Hummer H1 (2002+). Manual — part 49

_________________________________________________________

Cooling System 4-11

®

05745159

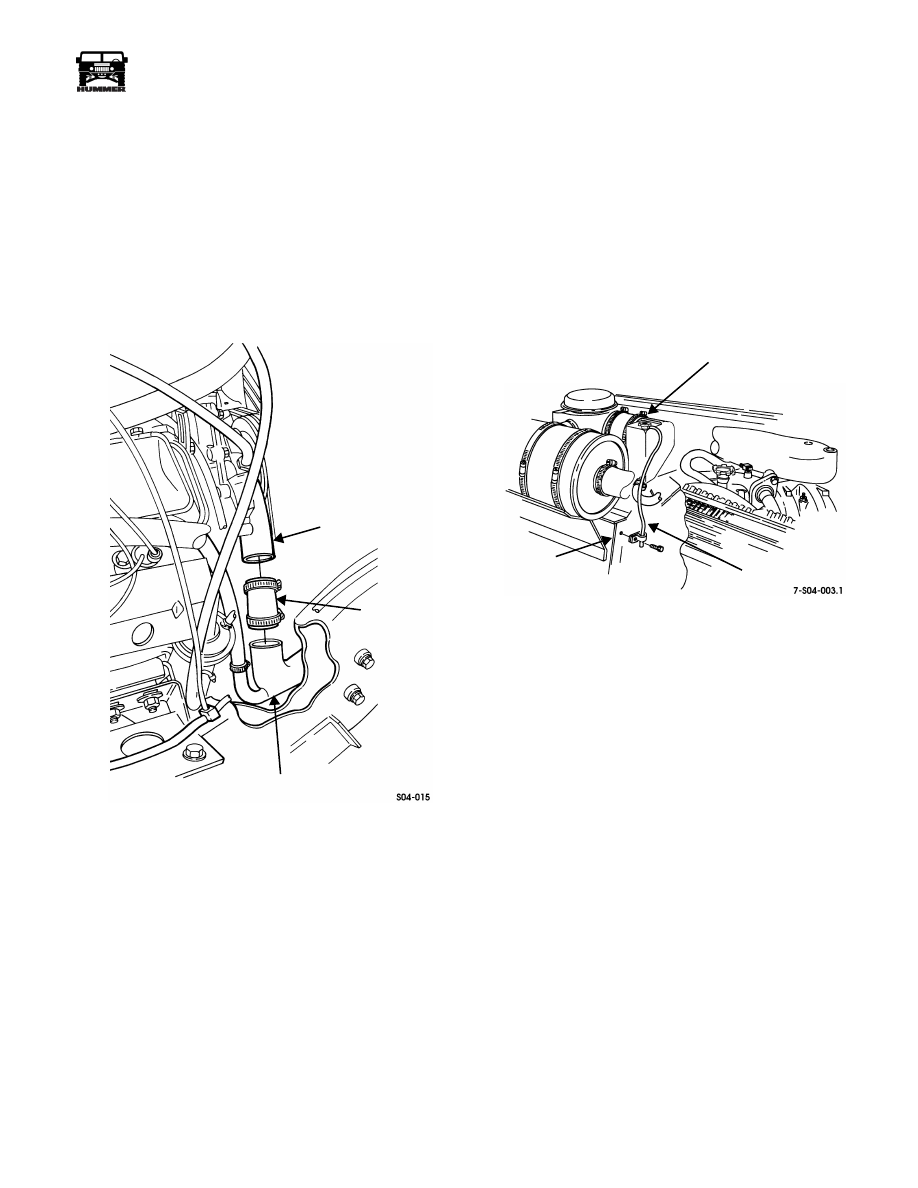

WATER PUMP INLET HOSE REPLACEMENT

Removal

1.

Drain cooling system.

2.

Loosen clamps and remove water pump inlet hose from

water pump and lower tube assembly (Figure 4-18).

Installation

1.

Connect water pump inlet hose to lower tube assembly and

water pump and tighten clamps (Figure 4-18).

2.

Fill cooling system.

Figure 4-18: Water Pump Inlet Hose Location

SURGE TANK OVERFLOW HOSE

REPLACEMENT

Removal

1.

Remove overflow hose from surge tank filler neck

(Figure 4-19).

2.

Remove screw, clamp, and overflow hose from body.

Installation

1.

Connect overflow hose to surge tank filler neck (Figure 4-19).

2.

Secure overflow hose to body with clamp and screw.

Figure 4-19: Surge Tank Overflow Hose Mounting

WATER PUMP

WATER PUMP

INLET HOSE

LOWER

TUBE ASSEMBLY

BODY

SURGE TANK FILLER NECK

OVERFLOW

HOSE

4-12

Cooling System

__________________________________________________________

®

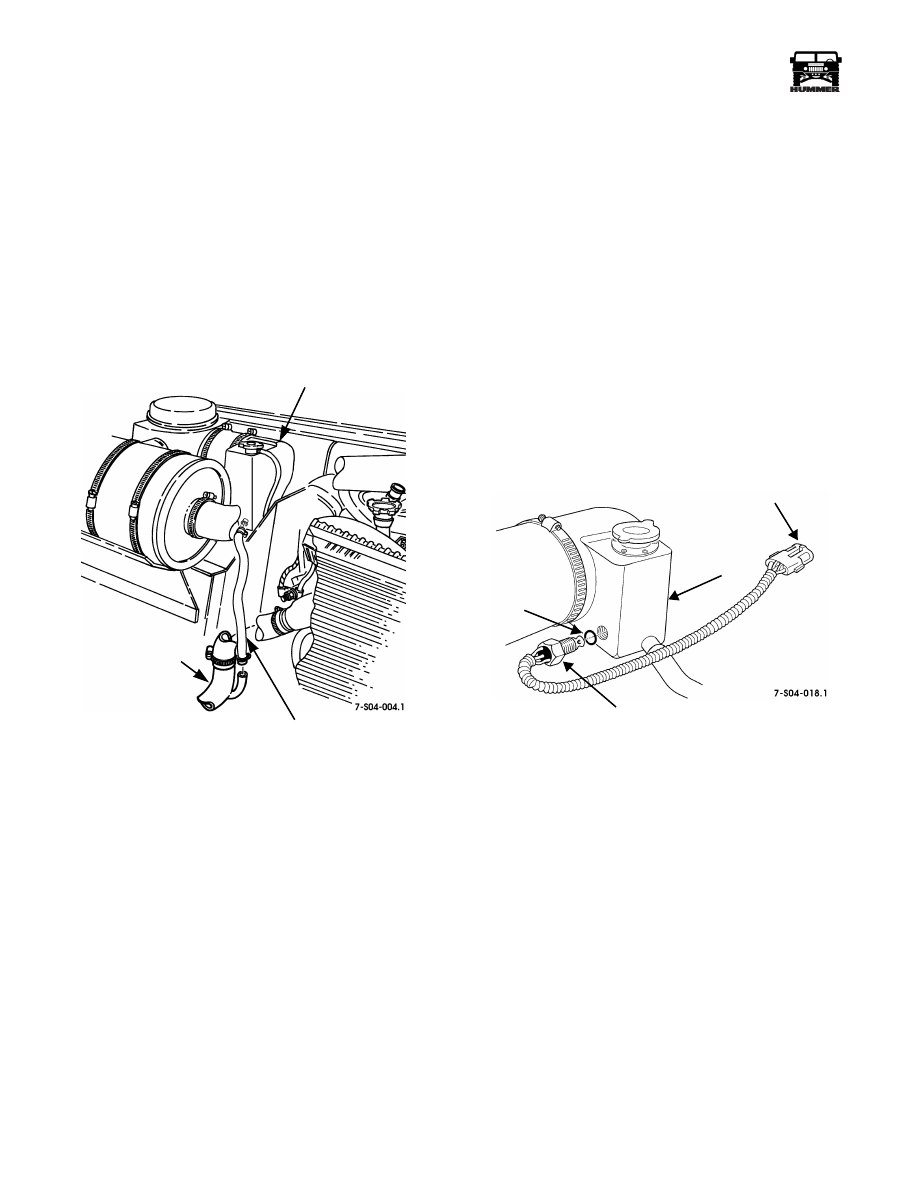

SURGE TANK-TO-LOWER RADIATOR TUBE

HOSE REPLACEMENT

Removal

1.

Drain cooling system.

2.

Loosen clamps and remove hose from surge tank and

lower tube assembly (Figure 4-20).

Installation

1.

Install hose on lower tube assembly and surge tank and

tighten clamps (Figure 4-20).

2.

Fill cooling system.

Figure 4-20: Surge Tank-to-Lower Tube Assembly

Hose Location

LOW COOLANT SENSOR

The coolant level sensor is a solid-state semi-conductor device.

The sensor’s resistance varies as a function of its temperature.

As voltage/current flows through the sensor, sensor tempera-

ture increases. In the presence of a liquid, in this case engine

coolant, the temperature of the sensor is controlled by transfer-

ring heat to the coolant. Should the coolant level drop below

the sensor, the heat and resistance of the sensor will rise. The

“Low Coolant” warning light will then illuminate in response

to the increased resistance at the sensor.

Removal

1.

Drain and collect coolant from surge tank.

2.

Disconnect the low coolant sensor electrical connector

from the engine harness connector.

3.

Remove the sensor and O-ring from the surge tank

(Figure 4-21)

Figure 4-21: Low Coolant Sensor

Installation

1.

Position O-ring on sensor and thread sensor into surge

tank (Figure 4-21).

2.

Plug the low coolant sensor electrical connector into the

engine harness connector

3.

Fill surge tank with coolant.

SURGE TANK

LOWER

TUBE ASSEMBLY

SURGE TANK-TO-LOWER TUBE

ASSEMBLY HOSE

SURGE

ELECTRICAL

LOW

O-RING

CONNECTOR

COOLANT

SENSOR

TANK

_________________________________________________________

Cooling System 4-13

®

05745159

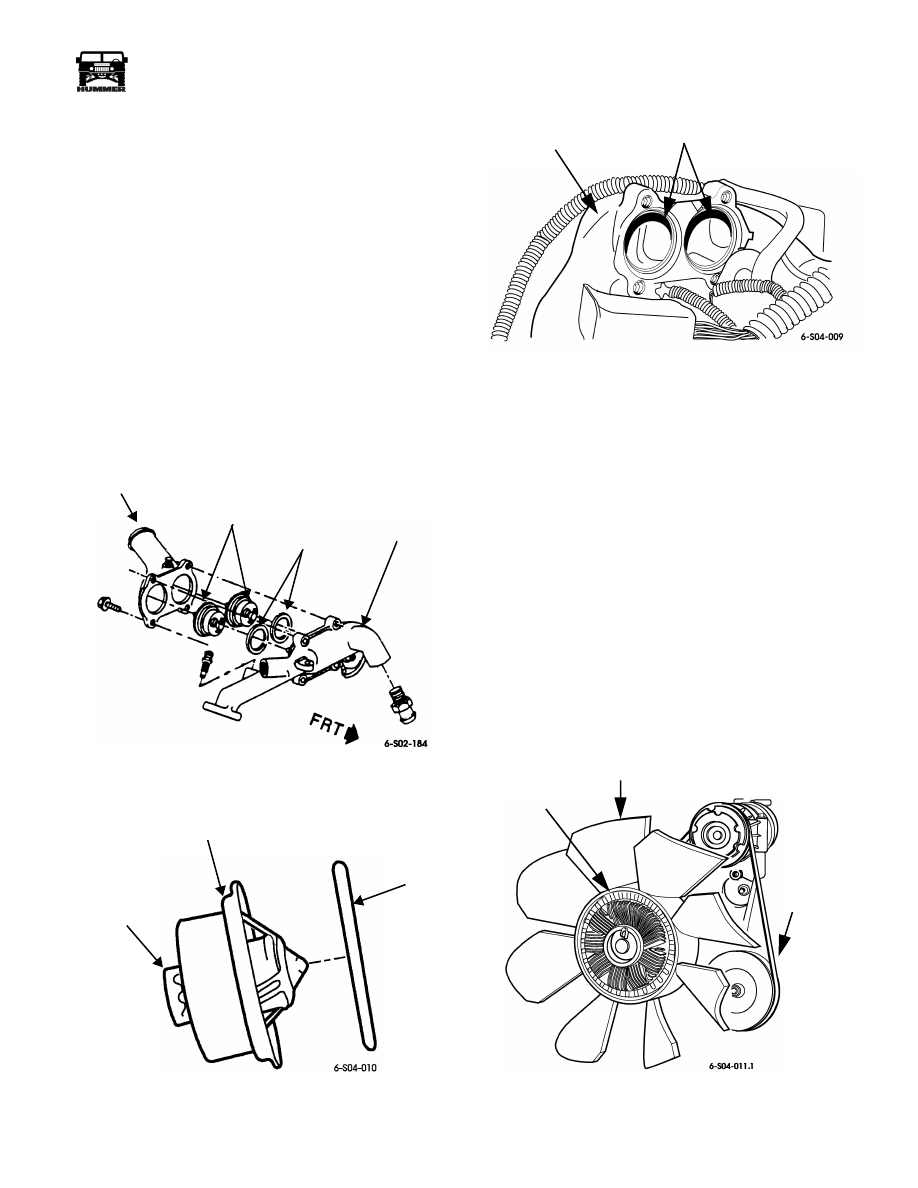

THERMOSTAT REPLACEMENT

1.

Drain engine coolant below level of water crossover.

2.

Remove bolts attaching thermostat cover to crossover

housing.

3.

Remove thermostat cover and gasket (Figure 4-22).

4.

Remove both thermostats (Figure 4-23).

5.

Position new thermostats in crossover housing

(Figure 4-24). Be sure thermostat seals are seated in

counterbores. Wax pellet end of each thermostat goes

toward engine.

6.

Apply Permatex no. 2 to both sides of thermostat housing

gasket. If gasket is not used, apply 3/16 in. (5 mm) bead of

Loctite 599, or Permatex Ultra Copper, or Ultra Black to

cover or crossover mounting surface.

7.

Install thermostat cover and tighten cover bolts securely.

8.

Fill and bleed cooling system.

Figure 4-22: Thermostat and Cover

Removal and Installation

Figure 4-23: Turbo Diesel Thermostat

Figure 4-24: Thermostat Location in Crossover

WATER PUMP AND ADAPTER PLATE

Removal

1.

Remove hood with aid of helper.

2.

Drain engine coolant.

3.

Discharge A/C system refrigerant with equipment set on

recovery mode.

4.

Remove radiator, shroud, coolers, and A/C condenser as

assembly.

5.

Loosen and remove serpentine drive belt.

6.

Remove fan and fan clutch (Figure 4-25).

7.

Disconnect hoses at water pump.

8.

Remove water pump and backing plate attaching bolts/

studs and remove pump and plate as assembly

(Figure 4-26).

9.

Remove water pump and gasket from plate (Figure 4-27).

10. Clean all gasket material and sealer from plate.

Figure 4-25: Fan and Clutch Mounting

THERMOSTAT

HOUSING

TWIN

GASKETS

WATER

CROSSOVER

THERMOSTATS

WAX PELLET

THERMOSTAT

SEAL

WATER

CROSSOVER

THERMOSTAT SEATS

AND COUNTER BORES

FAN CLUTCH

8-BLADE FAN

SERPENTINE

DRIVE BELT

4-14

Cooling System

__________________________________________________________

®

Installation

1.

If new pump is being installed, transfer hose adapter fit-

tings to new pump. Apply Loctite PST to fitting threads

beforehand.

2.

Apply coat of Permatex no. 2, Ultra Black, or Ultra

Copper to each side of water pump gasket. Then position

gasket on pump.

3.

Apply 1/8 - 3/16 in. (3.3-5 mm) wide bead of sealer to

backing plate (Figure 4-28). Encircle bolt hole at bottom

of plate with sealer as shown. Also apply sealer to threads

of bolt or stud used in this hole to avoid leaks.

4.

Install adapter plate and water pump on front cover.

Tighten all studs and short bolts marked A to 13-20 lb-ft

(18-27 N•m). Tighten large studs and large bolt marked B

to 25-37 lb-ft (34-50 N•m) (Figure 4-26).

5.

Attach hoses to water pump.

6.

Install fan and clutch.

7.

Install and adjust serpentine drive belt.

8.

Install radiator, shroud, coolers, and A/C condenser as

assembly.

9.

Evacuate and recharge A/C system.

10. Refill engine cooling system.

11. Install hood.

12. Start engine, bleed air from cooling system, and top off

coolant level.

Figure 4-26: Water Pump and Adapter Plate Removal/Installation

Figure 4-27: Water Pump

ADAPTER PLATE

FRONT

COVER

WATER PUMP

A

A

B

B

A

BYPASS ADAPTER

WATER PUMP

GASKET

BACKING PLATE

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст