Hummer H1 (2002+). Manual — part 255

____________________________________________________________

Accessories 13-13

®

05745159

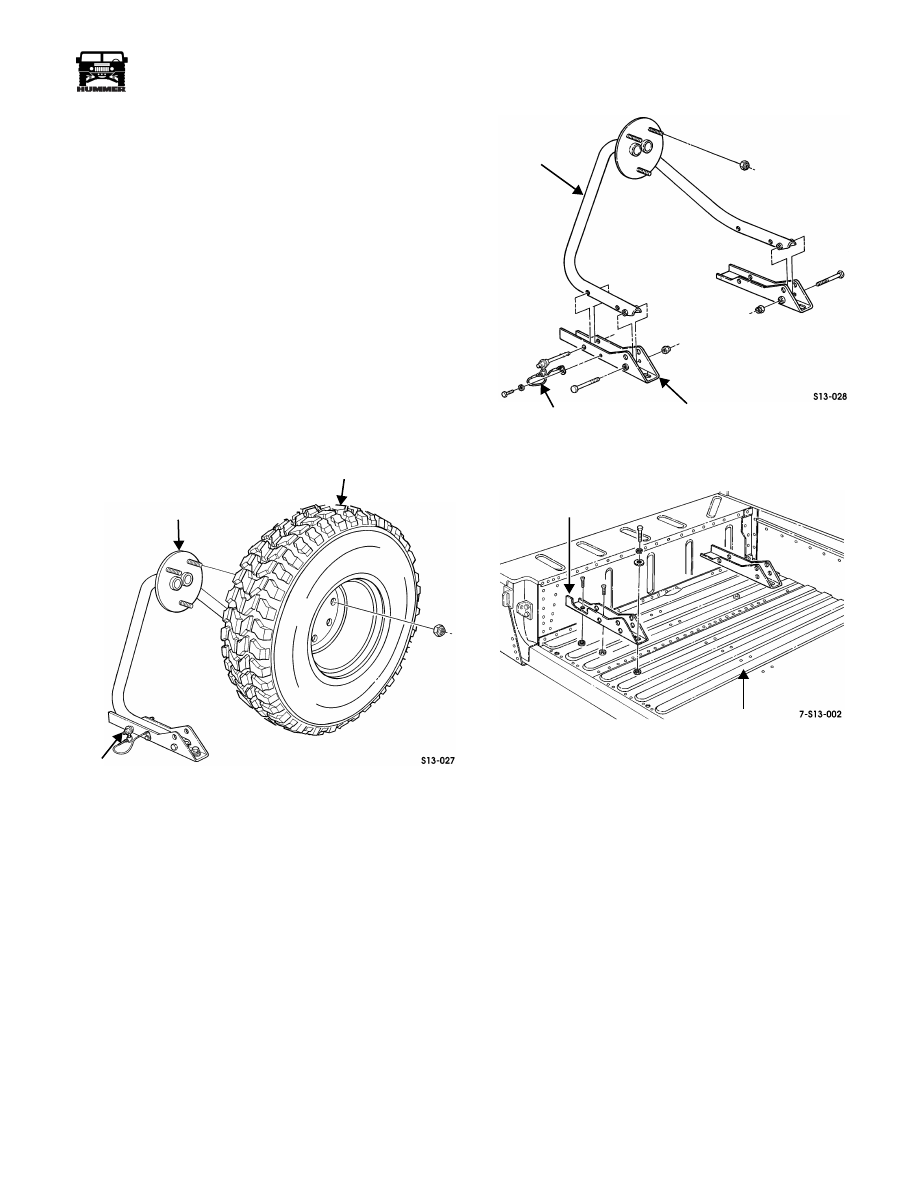

CARGO BED-MOUNTED SPARE TIRE CARRIER

REPLACEMENT

WARNING: Always support the tire and wheel assem-

bly when removing the lug nuts. The tire and wheel as-

sembly weighs approximately 160 lbs (72 kgs) and may

cause personal injury if it is not supported properly.

NOTE: Cargo bed-mounted spare tire carrier may be located

either directly behind the cab or at the left wheelhouse on two

door models. On four door models, spare tire carrier will be lo-

cated at the left wheelhouse.

Removal

NOTE: Perform steps 1 and 2 on vehicles with frame assem-

bly stowed in down position.

1.

Disconnect lock pins and raise frame assembly to upright

position (Figure 13-29).

Figure 13-29: Cargo Bed-Mounted Spare Tire

Carrier Appearance

2.

Secure frame assembly in upright position with lock pins.

3.

Remove lug nuts securing tire to frame assembly and

remove wheel/tire assembly.

4.

Remove self-tapping screws, lockwashers, and lanyard/lock

pin assemblies from mounting brackets (Figure 13-30).

5.

Remove locknuts, bolts and frame assembly from

mounting brackets.

6.

Remove screws securing mounting brackets to cargo floor

(Figure 13-31).

7.

Remove bolts, lockwashers, washers, and mounting

brackets from cargo floor.

Figure 13-30: Frame Assembly Mounting

Figure 13-31: Mounting Bracket Positioning

Installation

1.

Install mounting brackets on cargo floor with washers,

lockwashers, and bolts (Figure 13-31).

2.

Secure mounting brackets to cargo floor with screws.

Tighten screws to 44 lb-ft (60 N•m).

3.

Install frame assembly on mounting brackets with bolts

and locknuts (Figure 13-30).

4.

Install lanyard/lock pin assemblies on mounting brackets

and frame assembly with lockwashers and self-tapping

screws.

5.

With carrier in the upright position, install tire on frame

assembly with three lug nuts (Figure 13-29).

NOTE: Perform steps 6 and 7 to stow frame assembly in down

position.

6.

Disconnect lock pins and lower frame assembly to down

position.

7.

Connect lock pins.

FRAME ASSEMBLY

WHEEL/TIRE ASSEMBLY

LOCK

PIN

LANYARD AND

LOCK PIN ASSEMBLY

MOUNTING

BRACKET

FRAME

ASSEMBLY

MOUNTING

BRACKET

CARGO FLOOR

13-14

Accessories

_____________________________________________________________

®

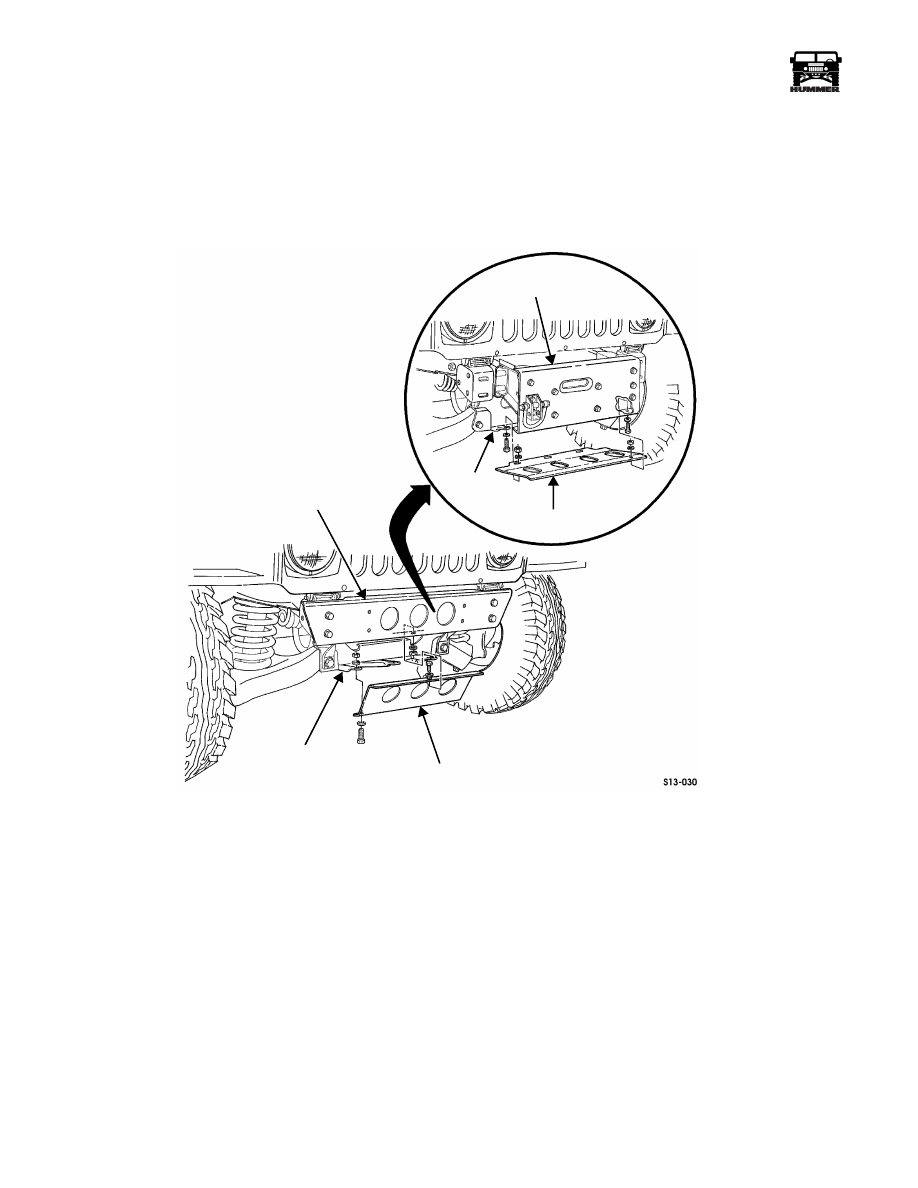

DRIVELINE PROTECTION

Skid Plate Replacement

Removal

1.

Remove locknuts, washers, bolts, and washers securing

skid plate to front shield (Figure 13-32).

NOTE: Go to step 3 for vehicles equipped with a winch.

2.

Remove locknuts, washers, bolts, washers, and skid plate

from front bumper.

3.

Remove locknuts, washers, bolts, washers, and winch skid

plate from winch bumper.

Figure 13-32: Skid Plate Mounting

Installation

NOTE: Go to step 2 for vehicles equipped with a winch.

1.

Install skid plate on front bumper with bolts, washers, and

locknuts. Tighten locknuts to 24 lb-ft (33 N•m)

(Figure 13-32).

2.

Install winch skid plate on winch bumper with bolts,

washers, and locknuts (Figure 13-32). Tighten locknuts to

24 lb-ft (33 N•m).

3.

Secure skid plate to front shield with bolts, washers, and

locknuts. Tighten locknuts to 24 lb-ft (33 N•m).

WINCH BUMPER

WINCH SKID PLATE

SKID PLATE

FRONT SHIELD

FRONT BUMPER

FRONT

SHIELD

____________________________________________________________

Accessories 13-15

®

05745159

Front Shield Replacement

Removal

1.

Remove locknuts, washers, bolts, and spacers securing

front shield to front crossmember and intermediate shield

(Figure 13-33).

2.

Remove locknuts, washers, bolts, and front shield from

skid plate.

Installation

1.

Install front shield on skid plate with bolts, washers, and

locknuts. Do not tighten locknuts (Figure 13-33).

2.

Secure front shield to front crossmember and intermediate

shield with spacers, bolts, washers, and locknuts.

3.

Tighten locknuts securing front shield to skid plate to 24

lb-ft (33 N•m). Tighten locknuts securing front shield to

crossmember and intermediate shield to 44 lb-ft (60 N•m).

Figure 13-33: Front Shield Mounting

SKID PLATE

FRONT SHIELD

FRONT CROSSMEMBER

INTERMEDIATE SHIELD

13-16

Accessories

_____________________________________________________________

®

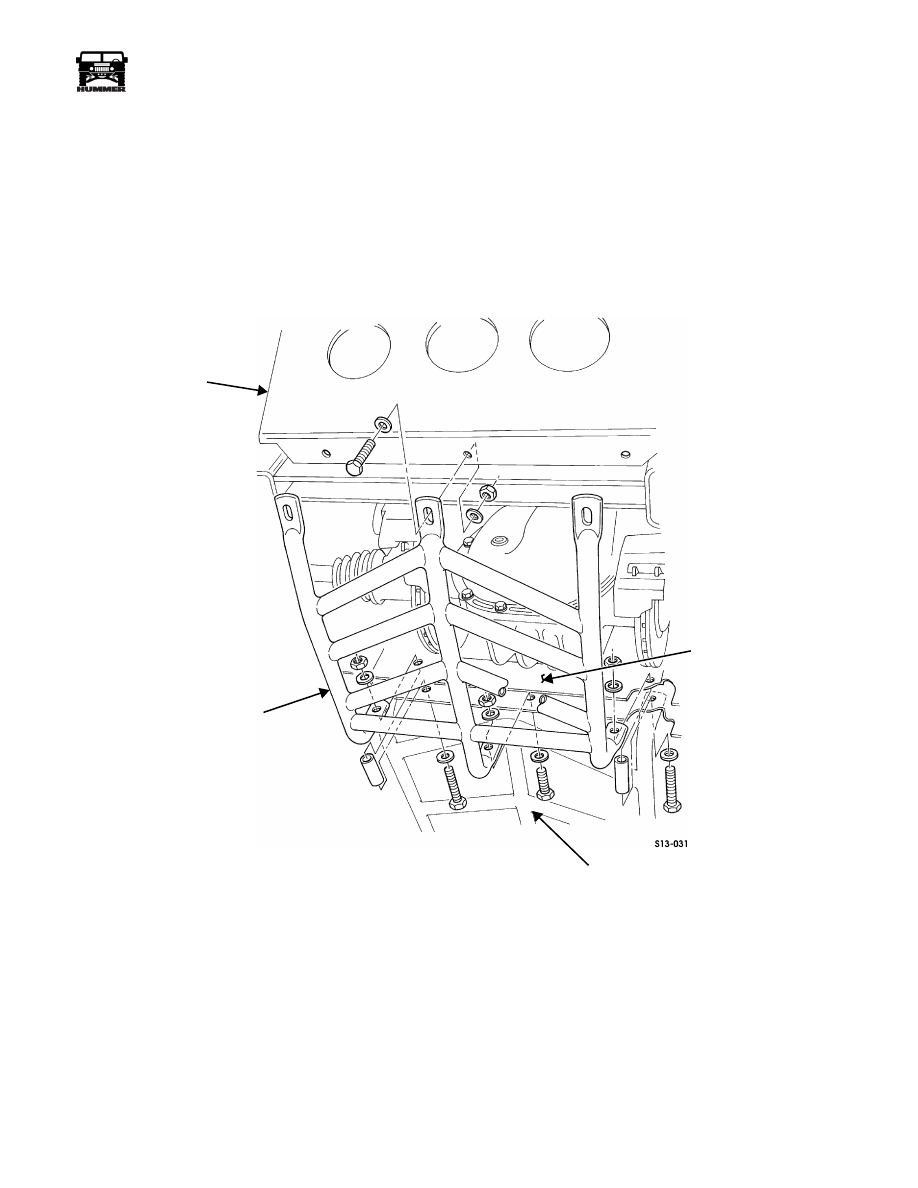

Intermediate Shield Replacement

Removal

1.

Remove six locknuts, washers, bolts, washers, and four

rubber washers securing two transmission support brack-

ets and intermediate shield to transmission mount cross-

member. Remove support brackets. Discard locknuts

(Figure 13-34).

Figure 13-34: Intermediate Shield

2.

Remove locknut, washer, capscrew, and washer securing

left support bracket to engine mount bracket and frame

rail. Discard locknut (Figure 13-35).

3.

Remove four locknuts, washers, bolts, washers, and left

support bracket from left mounting bracket. Discard

locknuts.

4.

Remove locknut, washer, capscrew, and washer securing

right support bracket to frame rail. Discard locknut

(Figure 13-36).

5.

Remove four locknuts, washers, bolts, washers, and right

support bracket from right mounting bracket. Discard

locknuts.

6.

Remove two locknuts, washers, bolts, washers, spacers,

and intermediate shield from front crossmember and front

shield. Discard locknuts (Figure 13-37).

Figure 13-35: Left Support Bracket

Figure 13-36: Right Support Bracket

INTERMEDIATE

SHIELD

TRANSMISSION

SUPPORT

BRACKET

RUBBER

WASHERS

TRANSMISSION

MOUNT

CROSSMEMBER

ENGINE

MOUNT

BRACKET

FRAME

RAIL

LEFT SUPPORT

BRACKET

LEFT MOUNTING

BRACKET

FRAME RAIL

RIGHT SUPPORT

BRACKET

RIGHT MOUNTING

BRACKET

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст