Hummer H1 (2002+). Manual — part 142

________________________________________

Axles, Suspension, and Frame 9-29

®

05745159

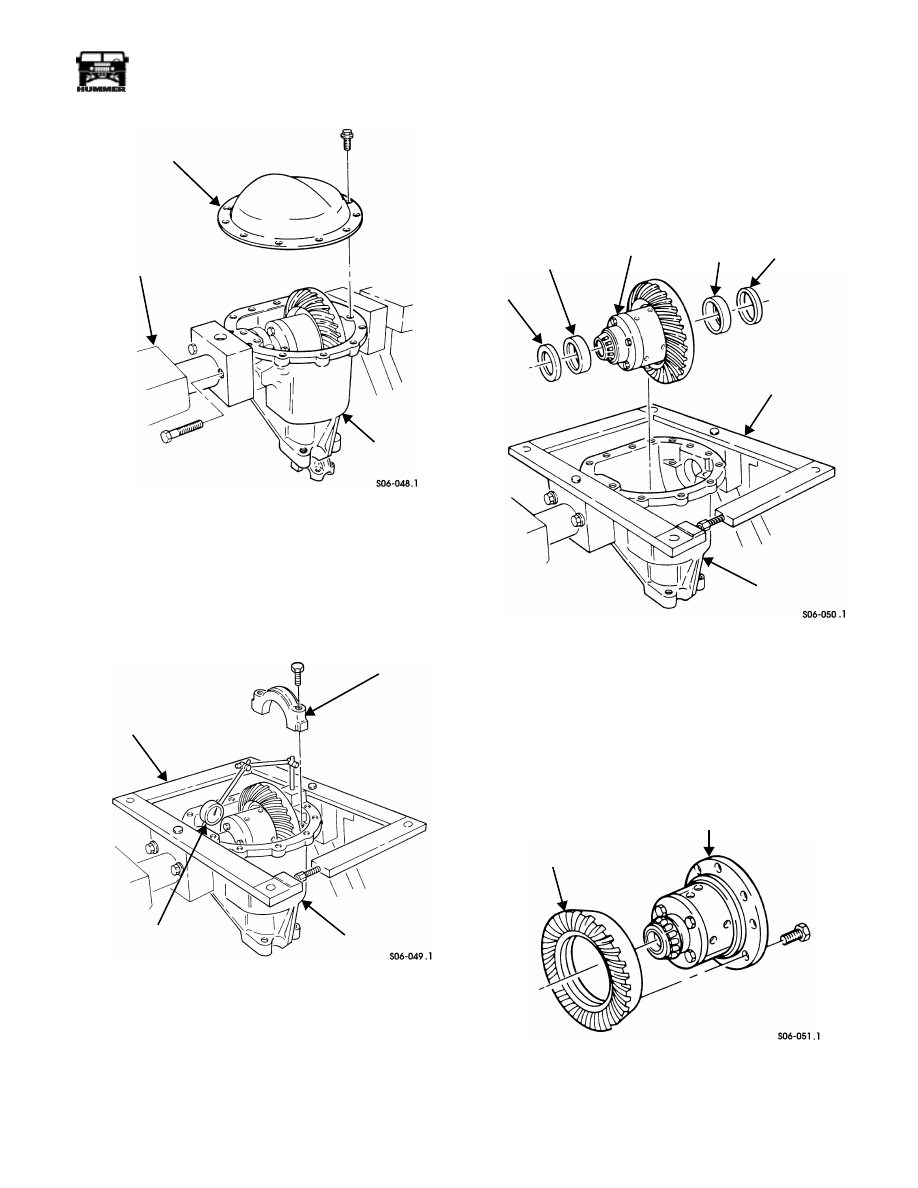

Figure 9-62: Axle Mounted In Holding Fixture

7.

Position housing so cover faces up. Remove twelve bolts

and cover from housing (Figure 9-62).

8.

Mark bearing caps and housing for assembly and remove

bearing caps (Figure 9-63).

Figure 9-63: Housing Spreader Mounting

9.

Install axle housing spreader J–3409-01 into holes in axle

holding fixture adapters and install dial indicator J–8001

to read from each end of housing as shown. Then set dial

indicator at 0.020 in. (0.5 mm).

CAUTION: Over-tightening of axle housing spreader will

damage axle housing.

10. Spread housing 0.010 in. (0.25 mm) and remove dial

indicator.

11. Remove differential assembly, two bearing cups, and

shims from housing (Figure 9-64). Tag bearing shims and

bearing cups for assembly.

Figure 9-64: Differential Assembly

12. Relieve pressure on axle housing spreader and remove

from housing.

CAUTION: To avoid damage, do not chisel or wedge ring

gear from axle assembly.

13. Remove eight bolts and ring gear from differential

assembly (Figure 9-65).

Figure 9-65: Ring Gear Removal

14. Rotate housing 90 degrees. Secure cover to housing with

two bolts (Figure 9-66).

DIFFERENTIAL

AXLE

AXLE HOLDING

FIXTURE J–3409-01

COVER

HOUSING

BEARING CAP

AXLE

HOUSING

SPREADER

HOUSING

DIAL INDICATOR

J–24385-01

J–8001

SHIM

BEARING CUP

DIFFERENTIAL

BEARING

SHIM

AXLE HOUSING

HOUSING

ASSEMBLY

CUP

SPREADER J–3409-01

DIFFERENTIAL ASSEMBLY

RING GEAR

9-30

Axles, Suspension, and Frame

_________________________________________

®

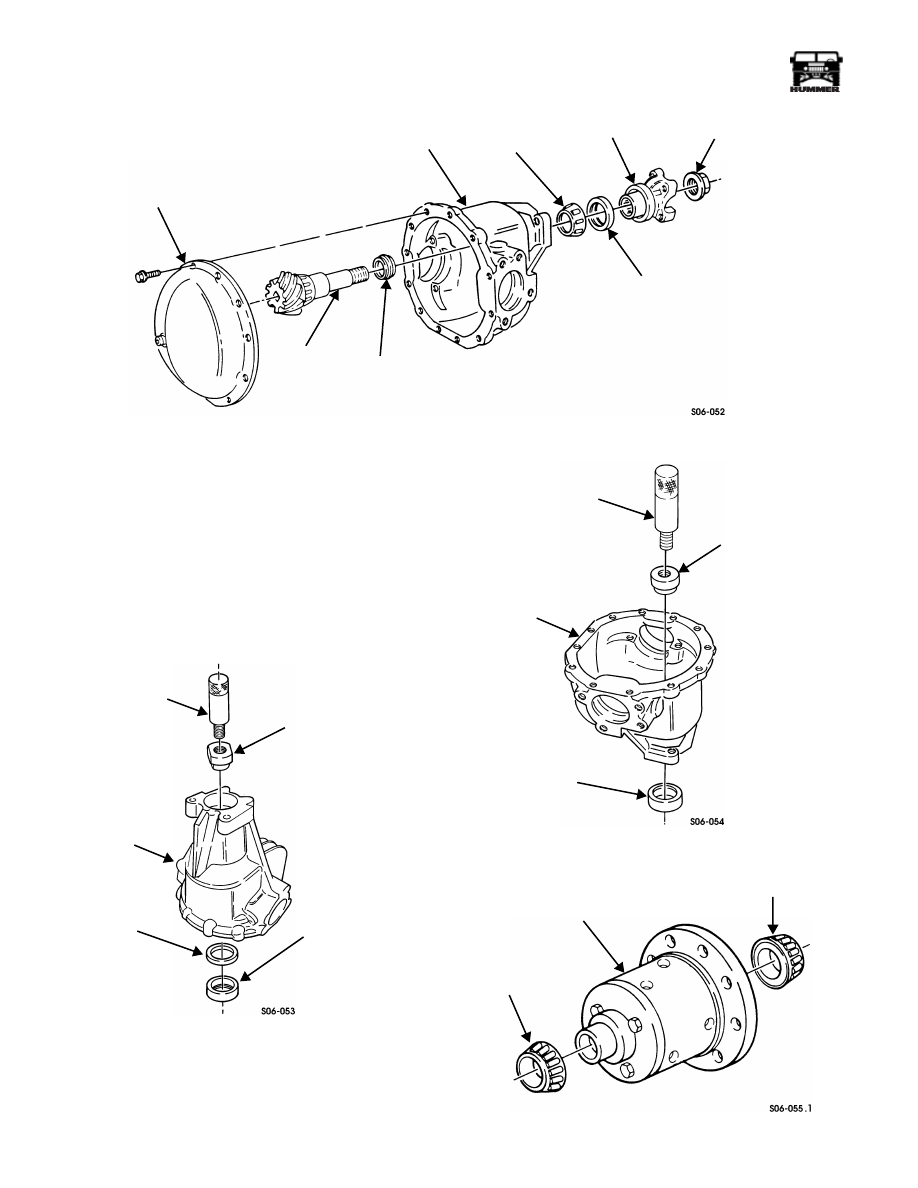

Figure 9-66: Axle Housing

15. Remove pinion nut and pinion yoke from pinion gear.

16. Drive pinion gear out of front pinion bearing.

17. Remove cover, pinion gear, and collapsible spacer from

housing. Discard collapsible spacer.

18. Remove pinion seal and front pinion bearing from

housing. Discard pinion seal.

19. Rotate front of housing upward 90 degrees. Using driver

handle J–8092 and bearing cup remover J–21786, remove

pinion rear bearing cup and pinion depth shim from

housing (Figure 9-67).

Figure 9-67: Pinion Rear Bearing Cup Removal

20. Rotate housing 180 degrees. Using driver handle J–8092

and pinion front bearing cup remover J–21787, remove

front pinion bearing cup from housing (Figure 9-68).

Figure 9-68: Pinion Front Bearing Cup Removal

Figure 9-69: Differential Side Bearing Removal

COVER

PINION

COLLAPSIBLE

HOUSING

FRONT

PINION SEAL

PINION YOKE

PINION NUT

SPACER

GEAR

PINION

BEARING

DRIVER

BEARING CUP

REMOVER

PINION

PINION REAR

BEARING CUP

HOUSING

DEPTH

SHIM

HANDLE

J–8092

J–21786

DRIVER

HANDLE

BEARING CUP

REMOVER

HOUSING

PINION FRONT

BEARING CUP

J–21787

J–8092

DIFFERENTIAL

SIDE BEARING

DIFFERENTIAL

ASSEMBLY

DIFFERENTIAL

SIDE BEARING

________________________________________

Axles, Suspension, and Frame 9-31

®

05745159

Figure 9-70: Pinion Bearing Removal

21. Remove two differential side bearings from differential

assembly (Figure 9-69).

22. Remove rear pinion bearing from pinion gear (Figure 9-70).

23. Remove bearing from output shaft (Figure 9-71).

Figure 9-71: Output Shaft Bearing Removal

Cleaning and Inspection

NOTE:

Clean all components. Examine for wear or damage

and replace if necessary.

1.

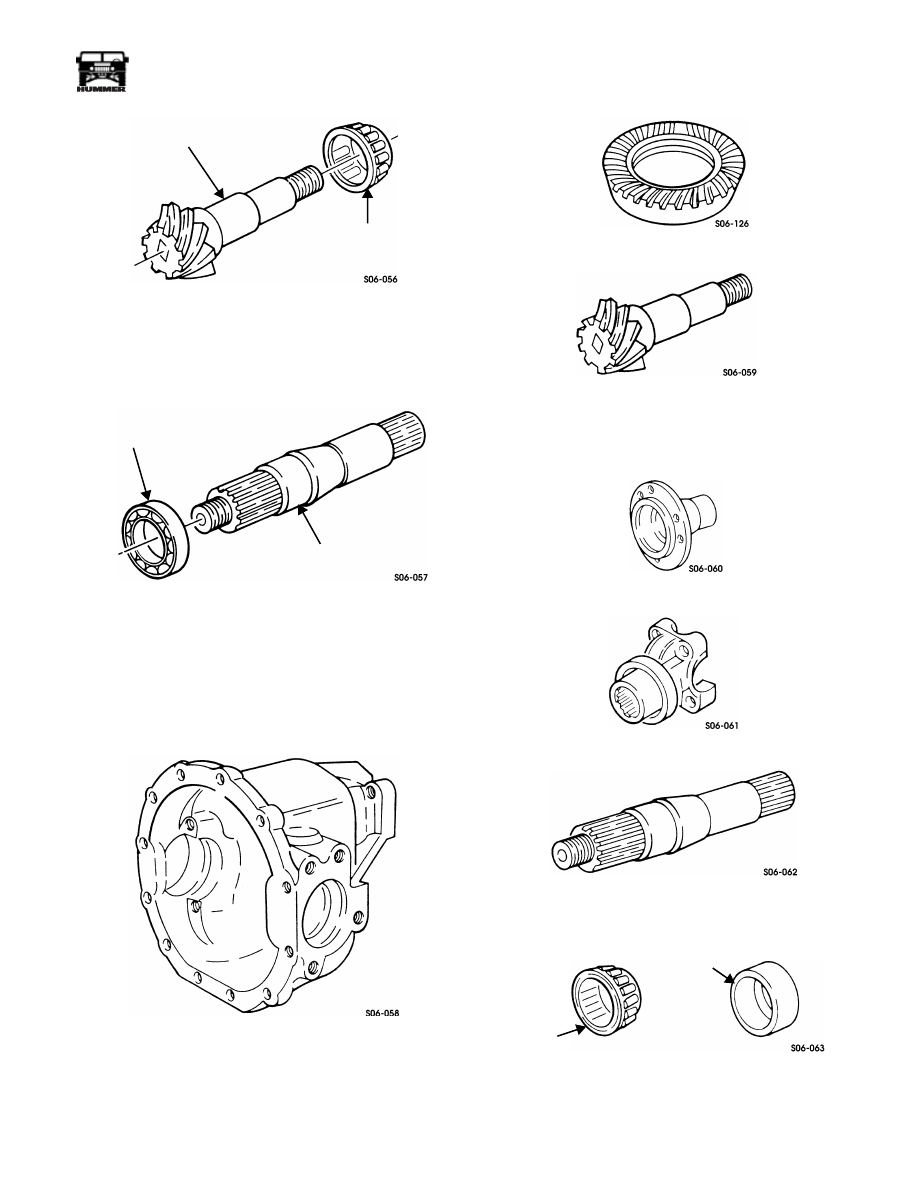

Inspect housing and all threaded holes for damage. Repair

any damaged threads with thread repair inserts. Replace

axle assembly if housing is damaged (Figure 9-72).

Figure 9-72: Housing

NOTE:

Ring and pinion gears must be replaced as matched set.

2.

Inspect splines and gear teeth on pinion gear and ring gear

for damage. Replace both pinion gear and ring gear if either

is damaged (Figure 9-73: and Figure 9-74:).

Figure 9-73: Ring Gear

Figure 9-74: Pinion Gear

3.

Inspect splines and sealing surfaces on output flanges,

pinion yoke, and output shaft for damage (Figure 9-75)

through (Figure 9-77).

Figure 9-75: Output Flange

Figure 9-76: Pinion Yoke

Figure 9-77: Output Shaft

4.

Inspect all bearings and bearing cups for damage

(Figure 9-78).

Figure 9-78: Bearing and Bearing Cup

5.

Inspect differential assembly case for damage

(Figure 9-79).

PINION GEAR

REAR PINION BEARING

BEARING

OUTPUT SHAFT

BEARING

BEARING

CUP

9-32

Axles, Suspension, and Frame

_________________________________________

®

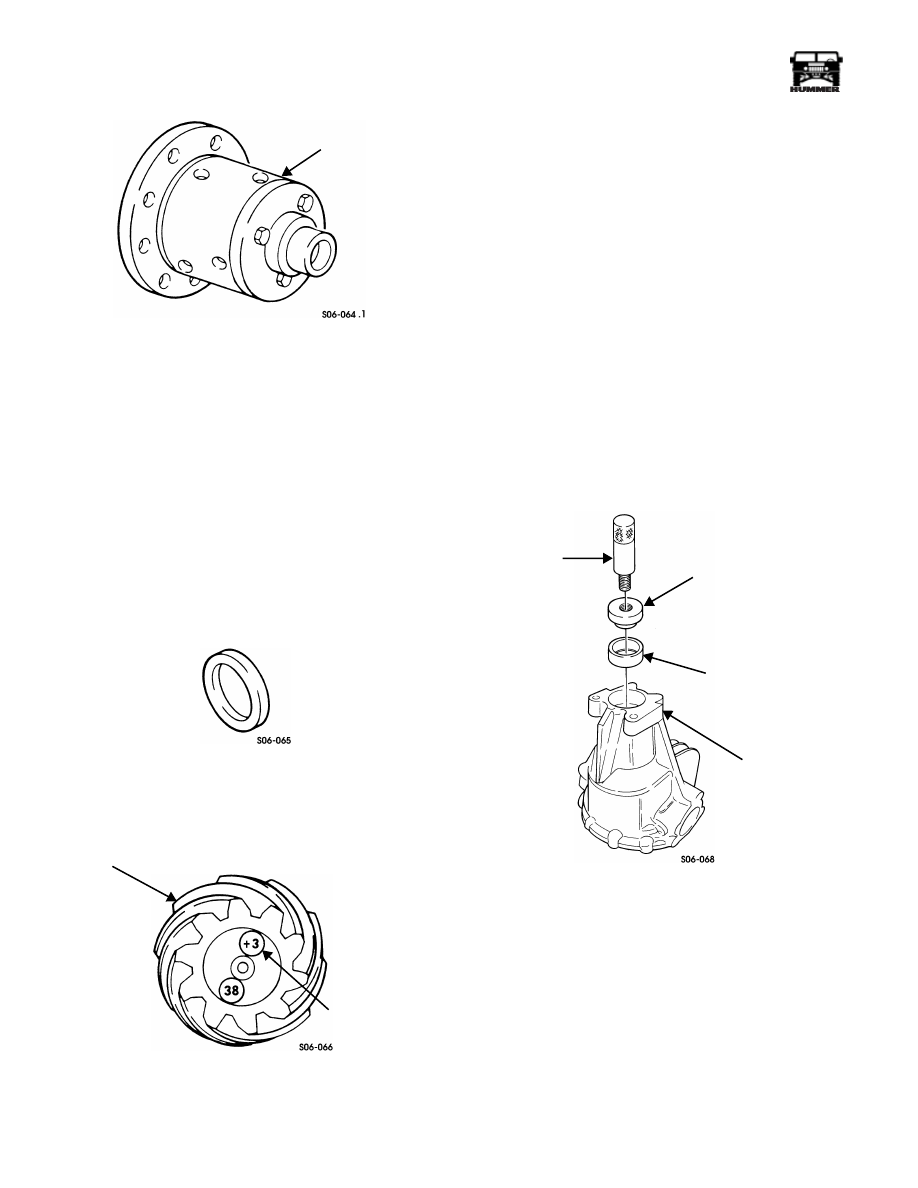

Figure 9-79: Differential Assembly

Axle Assembly

NOTE: PINION DEPTH SETTING

: Pinion gear depth is the

distance from the end face of the pinion to the center line of the

output shafts. The dimension is controlled by shims between

pinion gear rear bearing cup and differential housing. The pin-

ion gear is etched with two identifying numbers. The first num-

ber identifies ring gear and pinion gear as a matched set, and

the second number represents pinion depth variance. The sec-

ond number is preceded by a plus (+) or minus (-) which repre-

sents the amount the gear set varies from the standard setting of

2.547 in. (6.46 cm). If using original gear set, use original pin-

ion depth shim as a starter shim and proceed to step 4.

1.

Measure thickness of original pinion depth shim and

record for reference (Figure 9-80).

Figure 9-80: Pinion Depth Shim

2.

Check pinion depth variance number marked on old and

new pinion gears and record (Figure 9-81). Refer to

Table 4.

Figure 9-81: Pinion Depth Variance Number

Location

NOTE:

If the old pinion is marked -3 and the new pinion is

marked +2, the procedure would be as follows: Refer to Old

Pinion Marking column at left side of table and locate -3 in this

column. Then read to right, across table, until under +2 in New

Pinion Marking column. The box where two columns intersect

is amount of shim thickness change required. In this case, the

number in the intersecting box is -0.005 in. (0.13 mm) which

represents the amount to be subtracted from the old shim thick-

ness. If the box number had been a (+) figure, this amount

would be added to the old shim thickness. The actual pinion

depth measurement must be performed and final shim thick-

ness adjusted as necessary. Pinion shims are available from

0.084-0.111 in. (2.13-2.82 mm) in increments of 0.0005 in.

(0.0127 mm).

3.

Refer to Old and New Pinion Marking columns on pinion

variance table. Note on table where old and new pinion

depth variances intersect. This will determine amount to

be added or subtracted from original pinion depth shim for

desired pinion depth starter shim.

4.

Rotate housing so front pinion bearing cup bore faces up

(Figure 9-82).

Figure 9-82: Pinion Front Bearing Cup

Installation

DIFFERENTIAL

ASSEMBLY

PINION GEAR

PINION DEPTH

VARIANCE

NUMBER

DRIVER

HANDLE

BEARING CUP

INSTALLER

PINION FRONT

BEARING CUP

HOUSING

J–8092

J–8611-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст