Suzuki Grand Vitara JB416 / JB420. Manual — part 417

10B-34 Body Electrical Control System:

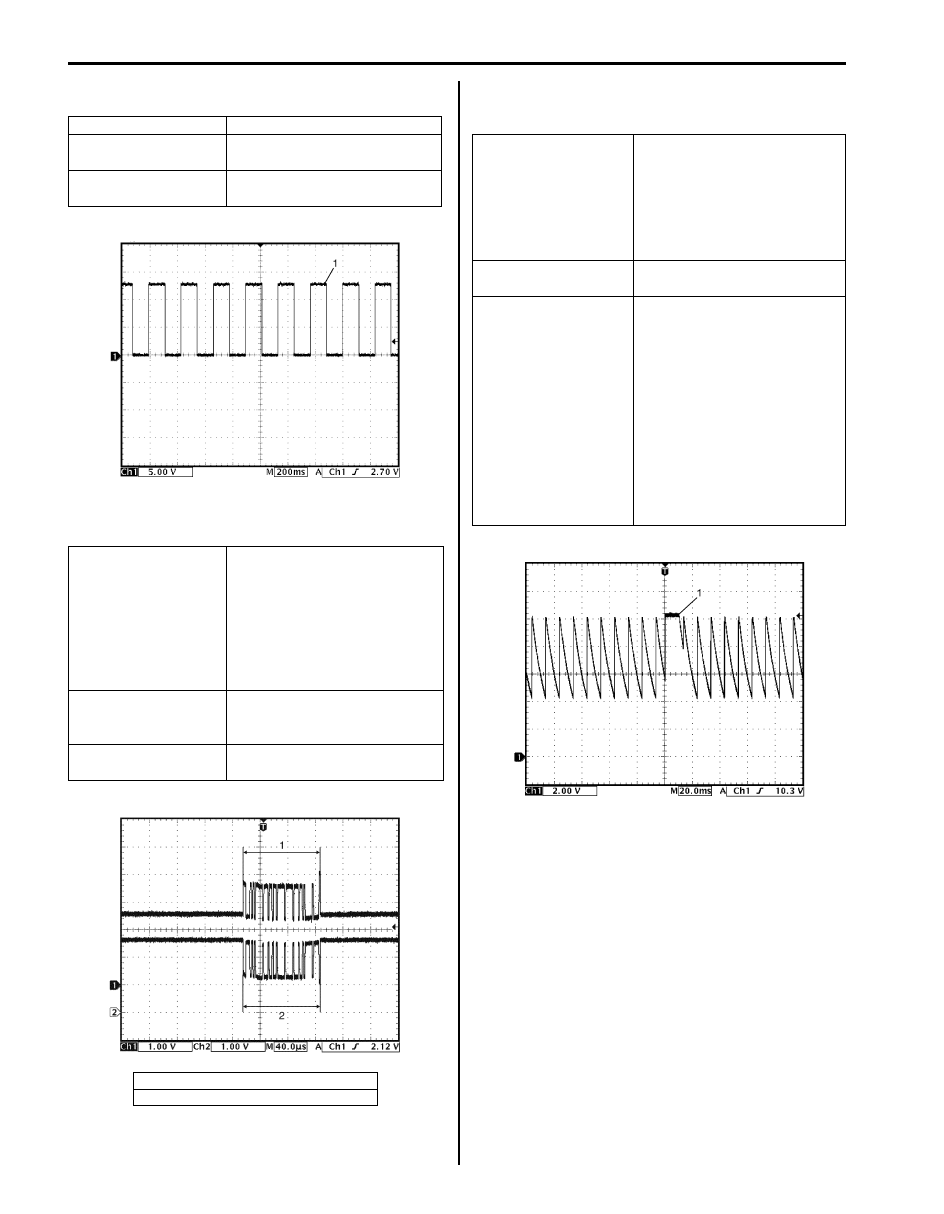

Reference waveform No. 5

Vehicle speed pulse output signal (1)

Reference waveform No. 6

CAN communication signal

Reference waveform No. 7

Brake fluid level, parking brake or driver seat belt switch

signal (1)

Measurement terminal CH1: “G30-22” to “G30-12”

Oscilloscope setting

CH1: 5 V / DIV

TIME: 200 ms / DIV

Measurement

condition

Vehicle speed at 10 km/h (6

mph)

Measurement terminal CAN communication signal for

DLC

CH1: “G31-1” to “G30-12”

CH2: “G31-3” to “G30-12”

CAN communication signal for

each control module

CH1: “G31-2” to “G30-12”

CH2: “G31-4” to “G30-12”

Oscilloscope setting

CH1: 1 V / DIV

CH2: 1 V / DIV

TIME: 40

µs / DIV

Measurement

condition

Ignition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I5JB0AA20017-01

I5JB0AA20018-01

Measurement terminal Brake fluid level switch signal:

CH1: “G31-7” to “G30-12”

Parking brake switch signal:

CH1: “G31-8” to “G30-12”

Driver side seat belt switch

signal:

CH1: “G31-40” to “G30-12”

Oscilloscope setting

CH1: 2 V / DIV

TIME: 20 ms / DIV

Measurement condition Brake fluid level switch:

• Ignition switch is at ON

position and brake fluid level

is at specified level

Parking brake switch:

• Ignition switch is at ON

position and parking brake

lever is released.

Driver side seat belt switch:

• Ignition switch is at ON

position and driver seat belt

is fastened

I5JB0AA20019-01

Body Electrical Control System: 10B-35

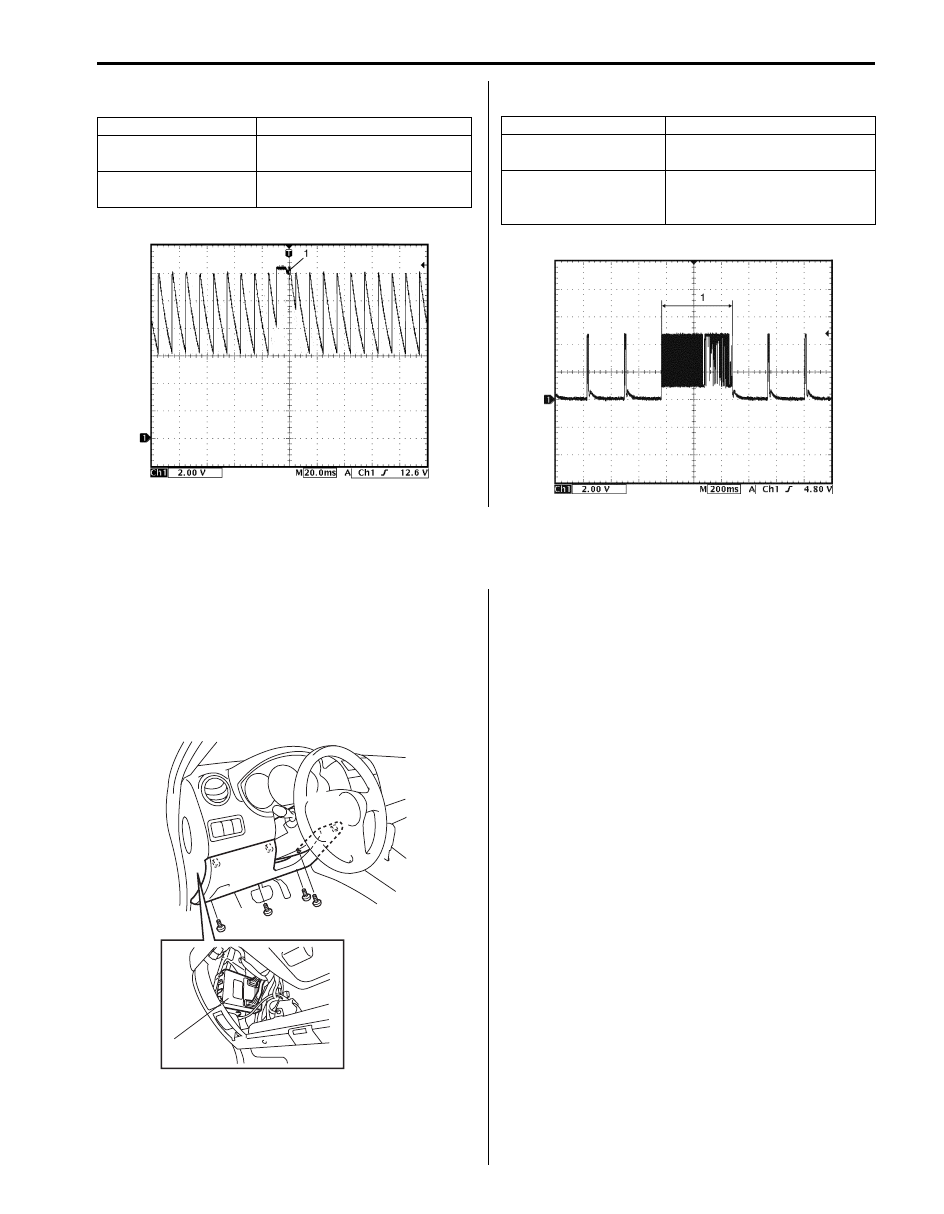

Reference waveform No. 8

Oil pressure switch signal (1)

Reference waveform No. 9

Keyless entry receiver signal (1)

Repair Instructions

BCM Removal and Installation

S5JB0AA206001

Removal

1) Disconnect negative cable from battery.

2) Remove steering column hole cover (1).

3) Disconnect connectors from BCM.

4) Remove BCM (2).

Installation

Reverse removal procedure for installation, noting

following point.

• Connect connectors securely until it clicks.

Outside Air Temperature Sensor Removal and

Installation

S5JB0AA206002

For removal and installation, refer to “Outside Air

Temperature Sensor Removal and Installation (If

Equipped) in Section 9C”.

Measurement terminal CH1: “G31-9” to “G30-12”

Oscilloscope setting

CH1: 2 V / DIV

TIME: 20 ms / DIV

Measurement

condition

Engine is running and oil

pressure is in normal condition

I5JB0AA20020-01

Measurement terminal CH2: “G31-19” to “G30-12”

Oscilloscope setting

CH2: 2 V / DIV

TIME: 200 ms / DIV

Measurement condition Lock or unlock button of key

less entry transmitter is

pushed

I5JB0AA20021-01

1

2

I5JB0AA20022-01

10B-36 Body Electrical Control System:

Outside Air Temperature Sensor Inspection

S5JB0AA206003

For inspection, refer to “Outside Air Temperature Sensor

Inspection (If Equipped) in Section 9C”.

DRL Function Setting Procedure

S5JB0AA206004

DRL is controlled by BCM which has a function to set

operable / non-operable mode of DRL. With a new BCM,

its DRL is set to the non-operable mode.

Therefore, when BCM has been replaced in the country

where DRL operation is required by the statutory

regulation, set DRL to the operable mode according to

the procedure described below.

Also, performing the same procedure when DRL is in the

operable mode will change DRL setting to the non-

operable mode.

1) Turn ignition switch to ON position.

2) Perform Steps a) through f) described blow within 15

seconds after Step 1).

a) Turn lighting switch to CLEARANCE position.

b) Turn lighting switch to OFF position.

c) Repeat Steps a) and b) five times.

d) Turn lighting switch to HEAD position.

e) Turn lighting switch to OFF position.

f) Repeat Steps a) and e) five times.

3) After Step f), buzzer sounds twice which indicates

that DRL has been set to operable mode.

NOTE

When DRL setting has been changed from

operable mode to non-operable mode, buzzer

sounds once.

4) After confirming buzzer, turn ignition switch to OFF

position.

Special Tools and Equipment

Special Tool

S5JB0AA208001

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. Power

supply )

Immobilizer Control System: 10C-1

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing Troubles

S5JB0AA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well

as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection.

• Communication of ECM, BCM, and combination

meter is established by CAN (Computer Area

Network). Therefore, handle CAN communication

lines with care referring to “Precaution for CAN

Communication System in Section 00”.

Precaution in Replacing ECM

S5JB0AA300002

• If ECM is replaced with new or used one without the

functionality for the immobilizer control system, the

engine will not be started. In case of the above, check

if the newly installed ECM has the functionality for the

immobilizer control system referring to its part

number.

• After ECM is replaced with new one or used one, the

transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precautions in Handling Immobilizer Control

System

S5JB0AA300003

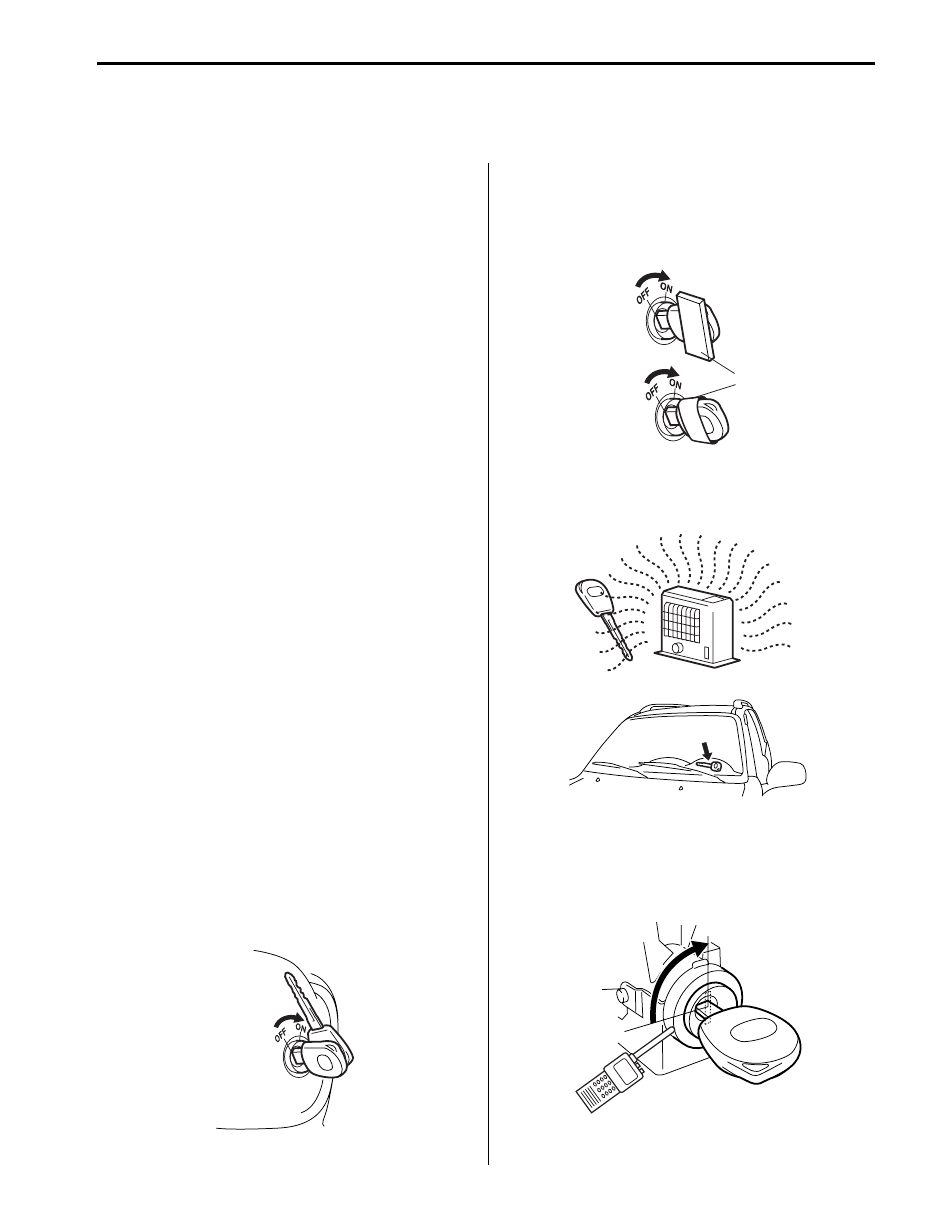

• Do not turn ON ignition switch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer control system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key

with any type of metal (1) wrapped its grip or in

contact with it. Or, the immobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

• Do not leave ignition key in a place where

temperature is high. High temperature may cause

damage to the transponder built in the ignition key.

• Do not turn ignition switch to ON position by bringing

radio antenna close to coil antenna. Or, the

immobilizer control system may detect some

abnormal condition and prevent the engine from

starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

I3RH0AA30003-01

I3RH0AA30004-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст