Hummer H1 (2002+). Manual — part 200

______________________________________________________

Electrical System 12-27

®

05745159

Alternator Assembly

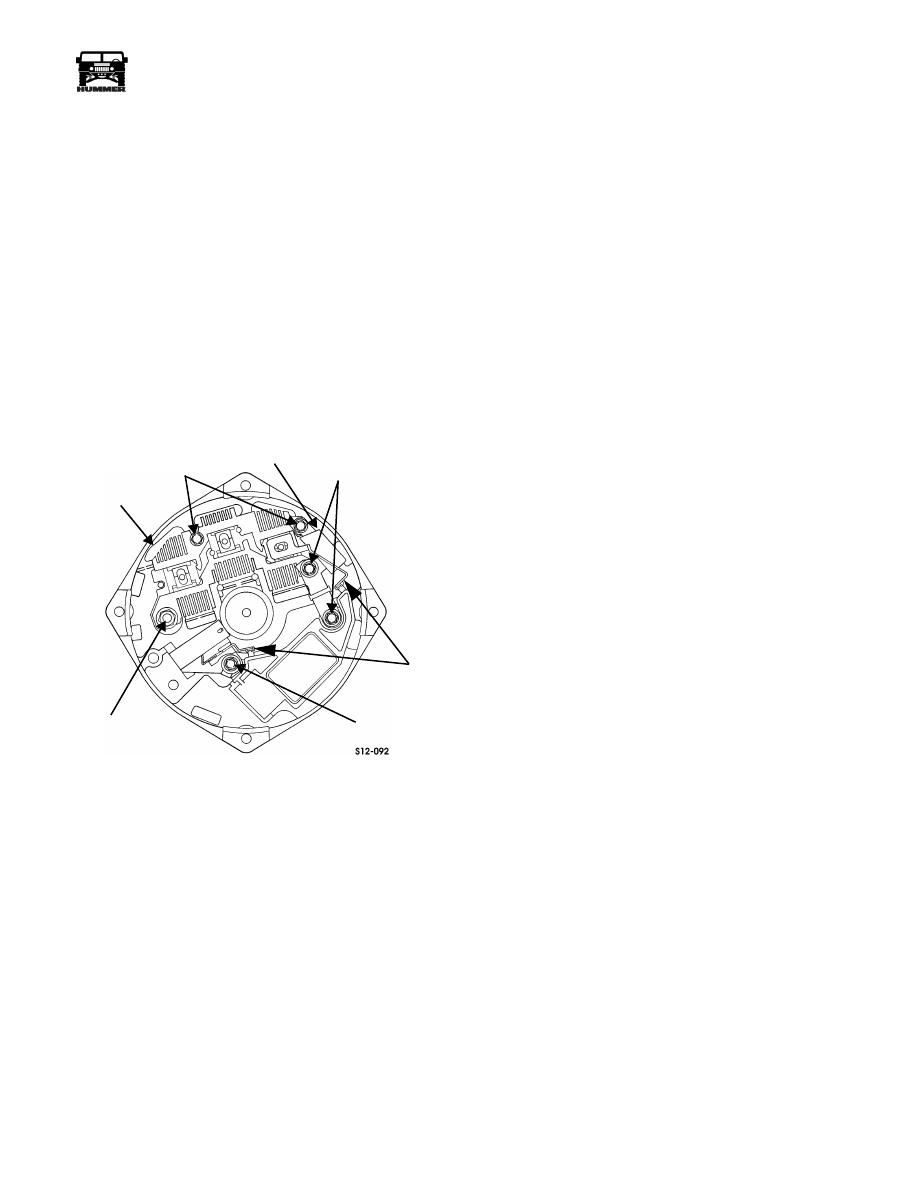

1.

Install bearing on rotor shaft. Seat bearing against shoul-

der (Figure 12-38).

2.

Assemble springs and brushes in brush holder and retain

with fabricated pin. Pin holds brushes compressed in brush

holder and will be removed after assembly.

3.

Install rectifier bridge in slip ring end frame and install

screw, output stud insulator, and nut.

4.

Assemble and install brush holder and regulator. Solder

connection between brush holder and regulator if either

part was replaced.

5.

Slide regulator connector strap into regulator contact and

solder together.

6.

Slip capacitor strap under connector strap and position on

rectifier bridge and regulator. Secure capacitor strap with

screw and two insulated screws (Figure 12-51).

Figure 12-51: Rectifier Bridge and Capacitor Strap

Location

7.

Attach stator leads to rectifier bridge and secure leads with

nuts.

8.

Install thick collar on rotor shaft (Figure 12-38).

9.

Insert rotor shaft through drive end frame and seat bearing

against thick collar.

10. Install thin collar, fan, and pulley on rotor shaft and secure

with washer and nut. Tighten nut to 40-80 lb-ft (54-109

N•m).

11. Carefully insert rotor through stator and seat ball bearing

in slip ring end frame. Be sure drive end frame and stator

are aligned and seated.

12. Install through-bolts. Tighten through-bolts evenly to

remove any slack.

13. Verify that rotor turns smoothly.

14. Remove brush retaining pin from brush holder. Be sure

brushes extend out brush holder and contact slip rings.

STUD

NUT

SCREWS

INSULATED

SCREWS

SCREW

AND WASHER

RECTIFIER

BRIDGE

CAPACITOR

STRAP

SOLDERED

CONNECTION

4-1-00

12-28

Electrical System

_______________________________________________________

®

Alternator Inoperative (No Charge)

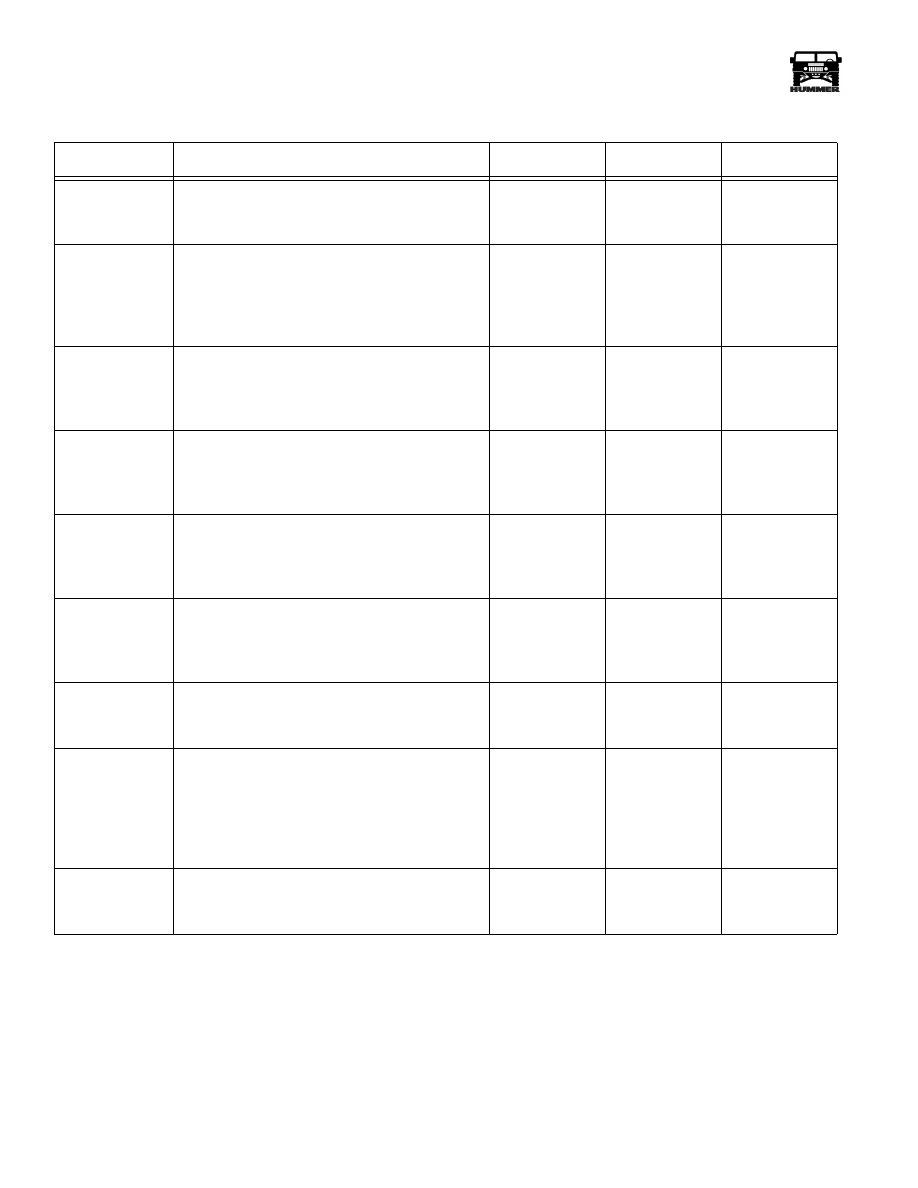

Step

Action

Value(s)

Yes

No

1

Perform visual inspection on belt, pulleys and

battery cables. Is everything in normal operating

condition

Go to step 2.

Repair and

recheck system.

2

Using a battery load tester, place amp pickup on

the alternator fusable link wire. Start and run

vehicle at 1500 rpm, load the vehicle batteries

with 100 amps for 15 seconds. Does charging sys-

tem produce equivalent amperage.

>100 amps

Go to step 7.

go to step 3.

3

Perform battery check, refer to “battery checking

procedure” in this section. Are batteries in good

condition

Go to step 4.

Replace batter-

ies and recheck

charging sys-

tem.

4

Using a DVOM set to measure voltage, place the

negative lead on a good engine ground. Probe the

Batt. terminal on the back of the alternator. Is

voltage present?

12v

Go to step 8.

Go to step 5.

5

Using a DVOM set to measure resistance, mea-

sure resistance between the alternator case and a

negative battery connection. Is resistance below

specification.

<.2

Ω

Go to step 6.

Locate and

repair bad

ground connec-

tion.

6

Disconnect the positive battery cables, using a

DVOM set to measure resistance, measure resis-

tance between the positive battery connection and

the Batt. terminal. Is resistance below specification.?

<.2

Ω

Go to step 8.

Inspect/repair

fusible link at

alternator Batt

terminal.

7

Does voltage gauge indicate a low charge condi-

tion?

Replace gauge

and check oper-

ation.

No problem

found at this

time.

8

Using a DVOM set to measure voltage, and the

pink ignition lead disconnected from the alterna-

tor, place the negative lead on a good engine

ground and the positive lead on the pink ignition

lead. Turn the ignition key to on, is voltage

present?

12v

Go to step 9.

Locate and

repair open or

short to ground

in engine igni-

tion feed circuit.

9

Check for expanded female terminal in engine

harness connector in the alternator ignition feed

connector. Is a faulty connection found?

Replace female

terminal

Replace the

alternator

4-1-00

______________________________________________________

Electrical System 12-29

®

05745159

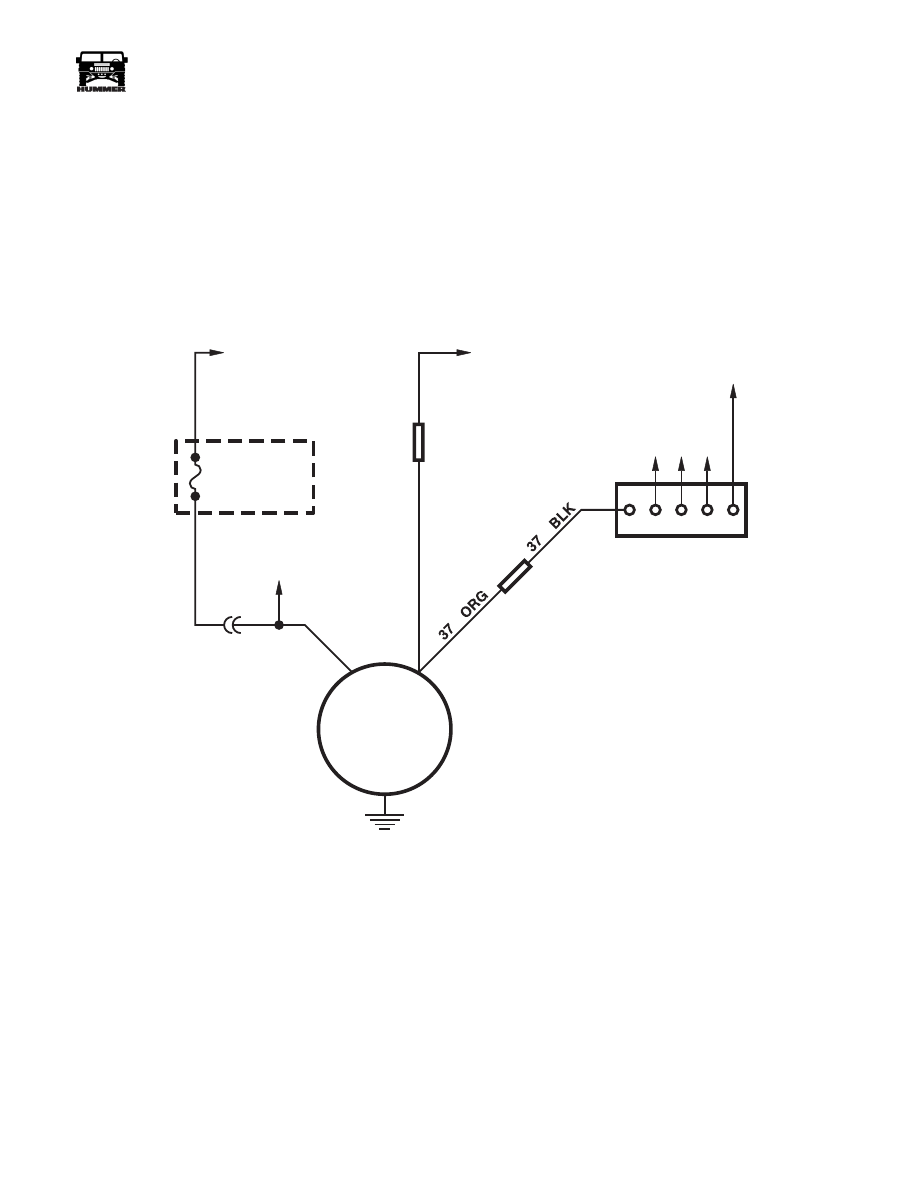

Figure 12-52: Alternator Schematic

9-S12-089

ALTERNATOR

FUSE

3B EXTERIOR

20 AMP

C4-3

PNK

EXTERIOR

POWER BUS

TO POSITIVE

BATTERY CABLE

TO EXTERIOR

FUSE BOX

TO INTERIOR

FUSE BOX

FUSIBLE

LINK

FUSIBLE

LINK

ORG

RED

TO

LOW COOLANT

SENSOR

HOT IN RUN AND START

BATTERY TERMINAL

IGN FEED

291

4-1-00

12-30

Electrical System

_______________________________________________________

®

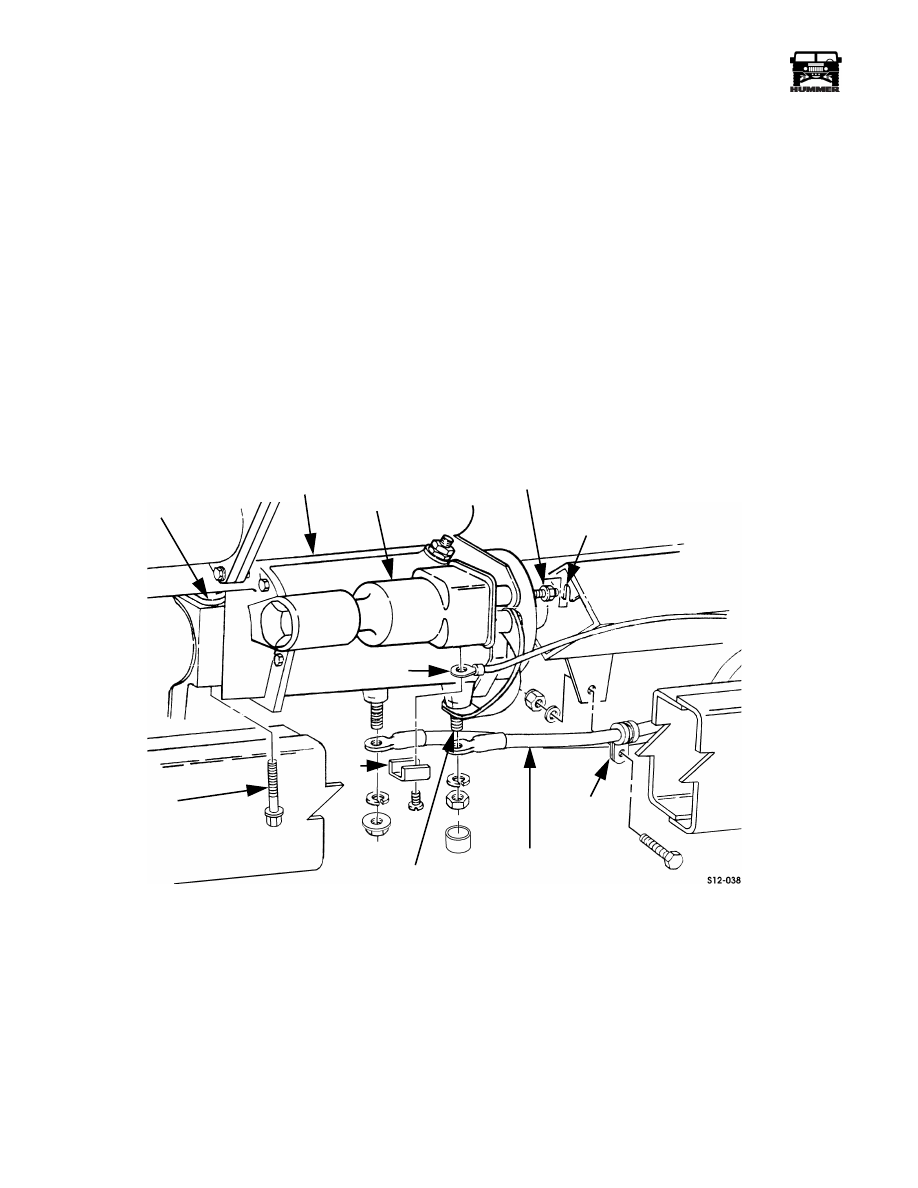

STARTER

Removal

1.

Disconnect battery negative cable(s) and winch negative

cable, if equipped.

2.

Remove converter housing cover.

3.

Remove cap and/or adhesive sealant from starter terminal

(Figure 12-53).

4.

Disconnect starter cable or cables from starter terminals

(Figures 12-53 and 12-54).

5.

Disconnect solenoid wire from solenoid.

6.

Remove starter cable clamp.

7.

Loosen locknut and washer securing stud at front of starter

to bracket.

8.

Have helper support starter and remove starter bolts. Then

lower and remove starter and shim (if used).

Installation

1.

Position shim pack on starter.

2.

Position starter in converter housing.

3.

Slide starter stud into chassis bracket. Be sure stud nut and

washer are behind bracket.

4.

Install and tighten starter bolts to 40 lb-ft (54 N•m).

5.

Tighten stud nut to 24 lb-ft (33 N•m).

6.

Attach starter cable clamp to chassis.

7.

Connect solenoid wire to solenoid terminal with clip and

screw. Tighten screw to 22 lb-in. (2 N•m).

8.

Connect starter cable to starter terminal. Tighten nut to 25-

31 lb-ft (34-42 N•m).

9.

Cover starter terminal and solenoid terminal with silicone

sealer.

10. Install converter housing covers.

11. Connect battery negative cable.

Figure 12-53: Starter Mounting

STARTER

STARTER

SOLENOID

TERMINAL

CLAMP

STARTER BOLT

CABLE

SOLENOID WIRE

CLIP

SHIM PACK

STARTER STUD

CHASSIS

BRACKET

4-1-00

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст