Hummer H1 (2002+). Manual — part 141

________________________________________

Axles, Suspension, and Frame 9-25

®

05745159

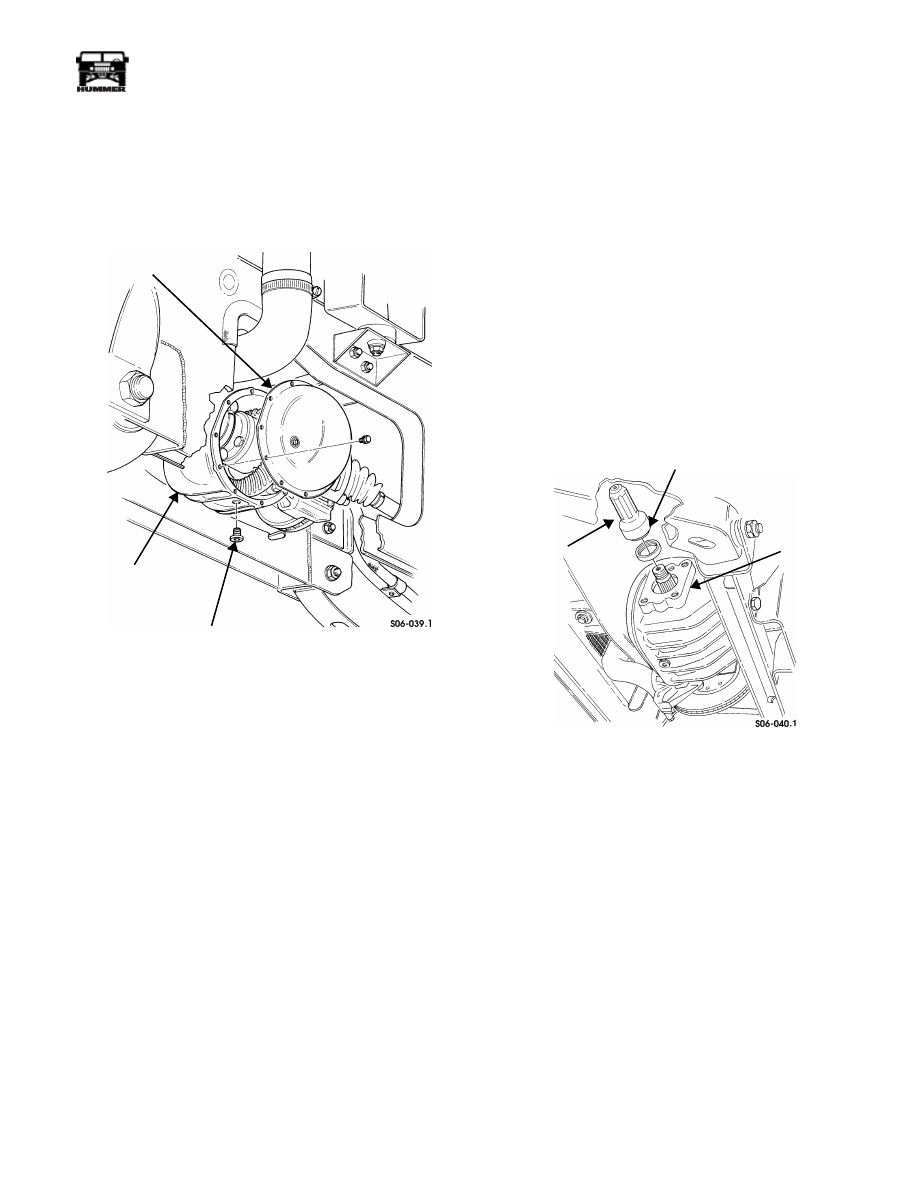

AXLE ASSEMBLY COVER SERVICE

Removal

1.

Remove drainplug from axle assembly and drain axle

assembly (Figure 9-53).

2.

Remove twelve bolts and cover from axle assembly.

Figure 9-53: Axle Assembly Cover Service

Cleaning and Inspection

NOTE:

Clean all components, examine for wear or damage,

and replace if necessary.

1.

Clean axle assembly cover, bolts, and axle assembly with

solvent (Figure 9-53).

2.

Inspect axle assembly cover for cracks, wear, or breaks.

Installation

1.

Apply RTV sealant to cover sealing surface and secure

cover to axle assembly with twelve bolts. Tighten bolts to

16 lb-ft (22 N•m).

2.

Thread drainplug into axle assembly and tighten to 13-18

lb-ft (18-25 N•m) (Figure 9-53).

3.

Fill axle assembly to proper oil level (Section 1).

AXLE OUTPUT SHAFT SEAL REPLACEMENT

Removal

1.

Remove brake caliper and yoke from caliper adapter (dis-

connect park brake cable from rear calipers) and support

caliper to the side being careful not to kink brake line.

2.

Disconnect halfshaft at the axle flange and swing off to

the side.

3.

Remove the brake rotor.

4.

Remove the axle output flange retaining nut and the

flange.

5.

Support the axle assembly, disconnect and move the axle

assembly support bracket over to gain access to the output

seal.

6.

Remove output shaft seal from axle (Figure 9-54).

Figure 9-54: Axle Output Shaft Seal Replacement

Installation

1.

Using seal installer J–38869, install output shaft seal in

axle assembly (Figure 9-54).

2.

Install axle assembly support bracket.

3.

Install axle output shaft flange and nut using Loctite 242

(or equivalent) and torque to 166-196 lb ft (224-265 N.m).

4.

Install brake rotor and halfshaft. Use bolts with preapplied

Loctite or original bolts with Loctite 272 (or equivalent),

cam-lock washers and torque 57 lb ft (77 N.m).

5.

Install brake caliper and yoke using Loctite 272 (or

equivalent) (connect park brake cable on rear calipers) and

torque to 40 lb ft (54 N.m).

AXLE COVER

AXLE ASSEMBLY

DRAINPLUG

AXLE SHAFT

OUTPUT

SHAFT

SEAL

AXLE

AND SEAL

INSTALLER

ASSEMBLY

J–38869

9-26

Axles, Suspension, and Frame

_________________________________________

®

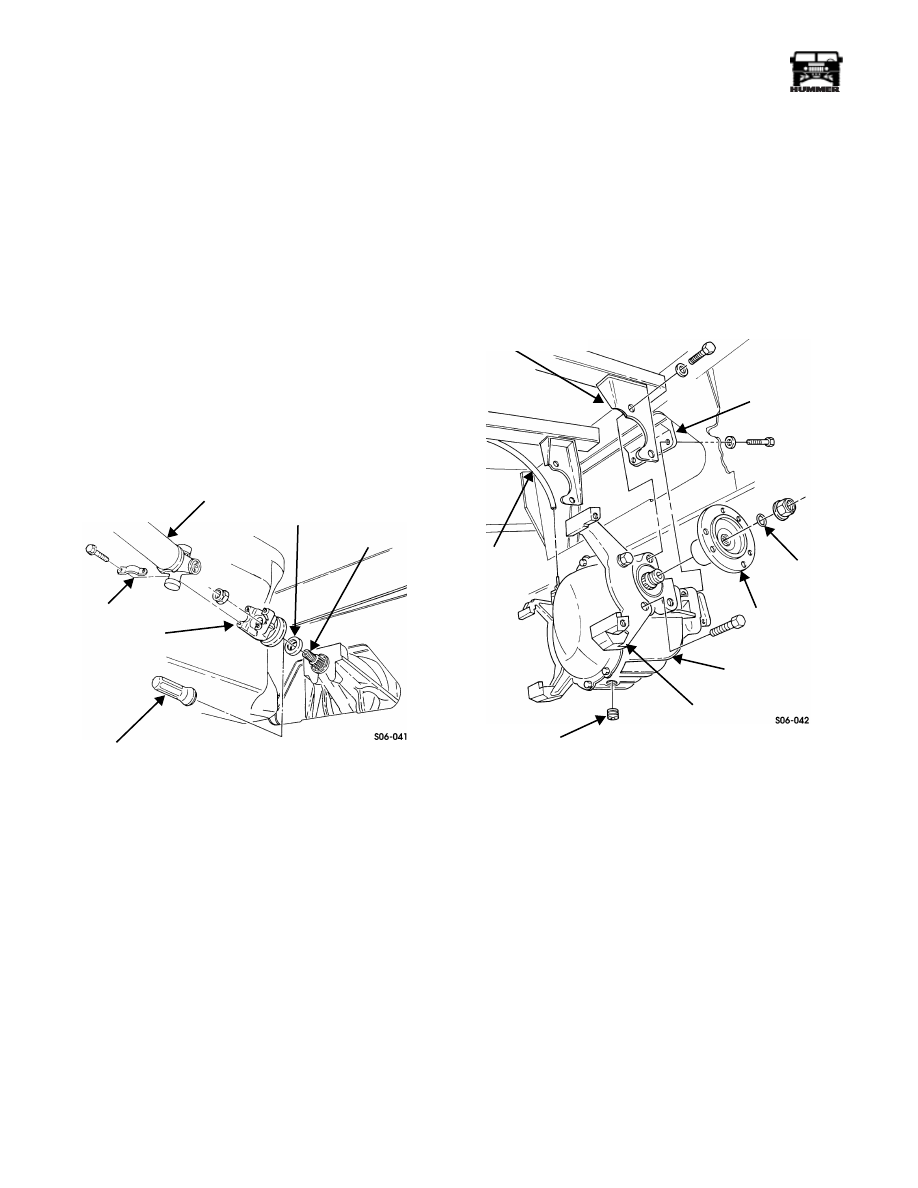

PINION SEAL REPLACEMENT

NOTE:

Removal and installation procedures for pinion seals

are basically the same for front and rear axle assemblies. This

procedure covers the rear axle assembly pinion seal.

Removal

1.

Remove six bolts, cam-lock washers, and halfshaft from

each output flange rotor.

2.

Remove four bolts, two straps, and rear propeller shaft

from pinion yoke (Figure 9-55).

3.

Using a lb-in torque wrench, measure torque required to

rotate pinion and record measurement.

4.

Count and record number of exposed threads on end of

pinion and mark locknut and pinion for assembly.

5.

Remove locknut and pinion yoke from pinion.

6.

Remove pinion seal from pinion.

Figure 9-55: Pinion Seal Replacement

Installation

1.

Using yoke seal installer J–29162, install pinion seal on

pinion (Figure 9-55).

2.

Secure pinion yoke to pinion with locknut.

3.

Tighten locknut to original position.

4.

Tighten locknut in small increments, until torque required

to rotate pinion exceeds original measurement by 2 lb-in

(0.2 N•m).

5.

Secure rear propeller shaft to pinion yoke with four bolts

and two straps. Tighten bolts to 27 lb-ft (37 N•m).

6.

Apply Loctite 272 to halfshaft mounting bolts.

7.

Secure halfshaft to each output flange and rotor with

twelve cam-lock washers and six bolts. Tighten to 57 lb-ft

(77 N•m).

AXLE ASSEMBLY REPLACEMENT

Removal

NOTE:

Removal and installation procedures are basically the

same for front and rear axle assemblies. This procedure covers

both front and rear axle assemblies except where noted.

1.

Remove service brake rotors (Section 7).

2.

Remove drainplug from axle assembly. Allow oil to drain

and install drainplug (Figure 9-56).

Figure 9-56: Rear Axle Assembly Mounting

3.

Remove four bolts, two straps, and rear propeller shaft

from pinion yoke (Figure 9-57).

4.

Remove rear propeller shaft from transfer case.

NOTE:

No washers are required when securing front axle as-

sembly to mounting bracket.

5.

Remove two bolts and washers securing axle assembly to

mounting bracket (Figure 9-56).

6.

Remove two locknuts, four O-ring seals and two output

flanges from axle assembly. Discard locknuts and O-ring

seals.

REAR

STRAP

PINION YOKE

YOKE SEAL

PINION SEAL

PINION

INSTALLER

PROPELLER

SHAFT

J–29162

VENT LINE

MOUNTING

RUBBER

OUTPUT

AXLE ASSEMBLY

BRAKE

DRAINPLUG

CALIPER

ADAPTER

FLANGE

WASHER

BRACKET

AXLE ASSEMBLY

SUPPORT BRACKET

________________________________________

Axles, Suspension, and Frame 9-27

®

05745159

WARNING: Axle assembly must be supported during

removal and installation. Failure to do this may cause

personal injury or damage to equipment.

7.

Support axle assembly.

8.

Remove four bolts and washers securing axle assembly to

side mounting brackets.

9.

Lower axle assembly slightly and disconnect vent line

from axle assembly.

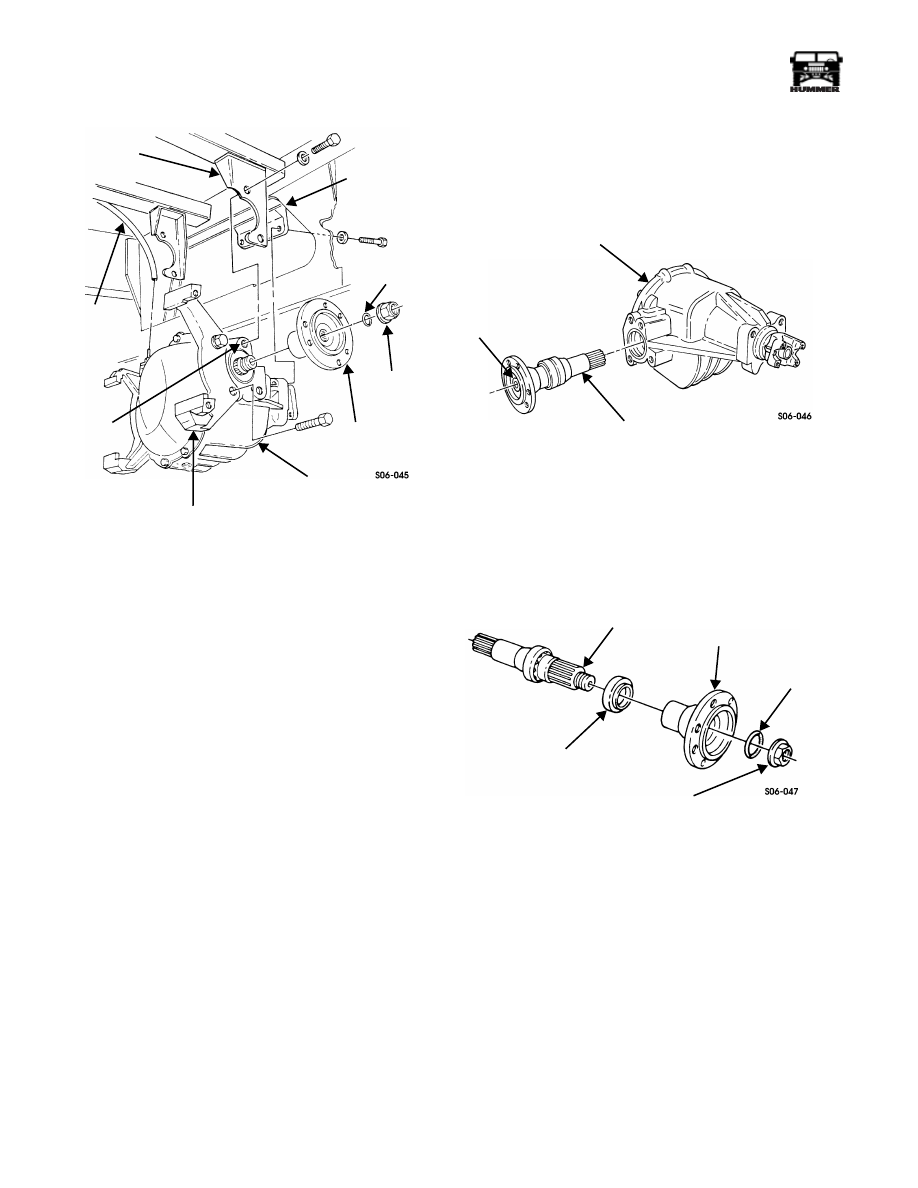

10. Remove axle assembly.

11. Remove four bolts and two brake caliper adapters from

axle assembly.

12. Using a lb-in torque wrench, measure torque required to

rotate pinion and record measurement.

13. Count and record number of exposed threads on end of

pinion and mark locknut and pinion for assembly.

14. Remove locknut and rear pinion yoke from axle assembly

(Figure 9-58).

Figure 9-57: Rear Propeller Shaft Removal

Figure 9-58: Pinion Yoke Removal

Installation

1.

Secure rear pinion yoke to axle assembly with locknut

(Figure 9-58).

2.

Tighten locknut in small increments, until torque required

to rotate pinion yoke exceeds original measurement by 2

lb-in (0.2 N•m).

3.

Apply thread-locking compound to axle assembly tapped

holes. Secure two brake caliper adapters to axle assembly

with four bolts. Tighten bolts to 110-140 lb-ft (149-190

N•m) (Figure 9-59).

TRANSFER CASE

PINION YOKE

STRAP

REAR

PROPELLER

SHAFT

AXLE ASSEMBLY

REAR PINION YOKE

LOCKNUT

9-28

Axles, Suspension, and Frame

_________________________________________

®

Figure 9-59: Rear Axle Assembly Installation

4.

Raise axle assembly into place and connect vent line.

5.

Apply thread-locking compound to axle assembly tapped

holes. Install axle assembly on side mounting brackets

with four washers and bolts.

6.

Secure two output flanges and two seals to axle assembly

with two locknuts. Tighten locknuts to 165-195 lb-ft (224-

264 N•m).

NOTE:

No washers required when securing front axle assem-

bly to mounting bracket.

7.

Apply thread-locking compound to bolts. Install two

washers, bolts, and axle assembly to mounting bracket.

8.

Tighten six bolts securing axle assembly to brackets to

110-139 lb-ft (149-188 N•m).

9.

Install rear propeller shaft in transfer case (Figure 9-57).

10. Secure rear propeller shaft to pinion yoke with four bolts

and two straps. Tighten bolts to 60 lb-ft (81 N•m)

(Figure 9-57).

11. Install service brake rotors (Section 7).

12. Fill axle assembly to proper oil level (Section 1).

13. Install vent line to axle assembly.

AXLE ASSEMBLY REPAIR

Disassembly

1.

Remove axle assembly.

2.

Loosen locknut on output shaft assembly (Figure 9-60).

Figure 9-60: Output Shaft Assembly Removal

3.

Using a slide hammer, remove output shaft assembly from

axle assembly.

4.

Remove locknut, seal washer, output flange and output

shaft seal from output shaft. Discard seal washer, output

shaft seal, and locknut (Figure 9-61).

Figure 9-61: Output Shaft Assembly Breakdown

5.

Repeat steps 2 through 4 for opposite side.

6.

Secure two axle holding fixture adapters to housing with

four bolts. Place housing in holding stand (Figure 9-62).

SIDE

VENT LINE

TAPPED

BRAKE

AXLE ASSEMBLY

OUTPUT

MOUNTING

MOUNTING

BRACKET

HOLES

BRACKET

FLANGE

CALIPER

ADAPTER

SEAL

LOCKNUT

WASHER

AXLE ASSEMBLY

OUTPUT SHAFT ASSEMBLY

LOCKNUT

OUTPUT SHAFT

OUTPUT SHAFT SEAL

OUTPUT

FLANGE

SEAL

LOCKNUT

WASHER

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст