Hummer H1 (2002+). Manual — part 144

________________________________________

Axles, Suspension, and Frame 9-37

®

05745159

33. Install differential assembly, bearing cups, and shims in

housing.

34. Install two bearing caps and four bolts in housing. Snug

bolts.

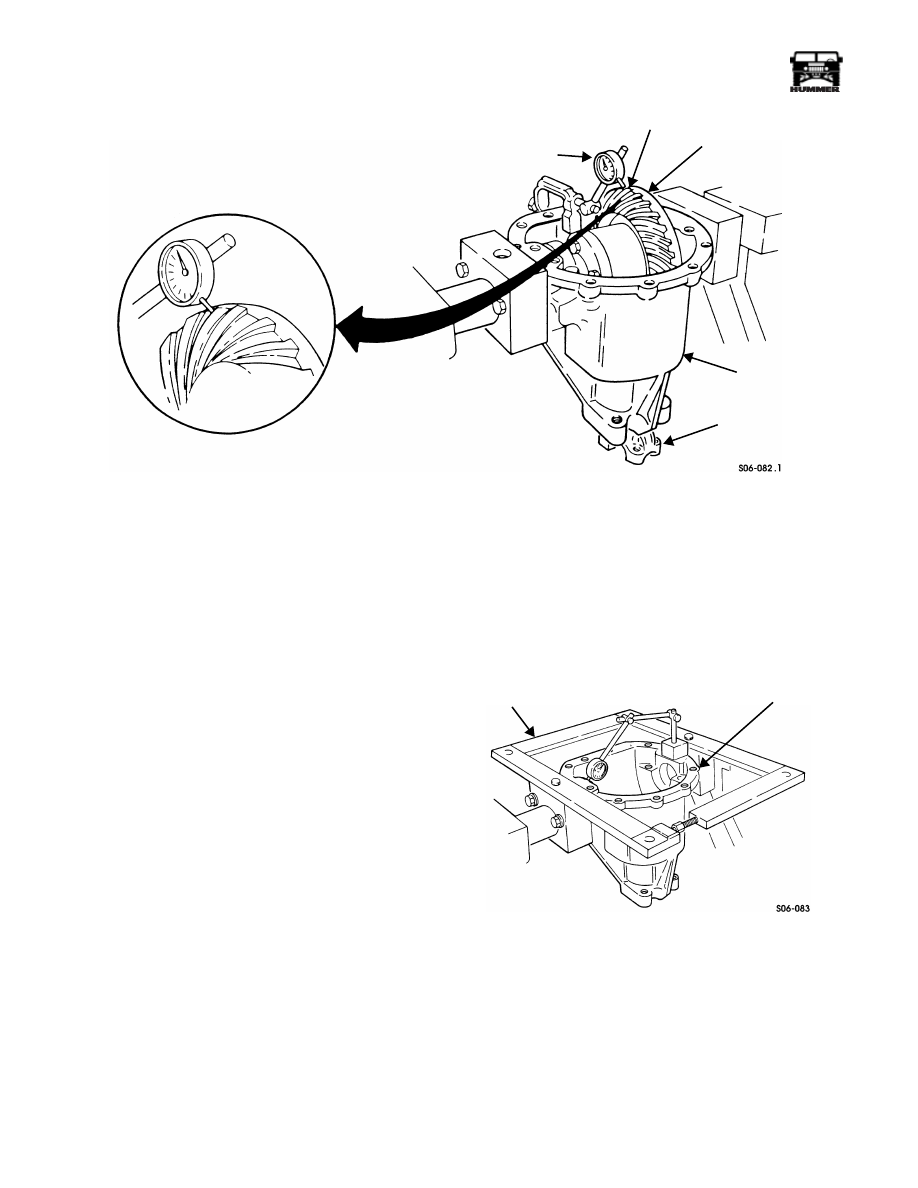

35. Mount dial indicator on housing and position indicator to

read off ring gear mounting surface of differential

assembly (Figure 9-94).

Figure 9-94: Dial Indicator Positioning For Case

Runout Check

36. Pry between differential assembly and bearing cap on one

side of indicator. Pry on opposite side to read end play.

37. Amount read on indicator is shim thickness that should be

added to side bearing shims to arrive at zero end play. Add

necessary shims and repeat procedure to ensure accuracy.

Figure 9-95: Ring Gear Guide Pin Installation

38. Tighten four bolts to 55-70 lb-ft (75-95 N•m).

39. Rotate differential assembly and check runout. Runout

should not exceed 0.002 in. (0.05 mm).

40. Remove dial indicator from housing.

NOTE:

Tag shims and bearing cups for assembly.

41. Remove four bolts, two bearing caps, bearing cups, shims,

and differential assembly from housing (Figure 9-96).

42. Install four guide pins in ring gear (Figure 9-95).

Figure 9-96: Differential Assembly Mounting

43. Support ring gear with wood blocks in press.

44. Press differential assembly on ring gear.

45. Remove four guide pins from ring gear.

46. Install ring gear on differential assembly with eight bolts.

Tighten bolts to 95-115 lb-ft (129-156 N•m).

47. Install side bearing shims, previously selected to remove

differential assembly side play, slide bearing cups, and

differential assembly in housing (Figure 9-96).

48. Install two bearing caps in housing with four bolts.

Tighten bolts to 55-70 lb-ft (75-95 N•m).

49. Attach dial indicator to housing and position indicator to

read off drive side of ring gear tooth at a right angle

(Figure 9-97).

RING GEAR

FLANGE OF CASE

DIAL INDICATOR

DIFFERENTIAL

CASE

RING GEAR

GUIDE PIN

BEARING

BEARING

DIFFERENTIAL

BEARING

BEARING

BEARING SHIM

HOUSING

CUP

SHIM

CAP

ASSEMBLY

CUP

9-38

Axles, Suspension, and Frame

_________________________________________

®

Figure 9-97: Checking Ring Gear Backlash

NOTE:

Backlash must be checked at four equally spaced

points on ring gear and must not vary more than 0.002 in. (0.05

mm) between four points checked.

50. Move ring gear back and forth while holding pinion yoke

stationary. Note backlash registered on indicator.

51. Ring gear backlash should be 0.005-0.009 in. (0.13-0.23

mm) with 0.008 in. (0.20 mm) desired. If backlash must be

adjusted perform steps 52 through 55, if not go to step 56.

NOTE:

Tag shims and bearing cups for assembly.

52. Remove four bolts, two bearing caps, bearing cups, shims,

and differential assembly from housing (Figure 9-96).

NOTE:

The following example will explain the procedure for

adjusting backlash: If side play was removed using 0.090 in.

(2.29 mm) shims on each side totaling 0.180 in. (4.57 mm) and

backlash, when checked, is found to be 0.011 in. (0.28 mm),

add 0.004 in. (0.10 mm) to shim on ring gear side and subtract

0.004 in. (0.10 mm) from shim on opposite side to correct

backlash. This will result in 0.094 in. (2.39 mm) shim on ring

gear side and 0.086 in. (2.18 mm) shim on other side. Backlash

will be approximately 0.007-0.008 in. (0.18 to 0.20 mm). Total

Shim Thickness remains 0.180 in. (4.57 mm).

53. To increase backlash, install thinner shim on ring gear side

and thicker shim on opposite side. To decrease backlash,

install thicker shim on ring gear side and thinner shim on

opposite side. Do not change total shim thickness.

54. Install shims, bearing cups, differential assembly, and

bearing caps in housing and secure with four bolts.

Tighten bolts to 55-70 lb-ft (75-95 N•m).

55. Mount dial indicator and recheck backlash. If necessary,

repeat steps 52 through 54.

56. Remove four bolts, bearing caps, bearing cup, shims, and

differential assembly from housing. Tag shims and

bearing cup for assembly.

57. Install axle housing spreader into holes in axle holding

fixture adapters and install dial indicator to read from each

end of housing. Indicator must have preload setting of

0.020 in. (0.50 mm) (Figure 9-98).

Figure 9-98: Axle Housing Spreader Mounting

CAUTION: Over-spreading of axle housing will damage

housing.

58. Spread housing 0.010 in. (0.25 mm) and remove dial

indicator.

NOTE:

Differential bearings must be preloaded to compen-

sate for heat and loads during operation.

RING GEAR TOOTH

RING GEAR

HOUSING

PINION YOKE

DIAL INDICATOR J–8001

AXLE

HOUSING

SPREADER

AXLE HOLDING

FIXTURE ADAPTER

J–24385-01

________________________________________

Axles, Suspension, and Frame 9-39

®

05745159

59. Preload differential side bearings by increasing shim

thickness at each side of differential assembly by 0.004 in.

(0.10 mm) for a total bearing preload of 0.008 in. (0.20

mm) (Figure 9-96).

60. Lubricate side bearings with gear oil and install

differential assembly, bearing cups, shims, and bearing

caps in housing and secure with four bolts (Figure 9-96).

NOTE:

Preloaded differential bearings may change backlash

setting. Check and correct backlash if necessary.

61. Remove housing spreader and tighten bolts to 55-70 lb-ft

(75-95 N•m).

62. Apply silicone sealant to cover sealing surface and secure

cover to housing with twelve bolts. Tighten bolts to 16 lb-

ft (22 N•m) (Figure 9-99).

Figure 9-99: Housing Cover Installation

63. Remove housing from holding fixture.

64. Remove four bolts and two axle holding fixture adapters

from housing.

65. Using press, install output shaft bearings on output shafts

(Figure 9-100).

Figure 9-100: Bearing Installation

66. Using axle shaft and seal installer J–33142, install output

shaft assemblies into axle assembly (Figure 9-101).

Figure 9-101: Axle Shaft And Seal Installer Usage

67. Using axle shaft and seal installer J–33142, install output

shaft seals in axle assembly (Figure 9-102).

Figure 9-102: Output Shaft Seal Installation

68. Lubricate sealing surface on output flanges with

lubricating oil (Figure 9-103).

Figure 9-103: Output Shaft Seal Installation

69. Install two output flanges, two seals, and two locknuts on

output shafts. Finger tighten locknuts.

70. Install axle assembly.

COVER

HOUSING

OUTPUT SHAFT BEARING

OUTPUT SHAFT

AXLE ASSEMBLY

OUTPUT SHAFT

ASSEMBLY

AXLE SHAFT

AND SEAL

INSTALLER

J–33142

AXLE ASSEMBLY

OUTPUT

AXLE SHAFT AND

SEAL INSTALLER J–33142

SHAFT SEAL

OUTPUT

OUTPUT

FLANGE

SHAFT

RUBBER

WASHER

9-40

Axles, Suspension, and Frame

_________________________________________

®

FRONT PROPELLER SHAFT AND

U-JOINT SERVICE

Front Shaft Removal

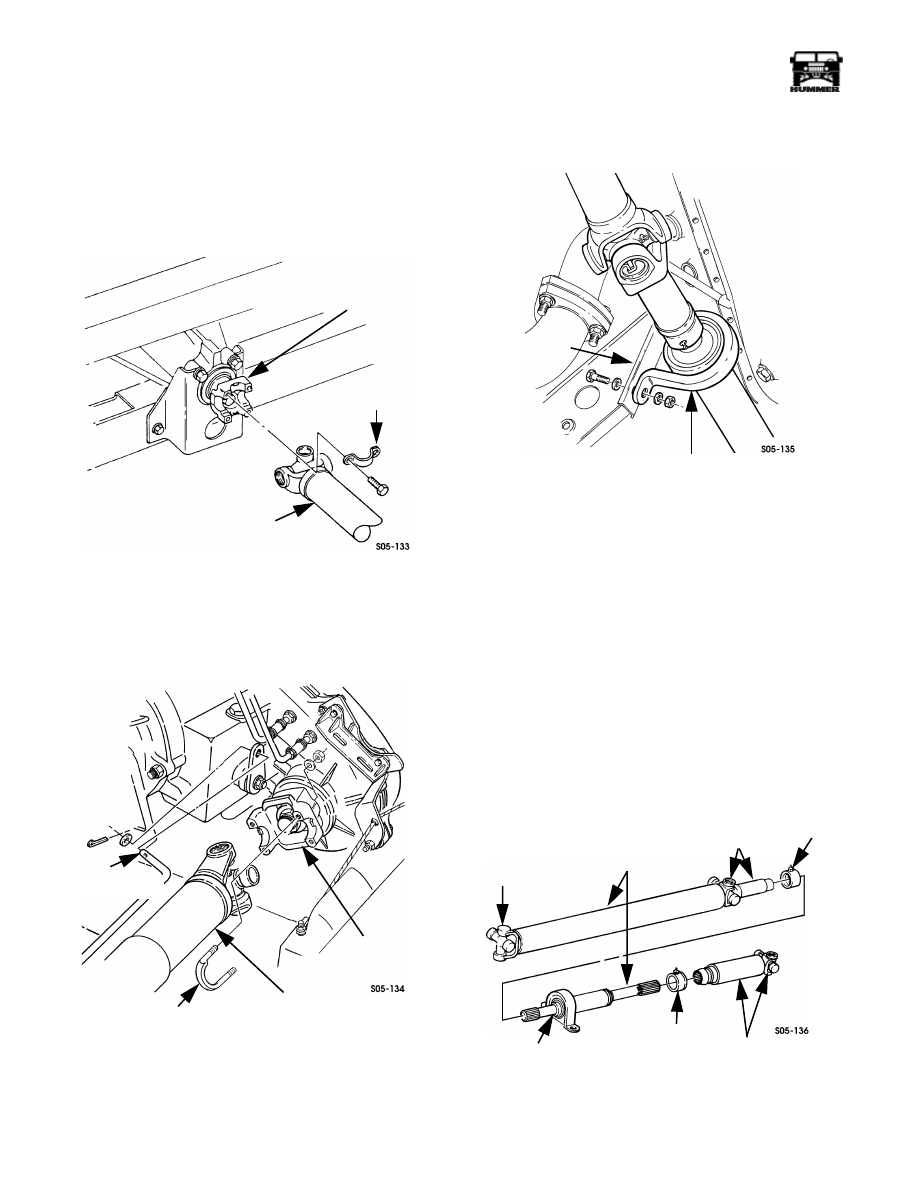

1.

Remove U-joint clamp bolts and straps. Then disconnect

shaft yoke (Figure 9-104).

Figure 9-104: Front Propeller Shaft

Attachment at Axle

2.

Remove U-bolt nuts and disconnect front shaft from

transfer case output yoke (Figure 9-105).

Figure 9-105: Front Propeller Shaft Attachment at

Transfer Case

3.

Disconnect transfer case shift rod at range lever.

4.

Remove bolts attaching center bearing to engine mount

(Figure 9-106).

Figure 9-106: Center Bearing Attachment

5.

Move front shaft forward, then rearward over top of

transfer case and remove from vehicle.

FRONT PROPELLER SHAFT DISASSEMBLY

AND OVERHAUL

1.

Mark slip yokes for assembly alignment.

2.

Mount shaft in vise and remove dust caps (Figure 9-107).

3.

Pull slip yokes off propshaft and separate shaft halves.

4.

Install standard bearing puller between center bearing and

shield.

5.

Mount assembly in shop press and press center bearing off

shaft.

6.

Remove shield from front propeller shaft.

Figure 9-107: Front Propeller Shaft Assembly

STRAP

FRONT

AXLE

YOKE

FRONT PROPELLER

SHAFT

TRANSFER CASE

OUTPUT YOKE

FRONT PROPELLER

U-BOLT

TRANSFER CASE

SHIFT ROD

SHAFT

CENTER BEARING

ENGINE MOUNT

U-JOINT

REAR SLIP YOKE

AND U-JOINT

DUST

CAP

FRONT

PROP

SHAFT

CENTER

BEARING

DUST

CAP

FRONT SLIP

YOKE AND

U-JOINT

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст