DAF LF45, LF55 Series. Manual — part 452

©

200436

2-29

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

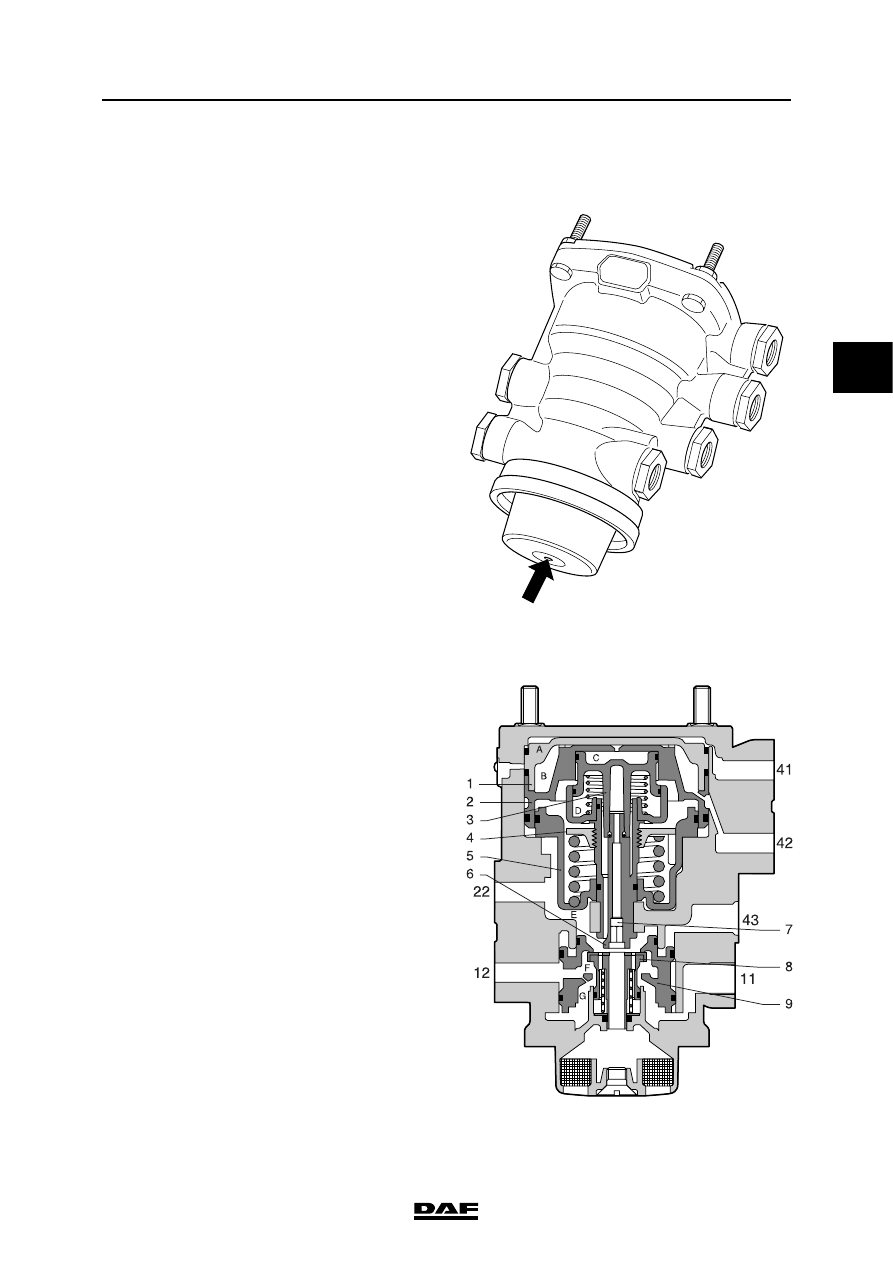

2.16 TRAILER CONTROL VALVE

Purpose

The purpose of the trailer vehicle control valve is

to pass on the brake commands from the prime

mover to the trailer vehicle.

Operation

Driving

Connecting point 11 is connected to a reservoir

and connecting point 43 to the parking brake

valve. Both are pressurised and in a state of

equilibrium. The service coupling head

communicates with the ambient air via

connecting point 22, valve 8 and the bleed vent

with damper.

41

42

43

11

12

22

R600335

R600340

OPERATION OF BRAKE COMPONENTS

2-30

©

200436

Description of components

3

ΛΦ45/55 series

6

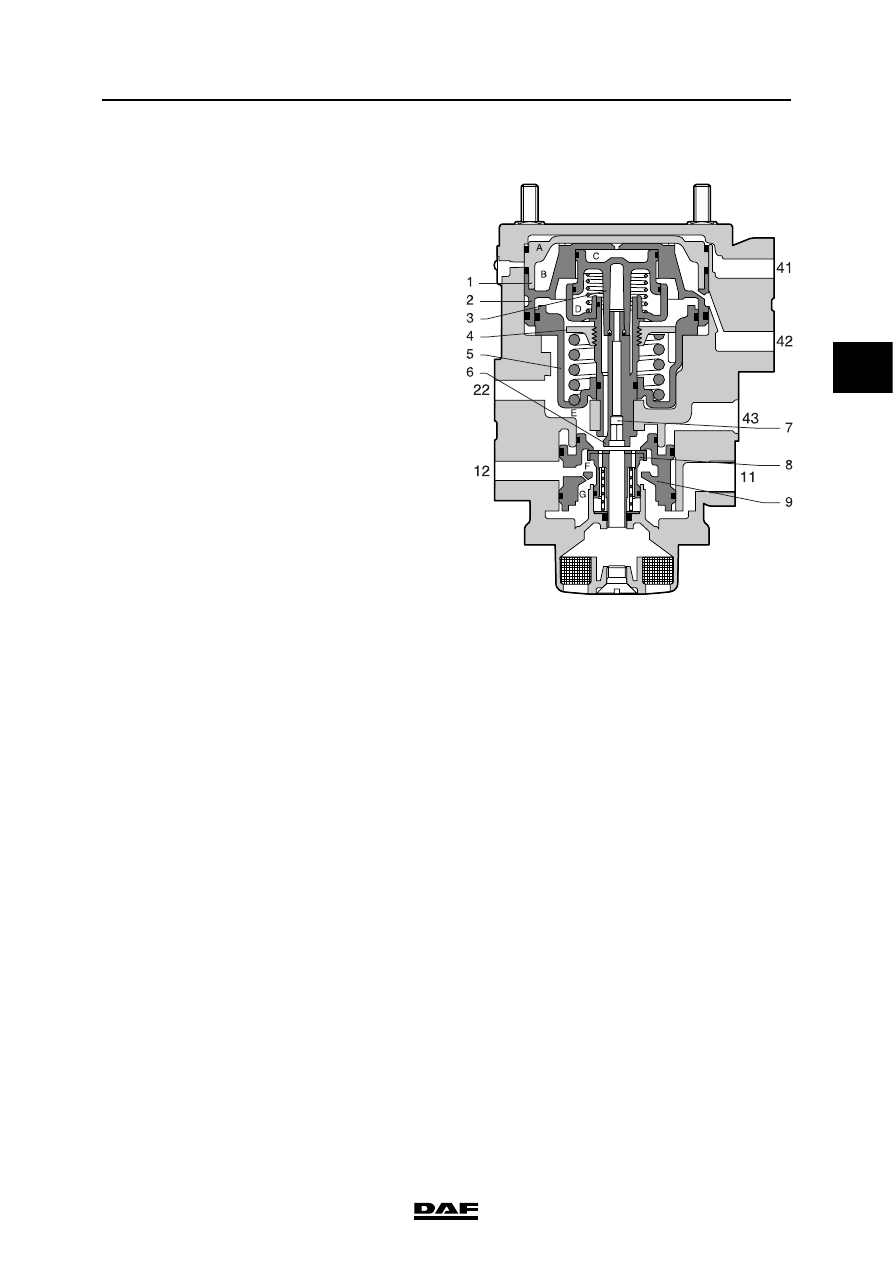

Braking with the service brake

Pressure build-up

Using the foot brake valve, circuit 1, connecting

point 41, and circuit 2, connecting point 42, are

pressurised.

This pushes down the pistons (1 and 2), causing

valve 8 to close the outlet and open the inlet. The

brake pressure at connecting point 11 can now

flow via valve 8 to connecting point 22, (yellow)

trailer vehicle service coupling head, and will

cause the trailer vehicle to brake.

Adjusting

When a pre-set output pressure has been

reached at connecting point 22, this pressure will

once again force the piston (5) upwards, thus

closing valve 8.

There is now a state of balance between the input

pressure at connecting point 41 and the output

pressure at connecting point 22.

Releasing

When the foot brake valve is released, the input

pressure at connecting points 41 and 42 falls

away. Pistons 1 and 2 are pushed upwards by the

spring under the spring retainer (4).

As a result, valve 8 is closed and the outlet

opened, linking connecting point 22 with the

bleed vent.

R600340

©

200436

2-31

Description of components

OPERATION OF BRAKE COMPONENTS

ΛΦ45/55 series

6

3

Advance

Pressure build-up

If the foot brake valve is used to build up pressure

at connecting points 41 and 42, the output

pressure at connecting point 22 will also move

piston 5 upwards, closing valve 8.

There is now a state of balance between the input

pressure at connecting point 41 and the output

pressure at connecting point 22.

Alteration

If adjusting screw 6 is turned clockwise, for

example, the spring retainer (4) will be moved

downwards, compressing the spring underneath

it. Therefore, if the operating pressure at

connecting points 41 and 42 remains the same, a

higher adjusting pressure will be needed under

piston 5. This adjusting pressure is also on the

yellow coupling head.

This increase of service pressure to the trailer

vehicle in relation to the braking pressure from

the prime mover is called advance.

For the setting procedure, see "Inspection and

adjustment".

Emergency brake

When the parking brake valve is moved into the

locking position, connecting point 43 will be

gradually bled.

Piston 9 moves upwards and valve 8 is opened.

Depending on the drop in pressure at connection

point 43, a pressure build-up will occur at

connection point 22. When a pre-set value has

been reached, valve 8 will close, so that a state of

equilibrium is achieved.

Parking brake

When the parking brake valve is in its maximum

position, causing the lever to be locked,

connecting point 43 is bled. As a consequence,

there is still output pressure at connecting

point 22.

Protection against breakage of service line

During braking, pressure will build up at

connecting point 22. The air necessary for this is

supplied from connecting point 11.

If the service line is broken, pressure will not build

up in space E, which will cause piston 9 to move

up and close against the bottom of valve 8. The

supply from connecting point 11 stagnates,

causing pressure to be delivered from connecting

point 12.

The pressure in the reservoir pipe drops and the

trailer brakes are applied.

R600340

OPERATION OF BRAKE COMPONENTS

2-32

©

200436

Description of components

3

ΛΦ45/55 series

6

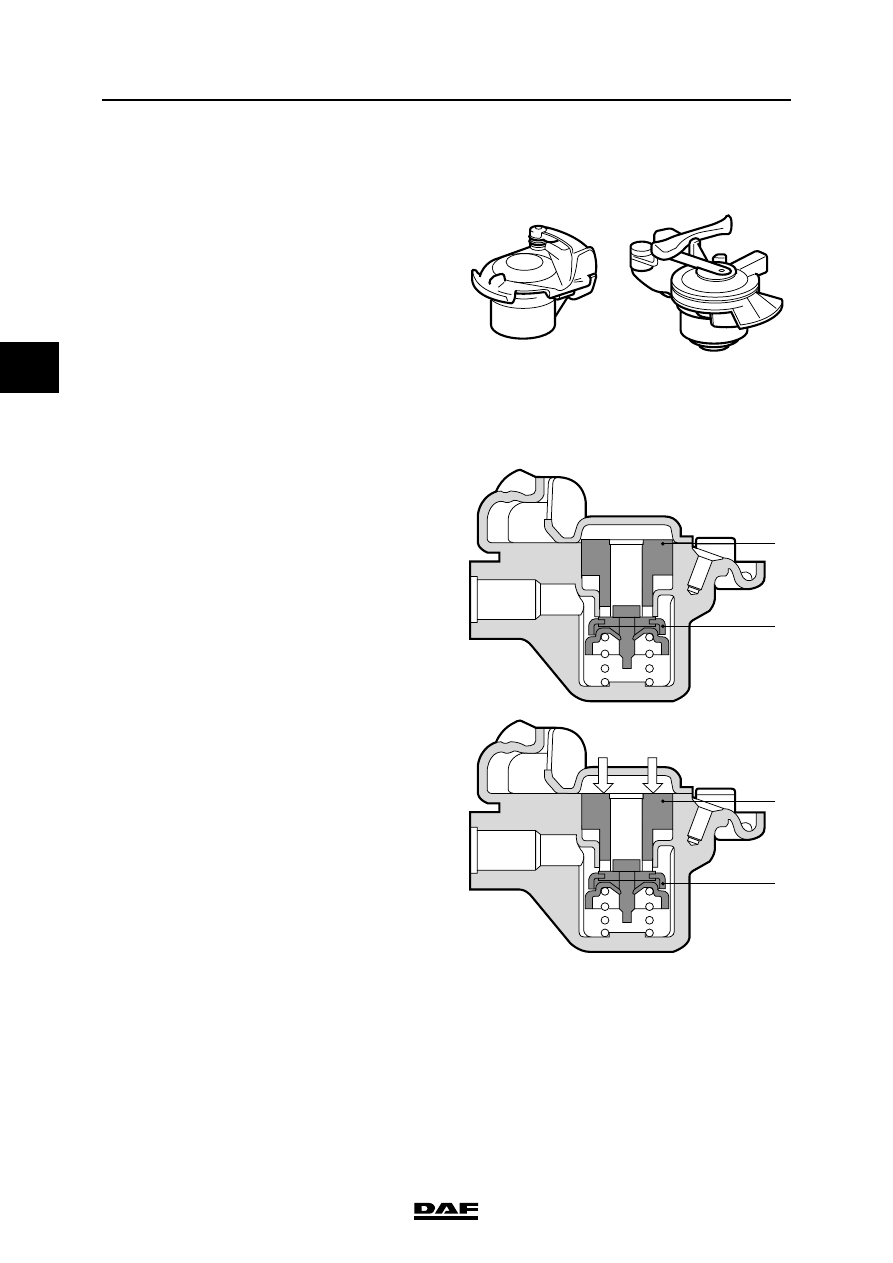

2.17 COUPLING HEAD

Application

With spring-loaded valve. Fitted in the dual-line

brake system of versions with trailer vehicle

connection.

If these automatic coupling heads are applied,

there is no need for an air cock.

Purpose

To connect the air brake system of the prime

mover with that of the trailer vehicle.

Operation

The spring-loaded valve (2) in the coupling head

ensures that the system is isolated from the

ambient air.

When coupling, turn the counter head until the

claws of the two heads rest against the stop

under the locking plates. This will prevent the

coupling head from disengaging spontaneously.

Because the two sealing rings (1) are pressed

against each other, the spring-loaded valve

remains open so that an air-tight connection is

achieved. When the heads are uncoupled, the

spring-loaded valve will seal off the pipe on the

prime mover.

The coupling head is equipped with a safety cam.

This is to prevent different coupling heads being

coupled to one another.

If no trailer vehicle is hooked up, the cover of the

coupling head must be closed, to avoid fouling.

R600899

R600900

2

1

R600901

2

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст