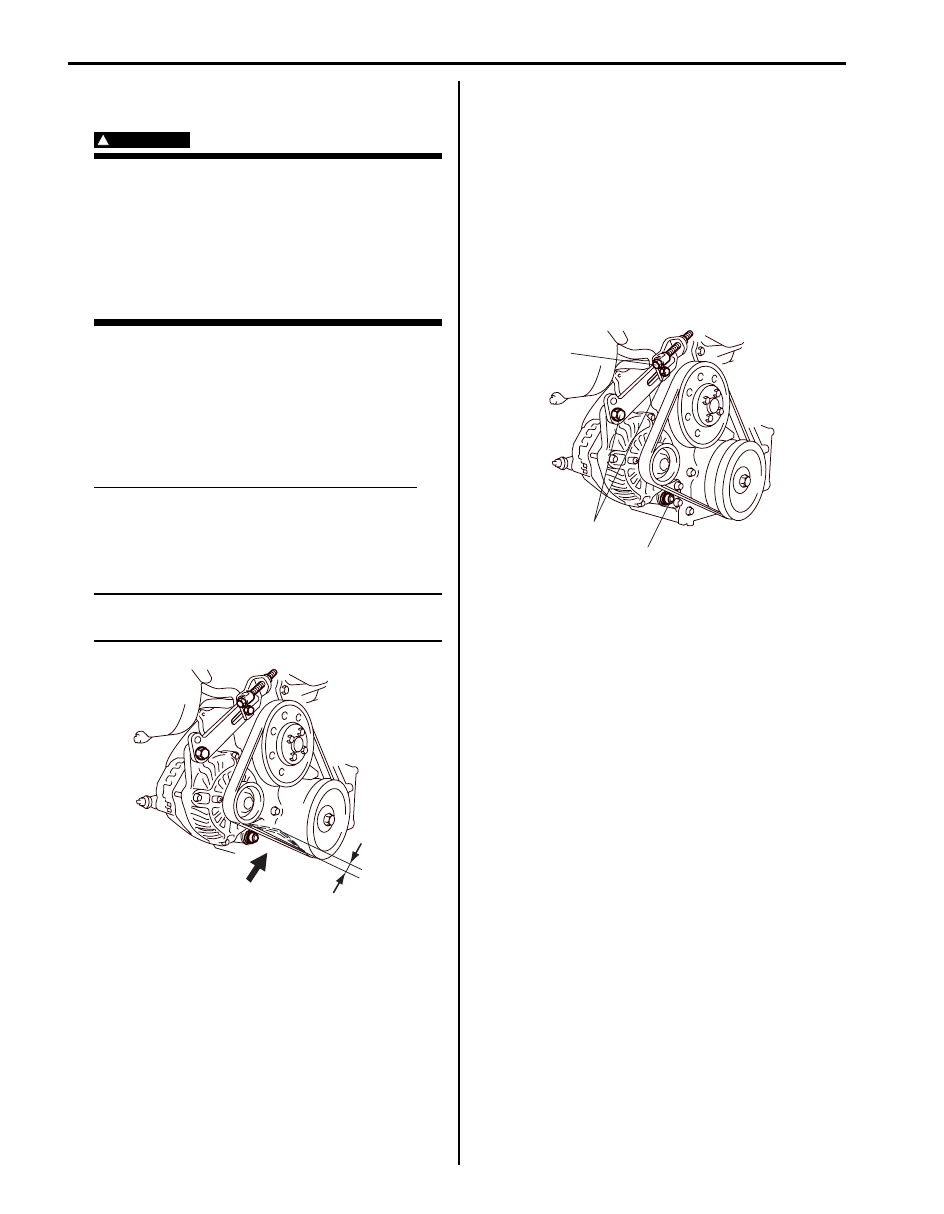

Water Pump and Generator Drive Belt Removal

and Installation (For M16 Engine)

S5JB0A1A06011

Removal

1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor

drive belt before removing water pump belt (1).

Refer to “P/S Pump and A/C Compressor (If

Equipped) Drive Belt Removal and Installation for

M16 Engine Model in Section 6C”.

3) Loosen drive belt adjusting bolt (2) and generator

pivot bolt (3).

4) Loosen water pump and generator drive belt

adjuster bolt (4) to displace generator and then

remove water pump belt.

Installation

1) Install belt (1) to water pump pulley (2), crankshaft

pulley (3) and generator pulley (4).

2) Adjust belt tension by referring to “Water Pump and

Generator Drive Belt Tension Inspection and

Adjustment (For M16 Engine)”.

3) If vehicle equipped with A/C, install compressor drive

belt referring to “P/S Pump and A/C Compressor (If

Equipped) Drive Belt Removal and Installation for

M16 Engine Model in Section 6C”.

4) Connect negative cable at battery.

1. Battery

4. Body ground bolt

2. Positive cable

5. Retainer

3. Negative cable

6. Nut

3

6

5

2

4

1

I5JB0A1A0007-01

4

2

3

1

I5JB0A1A0001-01

4

2

1

3

I5JB0A1A0002-01

1J-8 Charging System:

Water Pump and Generator Drive Belt Tension

Inspection and Adjustment (For M16 Engine)

S5JB0A1A06012

WARNING

!

• Disconnect negative cable at battery

before checking and adjusting belt

tension.

• To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

cap is taken off too soon.

1) Inspect belt for cracks, cuts, deformation, wear and

cleanliness. If it is necessary to replace belt, refer to

“Water Pump and Generator Drive Belt Removal and

Installation (For M16 Engine)”.

2) Check belt for tension. Belt is in proper tension when

it deflects the following specification under thumb

pressure (about 10 kg or 22 lb.).

Water pump / generator drive belt tension “a”

Existing belt: 7.0 – 8.5 mm (0.28 – 0.33 in.) as

deflection / 10 kg (22 lbs)

New belt: 5.5 – 6.5 mm (0.22 – 0.26 in.) as

deflection / 10 kg (22 lbs)

NOTE

When replacing belt with a new one, adjust

belt tension to 5.5 – 6.5 mm (0.22 – 0.26 in.).

3) If belt is too tight or too loose, adjust it to proper

tension by displacing generator position.

4) To adjust belt tension, loosen generator adjusting

bolt (3) and displace generator position by loosening

on tightening adjuster bolt.

5) Tighten generator adjusting bolt (1) and pivot bolts

(2) as specified torque.

Tightening torque

Generator adjusting bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft)

Generator pivot bolt (b): 52.5 N·m (5.25 kgf-m,

38.0 lb-ft)

6) Check belt for tension after turn crankshaft two

rotations clockwise.

7) Tightening generator adjuster bolt (3) as specified

torque.

Tightening torque

Generator adjuster bolt (c): 7.0 N·m (0.7 kgf-m,

5.0 lb-ft)

8) Connect negative cable at battery.

“a”

I5JB0A1A0008-01

1, (a)

2, (b)

3, (C)

I5JB0A1A0009-01

Charging System: 1J-9

Water Pump and Generator Drive Belt On-Vehicle Inspection (For J20 Engine)

S5JB0A1A06013

[Type A]

1) Disconnect negative cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanliness. If any of above conditions are found, replace belt,

referring to “Water Pump and Generator Drive Belt Removal and Installation (For J20 Engine)”.

3) Make sure that tension indicator “A” is within the range “a”.

If indicator “A” comes into the NG range “c” passing “b”, replace generator belt with a new one.

NOTE

Use mirror when checking belt tension.

[Type B]

• Inspect belt for cracks, cuts, deformation, wear and cleanliness. If any of these conditions are found, replace belt,

referring to “Water Pump and Generator Drive Belt Removal and Installation (For J20 Engine)”.

• Check to make sure that tension indicators are as follows in the figure by using mirror.

a. If the tension indicator “B” is found to the left of the indicator “A”, replace the generator belt.

b. If new generator belt has been installed, indicator “A” should be within “a” of the figure.

If it isn’t, it means that belt is not installed properly.

Reinstall it properly.

I1SQ01020003-01

I5JB0A1A0010-01

1. Water pump and generator drive belt

3. Water pump pulley

5. Tensioner

2. Crankshaft pulley

4. Tension pulley

6. Power steering pump pulley

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст