DAF LF45, LF55 Series. Manual — part 266

©

200508

1-1

Safety instructions

CLUTCH

ΛΦ45/55 series

3

9

1. SAFETY INSTRUCTIONS

1.1 SAFETY INSTRUCTIONS

Hydraulic fluid is toxic and can

therefore have a damaging effect on

your health. Any direct or indirect

physical contact should therefore be

avoided.

As hydraulic fluid is also corrosive it

may damage the paintwork of the

vehicle. Any contact between

hydraulic fluid and paintwork should

therefore be avoided.

Always use new and clean hydraulic

fluid which has been kept in a sealed

container that meets the

specifications. Hydraulic fluid which

has absorbed water (from the

ambient air) may have an adverse

effect on the operation of the clutch

system. Avoid any contact with

mineral oil. Even one drop of mineral

oil in the system will damage the

seals.

}

}

}

CLUTCH

1-2

©

200508

Safety instructions

9

ΛΦ45/55 series

3

©

200508

2-1

General

CLUTCH

ΛΦ45/55 series

3

9

2. GENERAL

2.1 SYSTEM DESCRIPTION, CLUTCH

The clutch is a single dry-plate clutch which is

hydraulically operated and pneumatically

assisted.

The clutch consists of:

-

flywheel

-

clutch plate

-

clutch release assembly

By clamping the clutch plate between the

flywheel and the clutch release assembly, a

torque can be transferred (by means of friction).

The extent of the torque that can be transferred

by the clutch is determined by multiplying the

maximum engine torque by a safety factor

(usually 1.3).

To clamp the clutch plate, a diaphragm

(pressure) spring is used in the clutch release

assembly.

A diaphragm spring constitutes a simple, strong

and cost-effective construction.

Another advantage of the diaphragm spring is

that the pressure exerted on a new clutch plate

almost equals the pressure exerted on a worn

clutch plate.

A diaphragm spring requires a self-centring thrust

bearing.

The type of clutch plate used depends on the

following factors.

The size of the clutch plate lining must

correspond to the desired service life.

The character of the engine (the engine

vibrations to be damped) determines the version

of the vibration damper design in the hub.

For the clutch plate to engage smoothly the lining

material must abut the flywheel and clutch

release assembly evenly at all places when

engaging.

CLUTCH

2-2

©

200508

General

9

ΛΦ45/55 series

3

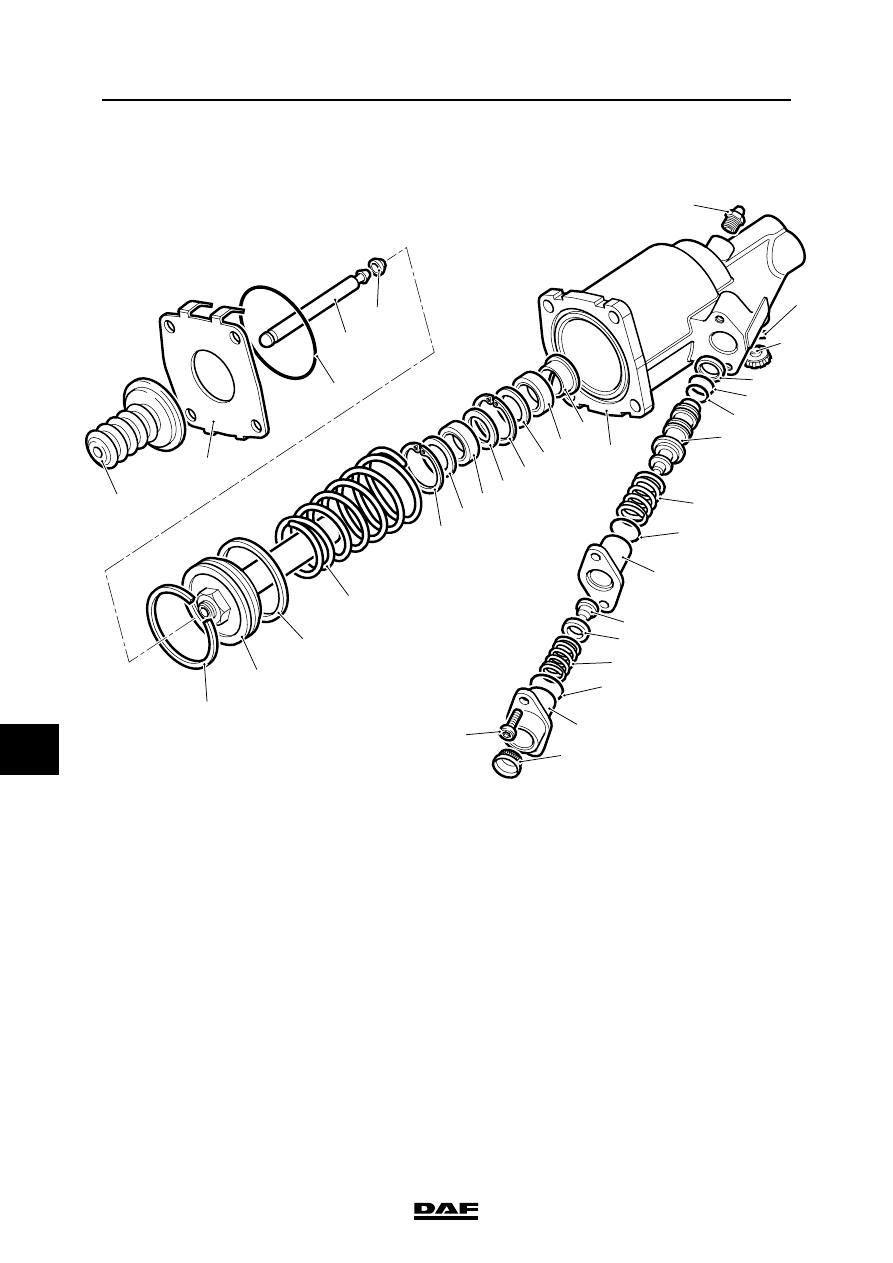

2.2 OVERVIEW DRAWING, CLUTCH SERVO

V3 00 436

17

31

16

19

18

20

21

22

23

24

25

26

27

28

29

30

32

2

1

6

7

8

9

10

11

12

11

10

11

13

14

15

3

4

5

1.

Rubber protective bellows

17.

Vent opening

2.

End-plate

18.

Blow-off nipple

3.

O-ring

19.

Piston seal

4.

Push rod

20.

O-ring

5.

Attachment ring for push rod

21.

O-ring

6.

Split seal

22.

Piston

7.

Piston

23.

Pressure spring

8.

Piston seal

24.

O-ring

9.

Conical spring

25.

Spring seat housing

10.

Circlip

26.

Inlet valve

11.

Washer

27.

Spring seat

12.

Seal, hydraulic part, front

28.

Reset spring

13.

Seal, hydraulic part, rear

29.

O-ring

14.

Split bearing

30.

Connector housing

15.

Booster housing

31.

Allen screw

16.

Bleed nipple

32.

Air filter

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст