DAF LF45, LF55 Series. Manual — part 451

©

200436

2-25

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

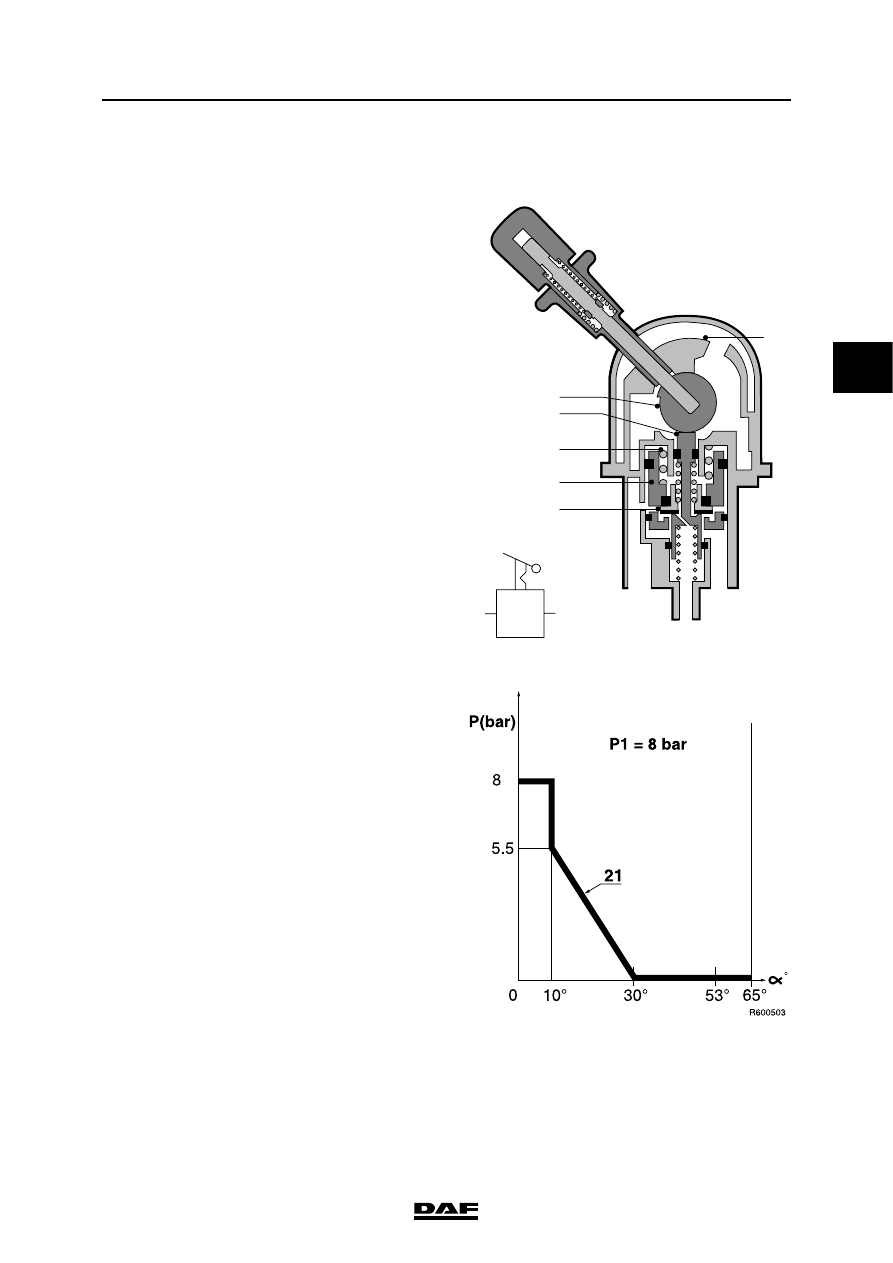

PARKING BRAKE VALVE WITHOUT TRAILER

VEHICLE CONNECTION

Purpose

The parking brake valve enables controlled

operation of the parking brake system of the

prime mover.

Operation

The parking brake valve has 2 positions:

-

driving

-

parking

Driving

With the handle in the driving position, there is a

through-connection of the supply pressure

(connecting point 1) to connecting point 2 for the

spring brake cylinders. The bleed vent is now

closed.

The output pressure at connecting point 2 is now

approx. 8 bar (see graph).

Emergency braking

If the handle is pulled a little backwards against

the spring pressure, tappet 3 will move

downwards via the eccentric (2). The space at

connecting point 21 can now be bled and as a

result the pressure at connecting point 21 will

drop. Spring 4 forces piston 5 down until valve 6

comes into contact with the seal collar of tappet

3. A state of equilibrium has now been achieved.

When the handle is moved against stop 7, the

bleed vent will remain open so that the spring

brakes are applied to maximum effect (max.

emergency brake position).

R600400

2

7

3

4

5

6

1

3

2

1

2

OPERATION OF BRAKE COMPONENTS

2-26

©

200436

Description of components

3

ΛΦ45/55 series

6

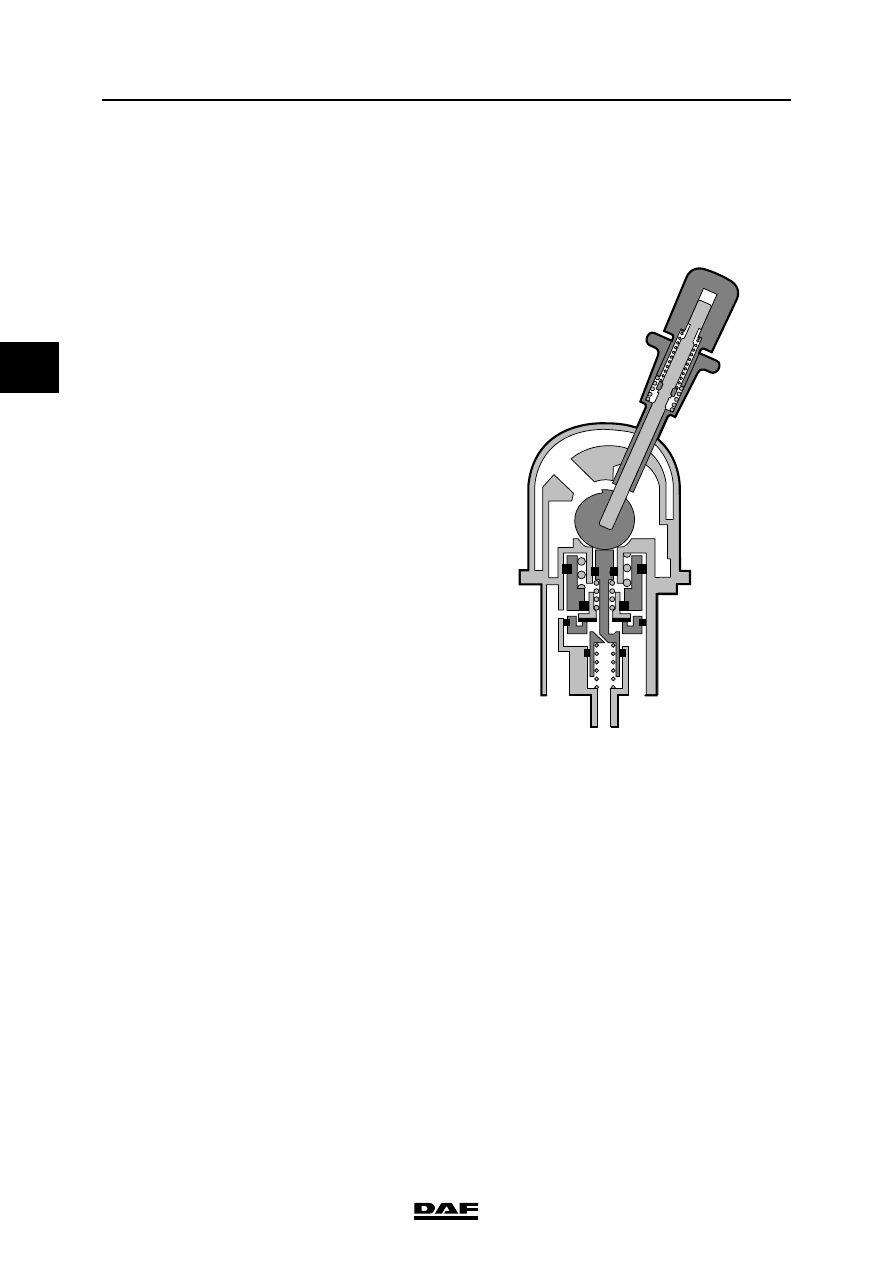

Parking

When the handle is pulled past stop 7, it is locked

in position.

Connecting point 2 is still pressureless, so that

the spring brakes operate at maximum capacity.

Releasing the brakes

When the handle is once again moved fully

forwards, tappet 3 will move upwards, seat

against valve 6 and push it from its seat in piston

5. As a result, the supply pressure can reach

connection point 2. The pressure at connecting

point 2 is now once more equal to the supply

pressure at connecting point 1.

3

2

1

R600402

©

200436

2-27

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

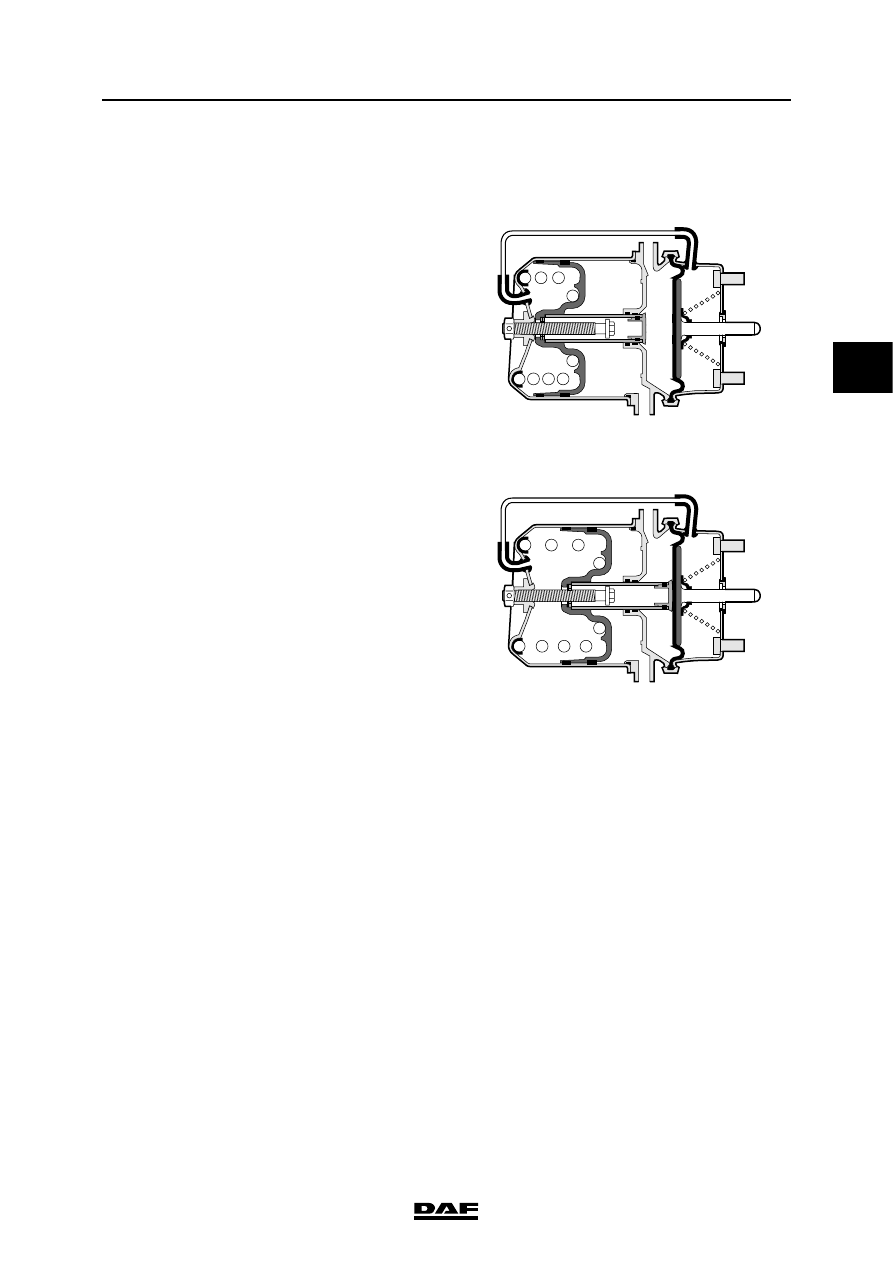

2.15 SPRING BRAKE CYLINDER

Purpose

The purpose of the spring brake cylinder is to

force the brake pads against the brake disc when

the service or parking brake is operated.

Spring brake cylinder operation

The spring brake cylinder consists of two parts: a

part for the service brake, which is designed as a

normal brake cylinder, and a part for the parking

brake, which is a spring brake cylinder.

Normal position during driving.

The air reservoirs must be at a safe pressure

before you start driving. If this is not the case, a

warning signal (e.g. a buzzer) will be given.

If this pressure is admitted to the spring brake

cylinder, the piston will compress the powerful

spring. The push rod is no longer under load and

the vehicle brake will be released due to the

operation of the spring, etc.

Service brake

Because the brake cylinder and the spring brake

cylinder are separate, the spring brake cannot

affect the operation of the service brake.

When the service brake is applied, the powerful

spring continues to be compressed, while there is

air pressure on the diaphragm of the brake

cylinder. When the foot brake valve is operated,

the compressed air passes through connection

point 11 into the chamber behind the diaphragm.

The diaphragm with push rod is pushed out

against the spring pressure.

The air on the other side of the diaphragm can

escape via bleed holes. When the brakes are

released, the spring forces the push rod and the

diaphragm back into their original position.

11

12

R600908

11

12

R600909

OPERATION OF BRAKE COMPONENTS

2-28

©

200436

Description of components

3

ΛΦ45/55 series

6

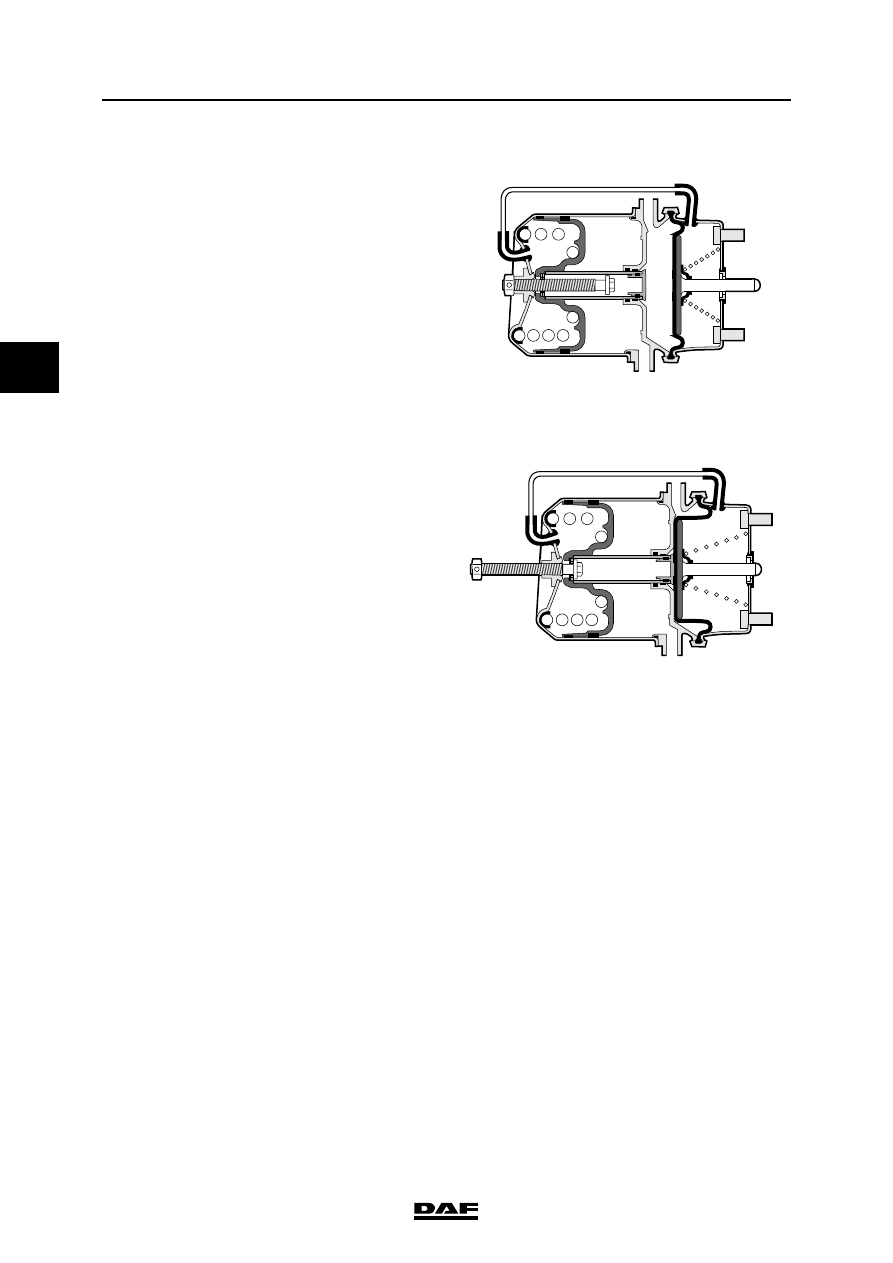

Parking brake

Connection point 12 is bled.

The powerful spring then forces the piston with

the piston tube against the diaphragm, so that the

push rod is forced outwards. Here use is made of

the continuously available energy of the

compressed, powerful spring.

Release tool, spring brake cylinder with

unscrewable release bolt

If, due to a failure, no compressed air is available

in the spring brake cylinder, the vehicle brakes

are automatically applied.

But it must still be possible to tow the vehicle.

The spring brake cylinder is therefore fitted with a

release bolt at the rear. By turning this bolt anti-

clockwise using a spanner, the powerful spring

will be compressed.

As the bolt is provided with a thrust bearing, the

torque required is not more than 20 - 40 Nm.

A pneumatic spanner must not be used for this

purpose.

Because the spring brakes have

been released mechanically, the

parking brake can no longer be

applied.

Once the failure has been remedied and

sufficient compressed air is available, the control

valve can be used to again admit air into the

spring brake cylinder.

The release bolt should then be screwed back in

with the spanner and tightened to the specified

torque. See "Technical data". The pressure in the

spring brake cylinder circuit should be at least

5.1 bar.

11

12

R600908

11

12

R600910

}

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст