Suzuki Grand Vitara JB416 / JB420. Manual — part 280

7B-11 Air Conditioning System:

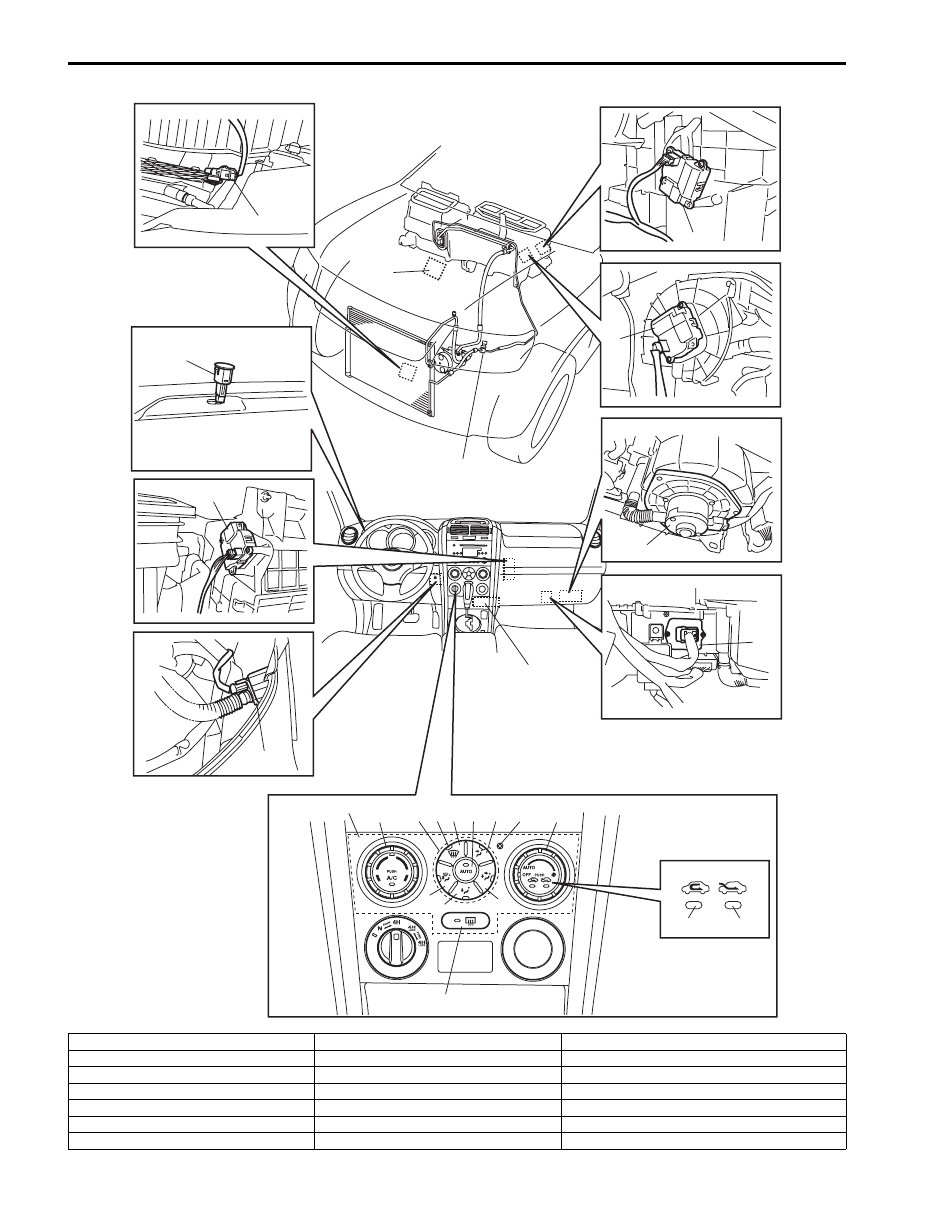

1

*2

*7

*3

*6

*11

*10

9

8

4

5

25

12

24 26

14

22

23

16

15

21

13

17

19

18

20

I5JB0A720009-07

1. Outside temperature sensor

10. Blower motor

19. Theft deterrent light

2. Sunload sensor

11. Blower motor controller

20. Blower speed selector / Air intake selector

3. Inside temperature sensor

12. Temperature selector / A/C switch

21. Rear defogger switch

4. ECT sensor

13. “DEF” switch

22. “REC” indicator lamp

5. Refrigerant pressure sensor

14. “DEF / FOOT” switch

23. “FRE” indicator lamp

6. Evaporator temperature sensor

15. “FOOT” switch

24. MODE selector

7. Air intake control actuator

16. “BI-LEVEL” switch

25. HVAC control module (vehicle with A/C)

Air Conditioning System: 7B-12

Diagnostic Information and Procedures

Air Conditioning System Check

S5JB0A7204007

To ensure that system diagnosis is done accurately and smoothly, read “Precautions in Diagnosing Trouble” and follow

“Air Conditioning System Check”.

8. Temperature control actuator

17. “VENT” switch

26. “DEF” indicator lamp

9. Air flow control actuator

18. “AUTO” switch

Step

Action

Yes

No

1

Customer complaint analysis

1) Perform “Customer Complaint Analysis”.

Was customer complaint analysis performed according to

instruction?

Go to Step 2.

Perform customer

complaint analysis.

2

Visual inspection

1) Perform “Visual Inspection”.

Is there any faulty condition?

Repair or replace

malfunction part.

Go to Step 3.

3

DTC check

1) Perform “DTC Check”.

Is it malfunction code?

Go to Step 4.

Go to Step 5.

4

Troubleshooting for DTC

1) Check and repair according to DTC diag. flow.

Are check and repair completed?

Go to Step 7.

Check and repair

malfunction part(s).

5

Check for intermittent problem

1) Check for intermittent problem.

Is there faulty condition?

Repair or replace

malfunction part(s).

Go to Step 6.

6

Air conditioning system symptom diagnosis

1) Inspect and repair referring to “A/C System Symptom

Are inspect and repair complete?

Go to Step 7.

Inspect and repair

malfunction part(s).

7

Final confirmation test

1) Perform DTC check.

Is there any DTC?

Go to Step 4.

Air Conditioning system

is good condition.

7B-13 Air Conditioning System:

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in the figure will facilitate collecting information to the

point required for proper analysis and diagnosis.

Customer questionnaire (example)

NOTE

The form is a standard sample. It should be modified according to conditions characteristic of each

market.

Visual Inspection

As a preliminary step, be sure to perform visual check of the items that support proper function of the air conditioning

system referring to “Visual Inspection”.

DTC Check

Refer to “DTC Check” for checking procedure.

Troubleshooting for DTC

Based on the DTC indicated in Step 4 and referring to applicable DTC flow, locate the cause of the trouble, namely in

a sensor, actuator, wire harness, connector, HVAC control module or other part and repair or replace faulty parts.

Check for Intermittent Problem

Check parts where an intermittent trouble is easy to occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section 00”.

Air Conditioning System Symptom Diagnosis

Check the parts or system suspected as a possible cause referring to “A/C System Symptom Diagnosis”.

Final Confirmation Test

Confirm that the problem symptom has gone and the air conditioning system is free from any abnormal conditions. If

what has been repaired is related to the malfunction DTC, check DTC once and confirm that no DTC is indicated.

Customer’s Name:

Model:

VIN:

Date of Issue:

Date Reg.

Date of Problem:

Mileage:

Problem Symptoms

• “FRE” indicator lamp abnormal: fails to turn ON / fails to go OFF / flashes

• Abnormal noise while “A/C” switch is turned ON: from compressor, from radiator fan

motor, other_______________

• Cool air does not come out:

• Radiator fan motor does not work:

• A/C compressor does not work:

• Blower fan motor does not work:

Frequency of Occurrence

• Continuous / Intermittent (_____ times a day, a month) / other_______________

Conditions for Occurrence of

Problem

• Vehicle at stop & A/C compressor is working:

• For some time after A/C switch is ON:

• When outside air temperature is high:

• When outside air temperature is low:

• All the time:

Environmental Condition

• Weather: fair / cloudy / rain / snow / other_______________

• Temperature: _____

°F (_____ °C)

DTC

• First check: Normal code / malfunction code (__________)

• Second check: Normal code / malfunction code (__________)

Air Conditioning System: 7B-14

DTC Check

S5JB0A7204028

NOTE

To know how to use SUZUKI scan tool in

detail, refer to its operator’s manual.

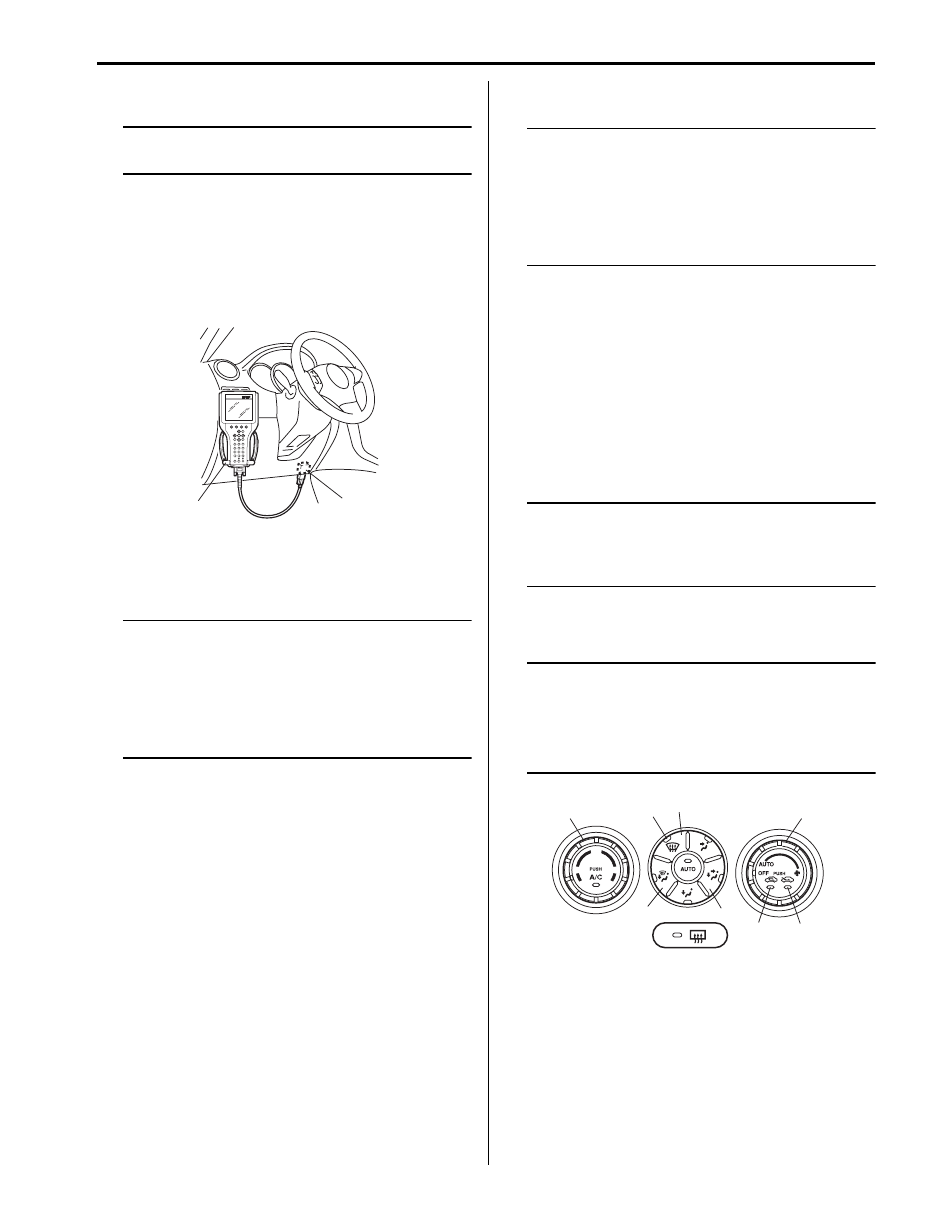

Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel.

Special tool

(A): SUZUKI scan tool

3) Apply light to sunload sensor vertically, holding

incandescent lamp of approximately 100 W about

100 mm (3.94 in.) away from sunload sensor.

NOTE

If B1504 is detected when vehicle is not

exposed to light (indoor, etc.), check again

for DTC with light from incandescent lamp

applied to sunload sensor, referring to

“Sunload Sensor Inspection”. If B1504 is not

detected in this check, sunload sensor is in

good condition.

4) Turn ignition switch to ON position.

5) Read DTC according to instructions displayed on

SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

If communication between scan tool and ECM

(PCM) is not possible, check if scan tool is

communicable by connecting it to ECM (PCM) in

another vehicle. If communication is possible in this

case, scan tool is good condition. Then check data

link connector and serial data line (circuit) in the

vehicle with which communication was not possible.

6) After completing the check, turn ignition switch OFF

position and disconnect SUZUKI scan tool from data

link connector (DLC).

Not Using SUZUKI Scan Tool

NOTE

If B1504 is detected when vehicle is not

exposed to light (indoor, etc.), check again

for DTC with light from incandescent lamp

applied to sunload sensor, referring to

“Sunload Sensor Inspection”. If B1504 is not

detected in this check, sunload sensor is in

good condition.

1) Apply light to sunload sensor vertically, holding

incandescent lamp of approximately 100 W about

100 mm (3.94 in.) away from sunload sensor.

2) Set the following selectors to specified positions

respectively with turn ignition switch OFF.

• Temperature selector (1): max cool position

• Blower speed selector (2): “OFF” position

3) While pressing “B/L” (BI-LEVEL) switch (3) and “D/F”

(defogger foot) switch (4) simultaneously turn

ignition switch to ON position.

NOTE

For 15 seconds after ignition switch is turned

on, both “REC” indicator lamp and “FRE”

indicator lamp light for in-system trouble

check.

4) Read DTC from flashing pattern of “FRE” indicator

(5) and “REC” indicator (6) referring to “DTC Table”.

NOTE

• Pressing “DEF” switch (7) alternates

display of current DTC and history DTC.

• “DEF” indicator lamp (8) remains off when

display is in current DTC mode and it lights

up when display is in history DTC mode.

(A)

1

I5JB0A720014-01

1

2

8

7

4

6

5

3

I5JB0A720015-04

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст