DAF LF45, LF55 Series. Manual — part 264

©

200508

4-3

Removal and installation

ALLISON MD 3060 AUTOMATIC GEARBOX

ΛΦ45/55 series

3

8

4.2 REMOVING AND INSTALLING OUTPUT SHAFT OIL SEAL

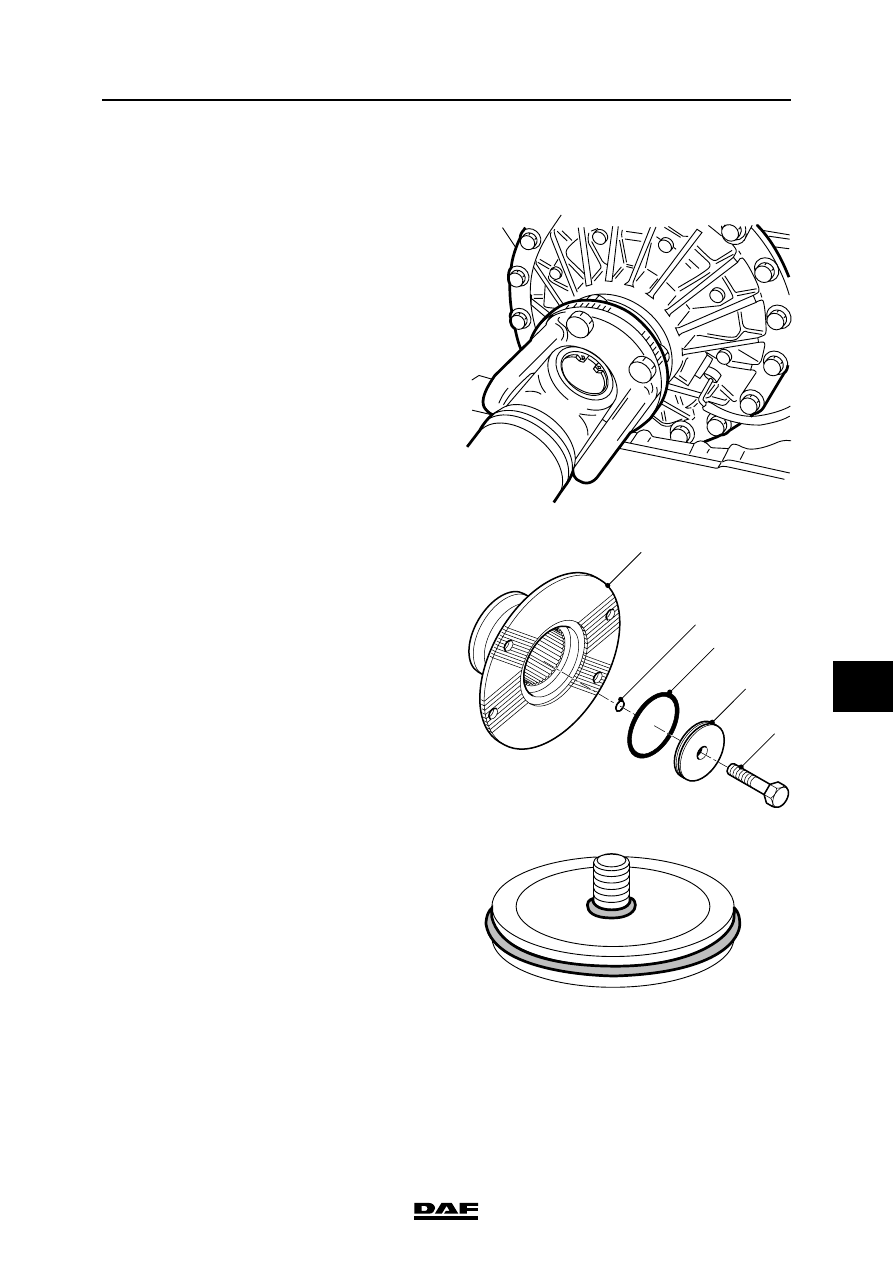

Removing output shaft oil seal

1.

Remove the prop shaft and secure it so that

it does not interfere with further operations.

2.

Unscrew the attachment bolt (5) of the flange

without removing it from the locking plate.

3.

Remove the bolt and locking plate from the

flange.

Pay attention to the sealing rings on the outer

circumference and on the inside of the

locking plate.

W 3 03 061

V300529

1

2

3

5

4

V300559

ALLISON MD 3060 AUTOMATIC GEARBOX

4-4

©

200508

Removal and installation

8

ΛΦ45/55 series

3

4.

Slide the flange off the output shaft or, if

necessary, use a tripod puller to pull it off the

shaft.

5.

Drill two holes in the external cover of the oil

seal and turn special tool (DAF no. 0484899)

into the oil seal. Pull the oil seal out of the

gearbox housing using special tool

(DAF no. 0694928).

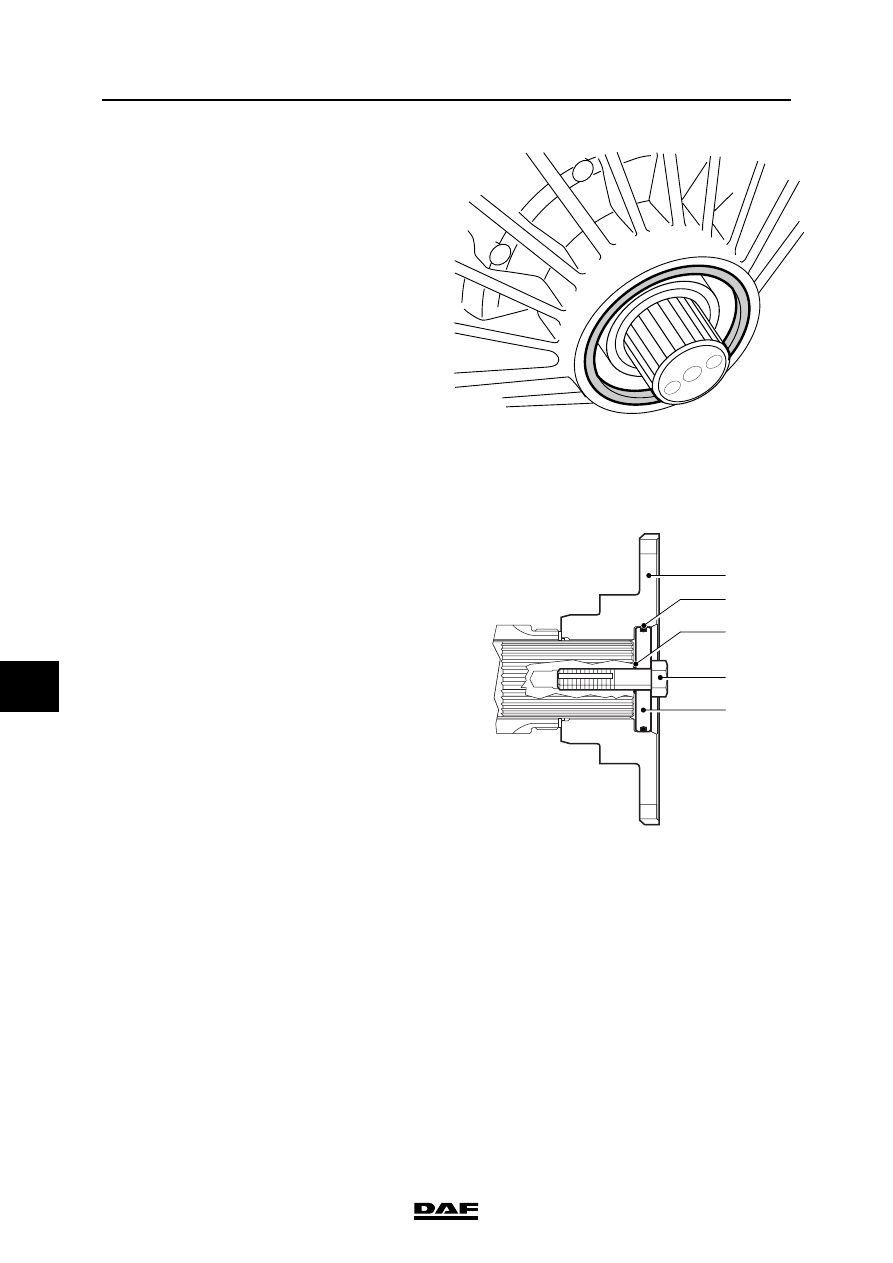

Installing output shaft oil seal

1.

Apply a small amount of liquid gasket to the

outside of oil seals fitted with a steel cover.

Apply a small amount of green soap to the

outside of oil seals fitted with a rubber cover.

2.

Fit the oil seal in the gearbox housing using

special tool (DAF no. 1240037).

3.

Apply a small amount of grease to the oil seal

lips and slide the flange over the output shaft

until it abuts.

4.

Fit new sealing rings (2, 3) to the locking

plate and fit it with the attachment bolt to the

flange (apply a small amount of grease to the

sealing rings).

Note:

The attachment bolts on the new gearboxes

are no longer secured by a locking plate, but

by the self-locking screw thread in the output

shaft.

5.

Hold the prop shaft flange in place with the

special tool (DAF no. 0484977).

6.

Tighten the attachment bolt (5) to the

specified torque. See "Technical data".

If the locking plate is not tightened to

the specified torque, there is a risk of

it getting bent during fitting, which

could lead to serious oil leakage.

W 3 03 062

V300530

1

5

4

3

2

}

©

200508

4-5

Removal and installation

ALLISON MD 3060 AUTOMATIC GEARBOX

ΛΦ45/55 series

3

8

4.3 REMOVAL AND INSTALLATION, OIL FILTERS

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

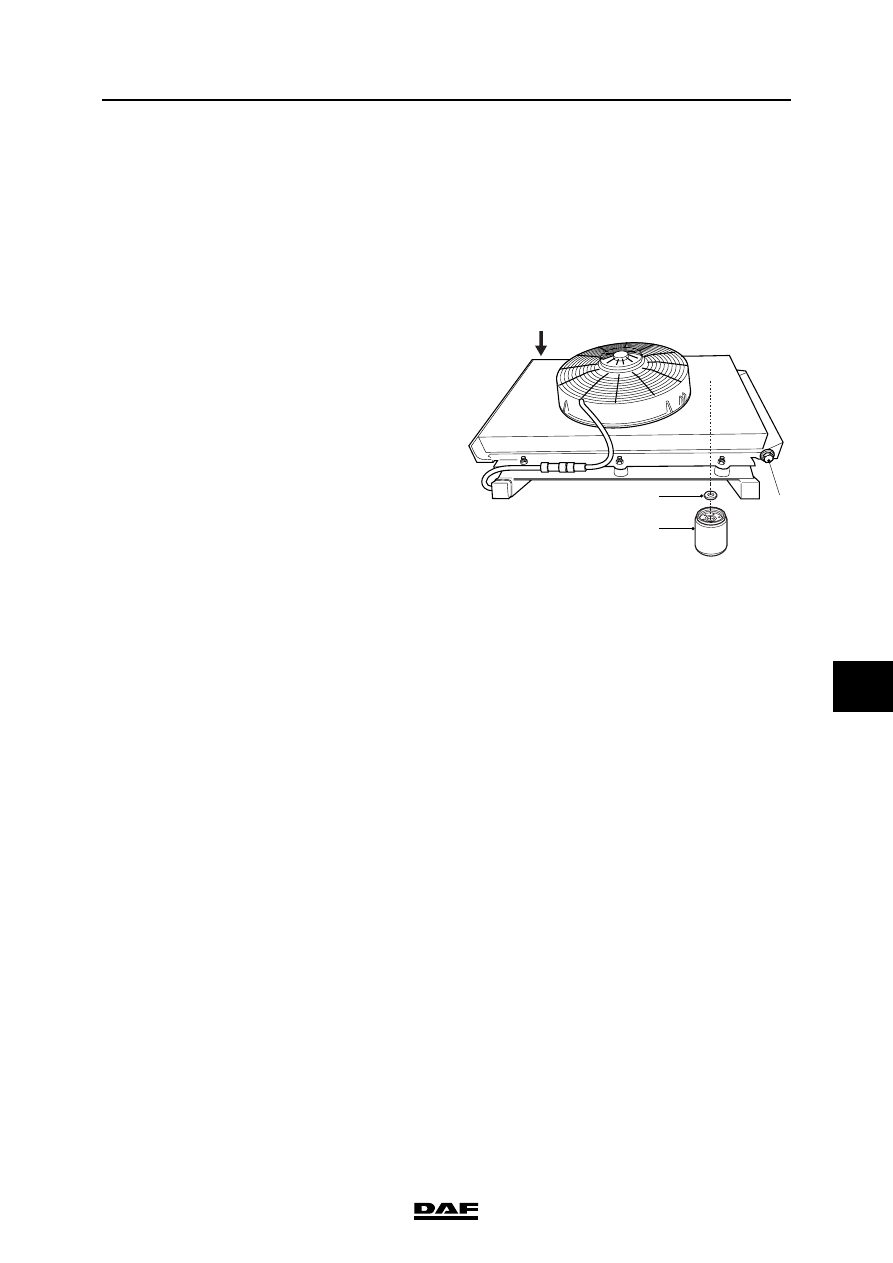

Allison MD 3060 automatic gearbox

Removing oil cooler oil filter

1.

Clean the oil filter (5), if fitted, and the

surrounding area.

2.

Loosen the oil filter on the heat exchanger.

Collect the oil that comes out.

3.

Remove the magnetic ring (4) and check it

for wear particles.

Note:

If there are large wear particles in the wear

swarf, this indicates excessive wear in the

gearbox and the cause must be ascertained.

4.

Clean the magnetic ring and the contact

surfaces on the heat exchanger.

Fitting oil cooler oil filter

1.

Fit the magnetic ring (4) on the heat

exchanger.

2.

If applicable, lightly lubricate the new oil filter

(5) with clean gearbox oil and fit it on the heat

exchanger.

3.

Tighten the oil filter until it touches the

contact surface. Manually tighten the oil filter

another 360

″.

4.

Check the oil level. See "Inspection and

adjustment".

}

5

4

6

3

V3 00 556

ALLISON MD 3060 AUTOMATIC GEARBOX

4-6

©

200508

Removal and installation

8

ΛΦ45/55 series

3

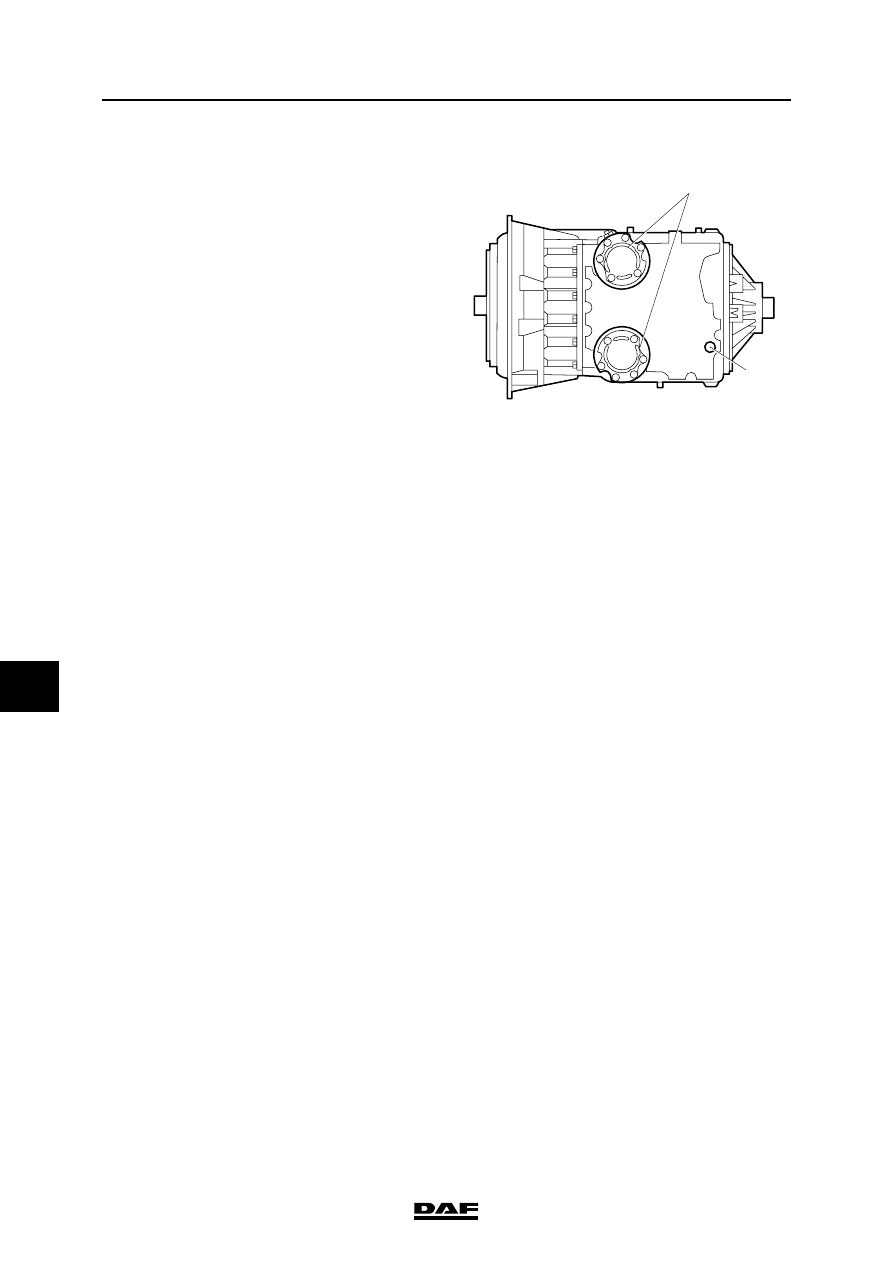

Removing oil filters

1.

Remove the attachment bolts from the filter

covers (2) and remove the filter covers.

Collect the oil that comes out.

2.

Remove the oil filters from the oil sump.

3.

Remove the various O-rings and the gasket

from the filter covers.

4.

Remove any gasket remains from the filter

covers and the contact surfaces.

Installing oil filters

1.

Lubricate the new O-rings with clean

gearbox oil and fit the various O-rings on the

filter covers.

Note:

Compare the new O-rings to the old ones to

ensure that the correct O-rings are used.

2.

Fit a new gasket on the filter covers.

3.

Lubricate the rubber inner ring of the oil filters

with clean gearbox oil and fit the oil filters on

the filter covers.

4.

Fit the filter covers together with the oil filters

on the gearbox and tighten the attachment

bolts to the specified torque. See "Technical

data".

5.

Check the oil level. See "Inspection and

adjustment".

V300371

2

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст